Patents

Literature

31results about How to "Safe to dry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

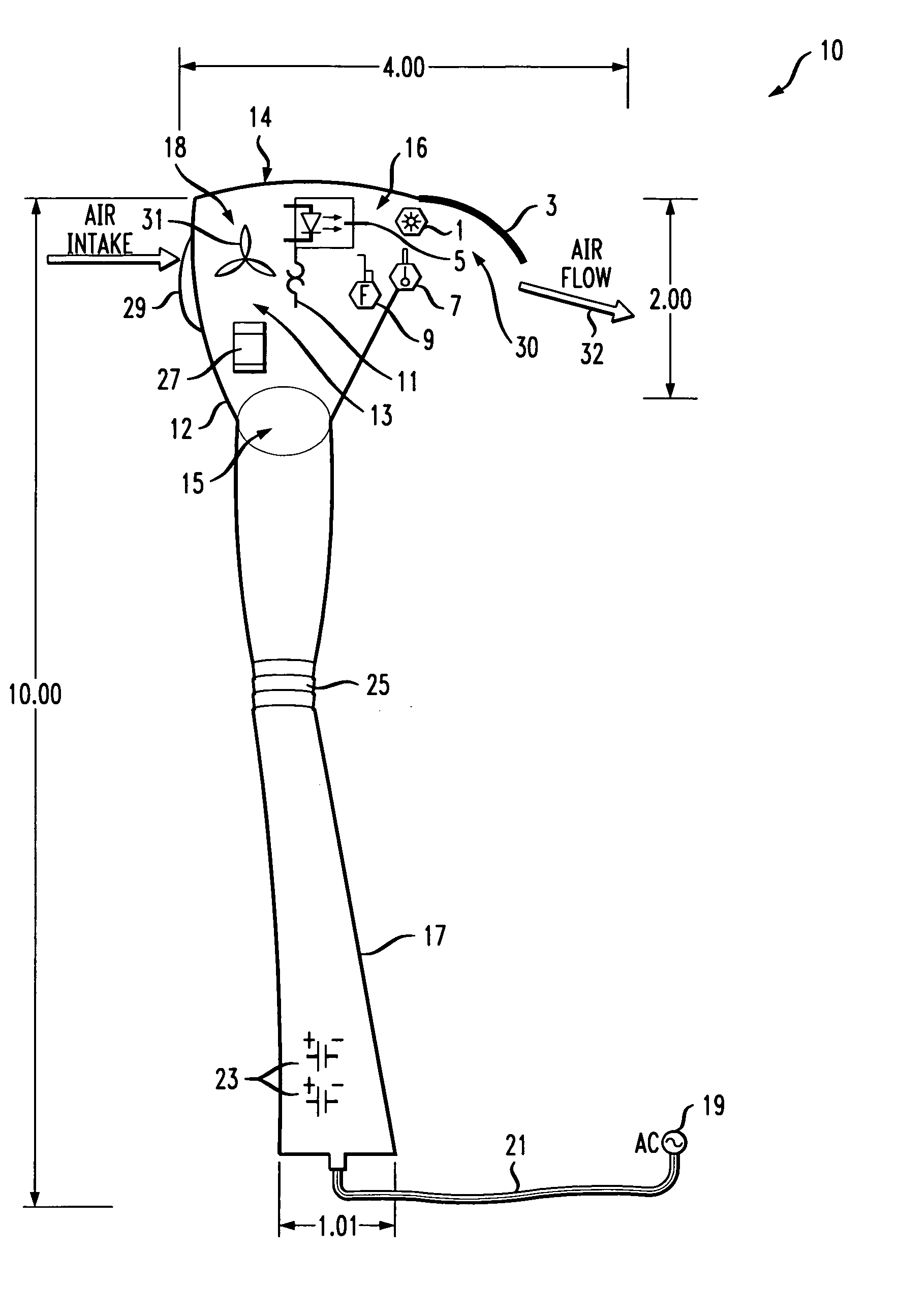

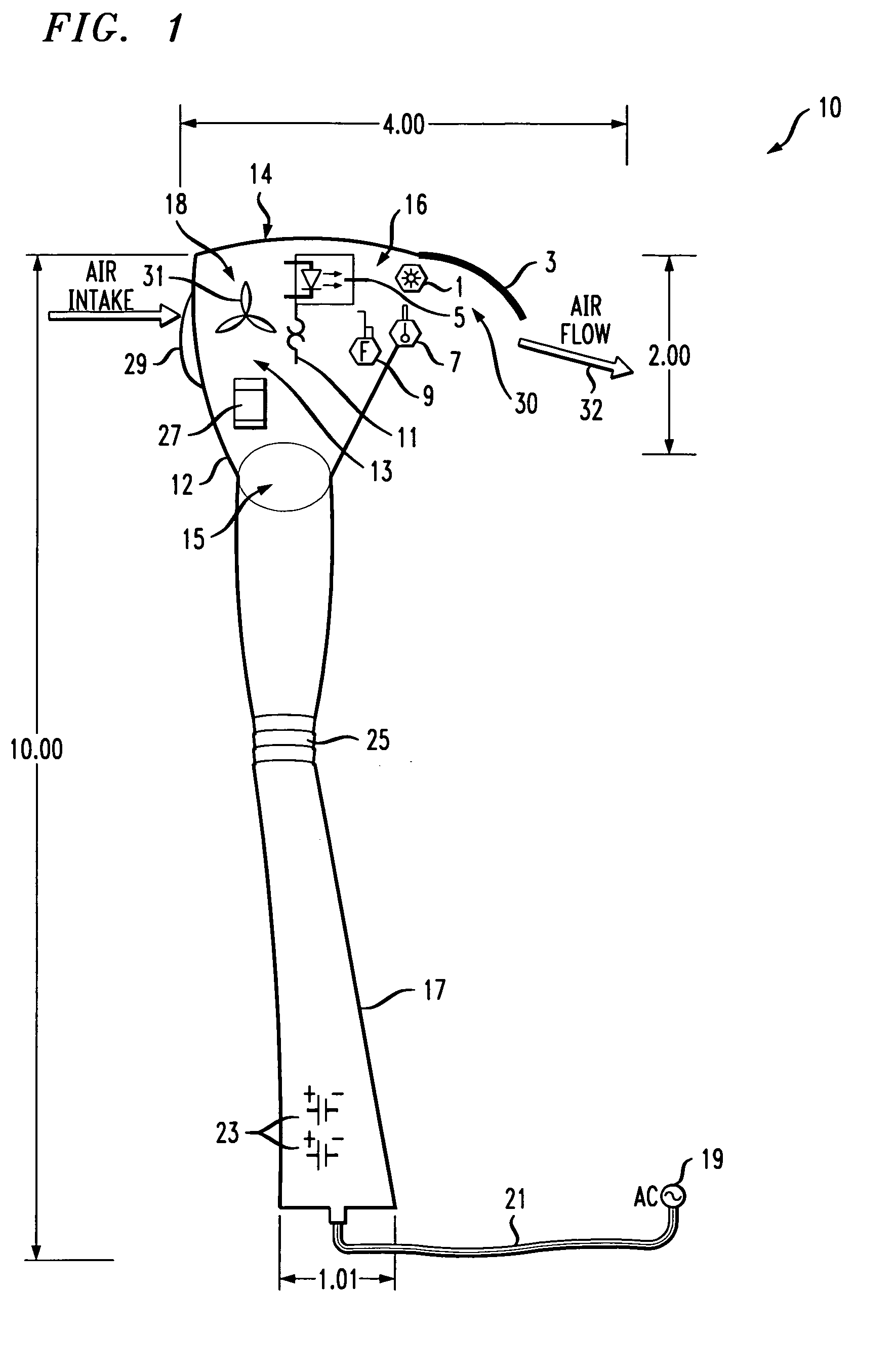

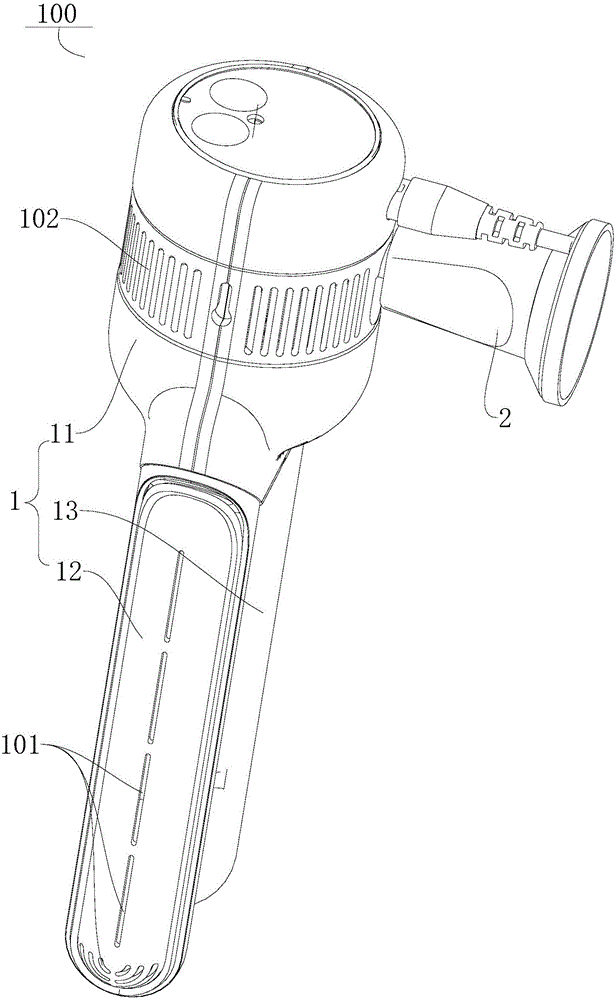

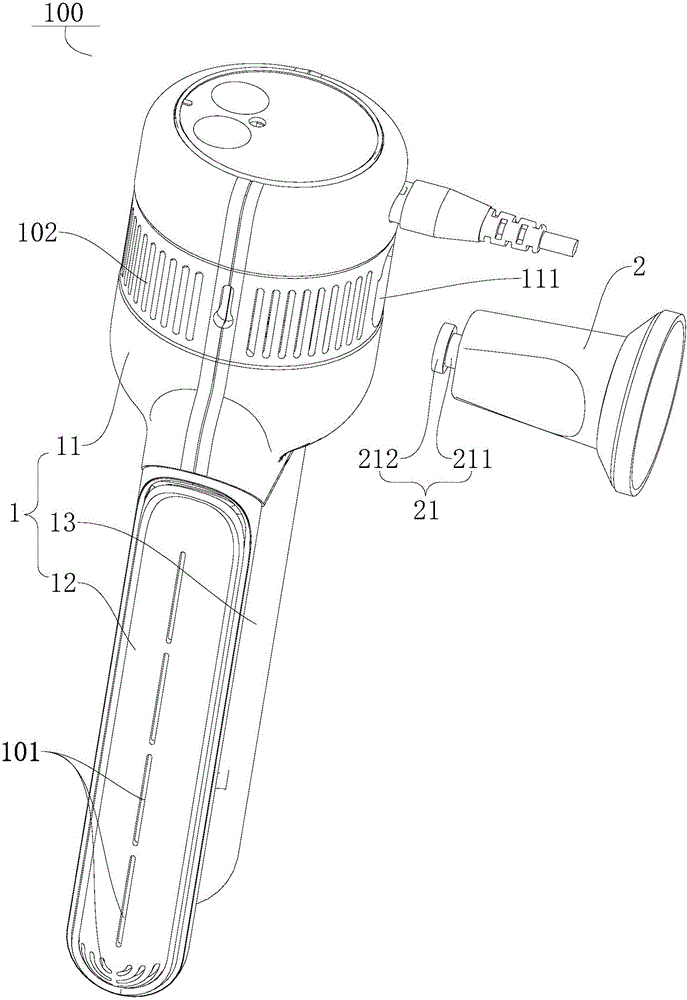

Therapeutic device for delivering controlled air stream flow and/or photodynamic light therapy

A therapeutic device for treating and preventing dermatological diseases and conditions, includes a housing comprising a head portion having an opening through which light energy exits the device and a handle; a light generating assembly adapted to generate and direct a preselected type of light energy to the skin; and moisture removing assembly operatively associated with the housing for removing moisture from the surface of the skin being treated.

