Production device and method of biological feeds

A technology for production equipment and biological feed, applied in the fields of feed, food science, application, etc., can solve the problems of high production cost, low production efficiency, and many manpower requirements, and achieve the prevention of high temperature sticking and rusting, and mixing uniformity. Good, prevent the effect of material residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] 1. Bio-feed production equipment

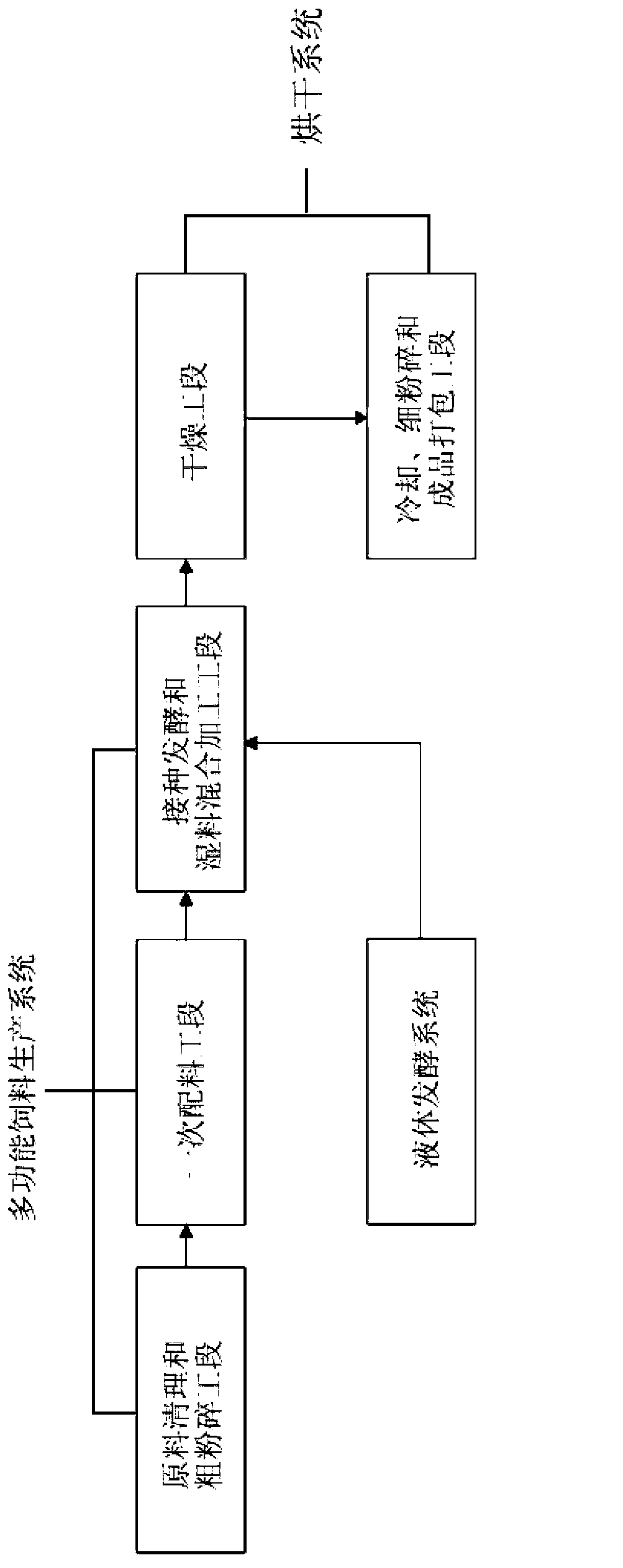

[0067] Such as figure 1 Shown, the production equipment of the biological feed provided by the present embodiment comprises:

