SCR (Selective Catalytic Reduction) urea solution mixer

A technology of solution mixing and urea, applied in mixers, dissolving, machines/engines, etc., can solve the problems of unstable reduction reaction, insufficient decomposition, uneven mixing, etc., achieve complex air flow conditions, improve mixing uniformity, Avoid the effect of excessive deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The core of the present invention is to provide an SCR urea solution mixer to improve the mixing uniformity of the urea solution, promote the full utilization of the urea solution, and ultimately reduce the problem of excessive deposition of urea.

[0033] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

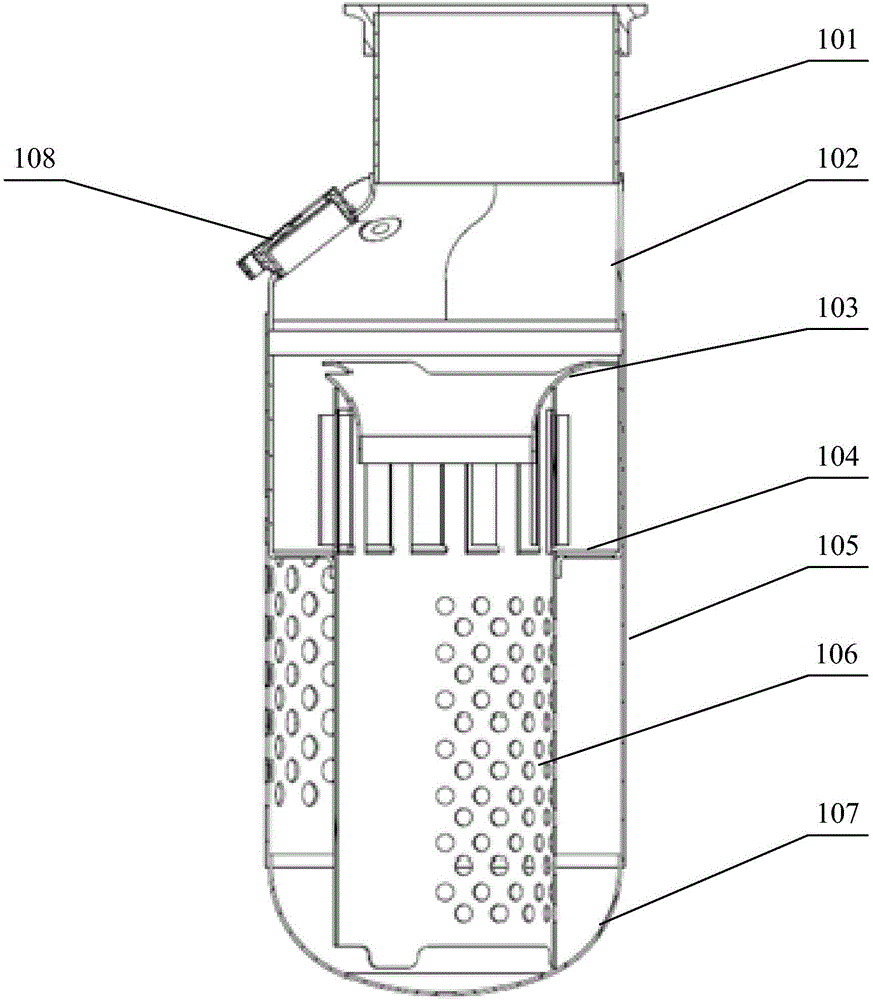

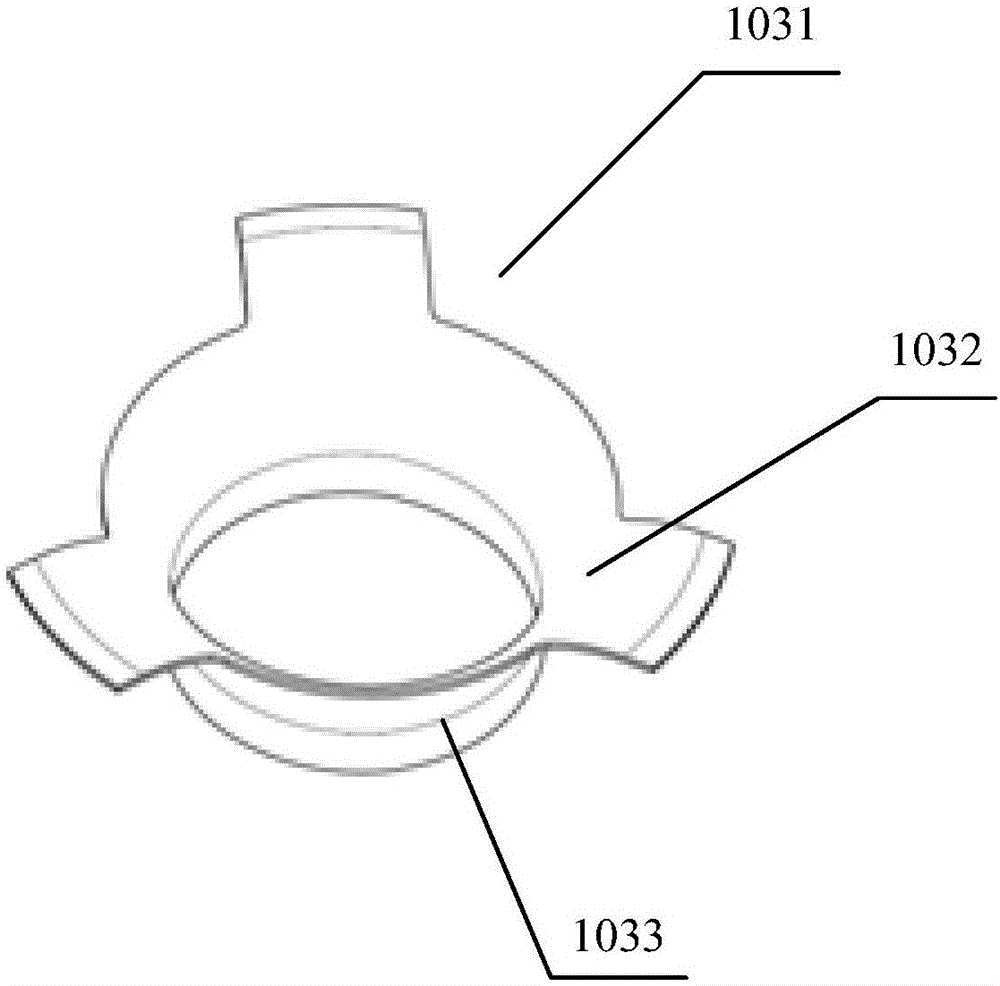

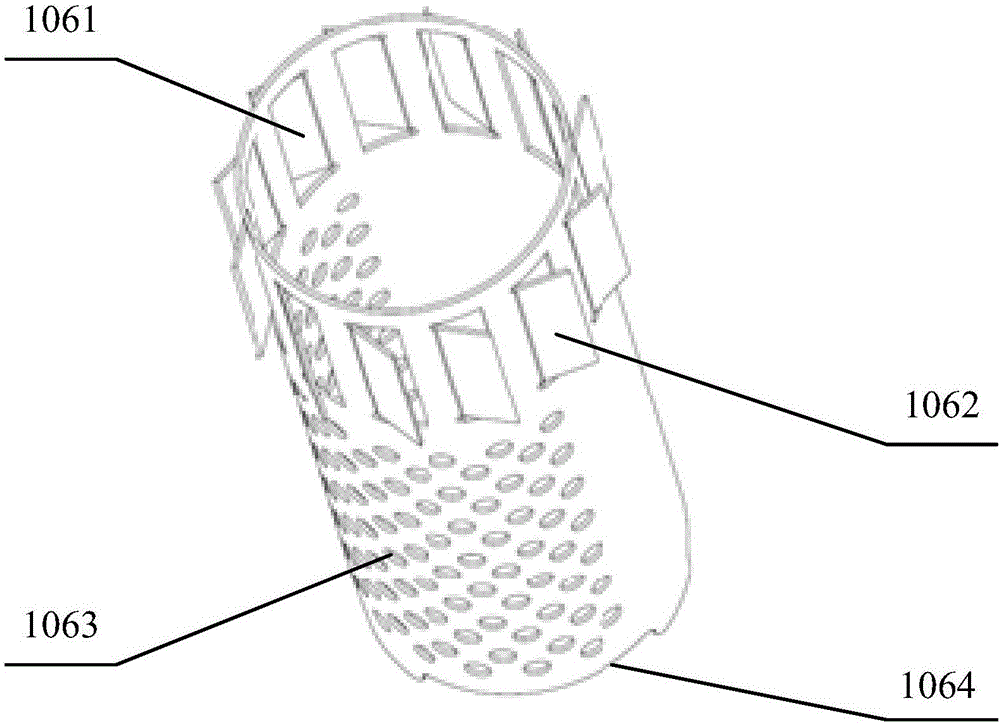

[0034] see figure 1 , image 3 and Figure 4 , figure 1 Schematic diagram of the structure of the SCR urea solution mixer provided for the embodiment of the present invention; image 3 Schematic diagram of the structure of the inner tube provided by the embodiment of the present invention; Figure 4 It is a schematic diagram of the structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com