Owner:GILSON DARCY J +2

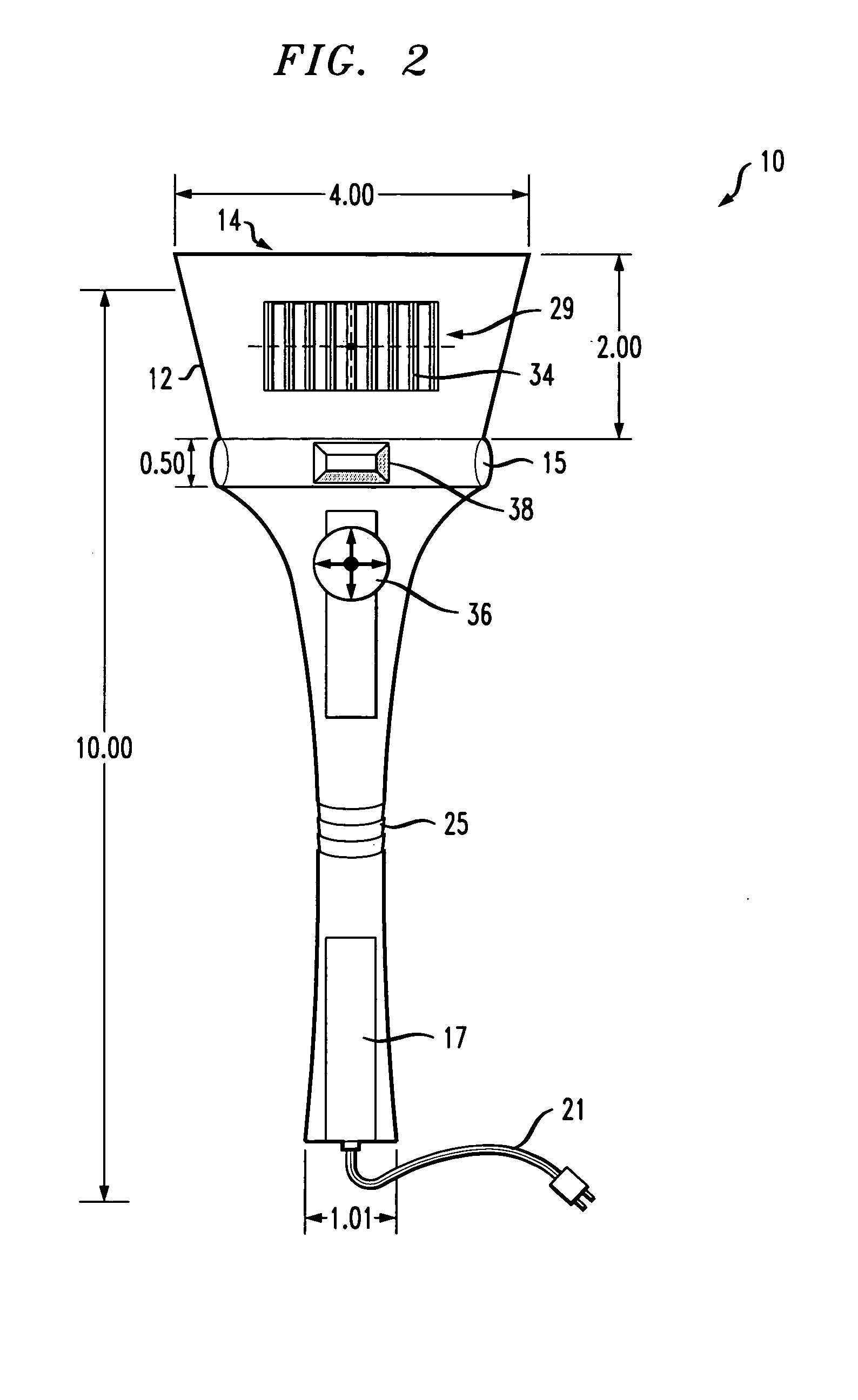

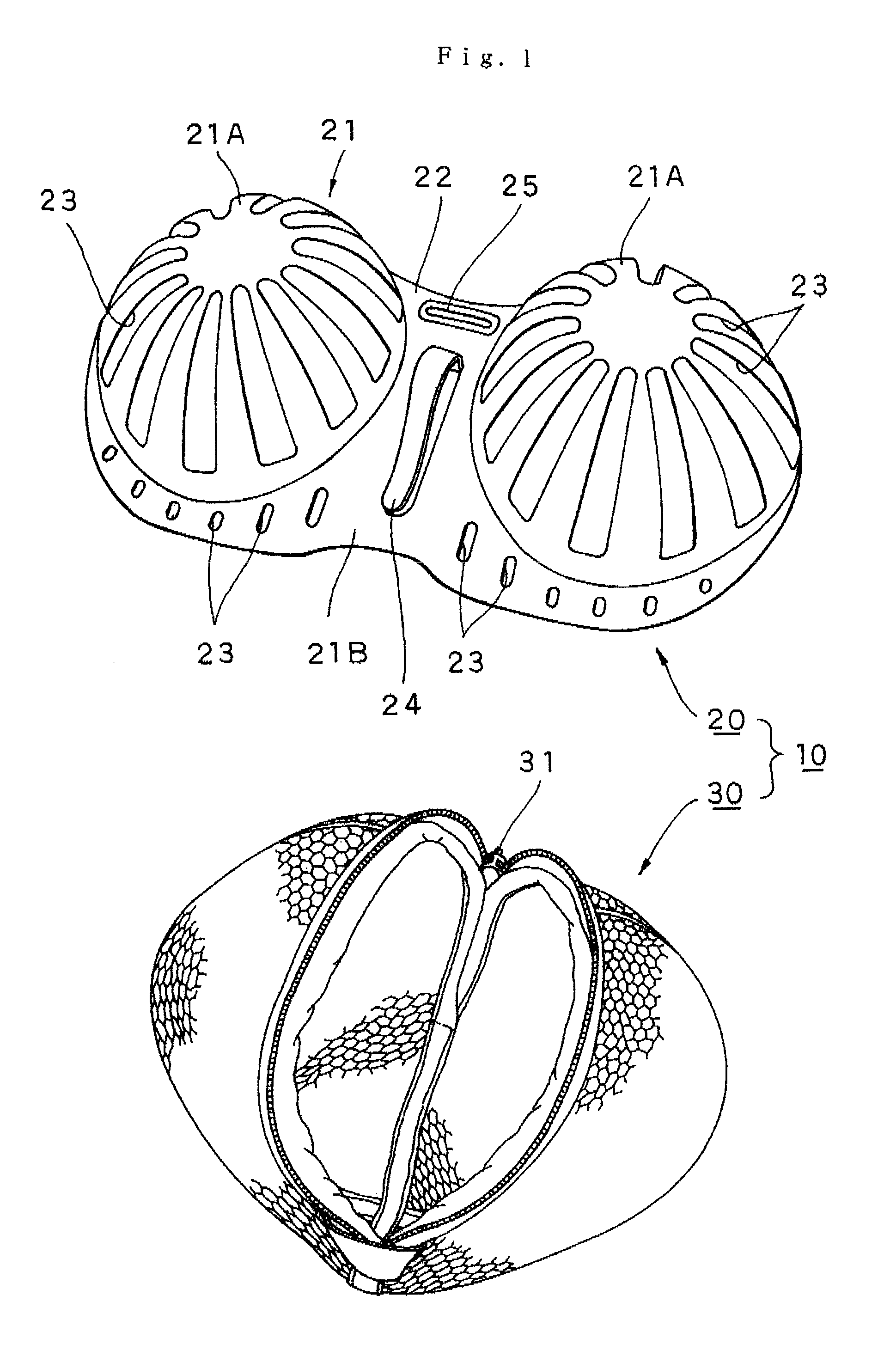

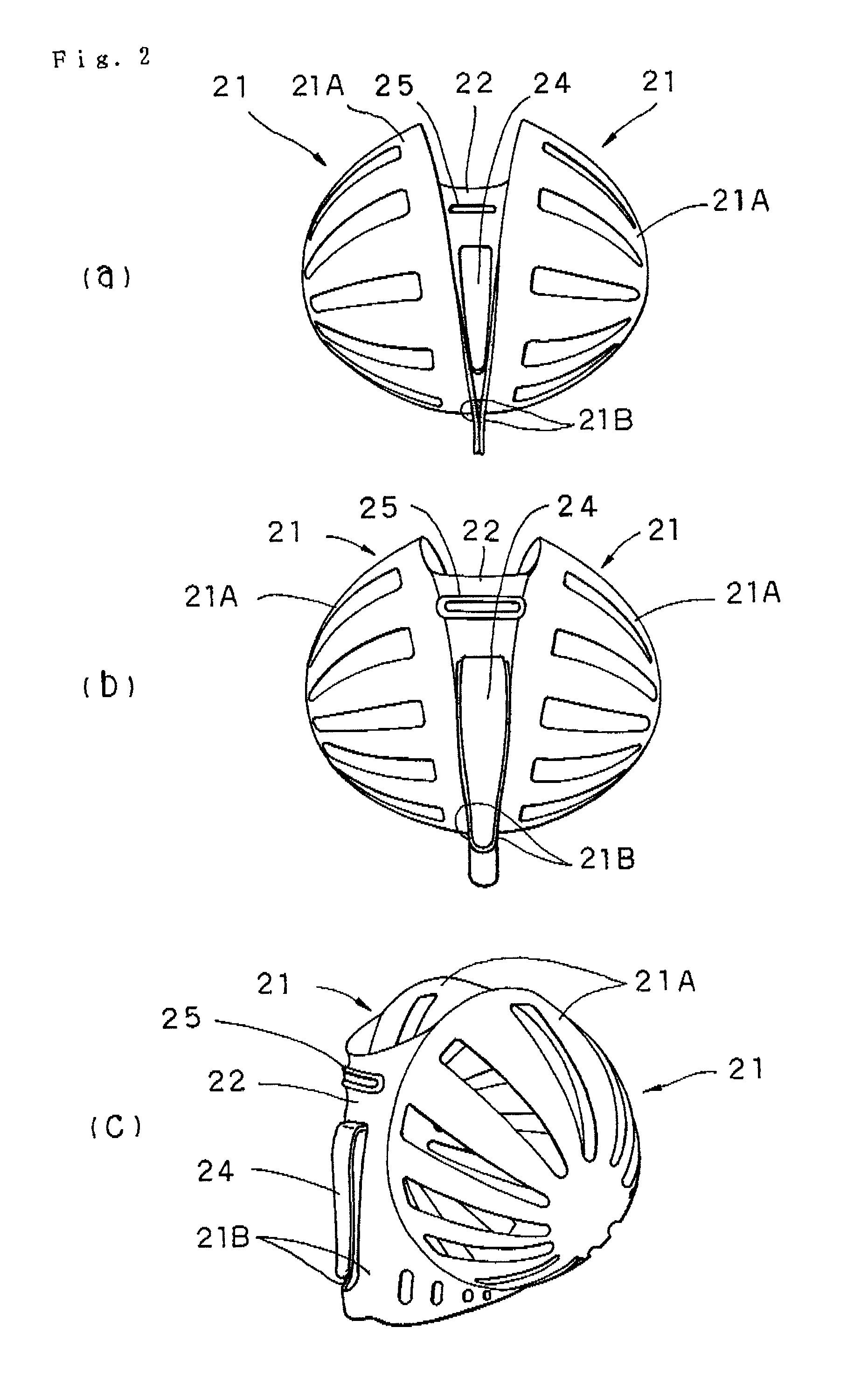

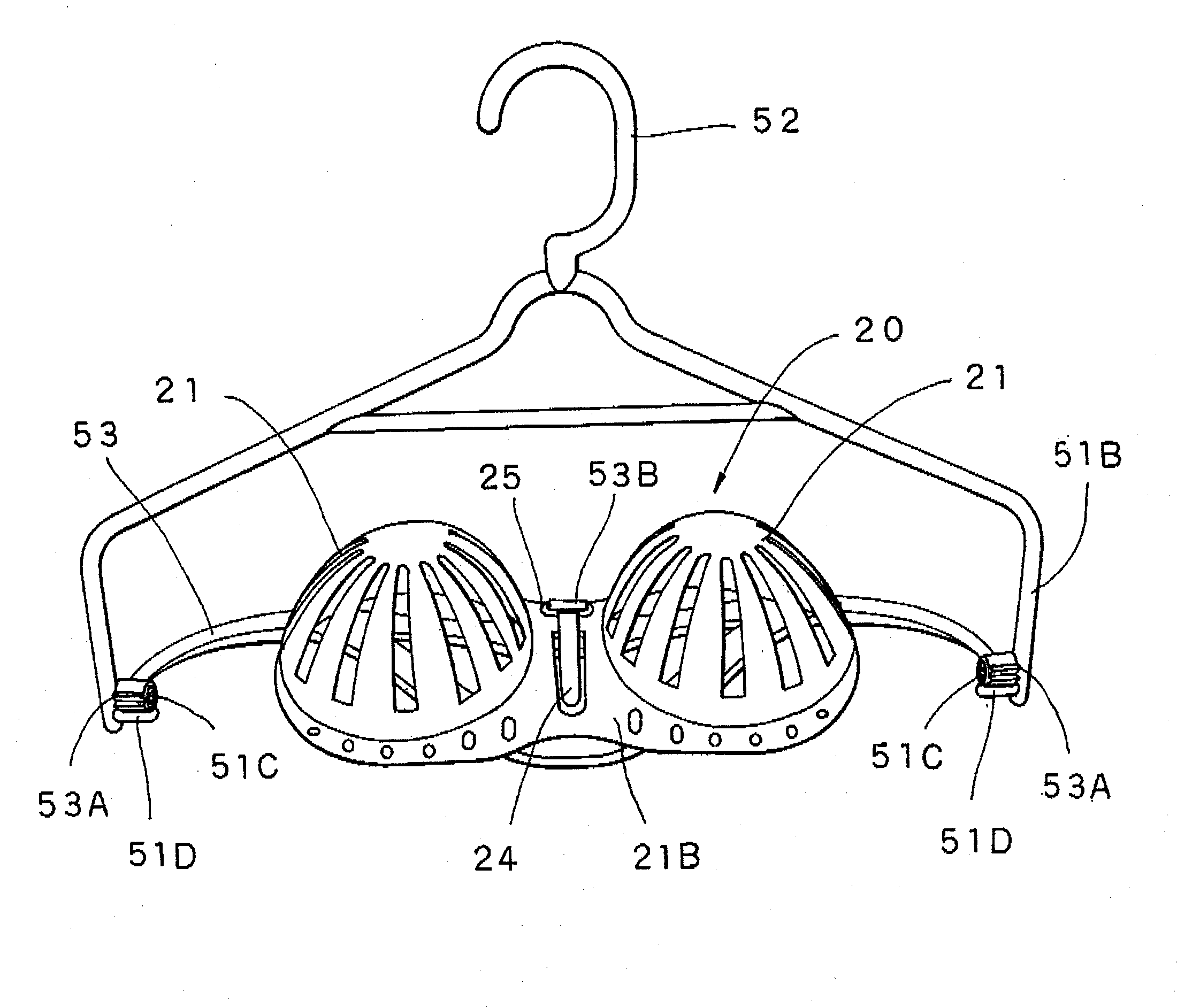

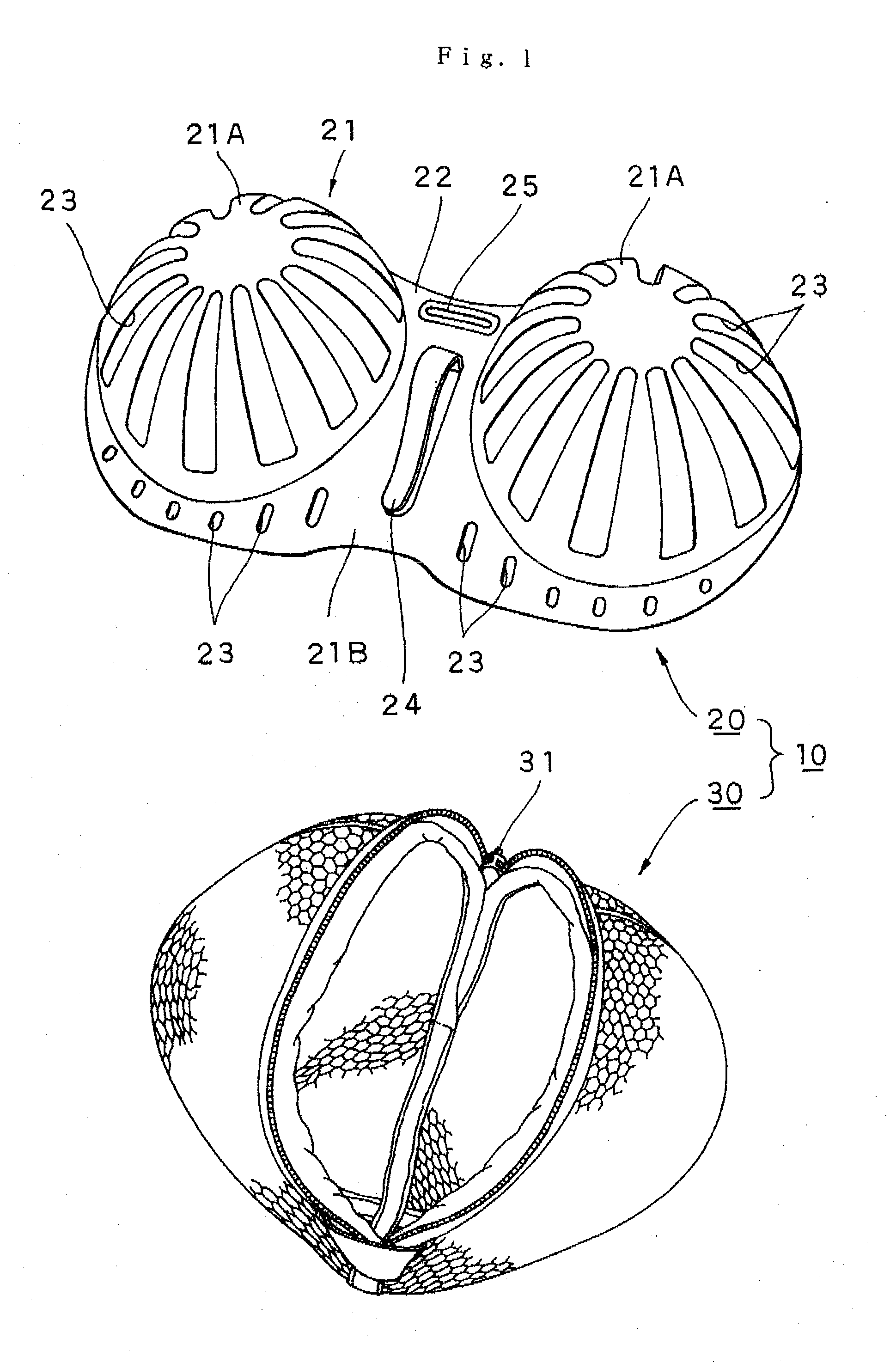

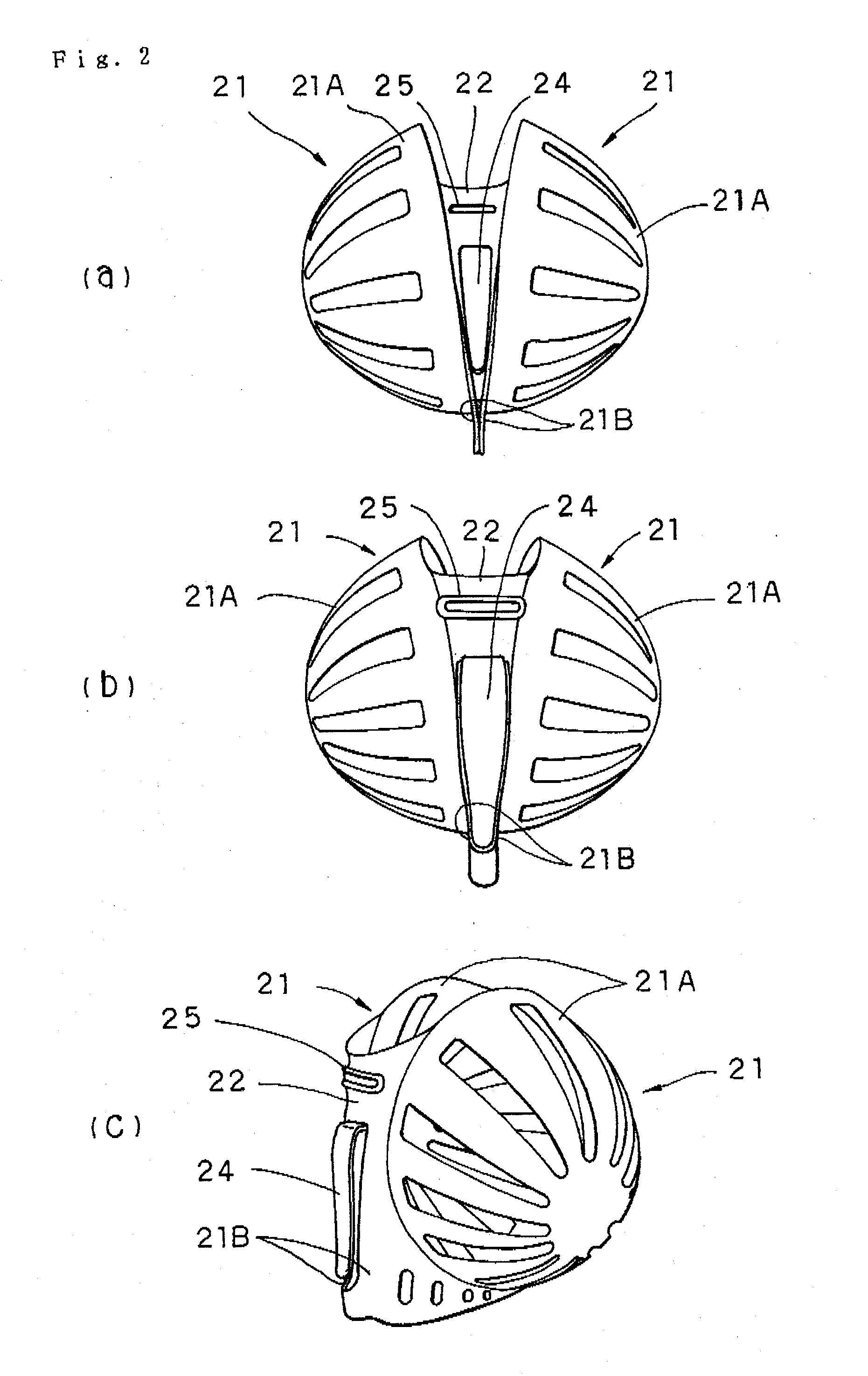

Brassier washing utensil

A brassiere holder is presented that includes two cup receiving portions, a connecting portion and a hook portion. When the cup receiving portions are pressed from the side, the connecting portion is elastically deformed to allow the two cup receiving portions to be folded back on each other such that a part of a flange portion of the two cup receiving portions is brought into contact with the other part of the flange portion and a gap gradually increasing toward the upper side is formed between the two cup receiving portions. In this manner, since the cup portions of the brassiere are formed in a shape similar to a shape obtained in a state in which a three-dimensional shape of a breast of a human being is folded into two, the cup portions are positioned as they are under their current state and are put in a soft net bag.

