Single crystal lithium-rich manganese-based anode material, preparation method thereof, lithium ion battery

A lithium-rich manganese-based, positive electrode material technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of low single crystallization degree of materials, uneven particle size, battery performance attenuation, etc., to achieve good power The effects of chemical properties, increased hardness, and reduced melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] ① Prepare a mixed salt solution of nickel sulfate, cobalt sulfate, and manganese sulfate with a molar ratio of Mn, Co, and Ni at 4:1:1, and the total metal ion concentration is 2moL / L.

[0070] ②Prepare a mixed solution of sodium hydroxide and ammonia, the concentration of sodium hydroxide is 2mol / L, and the concentration of ammonia is 3mol / L.

[0071] ③Add 25% by volume of deionized water in the reactor to the reactor, and pass the mixed solution of sodium hydroxide and ammonia into the reactor under the protection of an inert atmosphere such as nitrogen, and control the inlet flow rate of the metal salt solution to 0.5L / h. Adjust the flow rate of the mixed solution of sodium hydroxide and ammonia so that the pH of the system is maintained at 10.2, the process control reaction temperature is 55 degrees, the stirring speed is 600 rpm / min, after the feeding, continue to stir and age for 10 hours, and then filter the precipitated product , Washing, drying, sieving through a 4...

Embodiment 2

[0076] ① Prepare a mixed salt solution of nickel sulfate, cobalt sulfate, and manganese sulfate with a molar ratio of Mn, Co, and Ni at 4:1:1, and the total metal ion concentration is 2moL / L.

[0077] ②Prepare a mixed solution of sodium hydroxide and ammonia, the concentration of sodium hydroxide is 2mol / L, and the concentration of ammonia is 3mol / L.

[0078] ③Add 25% by volume of deionized water in the reactor to the reactor, and pass the mixed solution of sodium hydroxide and ammonia into the reactor under the protection of an inert atmosphere such as nitrogen, and control the inlet flow rate of the metal salt solution to 0.5L / h. Adjust the flow rate of the mixed solution of sodium hydroxide and ammonia so that the pH of the system is maintained at 10.2, the process control reaction temperature is 55 degrees, the stirring speed is 600 rpm / min, after the feeding, continue to stir and age for 10 hours, and then filter the precipitated product , Washing, drying, sieving through a 4...