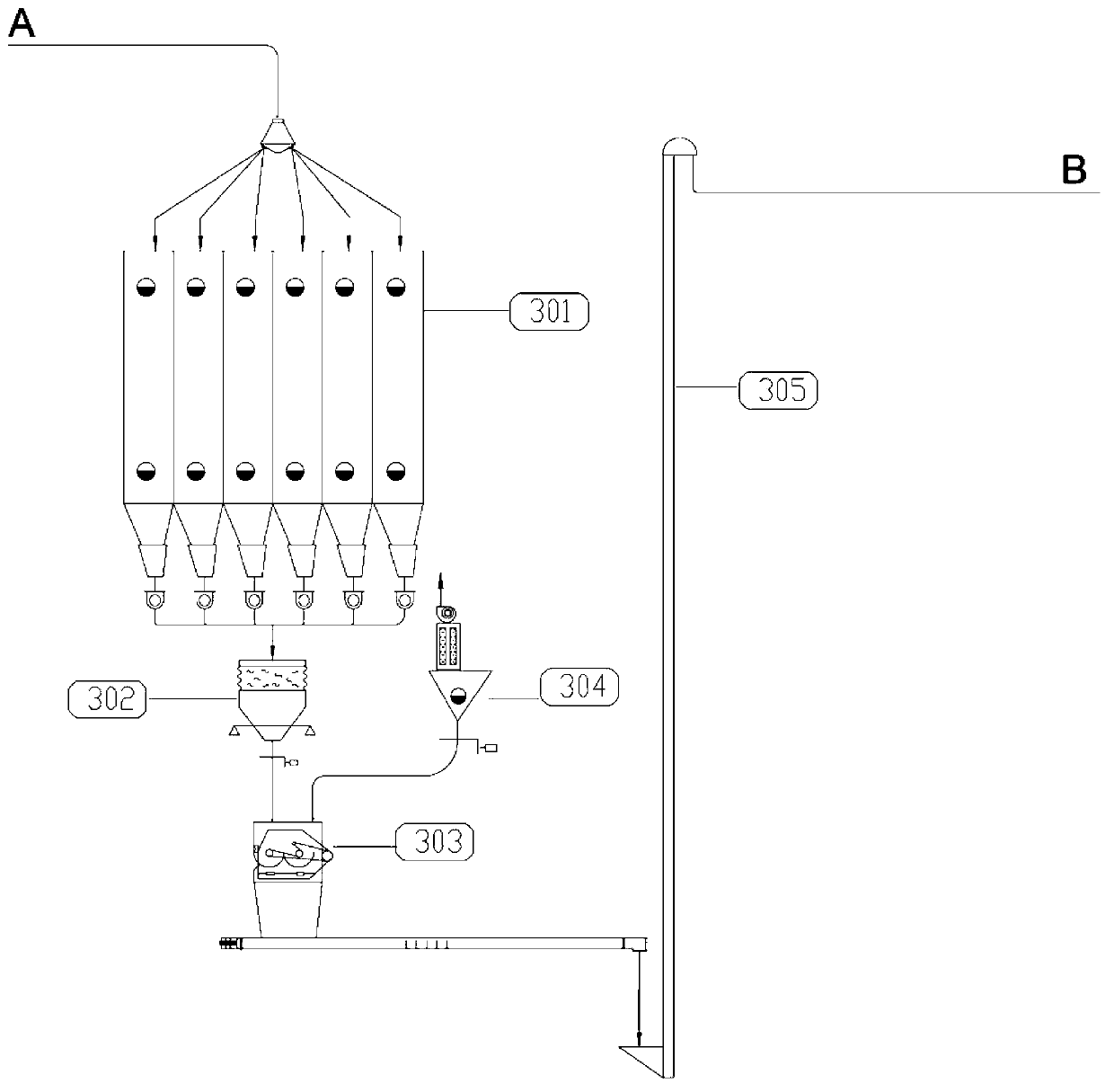

[0068] (1) Multifunctional feed production system, such as Figure 2-Figure 4 As shown, it also includes:

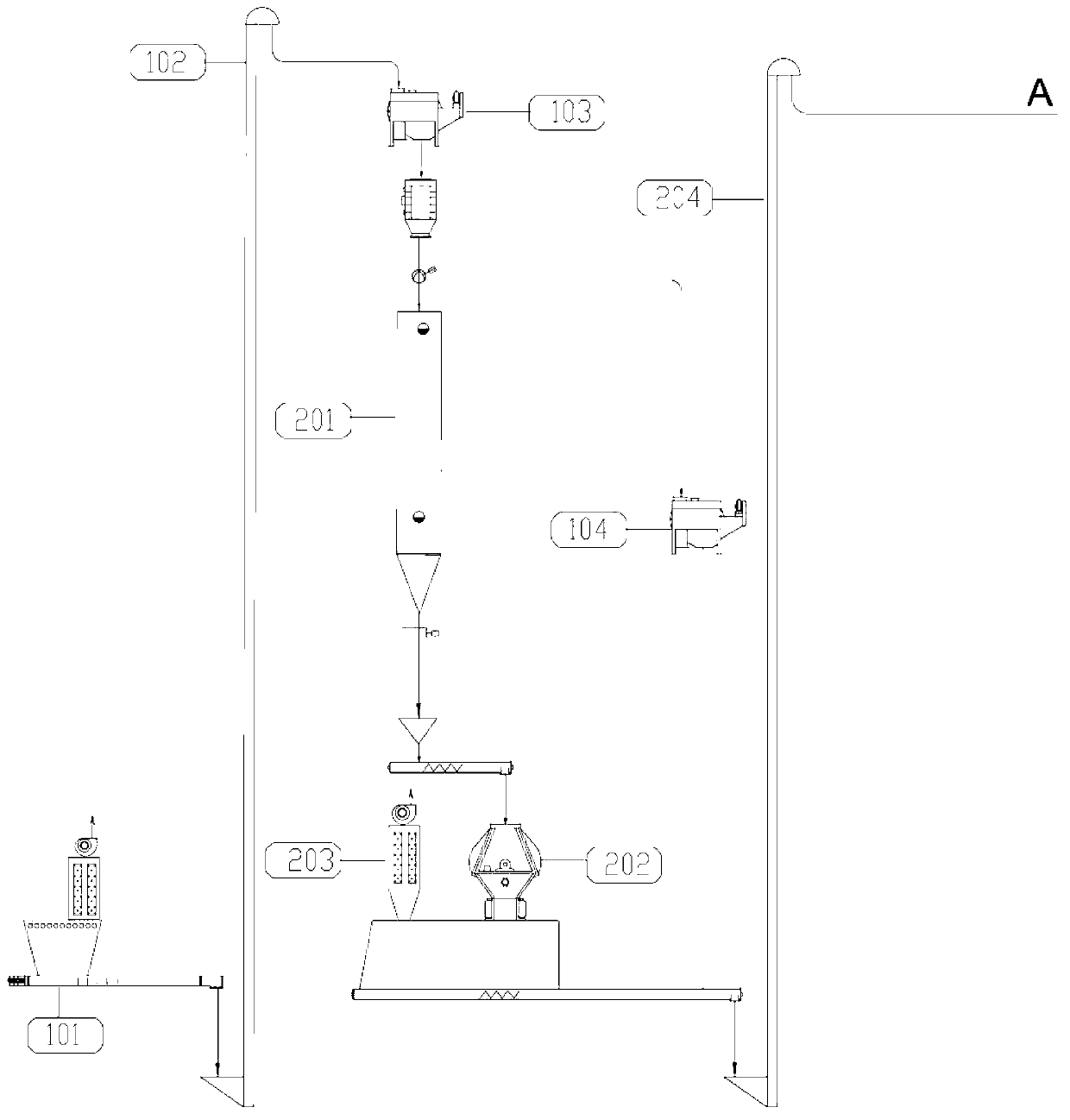

[0069] A. Raw material cleaning and coarse crushing section

[0070] Such as figure 2 As shown, it comprises: a self-cleaning type scraper machine 101 and a self-cleaning type hoist 102 for feeding, and a granular material initial cleaning screen 103, a granular material initial cleaning screen 103 sieve and a sieve are arranged at the end of the self-cleaning type hoisting machine 102. Connect a pulverizer feeding auger 201 and a powder primary cleaning sieve 104 respectively. A coarse pulverizer 202 and a pulse dust collector 203 are installed at the outlet of the crushing bin 201. After the coarse pulverizer 202 and the powder go out of the sieve 104 Connect a self-cleaning hoist 204, its end is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com