Owner:OKAZAKI YOSHIKI +1

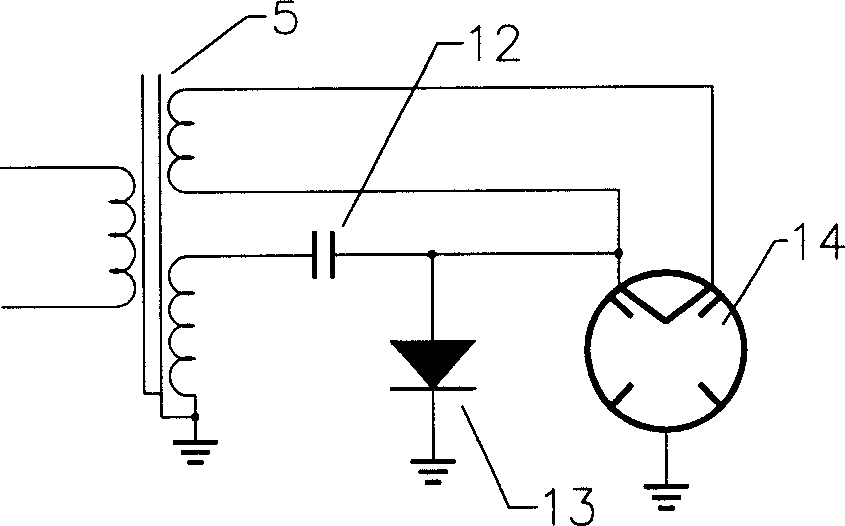

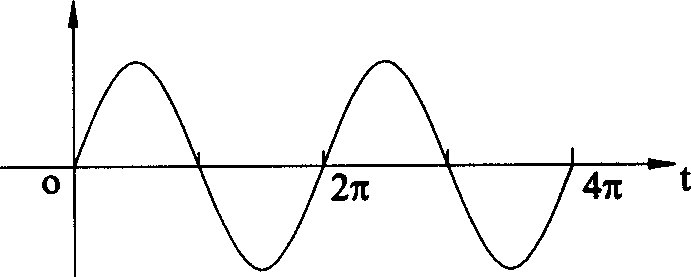

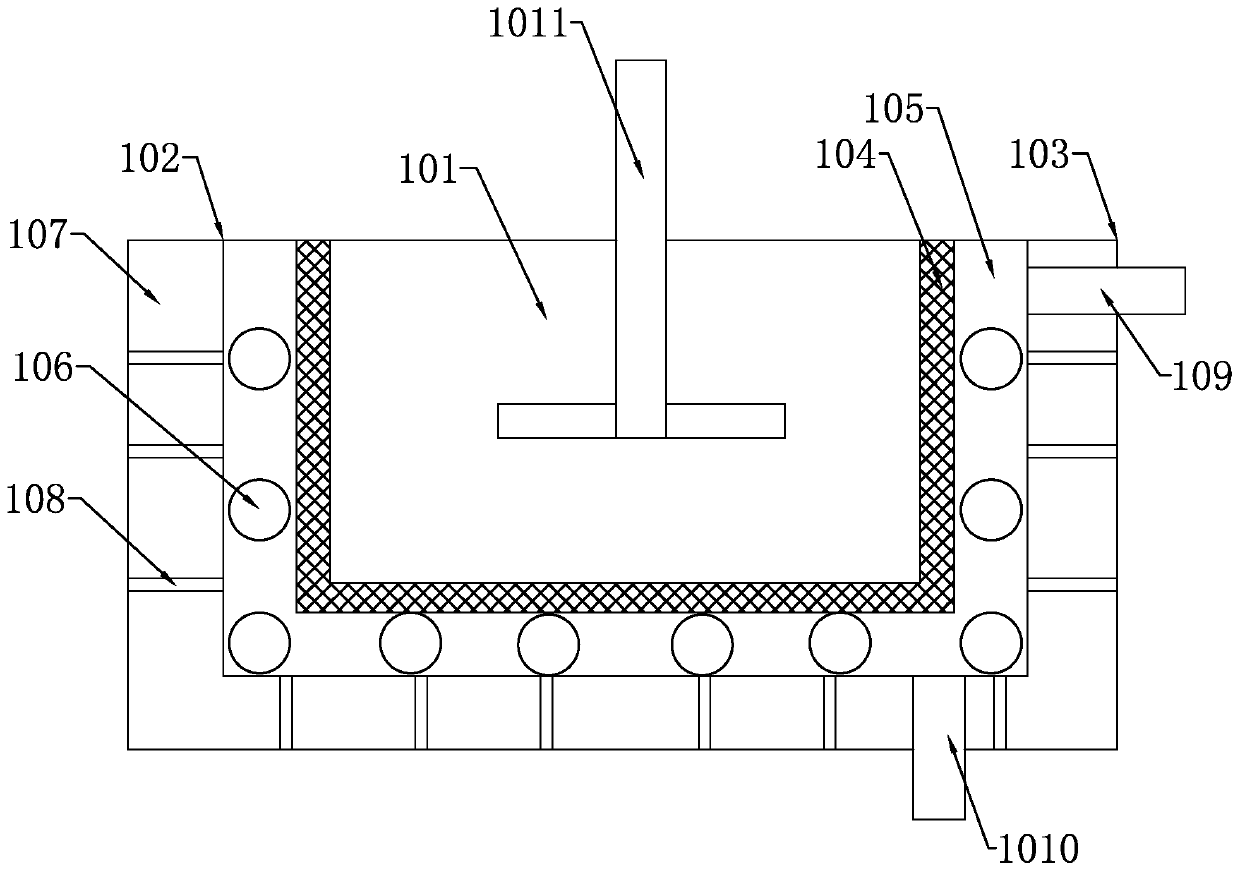

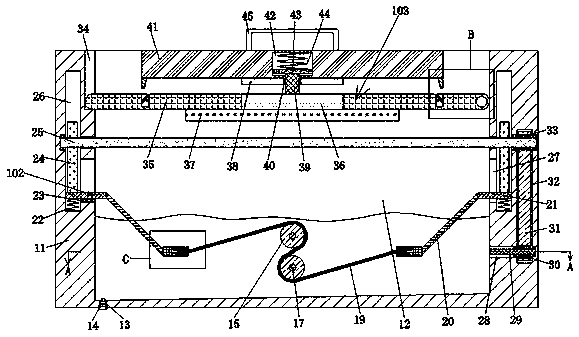

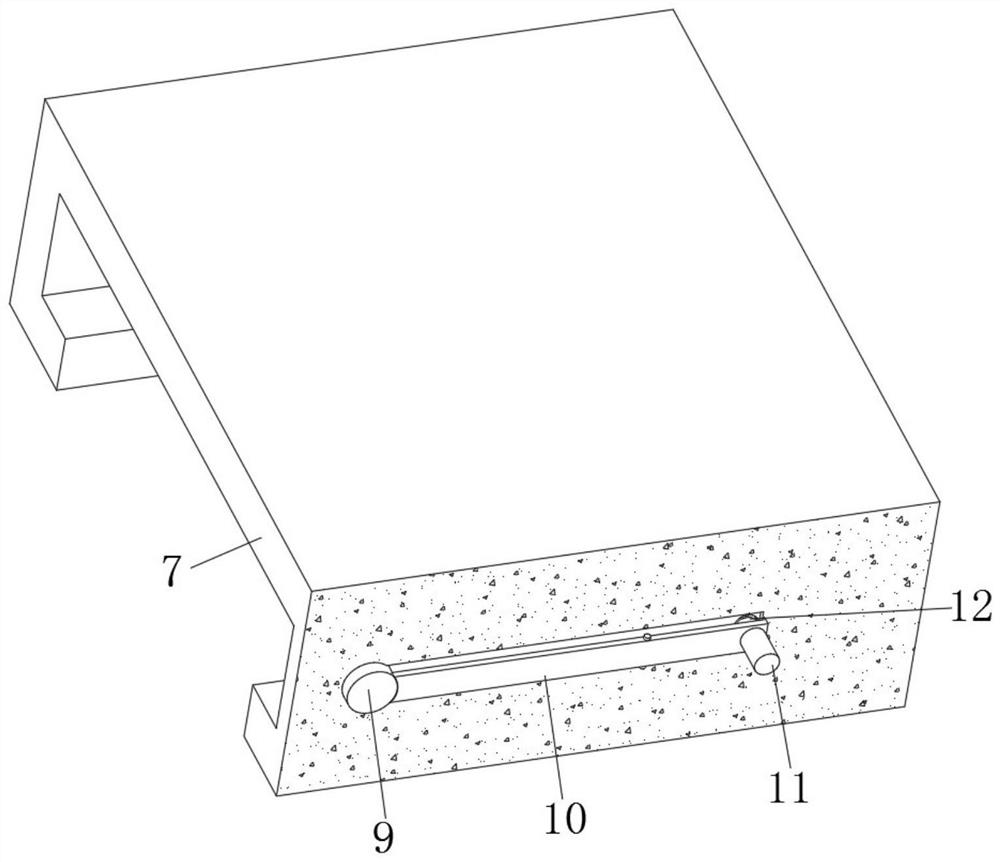

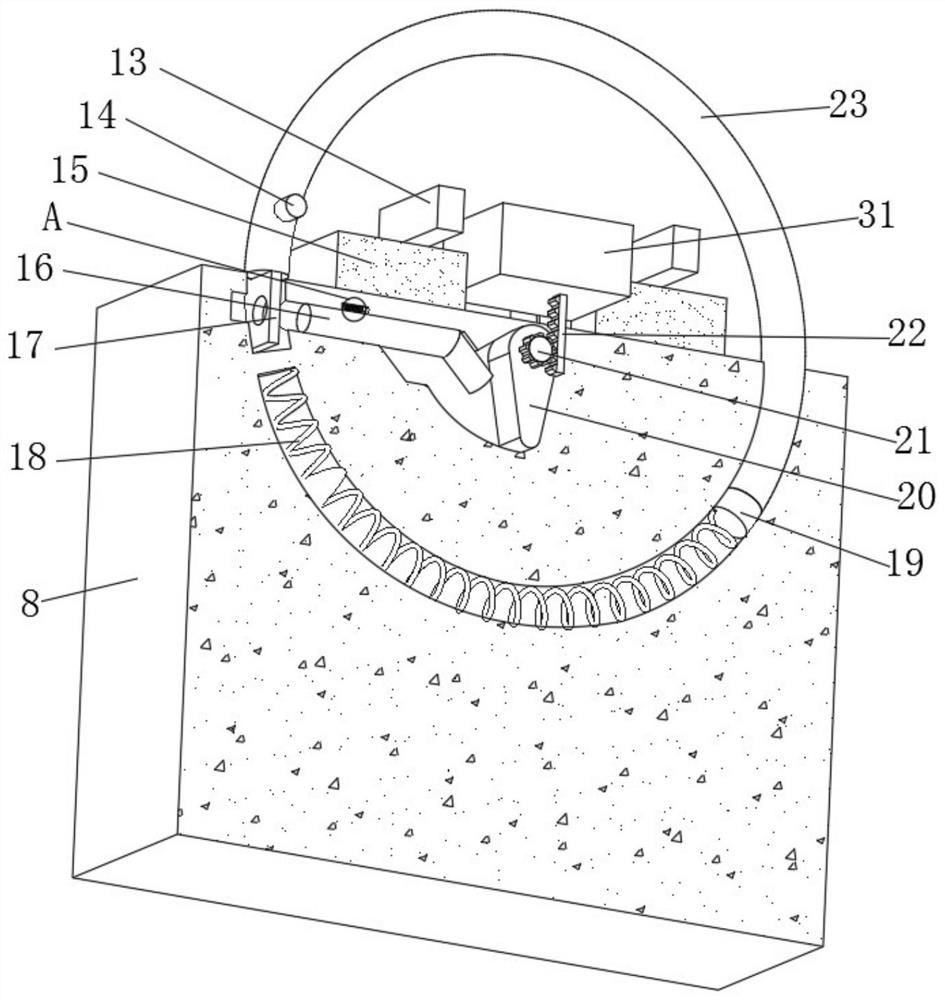

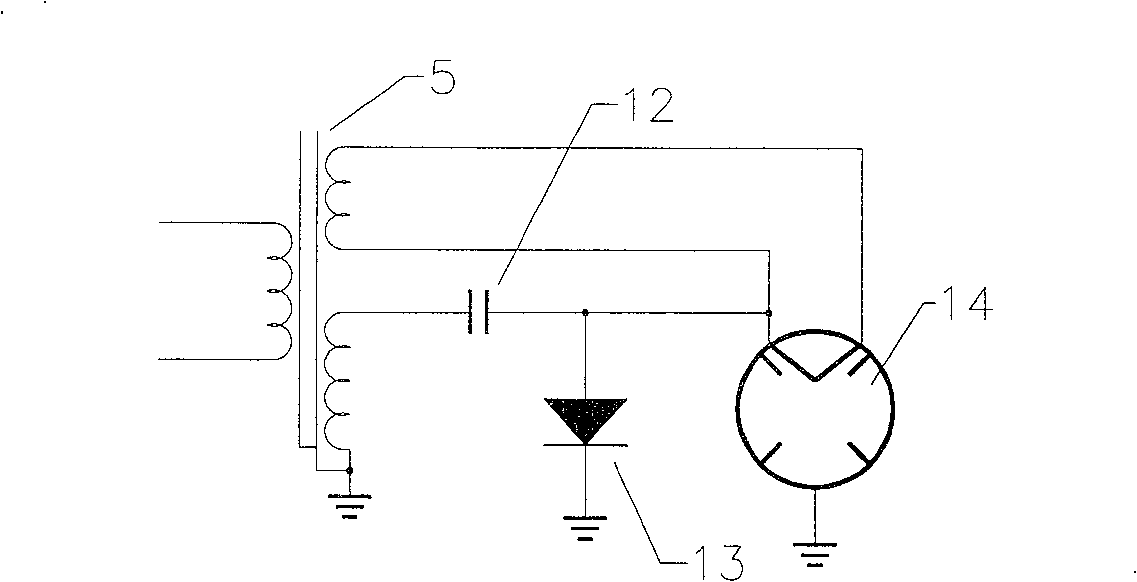

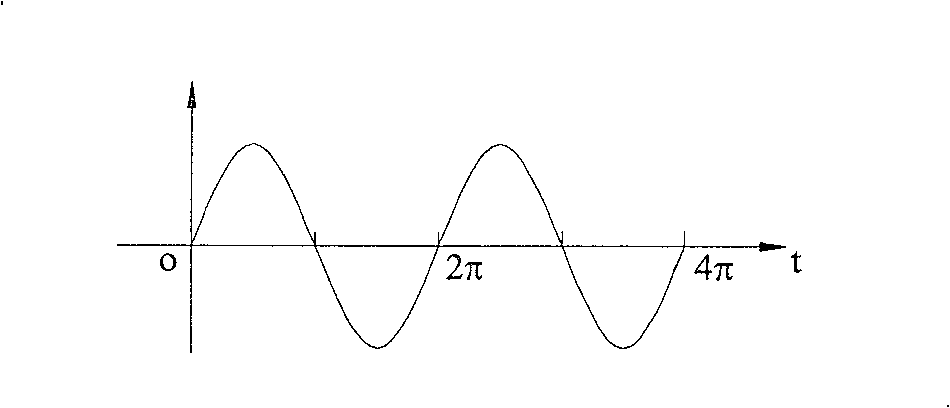

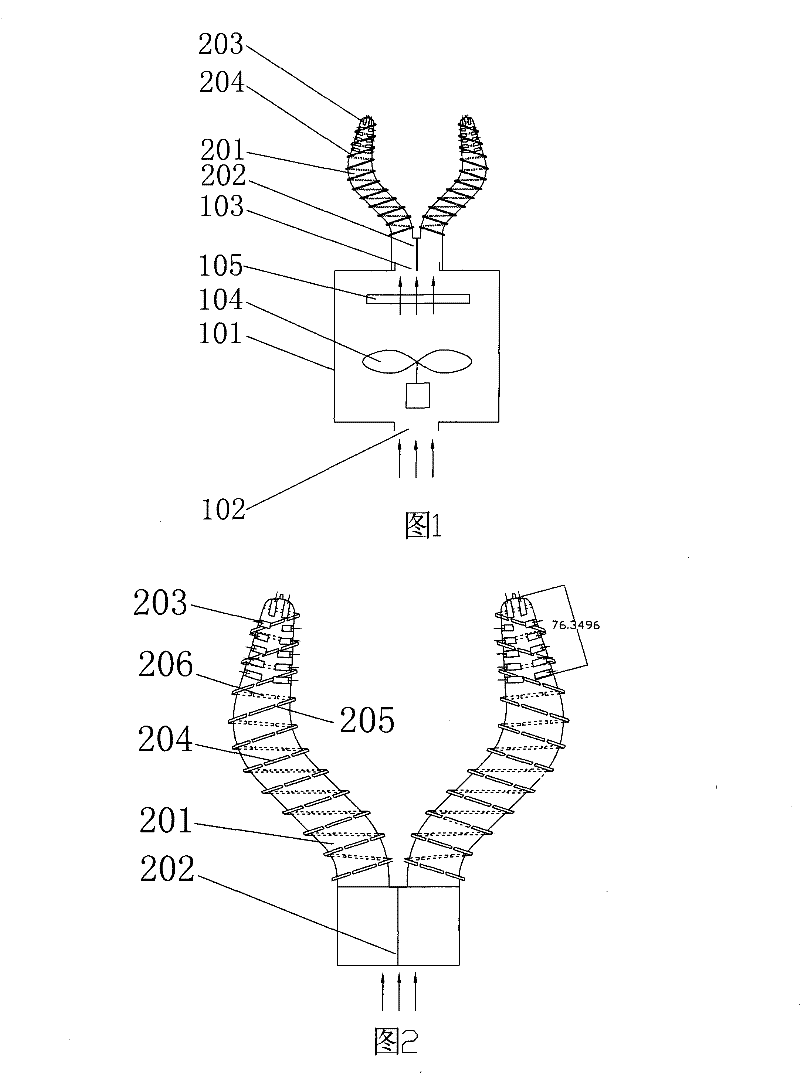

Microwave clohtes dryer

InactiveCN1760436AHeating evenly and more comprehensivelyIncreased average power densityMicrowave heatingTextiles and paperState of artMicrowave oven

The present invention relates to a microwave clothes drying machine. It is characterized by that said invention adopts the following technical measures: remaking half-wave voltage-multiplying rectifier circuit of high-voltage power supply of domestic microwave oven magnetron into full-wave rectifier circuit containing power regulation device, setting mutually perpendicular microwave activation directions to construct stereo microwave and adopting polygonal cabinet body or cylindrical or drum type reaction cavity, etc. to reduce microwave pulse peak power and raise microwave average power density, so that the microwave power can be flexibly regulated according to the number of clothes and the safety of drying process also can be raised.

Owner:成都骏元科技发展有限责任公司

Brassier washing utensil

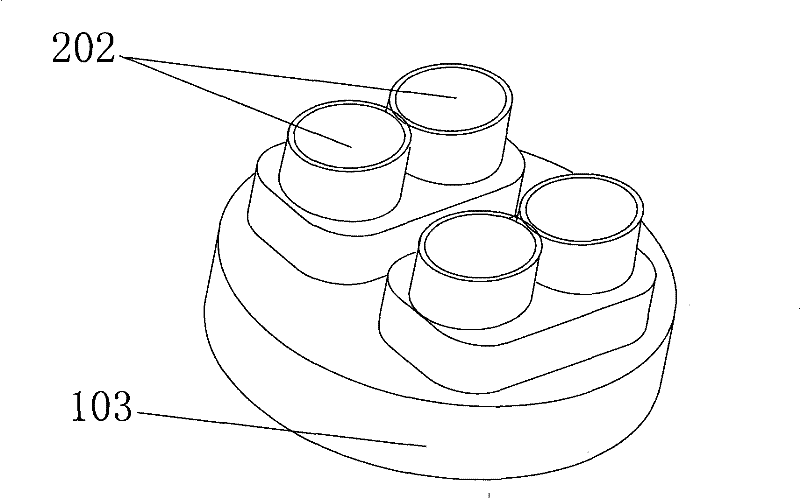

InactiveUS20080296322A1Safely washSafe to dryApparel holdersGarmentsThree dimensional shapeMechanical engineering

To provide an utensil adapted to wash a brassiere without loss of shape in cup portions, damage of fabric such as lace and cloth, and deformation and twisting of wires. A brassiere holder (20) is configured by two cup receiving portions (21), a connecting portion (22) and a hook portion (24). When the cup receiving portions are pressed from the side, the connecting portion is elastically deformed to allow the two cup receiving portions to be folded back on each other such that a part of a flange portion of the two cup receiving portions is brought into contact with the other part of the flange portion and a gap gradually increasing toward the upper side is formed between the two cup receiving portions. In this manner, since the cup portions (41) of the brassiere (40) are formed in a three-dimensional shape similar to a shape obtained in a state in which a three-dimensional shape of a breast of a human being is folded into two, the cup portions of the brassiere are positioned as they are under their current state and are put in a soft net bag (30) so as to be elastically held, and three-dimensional shapes of the cup portions and wires of the lower peripheral edges thereof can be kept.

Owner:OKAZAKI YOSHIKI +1

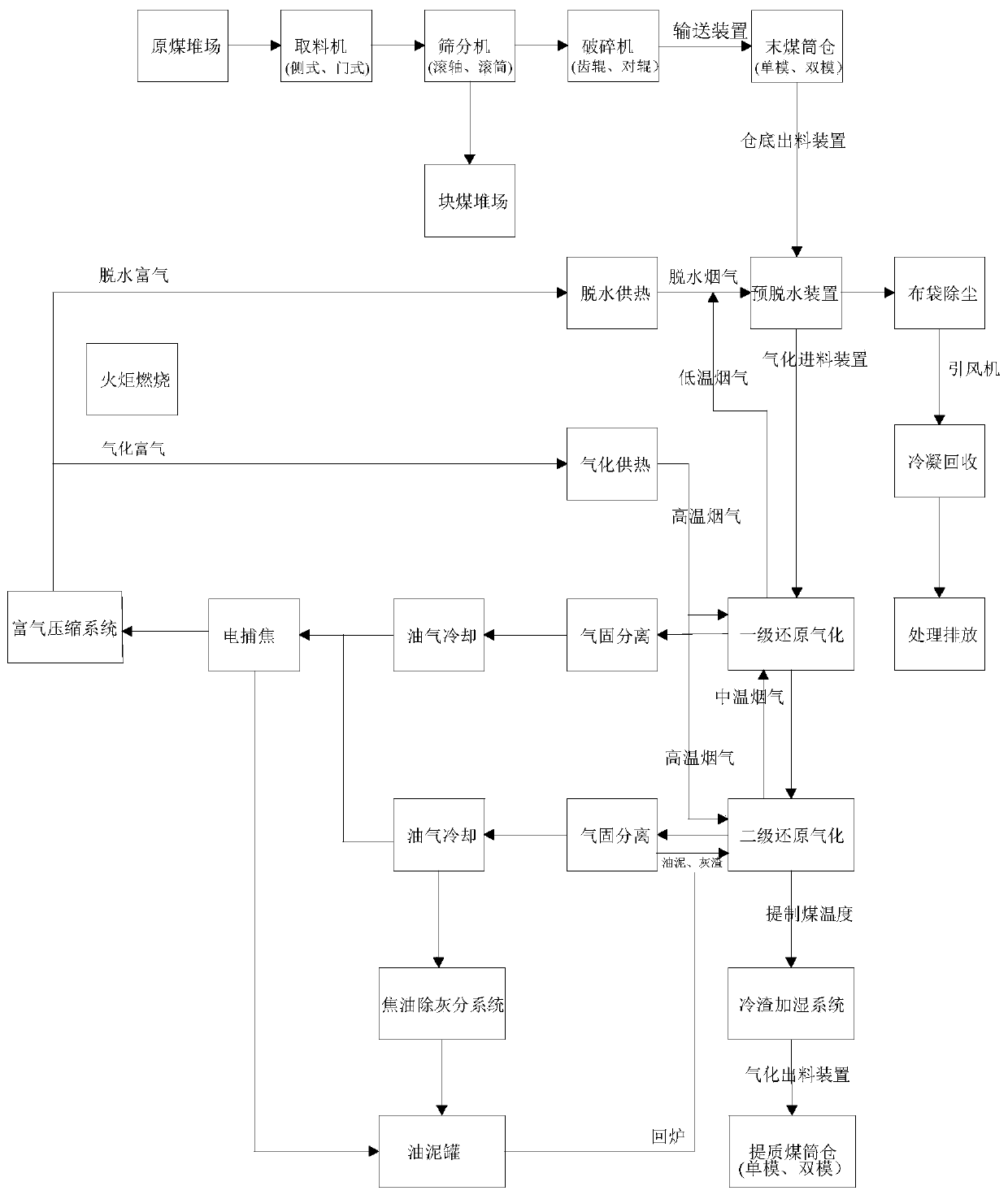

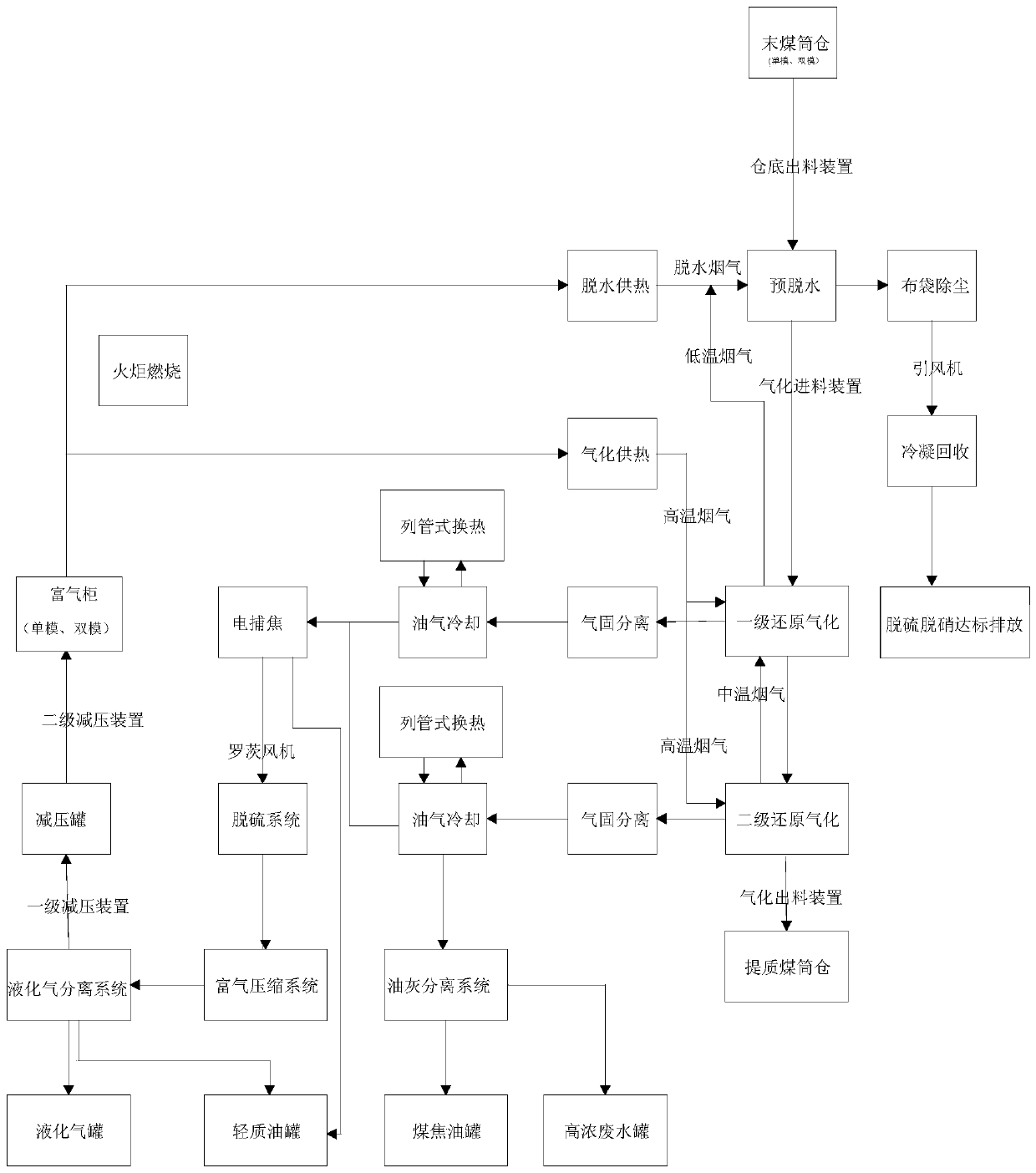

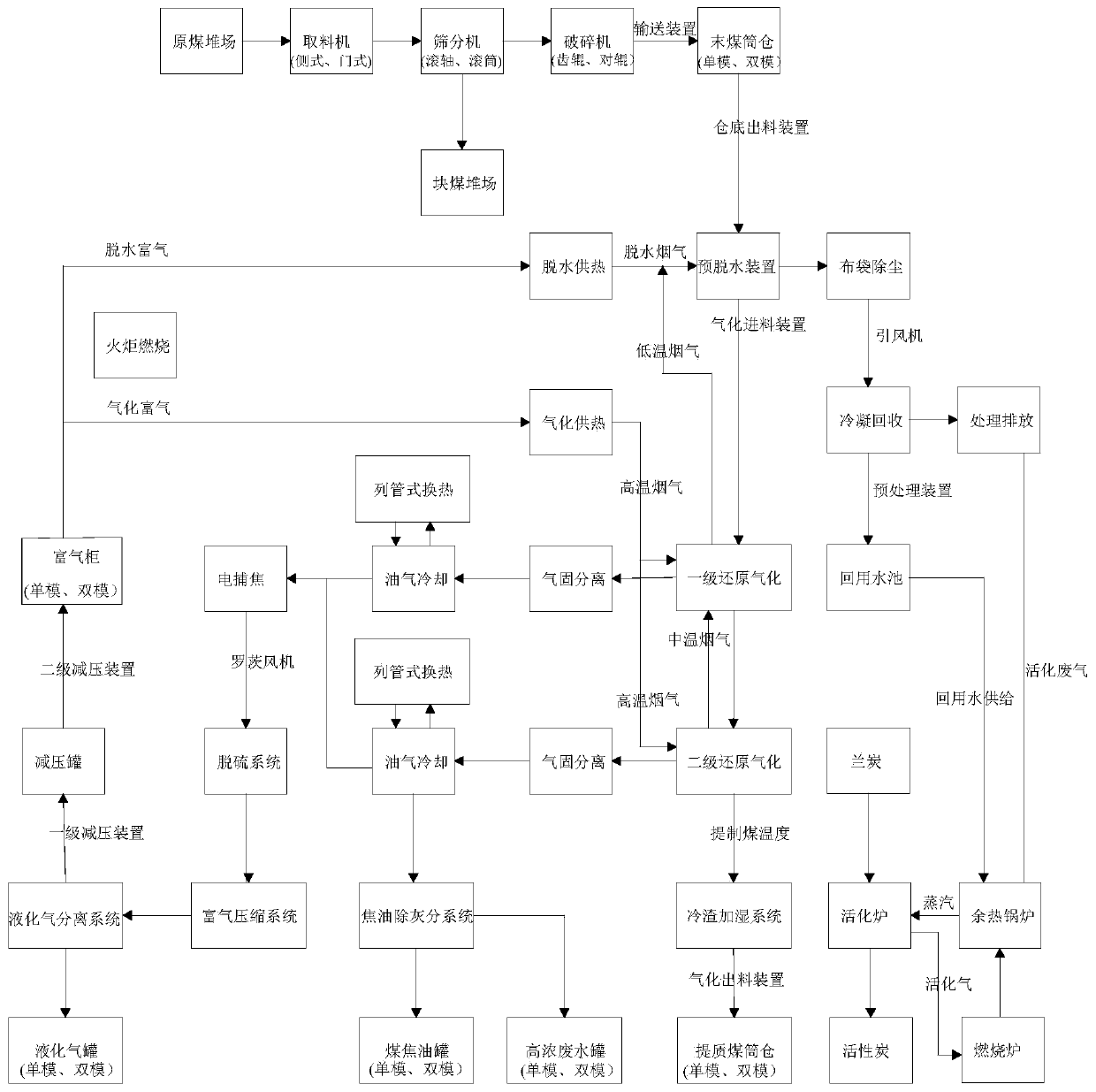

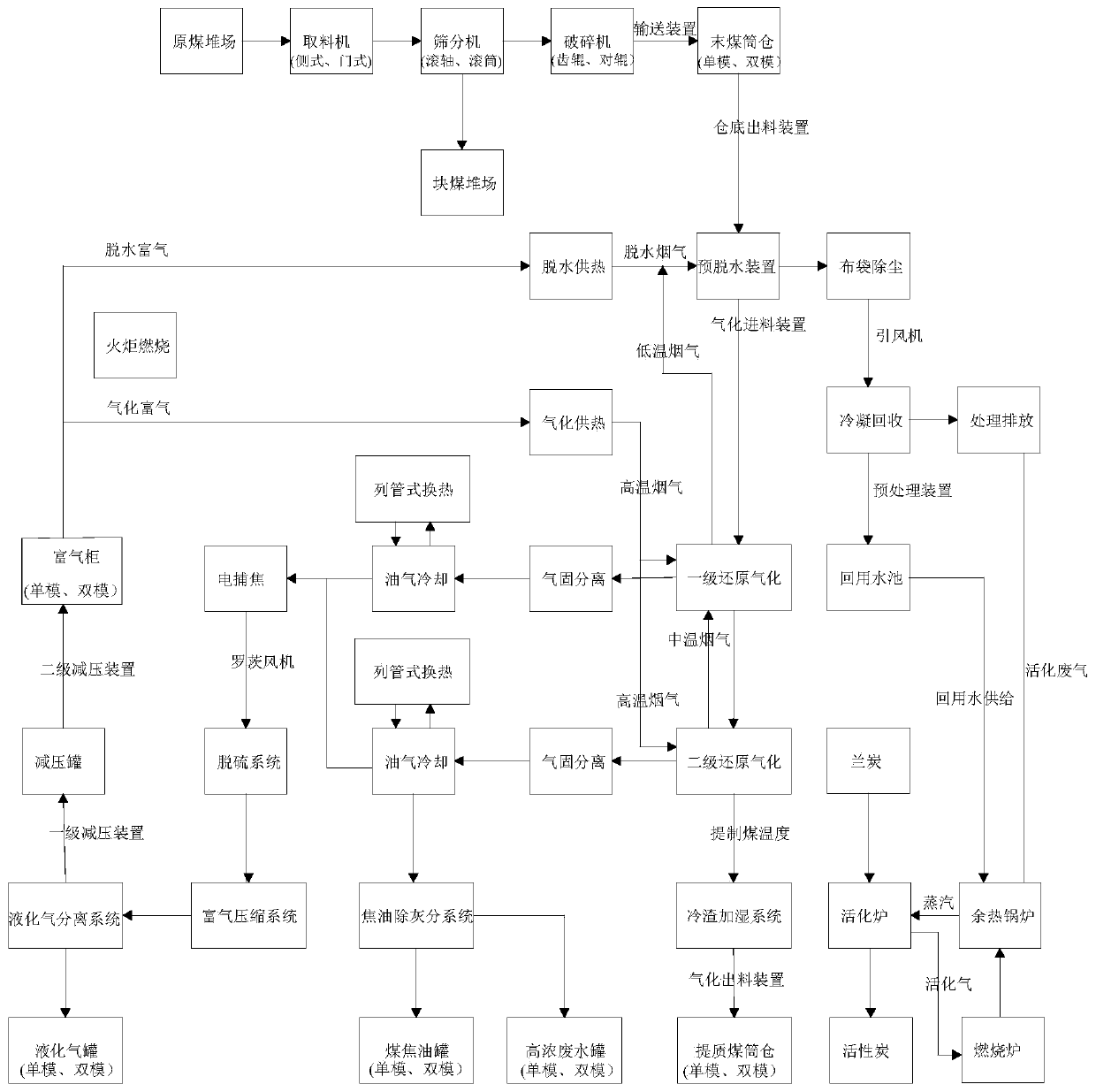

Method for gasification reduction of pulverized coal and separation and recycling of upgraded coal

