Strengthened heat exchange tube

A heat transfer tube and heat transfer tube technology, which is applied in the field of heat transfer tubes, can solve the problems such as the concentration of stress at the edge of the groove and the waste of the material at the groove part, the difficulty in removing the scale on the inner wall of the tube, and the difficulty in processing and forming the heat transfer tube. Wide application range, easy replacement, and improved pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

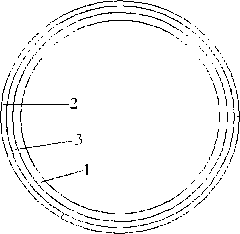

[0014] figure 1 Shown is an implementation example of an enhanced heat transfer tube according to the present invention. The enhanced heat transfer tube includes a heat exchange tube 1 , a strip-shaped metal sheet 2 , and a thermally conductive filler 3 .

[0015] Because of the enhanced heat transfer tube of the present invention, the outer surface of the heat exchange tube 1 is first cleaned, and then the cleaned heat exchange tube 1 is passed through the baffle plate and expanded to the tube plate, and the heat conduction filler 3 is selected from heat conduction silicone grease 1. Evenly cover the outer surface of the heat exchange tube 1 with thermally conductive silicone grease. The strip-shaped metal sheet 2 is tightly wound in a spiral shape on the outer surface of the heat exchange tube 1 covered with heat-conducting silicone grease, so as to ensure that the strip-shaped metal sheet 2 does not overlap and does not expose the heat-conducting silicone grease. There is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com