Method for gasification reduction of pulverized coal and separation and recycling of upgraded coal

A technology for separation, recovery and upgrading of coal, which is used in special forms of dry distillation, petroleum industry, coke ovens, etc., and can solve the problems of small processing capacity and difficult industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

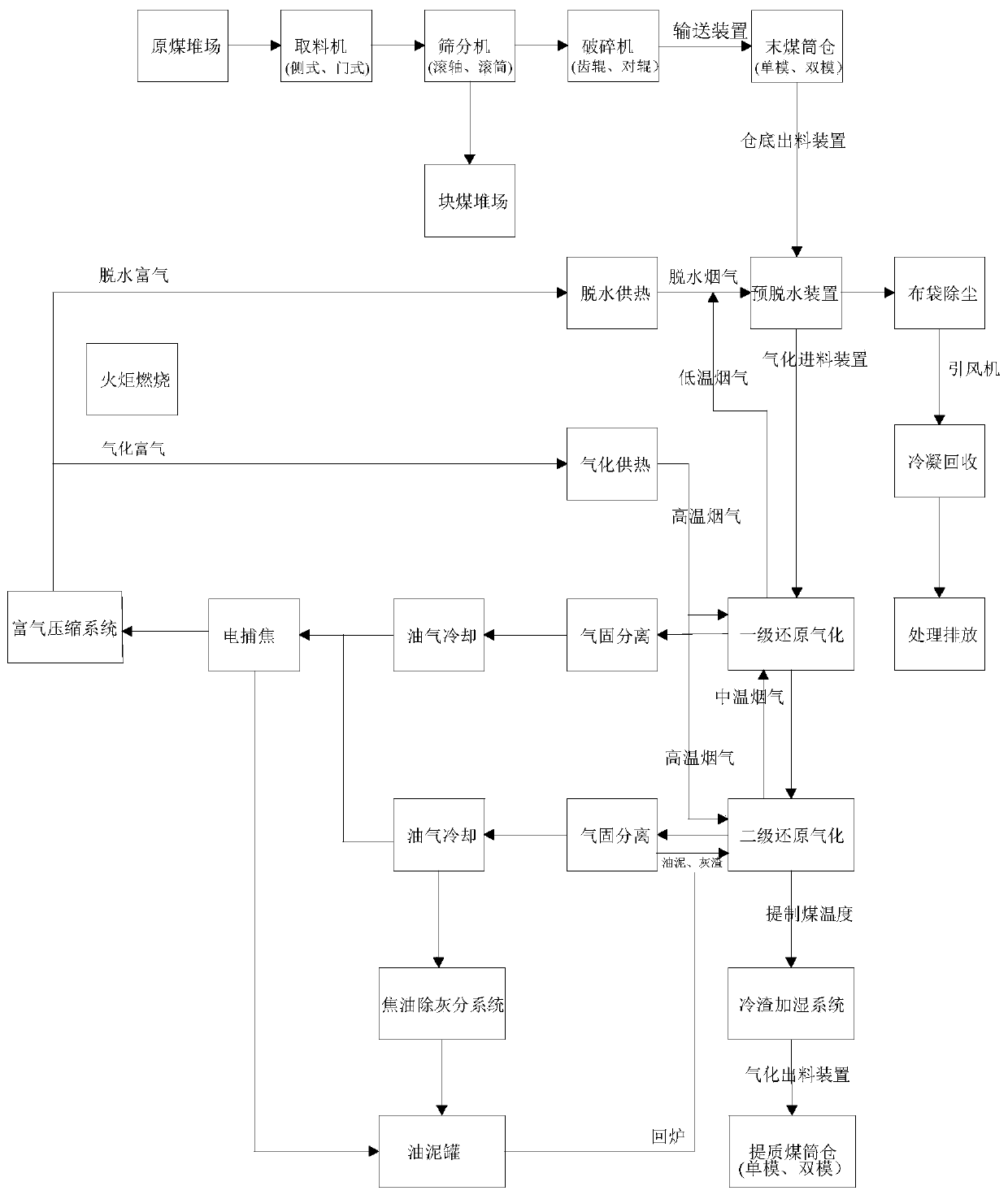

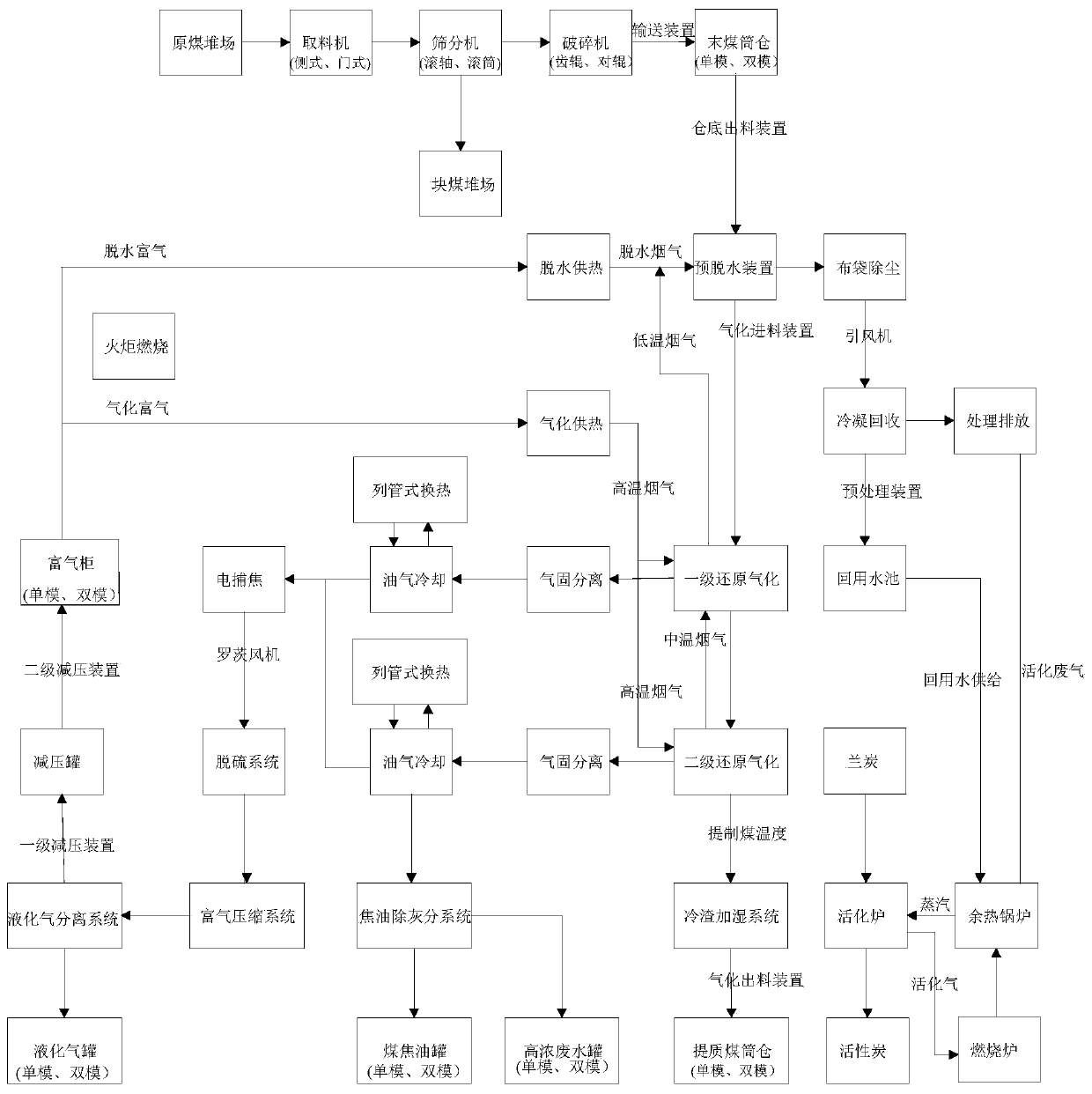

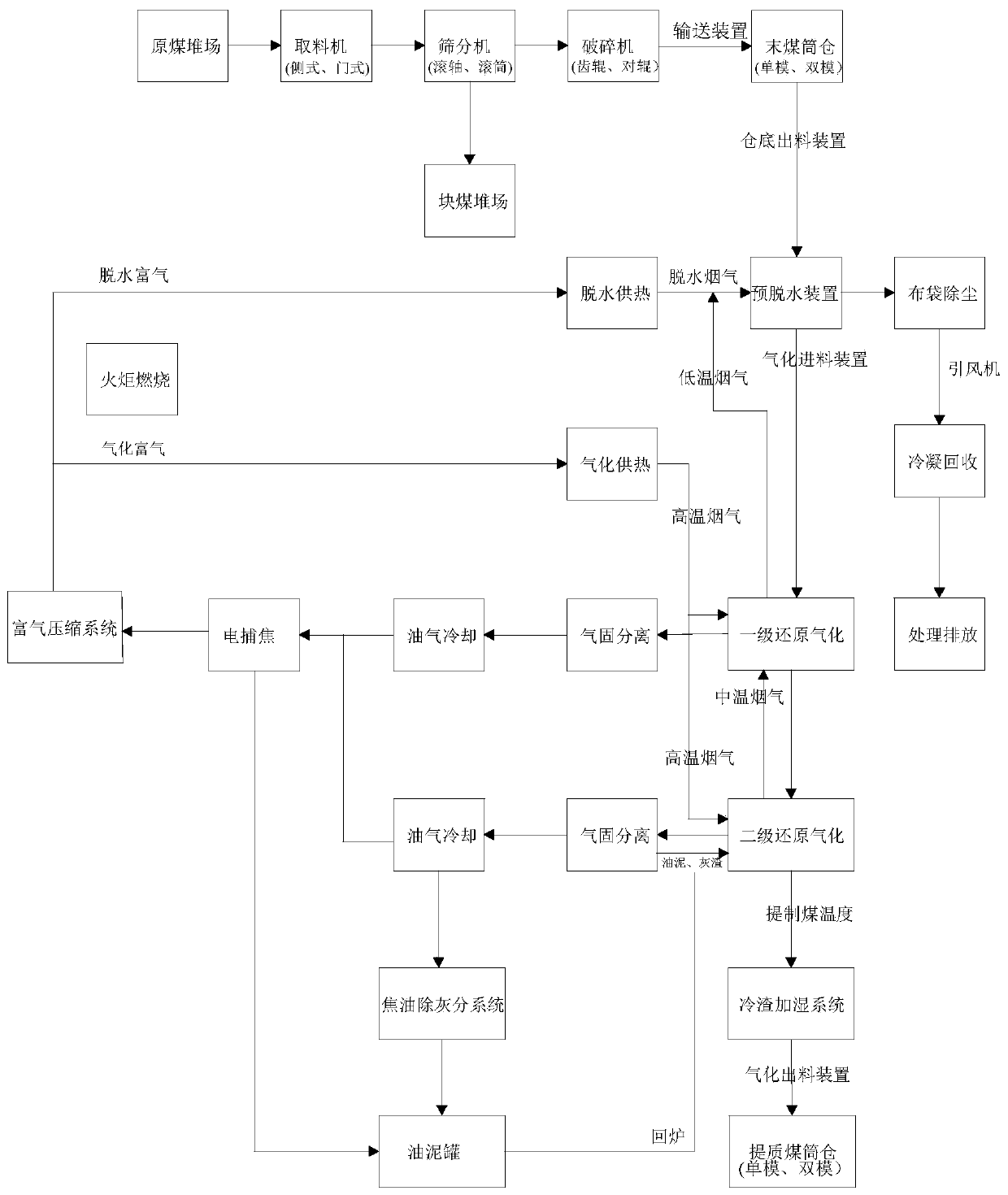

[0134] like figure 1 , figure 2 As shown, a method for pulverized coal gasification reduction and upgraded coal separation and recovery includes the following steps:

[0135] (1) Under the action of the reclaimer, the coal in the raw coal yard is screened by the screening machine, crushed by the crusher, and then enters the fine coal silo through the conveying device.

[0136] The coal stacked in the raw coal yard is reclaimed by a side-type scraper reclaimer with a reclaiming capacity of 400t / h, and the working time is calculated as 10h. Mainly for the lump coal to enter the lump coal yard for storage, and the under-sieve material with a particle size of ≤30mm will enter the roller crusher for crushing, with an optional output of 200t / h, and the crushed material with a particle size of ≤13mm will pass through the belt conveyor. It is sent to the powder coal silo, and the length of the belt conveyor is 55m.

[0137] (2) The pulverized coal in the fine coal silo enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com