PendingCN110003929AReduce productionNo lossEnergy inputOven incrustations prevention/removalSlagPulverizer

The invention discloses a method for gasification reduction of pulverized coal and separation and recycling of upgraded coal. The method comprises following steps: 1), raw coal is screened and pulverized by a pulverizer and pulverized coal enters a slack coal silo; 2), the pulverized coal in the slack coal silo is dried, then enters a primary gasification reduction device and a secondary gasification reduction device and is reacted sufficiently, an obtained material enters a cold slag humidification system and then enters an upgraded coal silo through a gasification discharging device, and anupgraded coal product is obtained; 4), ash residues obtained by a gas-solid separation system is conveyed to the secondary gasification reduction device, and oil sludge returns to the a secondary gasification device through an oil sludge conveying device; 5), a non-condensable gas is gasified to supply heat to a reaction system, and dewatered non-condensable gas and flue gas with waste heat supplyheat to a pre-dewatering device to dry a material; 6), flue gas containing dust and steam, which is produced by the pre-dewatering device, is subjected to cloth bag dedusting and condensation recovery successively under the power action of an induced draft fan.

Owner:浙江天禄环境科技有限公司

Preparation process and production equipment of antibacterial tissue

InactiveCN111576078AEnsure hygienic propertiesEffectively inhibit killing effectPaper/cardboardPhysical paper treatmentFiberBiochemical engineering

The invention relates to a preparation process and production equipment of an antibacterial tissue. The production equipment comprises a production line which is provided with a fermentation tank, a beater, a papermaking machine and a drying oven that are arranged in sequence. The process comprises the following steps: fermentation, extraction of decoction dreg fibers, extraction of medicinal components, papermaking, preparation of medicine liquid, spraying, and drying. According to the preparation process of the antibacterial tissue, harmful chemicals are not introduced in the pulping process, so the hygienic characteristic of fibers is ensured; medical components are extracted from waste pulping liquid and applied to body paper, so the prepared antibacterial tissue has good anti-inflammatory and antibacterial effects, presents extremely high functional characteristics and additional value, and is high in production efficiency and good in quality; and the preparation process is high in safety.

Owner:浙江旭荣新材料股份有限公司

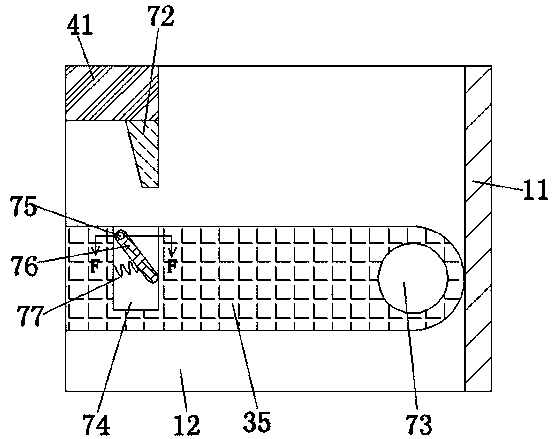

Drying clothes hanger assembly

ActiveCN105862374ASpeed up dryingSafe to dryOther drying apparatusTextiles and paperProcess engineeringClothes hanger

The invention discloses a drying clothes hanger assembly, which comprises a clothes hanger and a hook, wherein the clothes hanger is configured into the form suitable for suspending clothes; a drying device for drying clothes is arranged in the clothes hanger; the first end of the hook is detachably connected with the clothes hanger; and an installation part suitable for installing the drying clothes hanger assembly is arranged at the second end of the hook. According to the drying clothes hanger assembly, the drying device for drying the clothes is arranged in the clothes hanger; and the hook is detachably connected with the clothes hanger, so that the drying speed of the clothes can be improved; a user can relatively quickly, conveniently and safely dry the clothes. Meanwhile, the occupied space can also be reduced; carrying when the user travels is facilitated; and convenience is also increased for the user for drying the clothes.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Plastic headband cleaning device

InactiveCN110269576AComprehensive cleaningAvoid clutterHousehold cleanersCleaning using liquidsElectrical and Electronics engineering

The invention discloses a plastic headband cleaning device. The plastic headband cleaning device comprises a device body, a cleaning cavity is formed in the device body in an upward opening mode, a drive device is arranged in the inner wall of one side of the cleaning cavity, and the cleaning device is connected to the end, close to the cleaning cavity, of the drive device. The plastic headband cleaning device is simple in operation and convenient to use, headbands can be comprehensively cleaned, the headbands can be further prevented from being scattered or damaged after cleaning, and drying can be further carried out safely.

Owner:天津吉强饰品有限公司

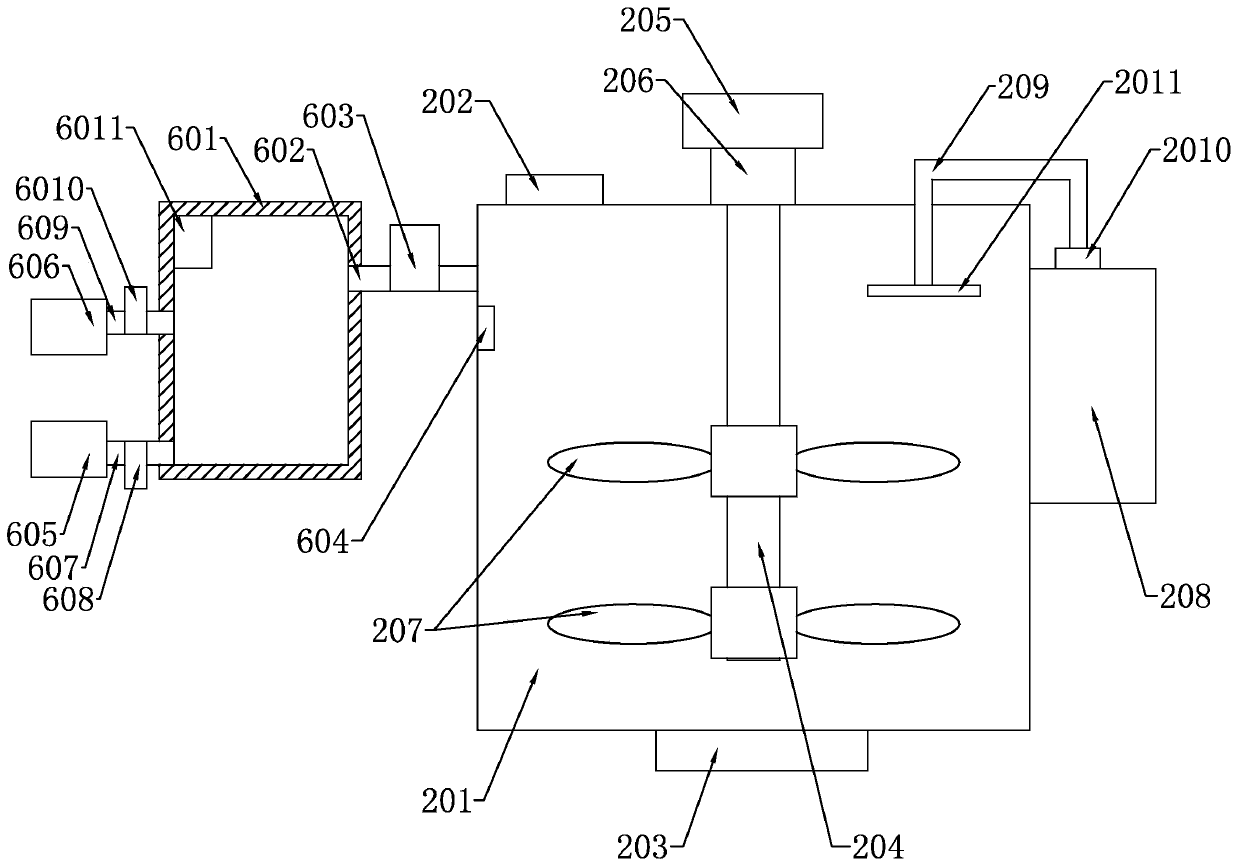

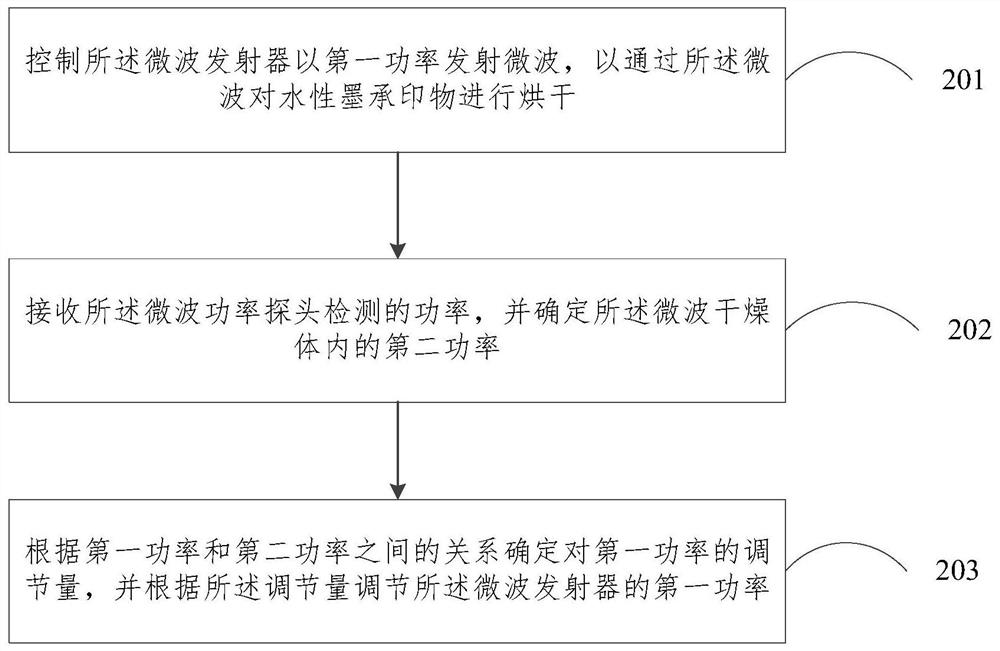

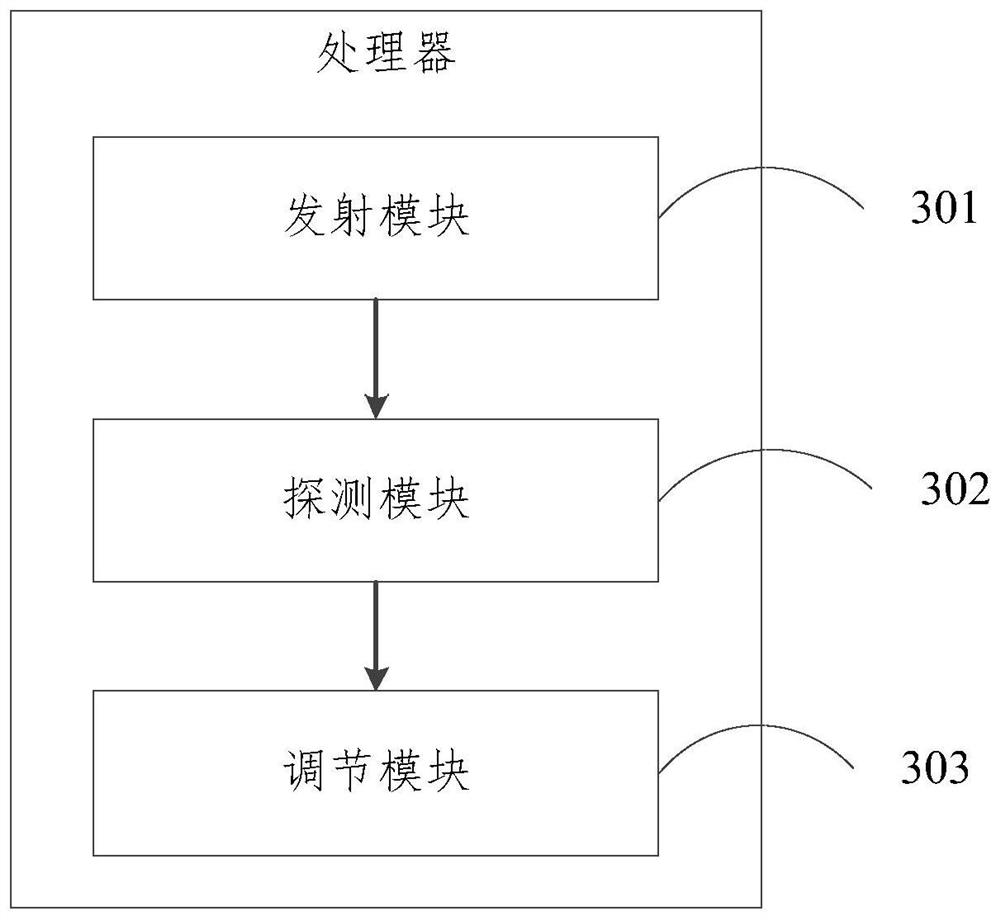

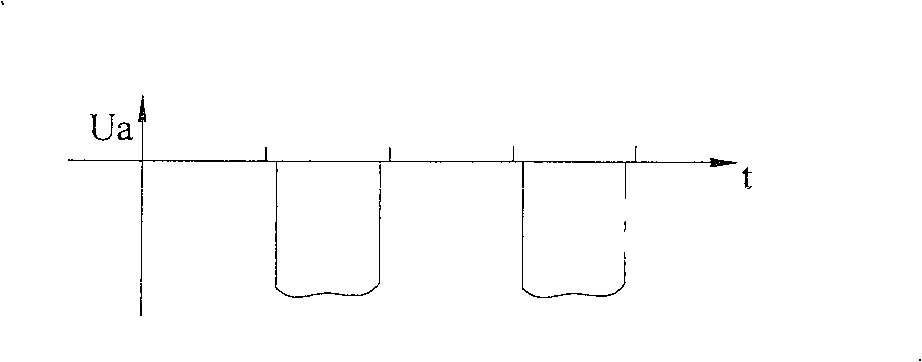

Ink-jet printing drying intelligent regulation and control method and device based on microwave detection

InactiveCN113147196ASafe to dryEfficient dryingMoisture content investigation using microwavesOther printing apparatusEngineeringMicrowave power

The invention provides an ink-jet printing drying intelligent regulation and control method and device based on microwave detection. The ink-jet printing drying intelligent regulation and control device based on microwave detection comprises a microwave emitter and a microwave power probe which are arranged in a microwave drying body. The method comprises the steps that the microwave emitter is controlled to emit microwaves at first power, and a water-based ink printing stock is dried through the microwaves; the power detected by the microwave power probe is received, and second power in the microwave drying body is determined; the adjusting amount of the first power is determined according to the relation between the first power and the second power, and the first power of the microwave emitter is adjusted according to the adjusting amount, so that intelligent control over the first power of the microwave emitter is achieved, and the water-based ink printing stock is safely and efficiently dried.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

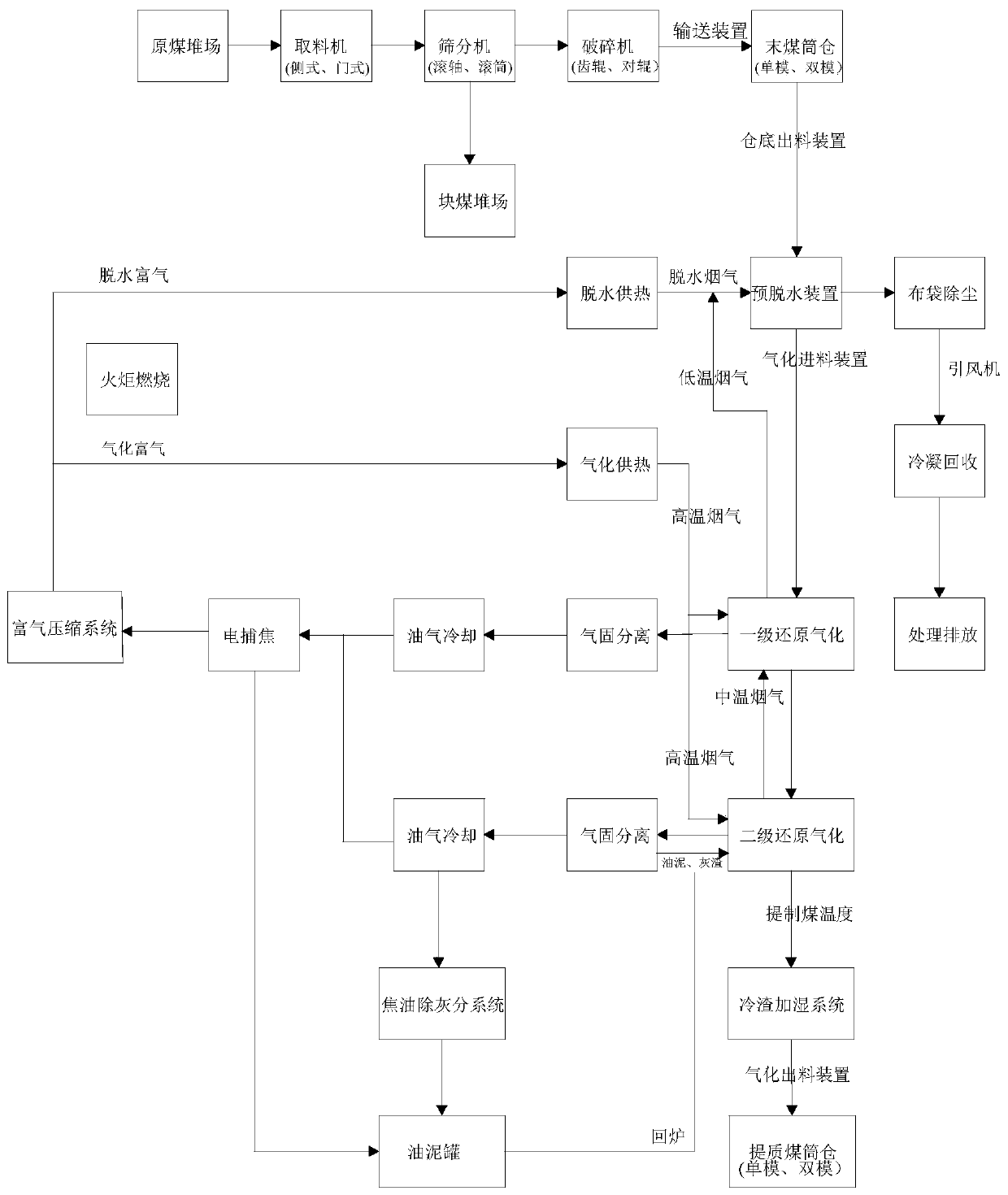

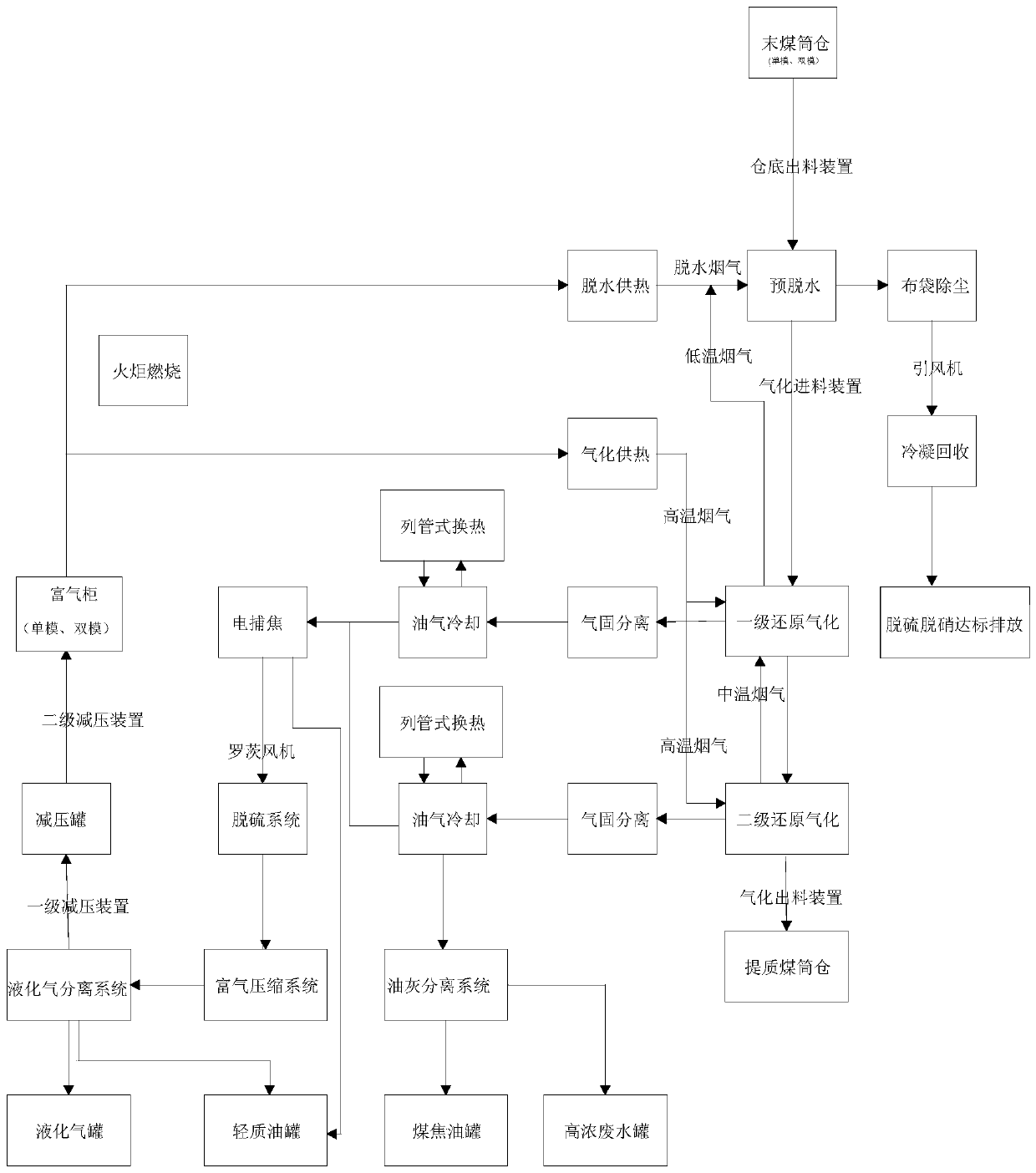

Method for gasification reduction of pulverized coal and separation and recycling of liquid

PendingCN110003928ASafe to dryEasy to dryEnergy inputOven incrustations prevention/removalSlagFlue gas

The invention discloses a method for gasification reduction of pulverized coal and separation and recycling of a liquid. The method comprises steps as follows: the pulverized coal is dried, the driedpulverized coal is subjected to primary gasification reduction and secondary gasification reduction and then enters a cold slag humidification system, and an upgraded coal product is obtained; oil andgas produced through the primary and secondary gasification reduction are subjected to gas-solid separation and oil-gas cooling respectively in sequence, and coal tar, wastewater and ash are obtained; rich gas obtained after the oil gas is cooled enters an electric tar catching device, and a certain amount of light oil and a small amount of ash are obtained; the rich gas enters a liquefied gas separation device for liquefied separation, and liquid oil and liquefied gas are obtained; the rich gas enters a reduced-pressure tank and a rich gas cabinet successively under the action of primary andsecondary pressure reducing devices, the rich gas from the rich gas cabinet produces high-temperature flue gas through gasification heat supply to supply a heat source to primary and secondary gasification reduction devices, and low-temperature flue gas produced after heat supply and hot air for dewatering heat supply are combined together to form dewatered flue gas so as to supply a heat sourceto a pre-dewatering device.