Embodiment 3

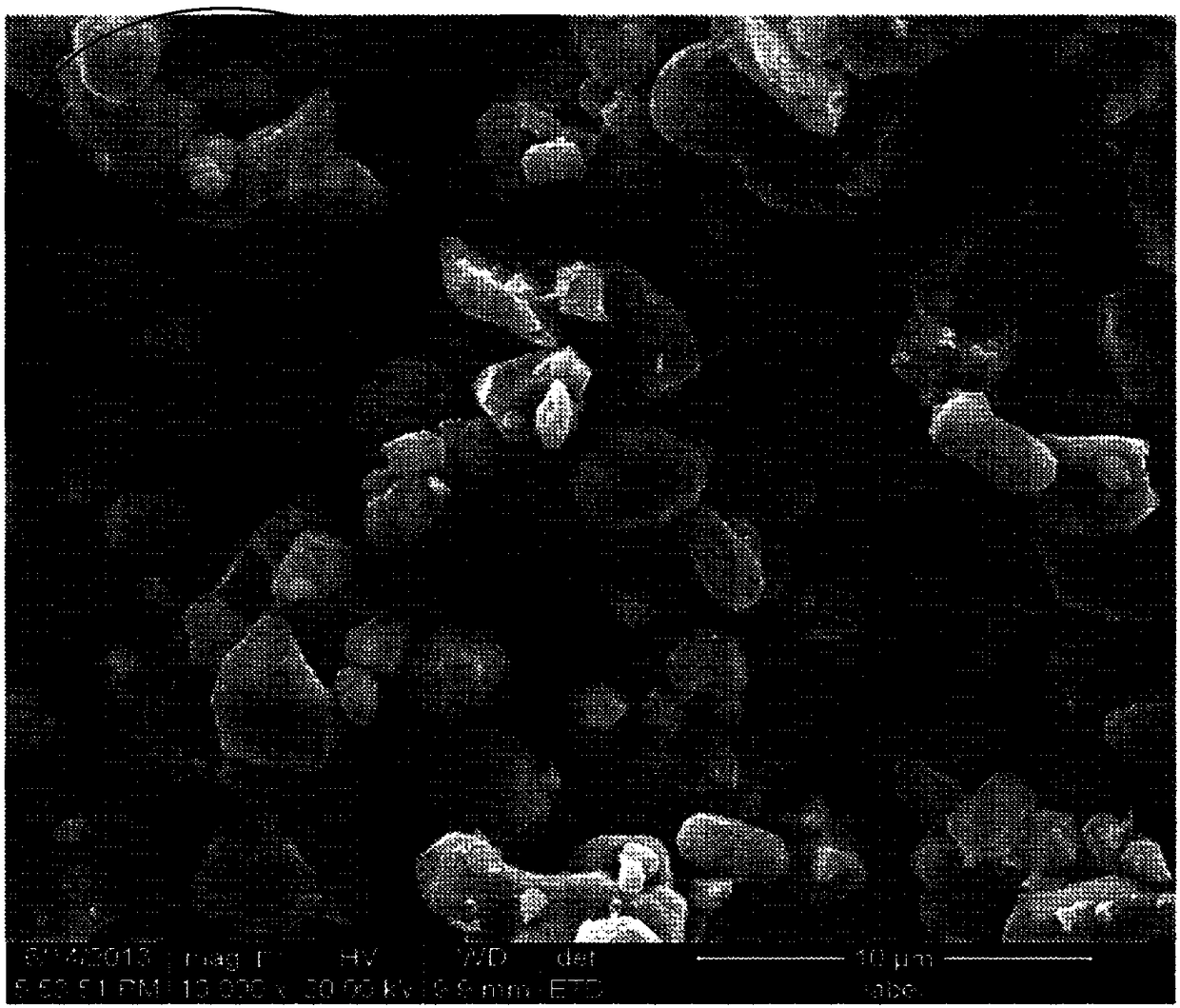

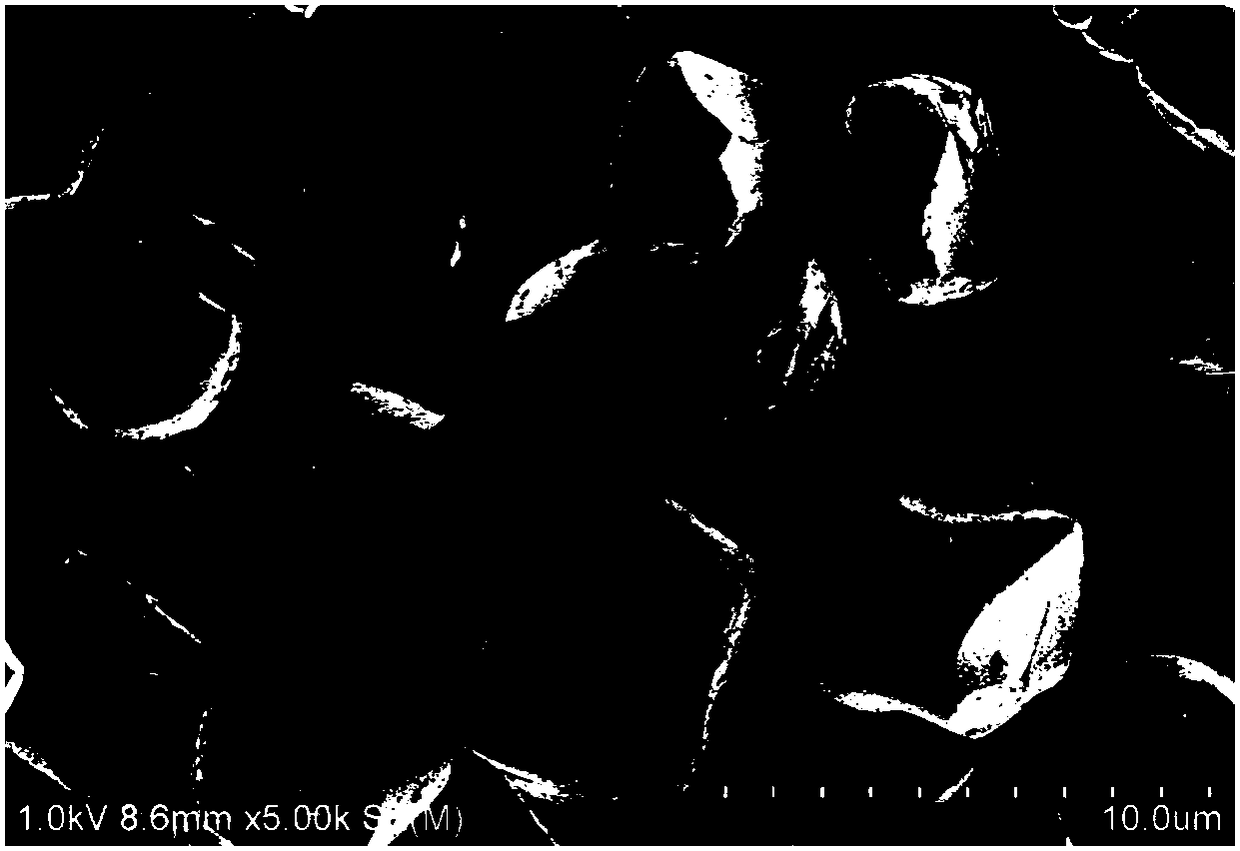

[0083] The difference between this example and Example 2 is only in the additives mixed in step ④. The additives are titanium oxide and boron oxide. The operation is as follows: the precursor obtained by co-precipitation in step ③ is calcined at 520°C for 8 hours, then cooled, After crushing and dispersing, it is passed through a 300-mesh sieve to obtain the oxide of the lithium-rich manganese-based material precursor with a smaller particle size (about 0.3um-6um), and then 100g of the precursor oxide and 0.5g of nano-TiO 2 , 0.2g B 2 O 3 And 71.4g of lithium carbonate (molar ratio Li / Me=1.2 / 0.8, Me is the molar sum of metal ions in the mixed salt solution) after mixing in a high-mixer, sintering at 920℃ for 12h, after crushing 400 mesh sieve, 0.5Li with single crystal morphology 2 MnO 3 ·0.5LiNi 1 / 3 Co 1 / 3 Mn 1 / 3 O 2 Lithium-rich manganese-based cathode material, observed with an electron microscope, its crystal grain shape is figure 2 very close.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com