Owner:浙江天禄环境科技有限公司

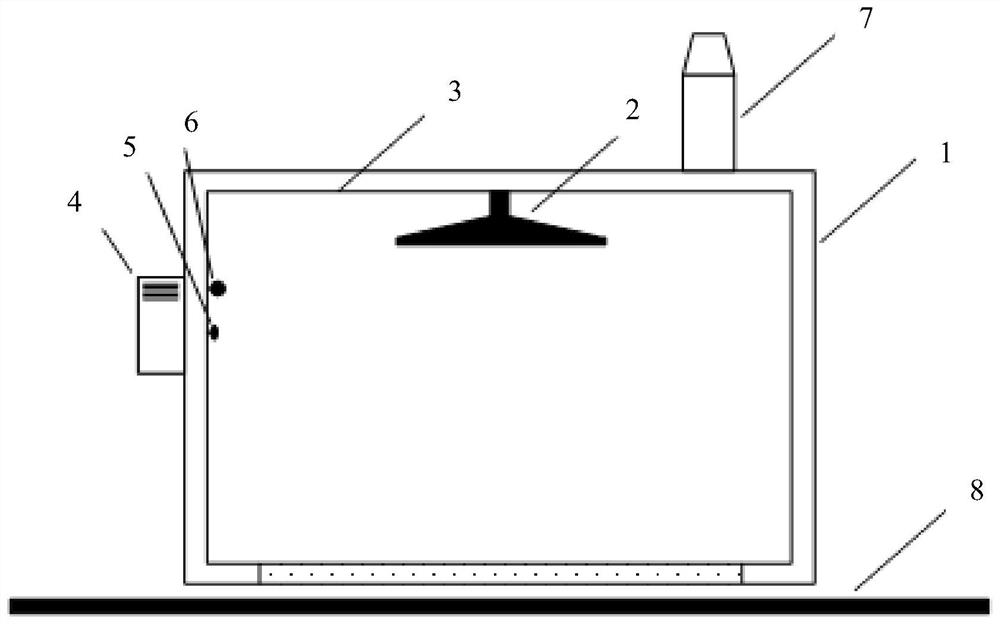

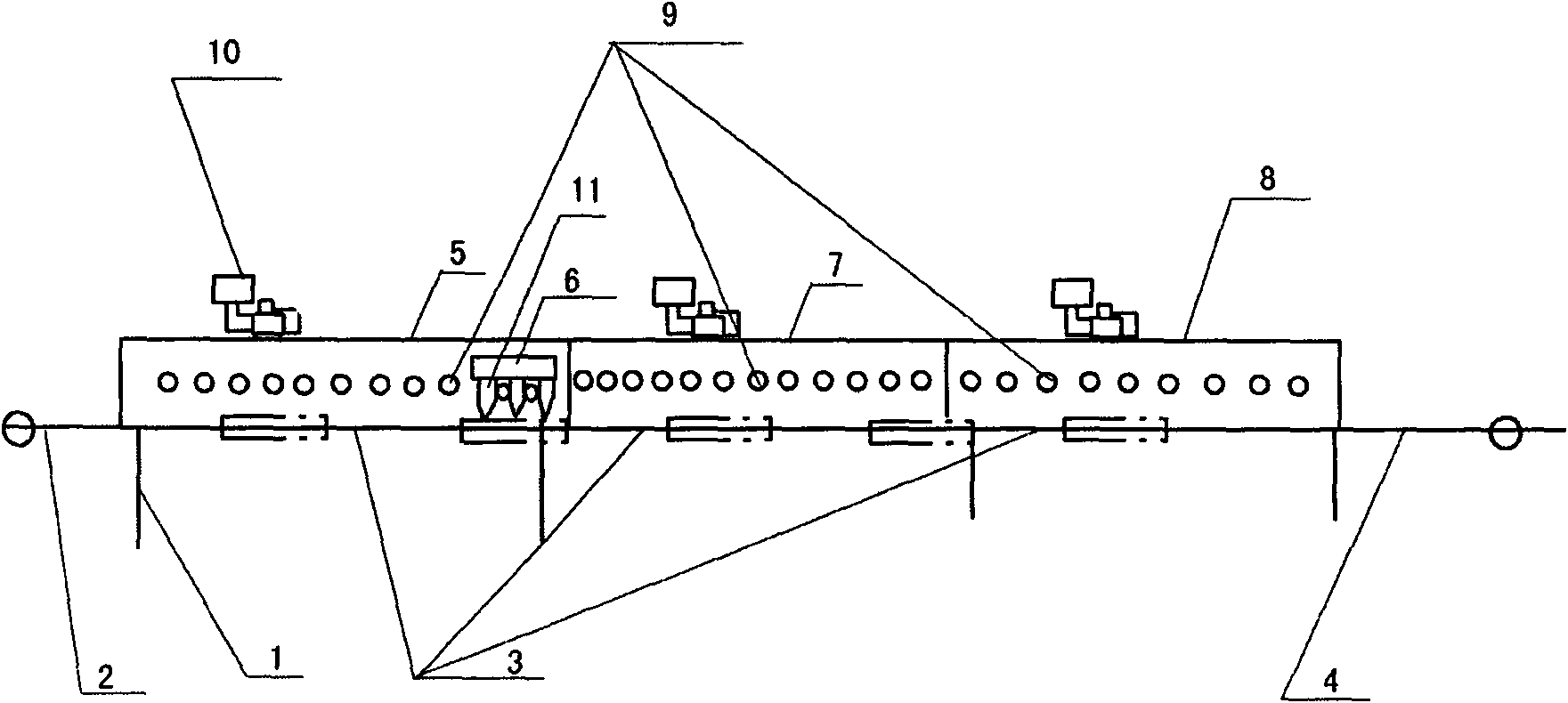

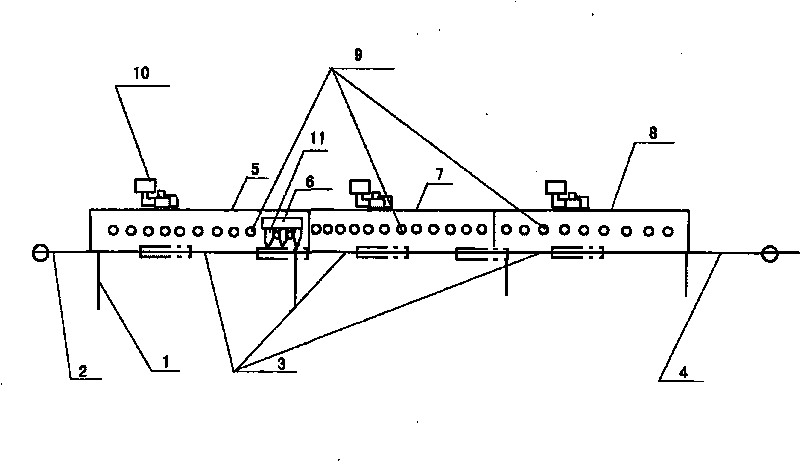

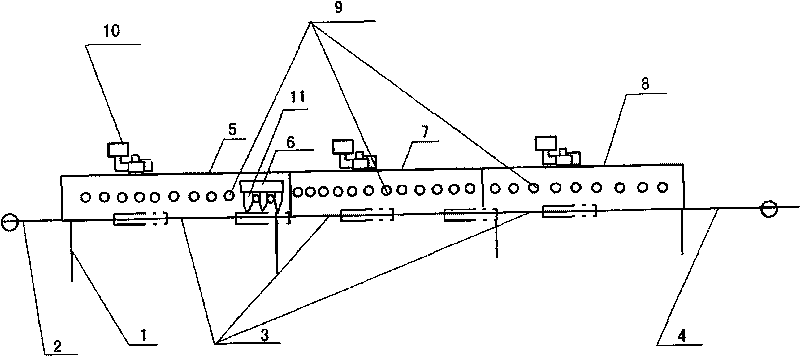

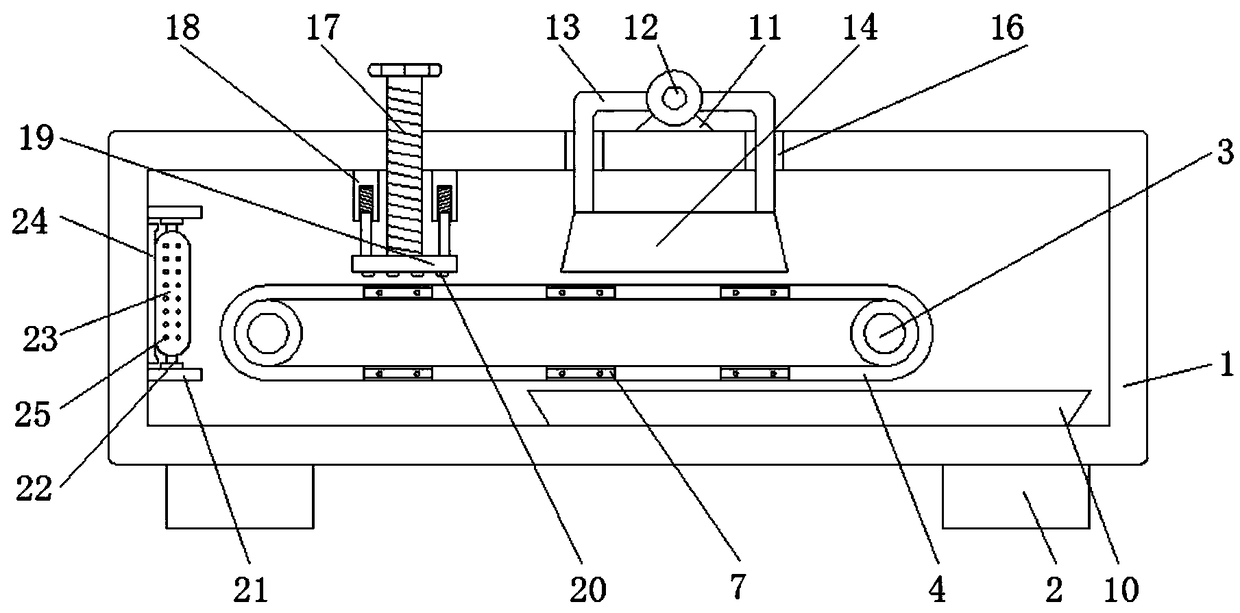

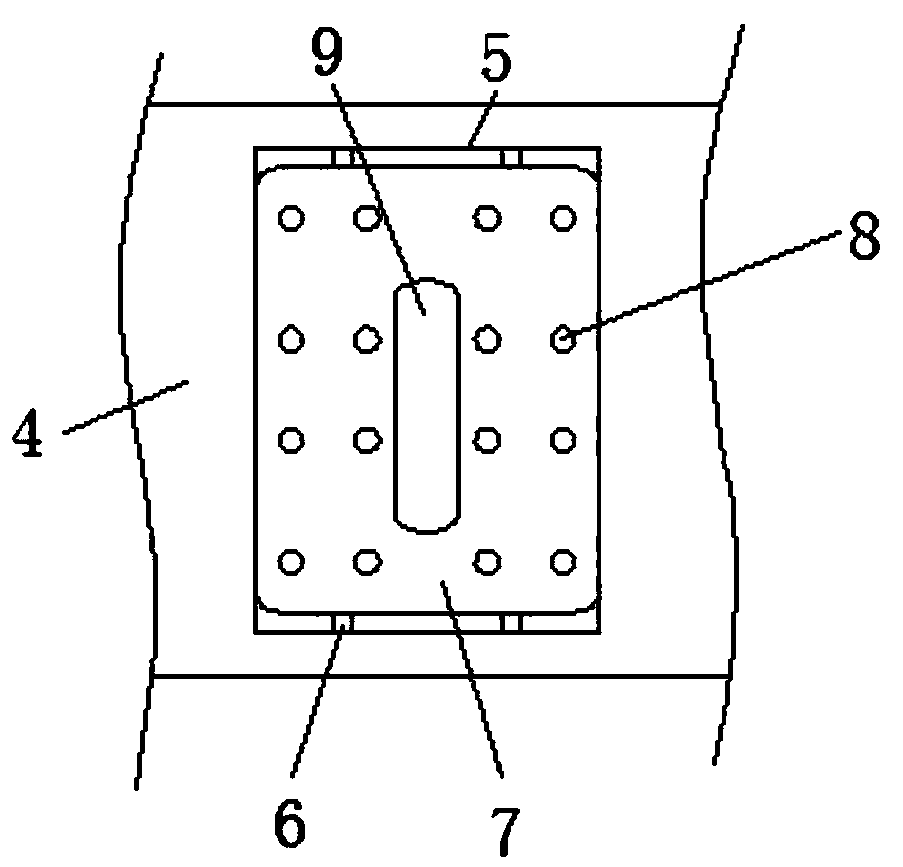

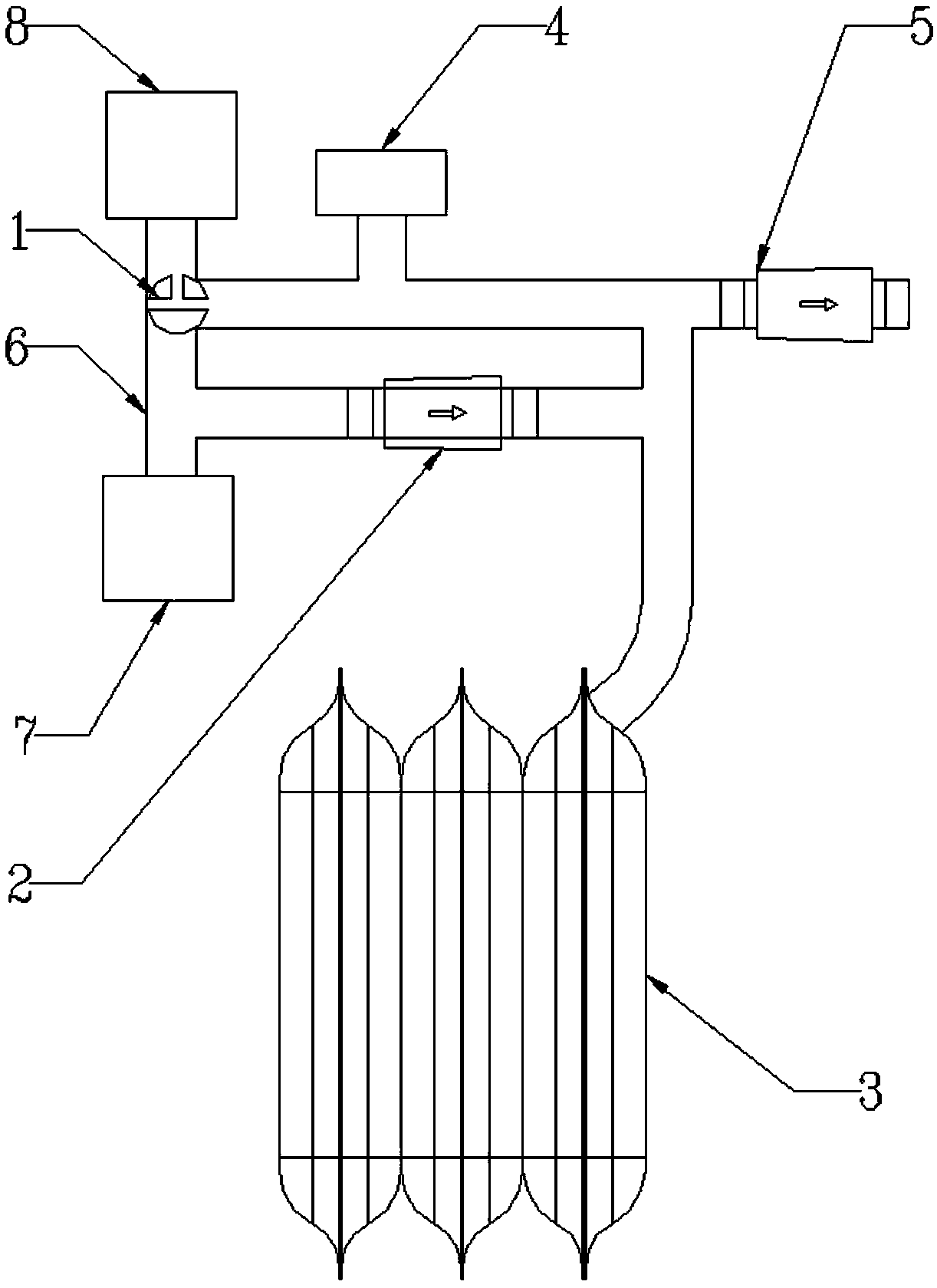

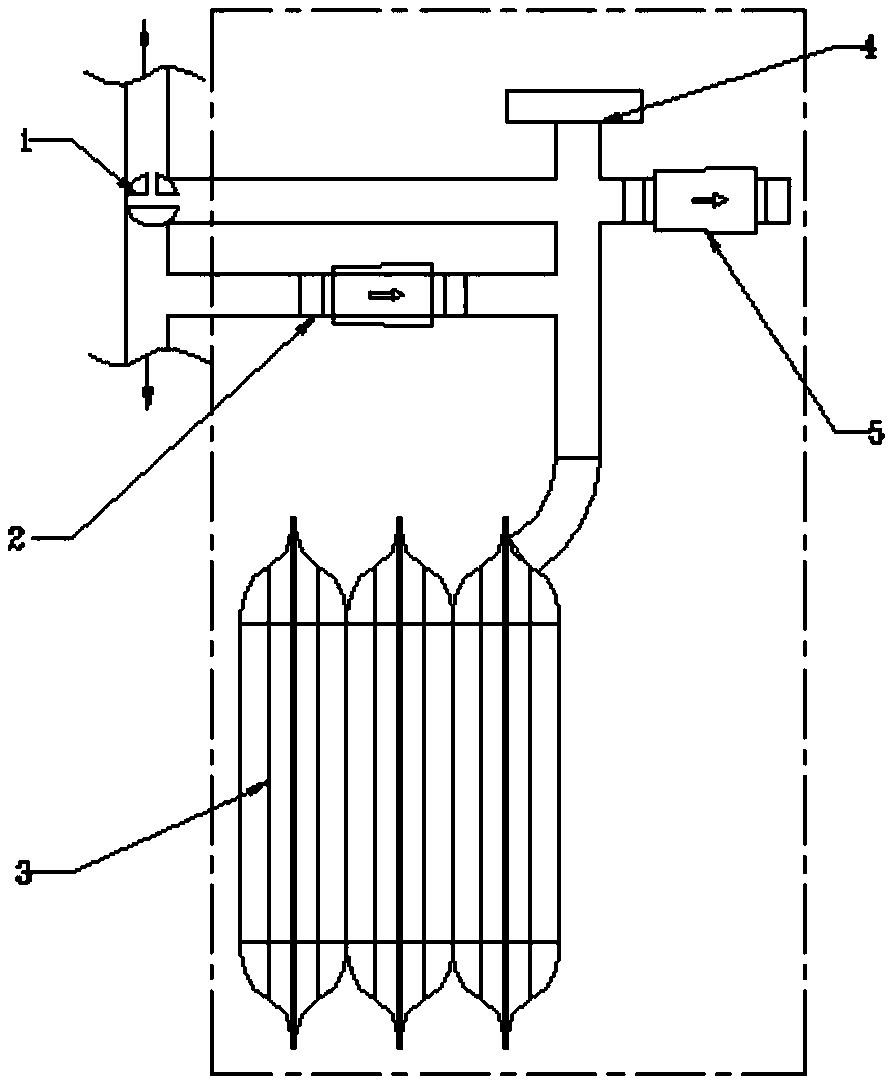

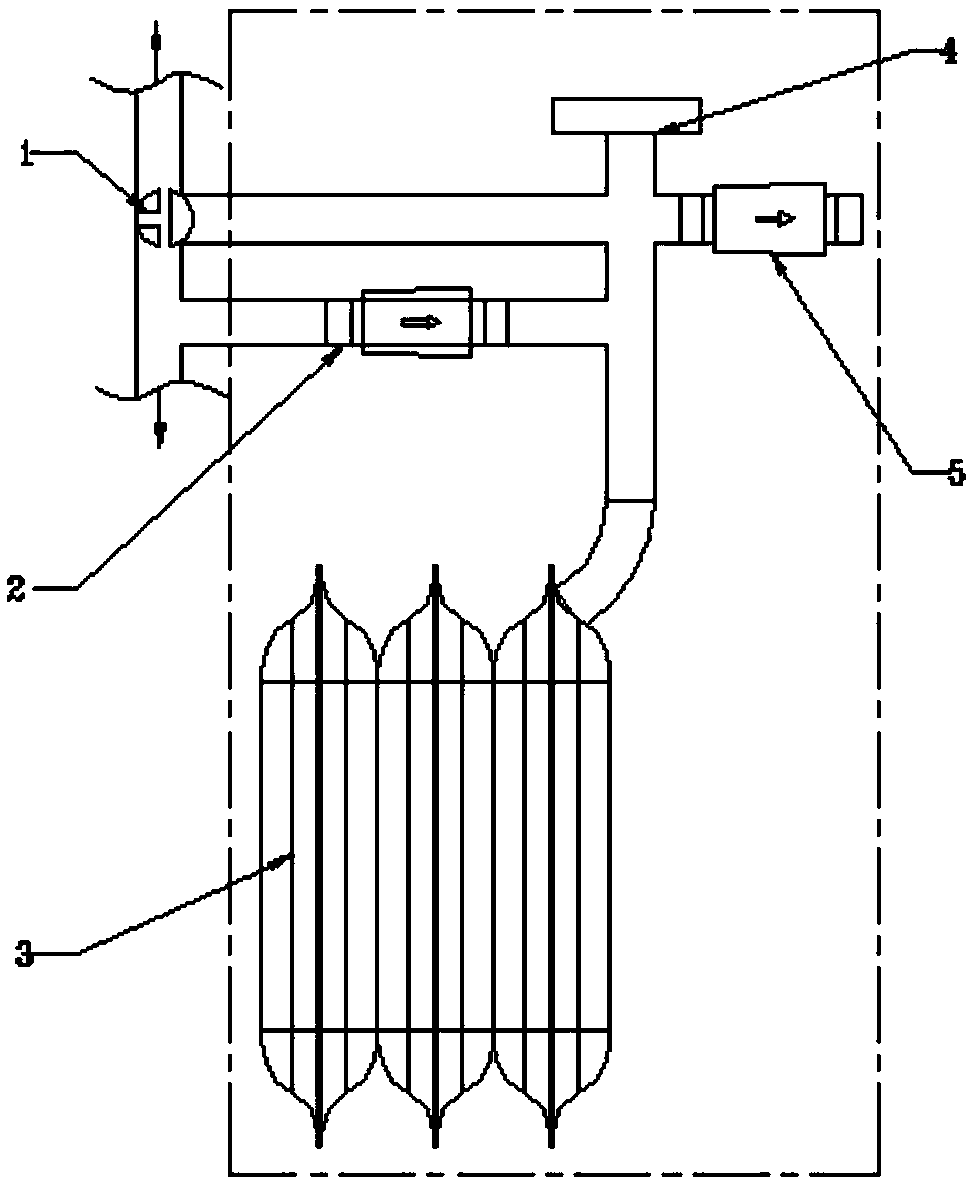

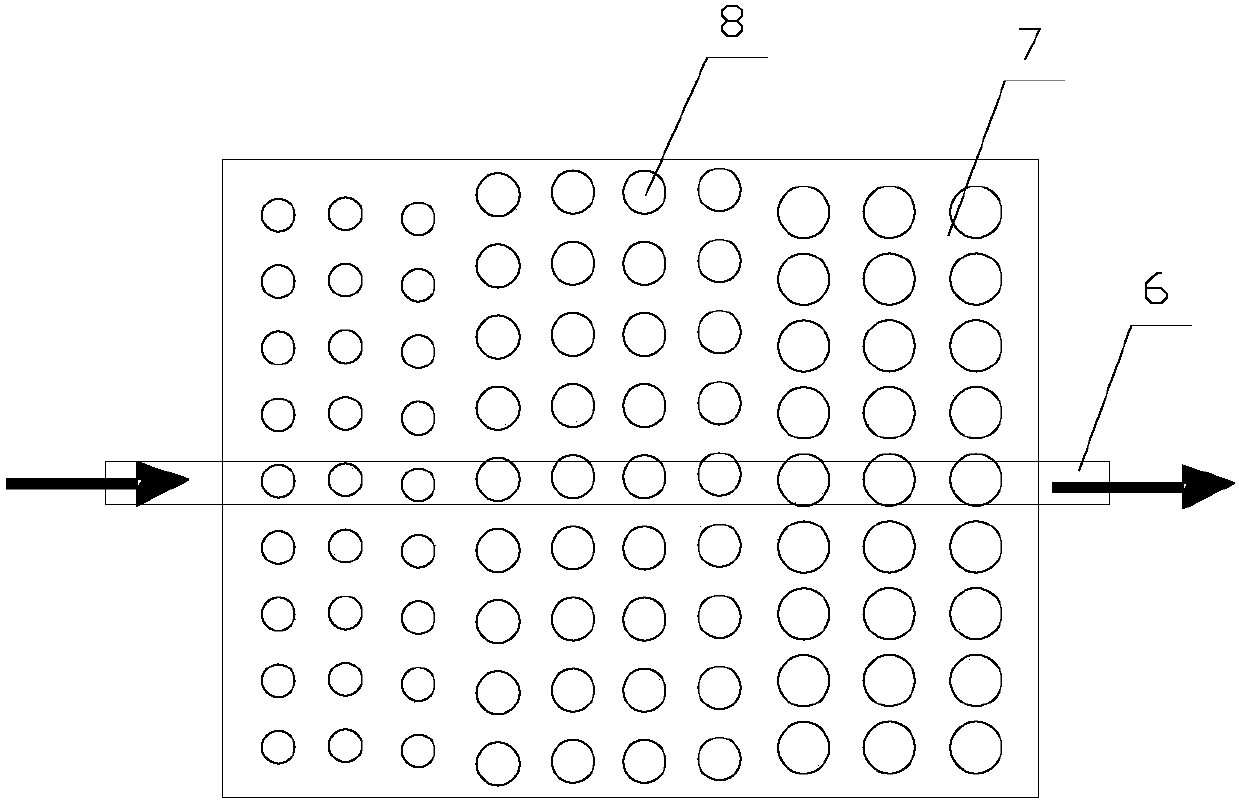

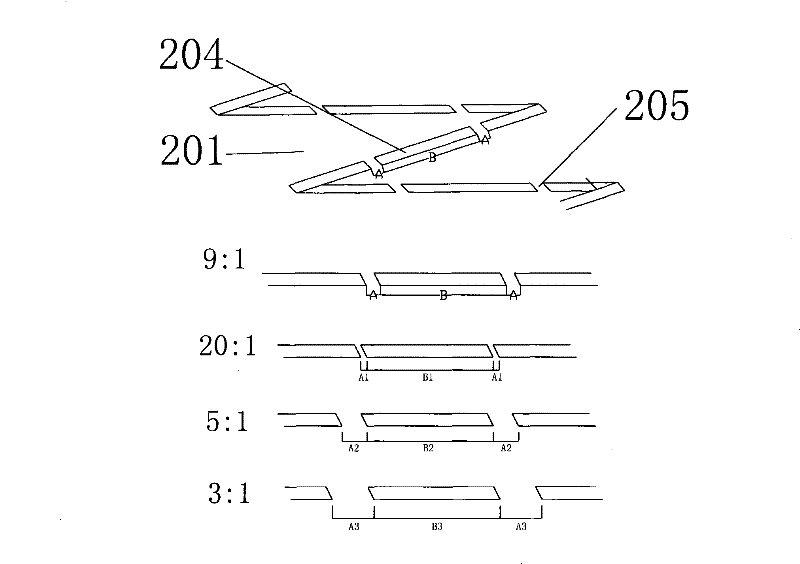

Drying device for heating by combining medium waves, short waves and spraying

InactiveCN101670336AEffectively adapt to needsPrevent deviationPretreated surfacesCoatingsEngineeringAir knife

The invention discloses a drying device for heating by combining medium waves, short waves and spraying. The drying device comprises a control part and a machine body (1), wherein the machine body (1) comprises a conveyor belt sequentially comprising the following parts: a charge-in section (2), a heating section (3) and a discharge section (4); a heating and drying device sequentially comprisingan IRI medium wave heating device (5), an air knife spraying and heating device (6), an IR2 short wave heating device (7) and an IR3 medium wave heating device (8) is arranged on the heating section (3), and heating pipe sets are respectively arranged in the IRI medium wave heating device (5), the air knife spraying and heating device (6), the IR2 short wave heating device (7) and the IR3 medium wave heating device (8); and the medium wave heating device (5), the air knife spraying and heating device (6), the IR2 short wave heating device (7) and the IR3 medium wave heating device (8) are covered on the upper part of the conveyor belt and opposite to the conveyor belt.

Owner:中材华晟科技无锡有限公司

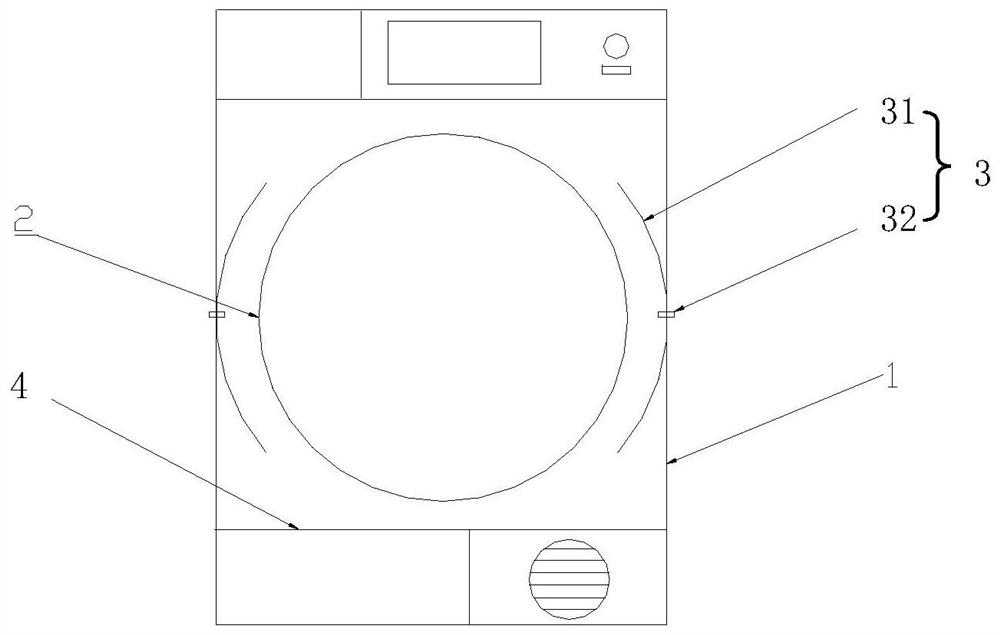

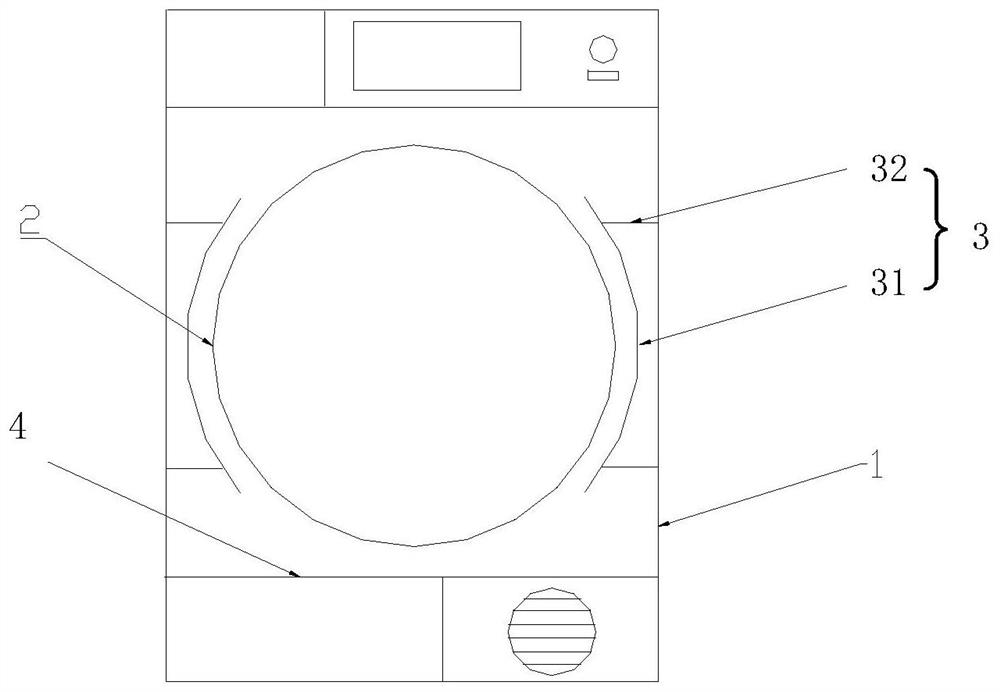

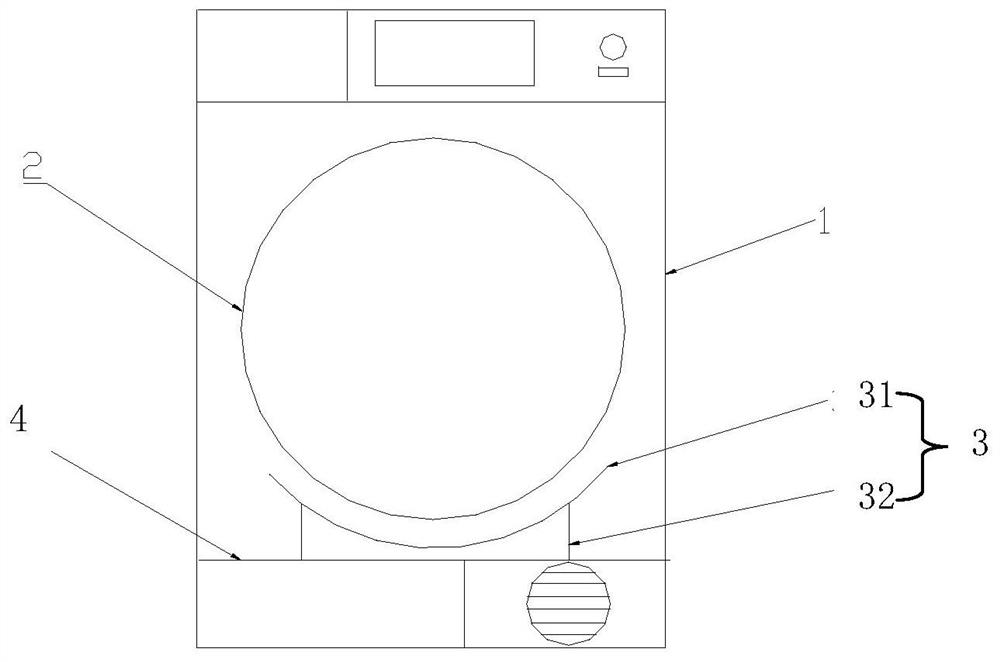

Control method of clothes dryer

PendingCN112481976AIncrease moisture contentReduce moisture contentTextiles and paperLaundry driersElectromagnetic heatingMechanical engineering

The invention discloses a control method of a clothes dryer. The clothes dryer comprises a roller and an electromagnetic heating module arranged outside the roller; when a drying program is entered, the electromagnetic heating module is started, and the roller is controlled to rotate at different rotating speeds along with the proceeding of the drying program. And while the electromagnetic heatingmodule is started, the roller is controlled to rotate at a first rotating speed V1, and after rotating for a certain time, the roller is decelerated to a second rotating speed V2 to rotate. The roller is controlled to rotate at different rotating speeds along with changes of the temperature in the roller, the drying degree of clothes and the like, and safer and more efficient drying is achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Drying agent and preparation method thereof

InactiveCN112121606ASafe to dryDry fastGas treatmentDispersed particle separationCelluloseMoisture absorption

The invention discloses a drying agent and a preparation method thereof, the drying agent is mainly composed of magnesium oxide and magnesium chloride, and the drying agent comprises the following components in parts by weight: 1090 parts of magnesium oxide with high magnesium oxide content, magnesium hydroxide, magnesium carbonate or a mixture of one or more of the magnesium oxide, the magnesiumhydroxide and the magnesium carbonate; 5-90 parts of anhydrous magnesium chloride with high magnesium chloride content or / and magnesium chloride with N crystal waters; aluminum oxide and / or clay, lignin and / or molecular sieve raw powder, glass fibers, carboxymethyl cellulose and the like are added, stirring and mixing, granulation, screening, drying and roasting are sequentially carried out, and the prepared drying agent is granular and extremely good in moisture absorption effect and still appears in a granular block shape after moisture absorption.

Owner:HANGZHOU HOMESONG PACKGING MATERIAL

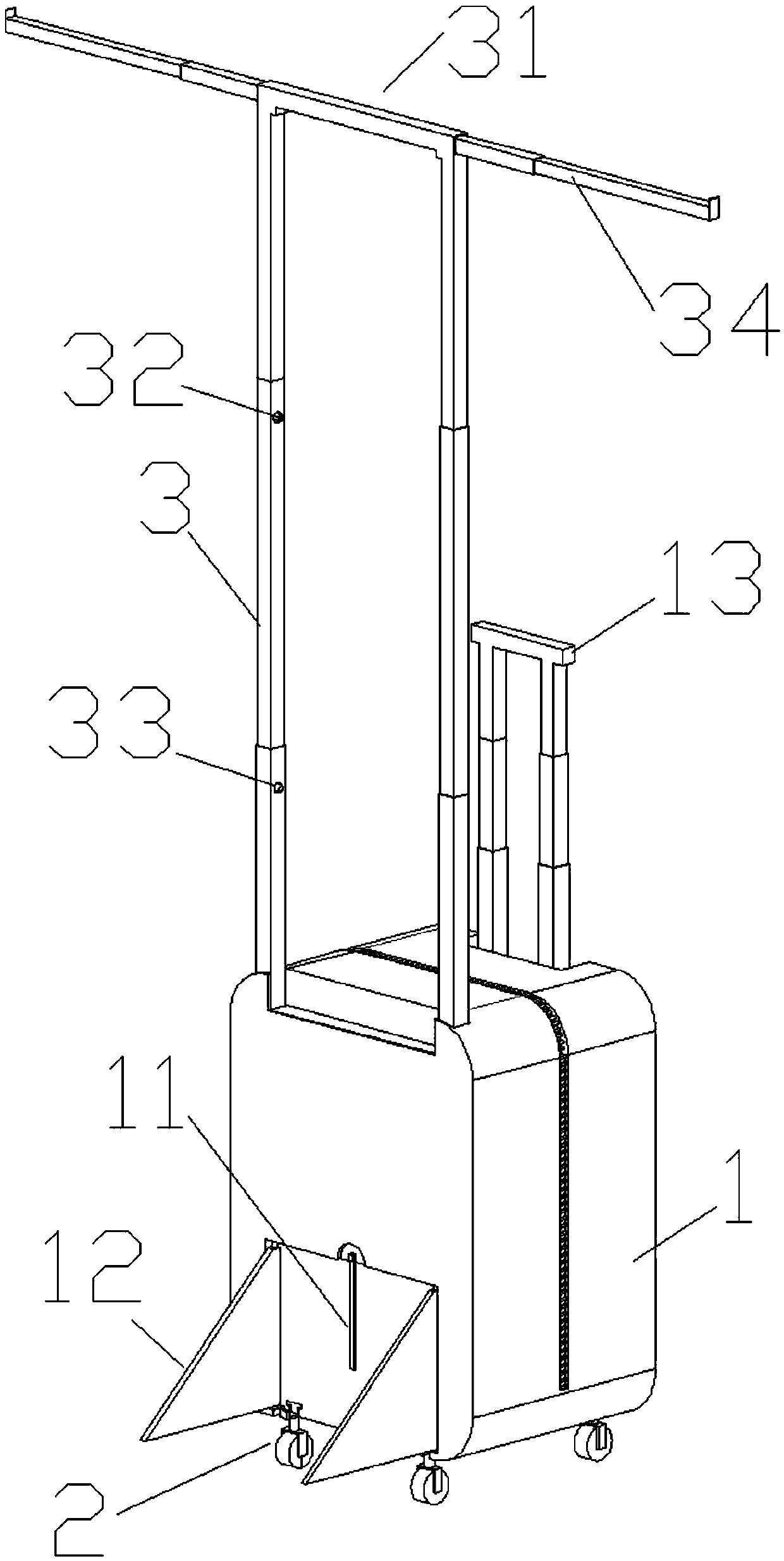

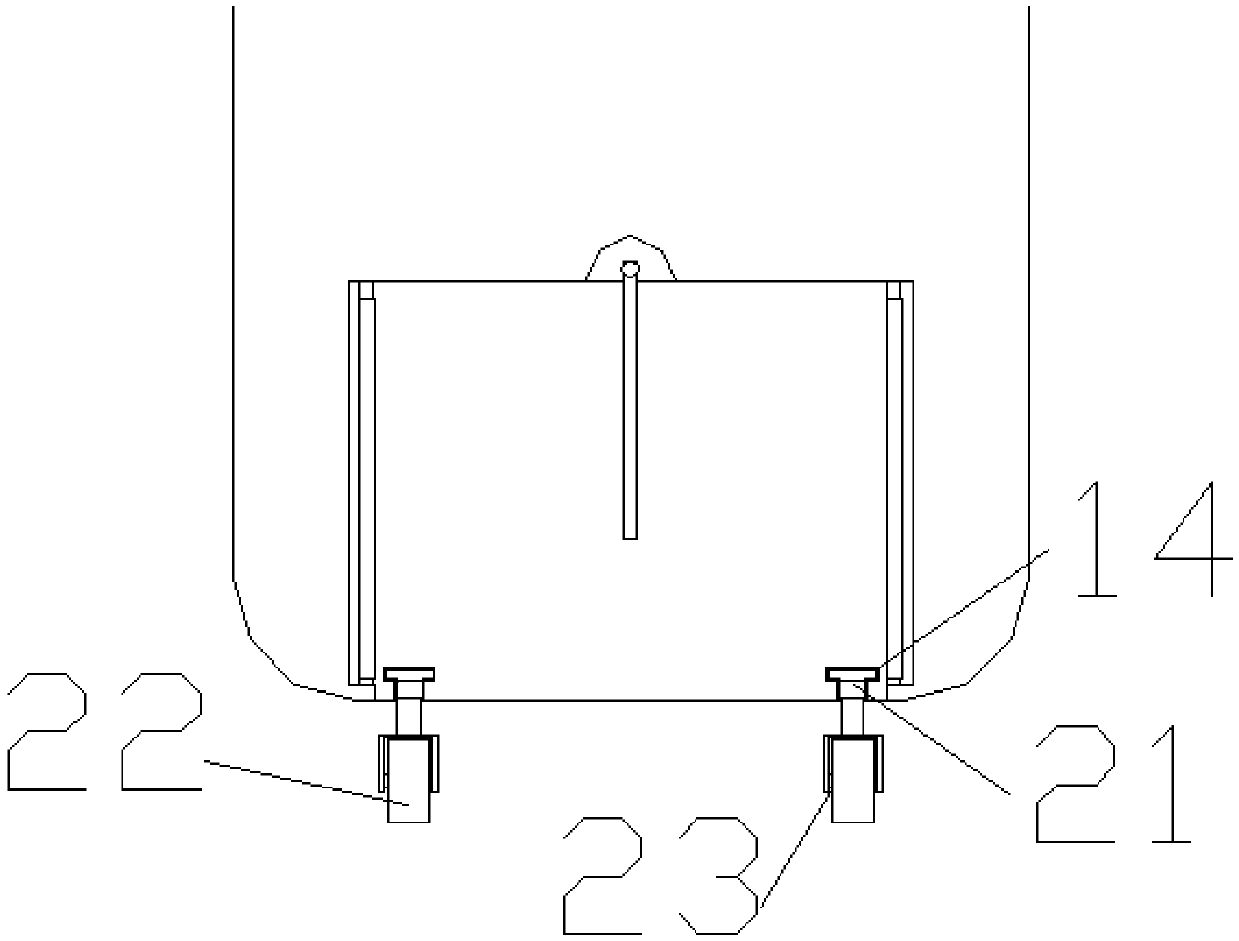

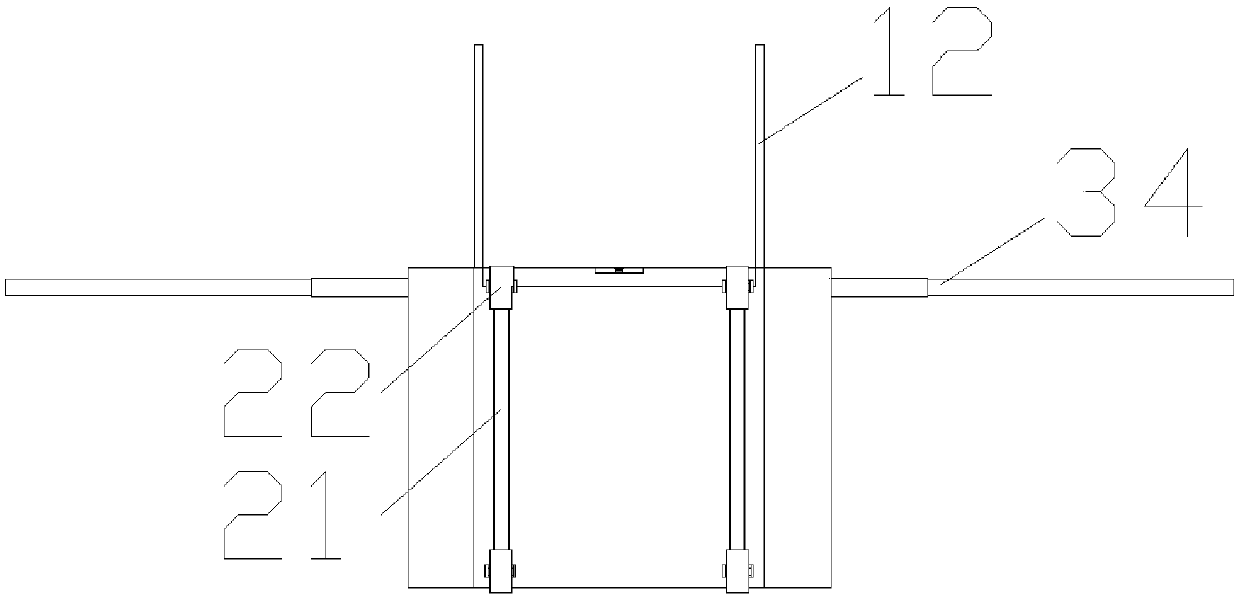

Luggage case with clothes airing function

The invention relates to a luggage case with a clothes airing function. The luggage case comprises a storage box, a detachable rolling device and a clothes hanger rod assembly, the detachable rollingdevice is located at the bottom of the storage box. The hanger rod assembly is positioned on the top edge of one side of the storage box; the detachable rolling device is composed of a T-shaped sliding rod base, idler wheels and an axle. The clothes hanger rod assembly is composed of a telescopic clothes hanger rod, a telescopic buckle, a buckle hole and a telescopic support. The luggage case is composed of a storage plate, a supporting plate, a telescopic pull rod and a bottom sliding groove. The T-shaped sliding rod base is embedded in the bottom sliding groove. The telescopic support is located on the upper edge of the telescopic clothes hanger rod and can be contracted into a groove in the upper end of the telescopic clothes hanger rod, the supporting plate is connected with the storage box through a shaft rod and can swing, the storage plate and the supporting plate are located at the lower end of the storage box on the same side of the clothes hanger rod assembly, and the telescopic pull rod is located on the upper edge of the opposite side of the storage box. The luggage case has the beneficial effect that the problem that it is inconvenient for a user to air clothes when the user goes out can be solved.

Owner:郑卓杰

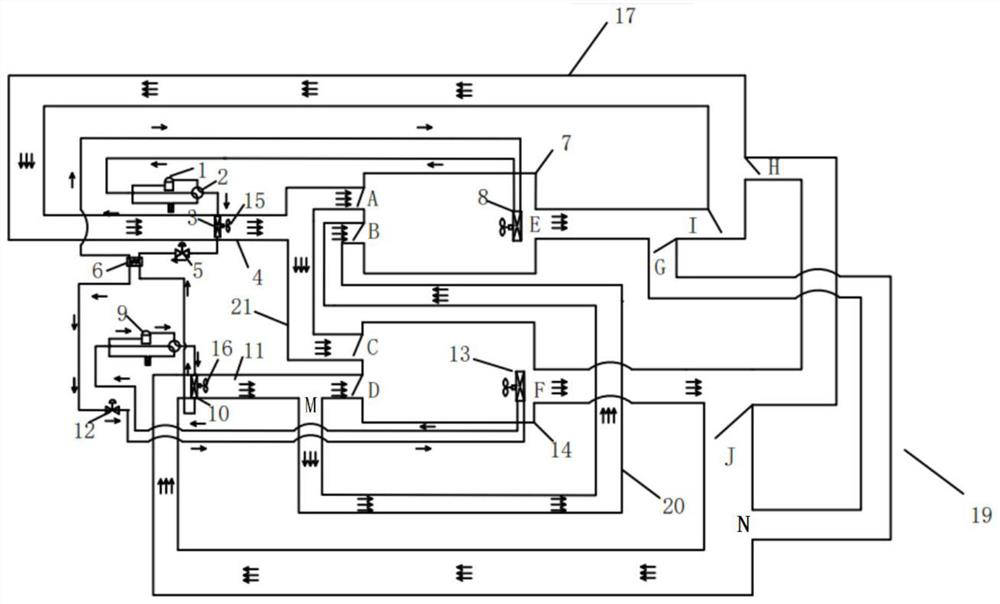

Efficient, energy-saving and graded heating heat pump drying system

ActiveCN112856950ATake advantage ofImprove drying efficiencyDrying gas arrangementsDrying chambers/containersIntermediate heat exchangerEngineering

The invention discloses an efficient, energy-saving and graded heating heat pump drying system. The drying system comprises a first system, a second system, a first drying room and a second drying room, a first evaporator is arranged in the first drying room, and a second evaporator is located in the second drying room; an intermediate heat exchanger communicates with a pipeline between a first electronic expansion valve and the first evaporator; the other surface of the intermediate heat exchanger communicates with a pipeline between a second condenser and a second electronic expansion valve; an air duct door A, an air duct door B and an air duct door E are arranged on the first drying room, and a first air duct is arranged between the air duct door A and the air duct door E; an opening is formed near the air duct door A of the first air duct and communicates with an air duct door C through a second air duct; and the air duct door C, an air duct door D and an air duct door F are arranged on the second drying room, a third air duct is arranged between the air duct door F and an air duct door H, a fourth air duct is arranged between the air duct door D and an air duct door J, a first condenser is arranged in the first air duct, and the second condenser is arranged in the fourth air duct.

Owner:GUANGDONG NEW ENERGY TECH DEV

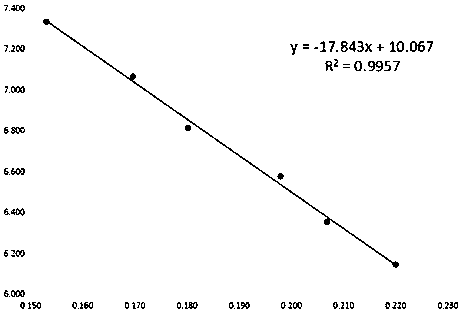

Simple, convenient and rapid determination method of non-sugar solids in yellow rice wine with alcohol concentration of 12-14%

InactiveCN107843570AImprove accuracyImprove reliabilityPreparing sample for investigationColor/spectral properties measurementsCooking & bakingAlcohol

A specific double-stranded DNA fragment has different degeneration degrees in ethanol-water systems with different mass-to-volume ratios of water and ethanol so as to cause difference of absorbance ina wavelength of 260nm, thereby establishing a brand-new determination method of non-sugar solids in the yellow rice wine with alcohol concentration of 12-14%. The specific double-stranded DNA fragment is shown in SEQ ID NO:1, and the relational expression between the absorbance x of the specific double-stranded DNA fragment and the mass-to-volume ratio y of water and ethanol in an ethanol-water system is as follows: y=-17.843x+10.067. The determination method of non-sugar solids is suitable for determination of the yellow rice wine with alcohol concentration of 12-14%, has good accuracy and reliability, is safer because of no need of long-time baking, is simple, convenient and rapid in operation, needs less wine sample amount, and is low in determination cost.

Owner:陈荷冰

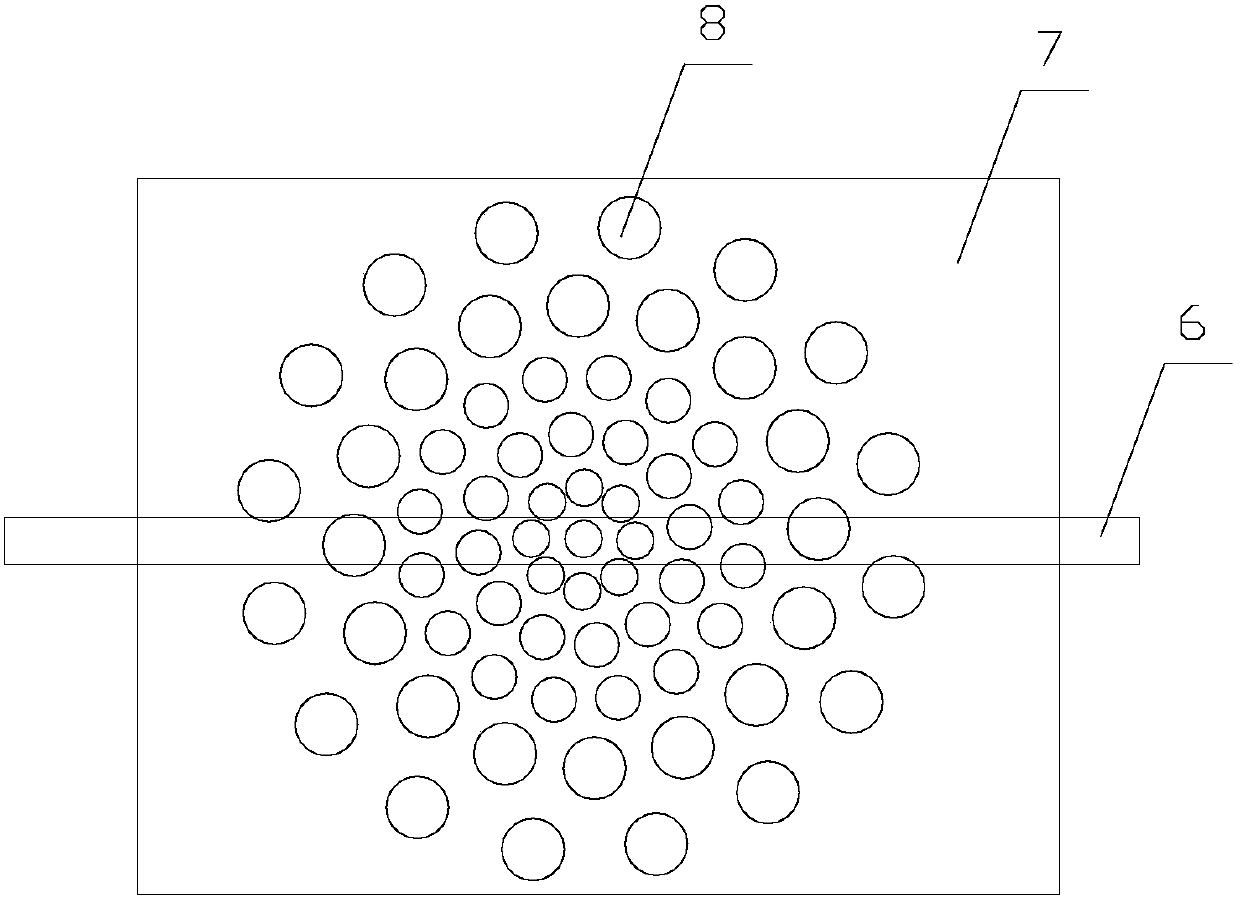

Drying device for heating by combining medium wave with jet

InactiveCN101698190AReasonable control switch rangeControl switch rangePretreated surfacesCoatingsAir knifeElectrical and Electronics engineering

The invention discloses a drying device for heating by combining medium wave with jet, comprising a control part and a body (1), wherein the body (1) comprises a transmission band which successively comprises a feed section (2), a heating section (3) and a discharging section (4); a heating and drying device is arranged on the heating section (3) and successively comprises an IR1 medium-wave heating device (5), an air knife jet heating device (6), an IR2 medium-wave heating device (7) and an IR3 medium-wave heating device (8); heating tube stacks are respectively arranged in the IR1 medium-wave heating device (5), the air knife jet heating device (6), the IR2 medium-wave heating device (7) and the IR3 medium-wave heating device (8); the IR1 medium-wave heating device (5), the air knife jet heating device (6), the IR2 medium-wave heating device (7) and the IR3 medium-wave heating device (8) cover the upper part of the transmission band and are opposite to the transmission band.

Owner:王兆进

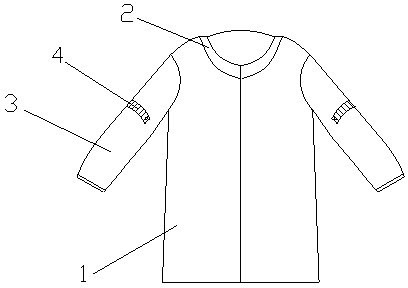

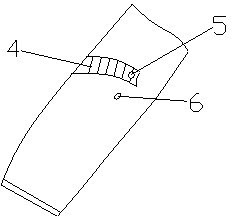

Convenient-to-dry sports wear

The invention discloses convenient-to-dry sports wear, which comprises a clothes body, a collar and sleeves, wherein fixing belts are additionally arranged on the outer surfaces of the sleeves, one ends of the fixing belts are sewed and connected with the sleeves, the other ends of the fixing belts and the sleeves are connected through buttons, the end parts of the fixing belts are provided with button holes, and the corresponding positions of the sleeves are provided with the buttons. The invention discloses the convenient-to-dry sports wear, the structural design of the sports wear is unique, the fixing belt structures are additionally arranged at the outer layers of the sleeves of the sports wear, the fixation effect can be conveniently realized with a clothes drying rod during the drying of the sports wear, the clothes are prevented from being blown away by strong wind, the drying of the sports wear is more convenient and safer, meanwhile, during the drying, the sleeves of the sports wear are in an unfolded state, and the sterilization effect of the clothes plus material can be effectively improved.

Owner:KUSN HUAHONG IMPORTS & EXPORTS

Household clothes hanger

The invention belongs to the technical field of hangers, particularly relates to a household clothes hanger, and aims to solve a problem that clothes hung on the clothes hanger are easy to blow over. The household clothes hanger comprises a supporting mechanism, a cross rod and a fixing mechanism, wherein sliding grooves are formed in the outer walls of the left side and the right side of the cross rod, and first sliding blocks are slidably connected to the inner walls of the sliding grooves; and a first groove is formed in the first sliding block, a first movable plate is rotatably connected to the inner wall of the first groove, and a first inserting rod is fixedly mounted at one end of the first movable plate. When the first round rod is pressed down, one end of the first movable plate moves, the other end of the first movable plate reversely moves to pull out the first inserting rod from the through hole, move the first sliding block leftwards and rightwards, loosen the first round rod and the first inserting rod and then insert the first inserting rod into the through hole, the first sliding block is fixed, and the clothes hanger is fixed in the fixing mechanism, namely the position of the clothes hanger can be fixed; and the clothes hanger does not slide to change the position, so the clothes are separated to be aired and dried more quickly.

Owner:杭州塔姆贸易有限公司

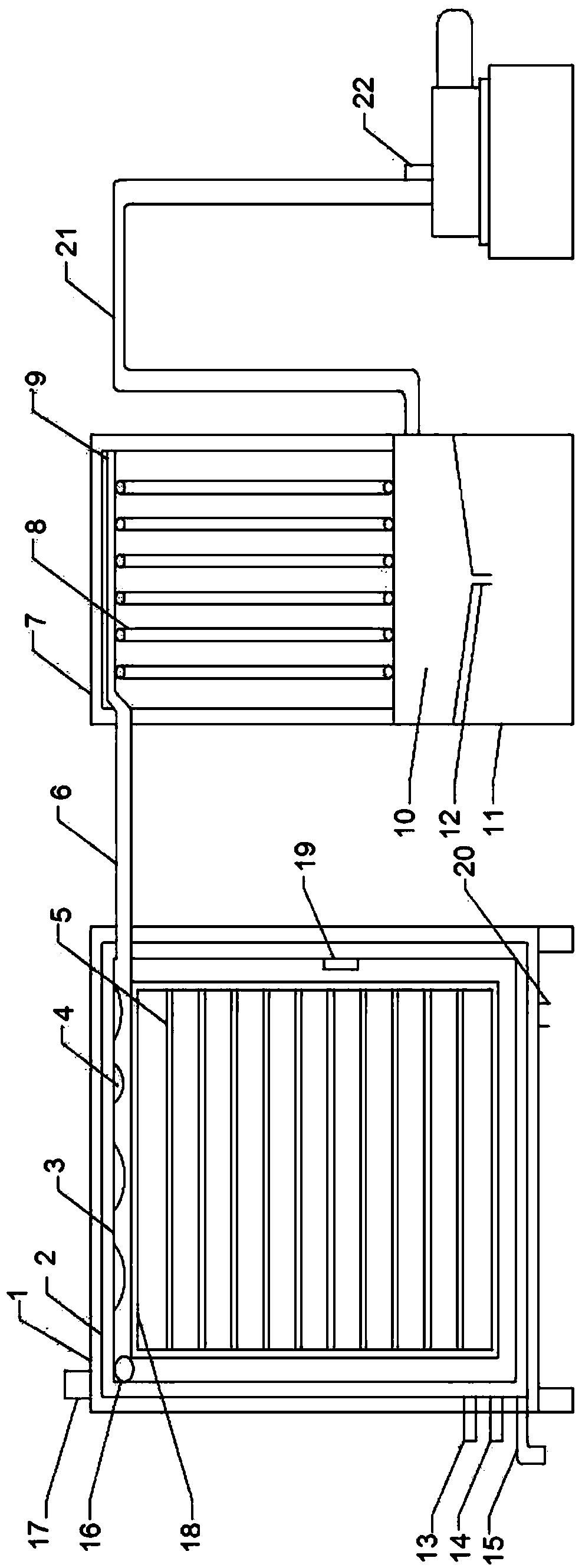

Microwave clothes dryer

InactiveCN100476062CHeating evenly and more comprehensivelyIncreased average power densityMicrowave heatingTextiles and paperState of artMicrowave oven

The present invention relates to a microwave clothes drying machine. It is characterized by that said invention adopts the following technical measures: remaking half-wave voltage-multiplying rectifier circuit of high-voltage power supply of domestic microwave oven magnetron into full-wave rectifier circuit containing power regulation device, setting mutually perpendicular microwave activation directions to construct stereo microwave and adopting polygonal cabinet body or cylindrical or drum type reaction cavity, etc. to reduce microwave pulse peak power and raise microwave average power density, so that the microwave power can be flexibly regulated according to the number of clothes and the safety of drying process also can be raised.

Owner:成都骏元科技发展有限责任公司

Circulation energy-saving drying oven for in-mold decoration

The invention discloses a circulation energy-saving drying oven for in-mold decoration. The circulation energy-saving drying oven comprises a box body, the bottom of the box body is fixedly connectedwith two supporting seats, two rotating shafts are rotationally connected to the back surface of the inner wall of the box body, the surfaces of the two rotating shafts are rotationally connected witha conveying belt, moreover, an empty groove is formed in the top of the conveying belt, moreover, the inner wall of the empty groove is rotationally connected with two rotating rods, the surfaces ofthe two rotating rods are rotationally connected with a containing plate, and a leaking hole is formed in the top of the containing plate. The drying oven has the advantages that the rotating shafts and the conveying belt are arranged so that objects needing to be dried can be moved circularly; the containing plate and a soft cushion are arranged so that the decoration objects can be more stably placed; the rotating rods and the leaking hole are arranged so that drying can be performed more conveniently; a collecting box is arranged so that the dried objects can be collected conveniently; andan air heater and an air conveying pipe are arranged so that the decoration objects on the conveying belt can be dried, then drying can be more concentrated, and the effects of being more energy-saving and environment-friendly are achieved.

Owner:铜陵马刻隆科技有限公司

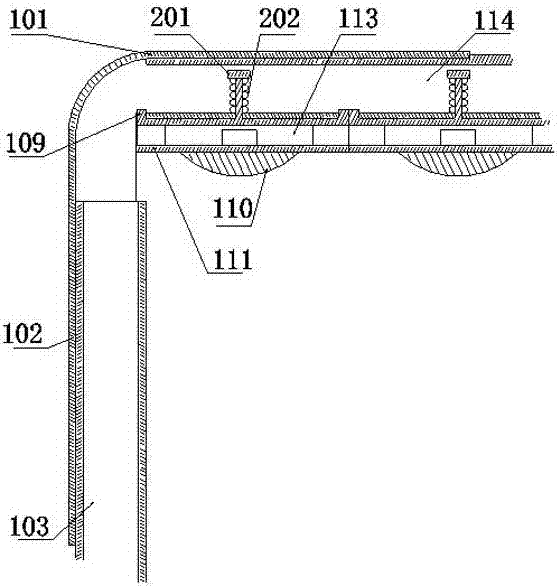

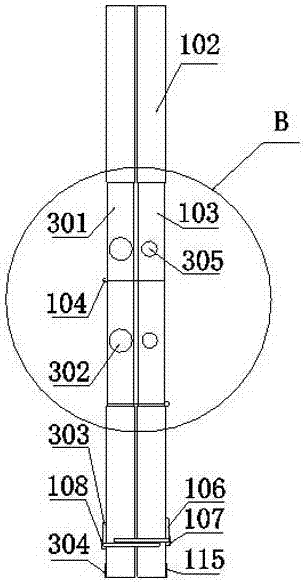

Maintenance-free respirator for transformer

PendingCN109300659ANo need to replaceDoes not cause agingTransformers/inductances coolingElectric component structural associationTransformerRespirator

The invention relates to a maintenance-free respirator for a transformer and mainly solves the technical problems inconvenient disassembly, time consuming and labor consuming, low construction efficiency and easy clogging of a prior respirator. According to the technical scheme, the maintenance-free respirator comprises a respirator, a respirator pipe and an expander, the expander comprises a three-way ball valve, a relief valve, a gulp valve, an air bag and an air pressure and temperature and humidity sensor, and the air outlet of the air bag is perpendicularly connected with the outlet of the gulp valve, the inlet of the relief valve and the three-way ball valve, the inlet of the gulp valve is connected with the respirator pipe, one end of the respirator pipe is connected with a horizontal connection port of the three-way ball valve, and the other end of the respirator pipe is connected with the respirator, another horizontal connection port of the three-way ball valve is connected with an oil pocket of the transformer, and the air pressure and temperature and humidity sensor is arranged on the pipe connecting the air bag and the three-way ball valve.

Owner:国网宁夏电力有限公司超高压公司 +2

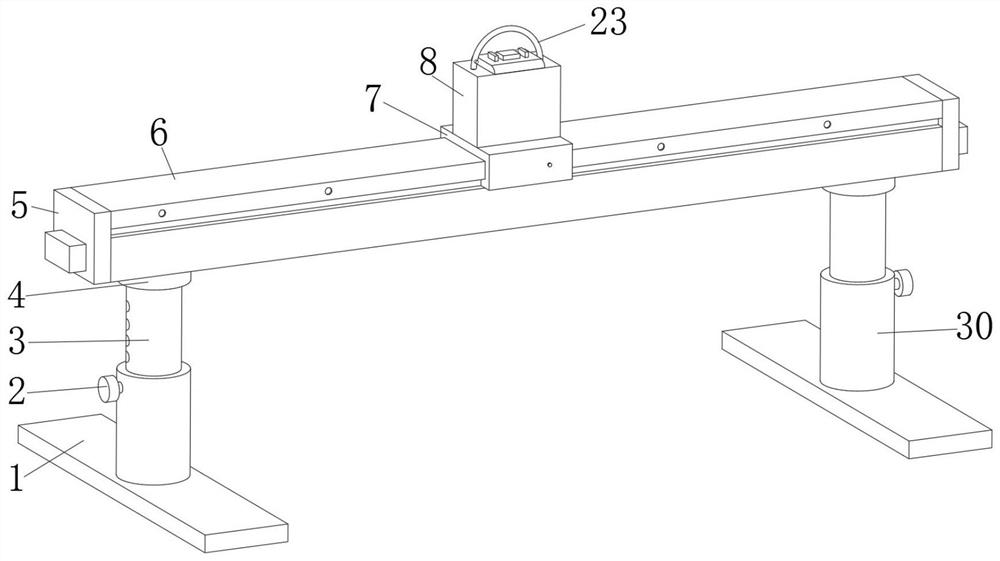

Multi-purpose component for drying and sun-curing clothes

InactiveCN107489004AFast and efficient dryingQuick and easy dryingTravelling sacksTextiles and paperEngineeringMultiple function

The invention provides a clothes drying and drying appliance which is simple to use, fast and efficient—a clothes drying and drying multi-purpose component, which can be used at home, and can also be used as an economical and practical multifunctional travel article that is convenient to carry. It is very economical and practical to dry and dry clothes quickly, easily, safely and securely during travelling. Whether at home or on the go, the telescopic bracket as one of the components can be used as a drying rack, or it can be quickly dried with a multi-purpose bag Dry, no matter what changes in the weather and the length of the journey, it can ensure that there are clean and dry clothes to change at any time. The clothes drying and airing multi-purpose assembly of the present invention is easy to carry, can be loaded into a suitcase without taking up space, and can also be appropriately adjusted according to the size of the suitcase. Versatile as a must-have for easy travel.

Owner:于卫华

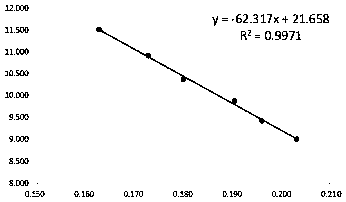

Simple and quick measurement method of non-sugar solids in yellow rice wine with alcoholic content of 8-10%

InactiveCN107643262AGood accuracy and reliabilityEasy and fast operationColor/spectral properties measurementsChemistryDouble strand dna

The invention establishes a brand new method for measuring non-sugar solids in yellow rice wine with alcoholic content of 8-10% by utilizing the principle that a specific double-stranded deoxyribonucleic acid (DNA) fragment has different denaturation degrees in ethanol-water systems with different mass volume ratios of water to ethanol, thus resulting in different degrees of absorbance at 260nm wavelength. The specific double-stranded DNA fragment is as shown in SEQ ID No. 1, and the relationship between the absorbance x of the specific double-stranded DNA fragment and the mass volume ratio yof the water to the ethanol in the ethanol-water system is y is equals to -62.317x + 21.658. The method for measuring the non-sugar solids is suitable for the determination of the yellow rice wine with the alcoholic content of 8-10%, has good accuracy and reliability; long-time drying does not need to be carried out, so that the method is safer; the method is simple and quick to operate, very small in amount of a needed wine sample and low in detection cost.

Owner:陈如凯

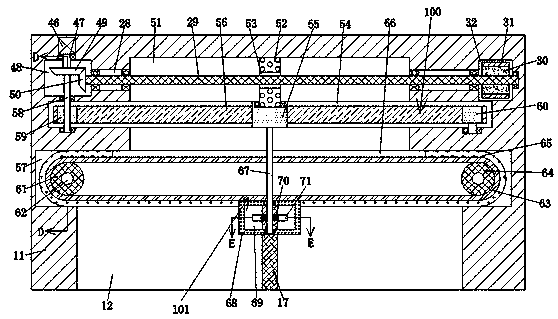

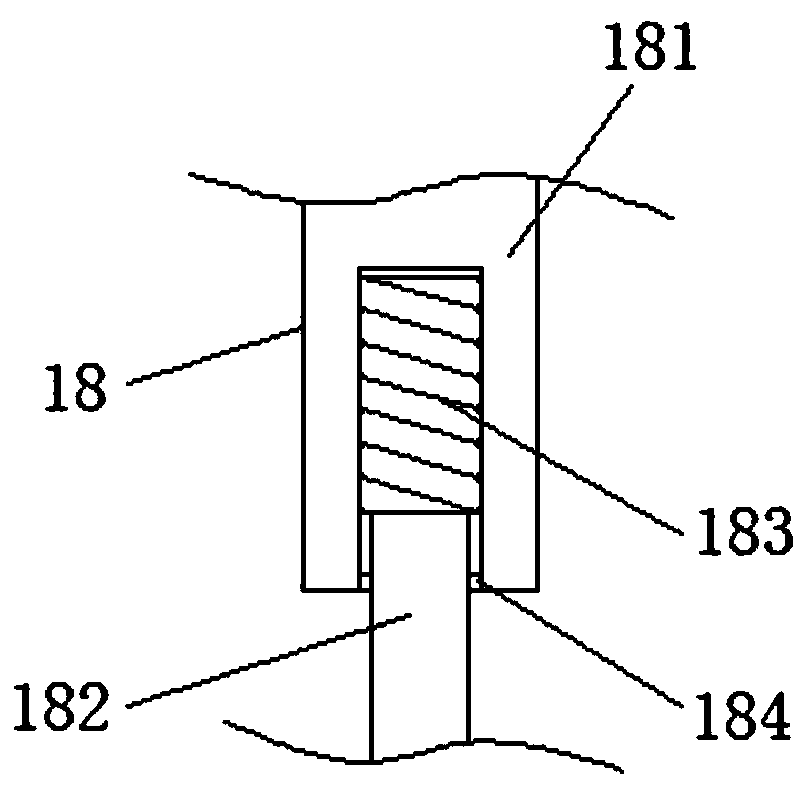

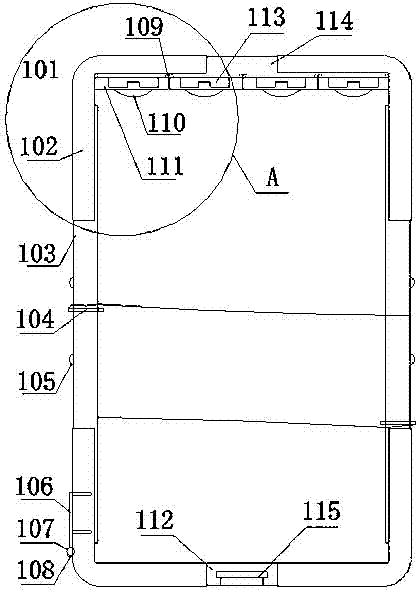

A dryer for fireworks beads and sulphur free propellants

ActiveCN105546949BSafe to dryImprove drying efficiencyGranular material dryingExplosive working-up apparatusAlcoholSulfur

The invention provides a dryer for firework pearls and sulfur-free propellant powder. The dryer comprises a drying module and an alcohol recycling module which are connected through a vacuum exhaust pipe. The drying module comprises an external insulation machine and an internal radiator installed inside the external insulation machine. A steam or hot water heat supply pipeline is installed inside a gap between the external insulation machine and the internal radiator. A plurality of layers of supporting frames for containing objects to be dried are arranged inside the internal radiator. An insurance automatic door is installed on the external insulation machine of the dryer. The alcohol recycling module comprises an alcohol recycling machine cooling water tank and a plurality of cooling vent pipes perpendicular to a horizontal line and arranged inside the alcohol recycling machine cooling water tank. The lower ends of the cooling vent pipes are communicated with an alcohol recycling chamber with no cold water. By adopting the vacuum dehumidification mode, materials are safely dried under the low-humidity environment, time is prolonged by 4-20 times compared with an existing drying mode, energy consumption is lowered by 4-20 times compared with the prior art, and the dryer is worthy of popularization.

Owner:LIUYANG HONGAN MACHINERY MFG CO LTD

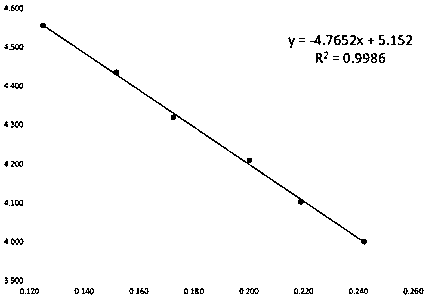

Method for easily, conveniently and quickly measuring non-sugar solid matters in yellow rice wine with alcohol content ranging from 18 degrees to 20 degrees

InactiveCN107807103AImprove accuracyImprove reliabilityColor/spectral properties measurementsAlcohol contentLuminosity

The invention discloses a novel method for measuring non-sugar solid matters in yellow rice wine with the alcohol content ranging from 18 degrees to 20 degrees. The novel method is established by theaid of difference in absorbance at the wave lengths of 260 nm caused by the difference of denaturation degrees of specific double-stranded DNA (deoxyribonucleic acid) fragments in ethyl alcohol watersystems with different water to ethyl alcohol mass and volume ratios. The specific double-stranded DNA fragments are shown as SEQ ID NO:1, and a relational expression of the absorbance x of the double-stranded DNA fragments and the mass and volume ratios of water and ethyl alcohol in the ethyl alcohol water systems is y=-4.7652*x+5.152. The novel method for measuring the non-sugar solid matters has the advantages that the novel method is applicable to measuring the yellow rice wine with the alcohol content of 18-20 degrees, is excellent in accuracy and reliability and low in detection cost, issafe and can be easily, conveniently and quickly implemented, long-time drying can be omitted, and only low wine sample volumes are required.

Owner:洪佳欣

Device for drying footwear

InactiveCN101496711BEven drying effectUniform sterilizationFootwear cleanersEngineeringSupport point

The invention discloses a drying device for shoes, which comprises an air heater, a fan, an air heating element and at least one shoe holder, wherein the inside of the air heater is provided with the fan for drawing air from an air heater air intake into the inside of the air heater and the air heating element for heating the air to generate hot air, the air heater air outlet of the air heater is communicated with an shoe holder air inlet arranged on the shoe holder, and the shoe holder comprises at least one shoe holder air outlet positioned on the front end of the shoe holder; and the outer surface of the shoe holder is provided with a shoe holder surface supporting point allowing a channel for ventilation to be formed between the outer surface of the shoe holder and the inner wall of ashoe. The device facilitates the uniform flow of hot air in the shoe, avoids the sole and the inner upper of the shoe blocking the air outlet and, at the same time, allows the hot air to pass through the walls of the innermost cavity and the outer cavity of the shoe to dry and sterilize the innermost and outer parts of the shoe uniformly. As the supporting point is relatively small, heat convection of the surrounding hot air can fully dry the wall, supported by the supporting point, of the inner cavity.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

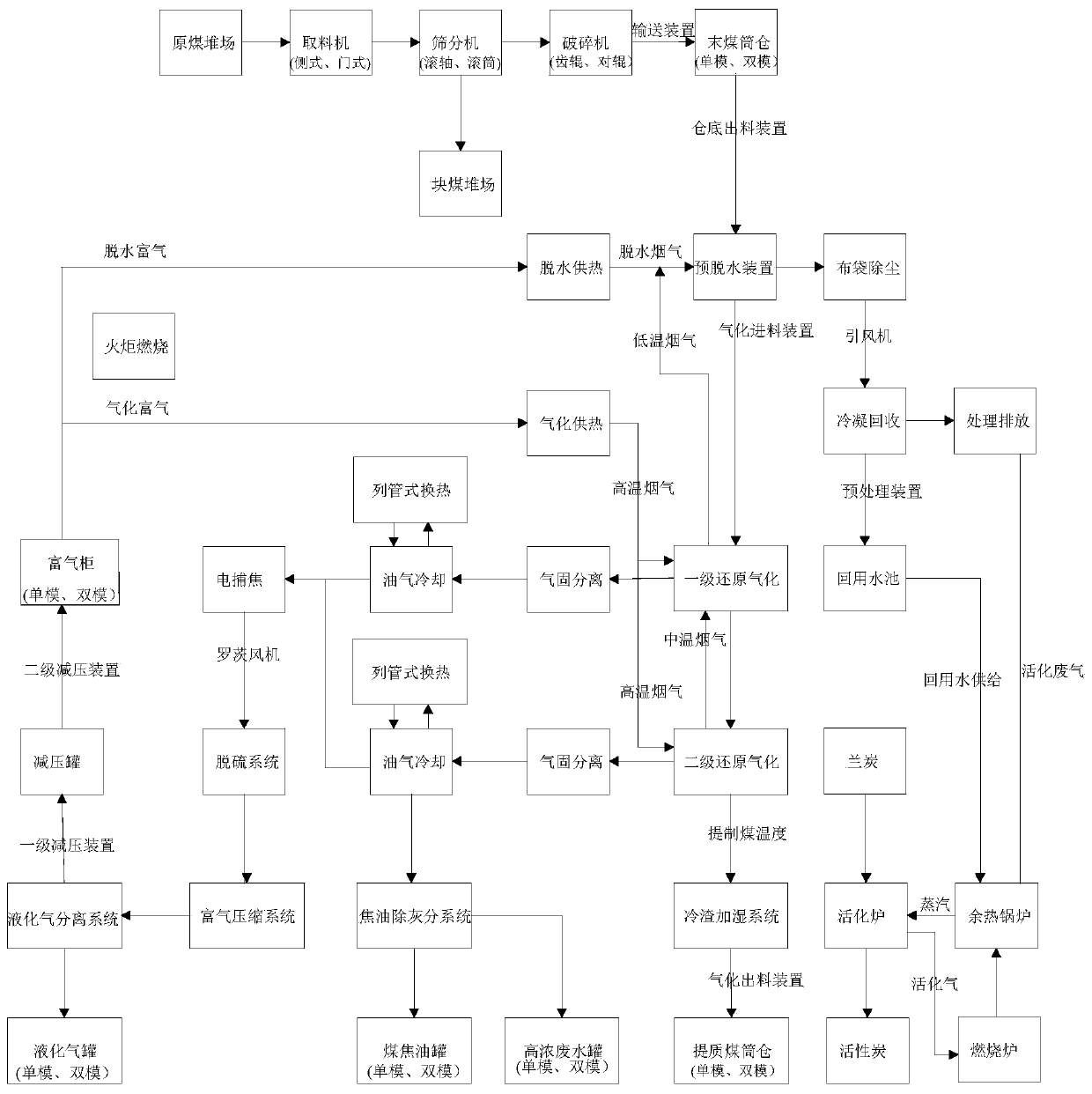

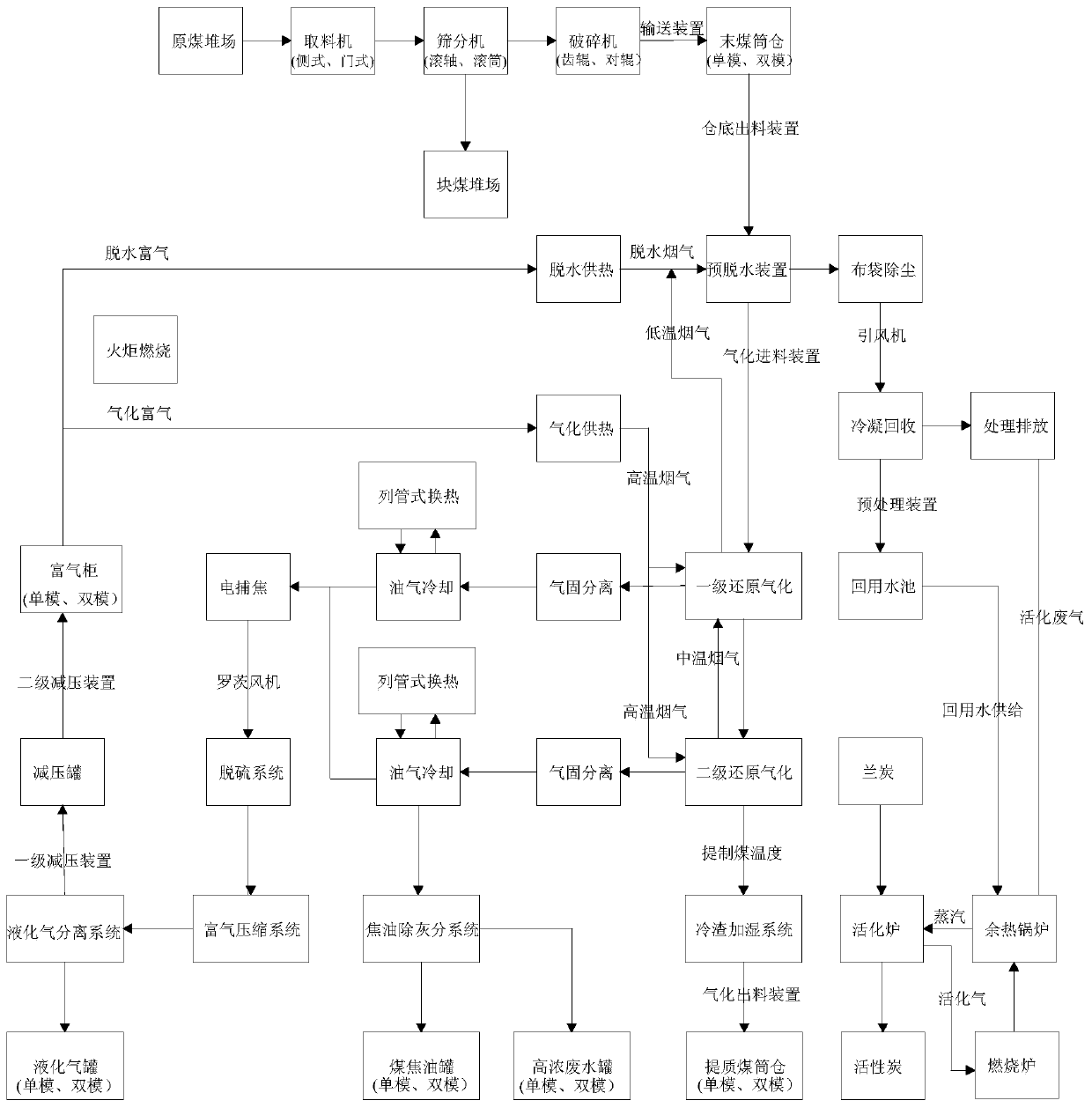

Method for gasification reduction and three-phase separation of pulverized coal and activated carbon preparation

PendingCN110003955AReduce stack heightReduce material frictionDrying solid materials with heatCarbon compoundsPulverizerActivated carbon

The invention provides a method for gasification reduction and three-phase separation of pulverized coal and activated carbon preparation. The method is characterized by comprising following steps: (1), coal is screened by a screening machine and pulverized by a pulverizer successively under the action of a material taking machine and pulverized coal enters a slack coal silo through a conveying device; 2), the pulverized coal is dried by a pre-dewatering device and then enters a primary gasification reduction device and a secondary gasification reduction device successively for reaction; solids enter a cold slag humidification system and then enter the silo; (3), high-temperature oil and gas are subjected to gas-solid separation and oil-gas cooling; a liquid enters a tar ash removing and separation system, and coal tar and wastewater are obtained; gas enters an electrical tar precipitator and a desulfurization system, and is compressed by a rich gas compression system; (4), rich gas passes through primary and secondary pressure reducing devices, and is gasified to supply heat to a reaction system, and the other rich gas dries materials after being dewatered; (5), flue gas containing dust and steam is subjected to bag dust removing and condensing recovery, and is discharged up to standard after treatment; (6), reuse water enters a waste heat boiler and is used as an activating agent to be subjected to an activation reaction with semi-coke entering an activating oven, and a finished activated carbon product is obtained.

Owner:浙江天禄环境科技有限公司

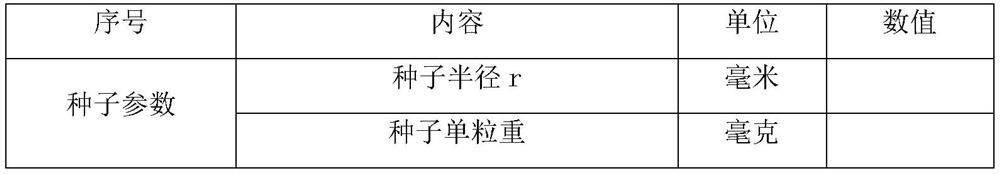

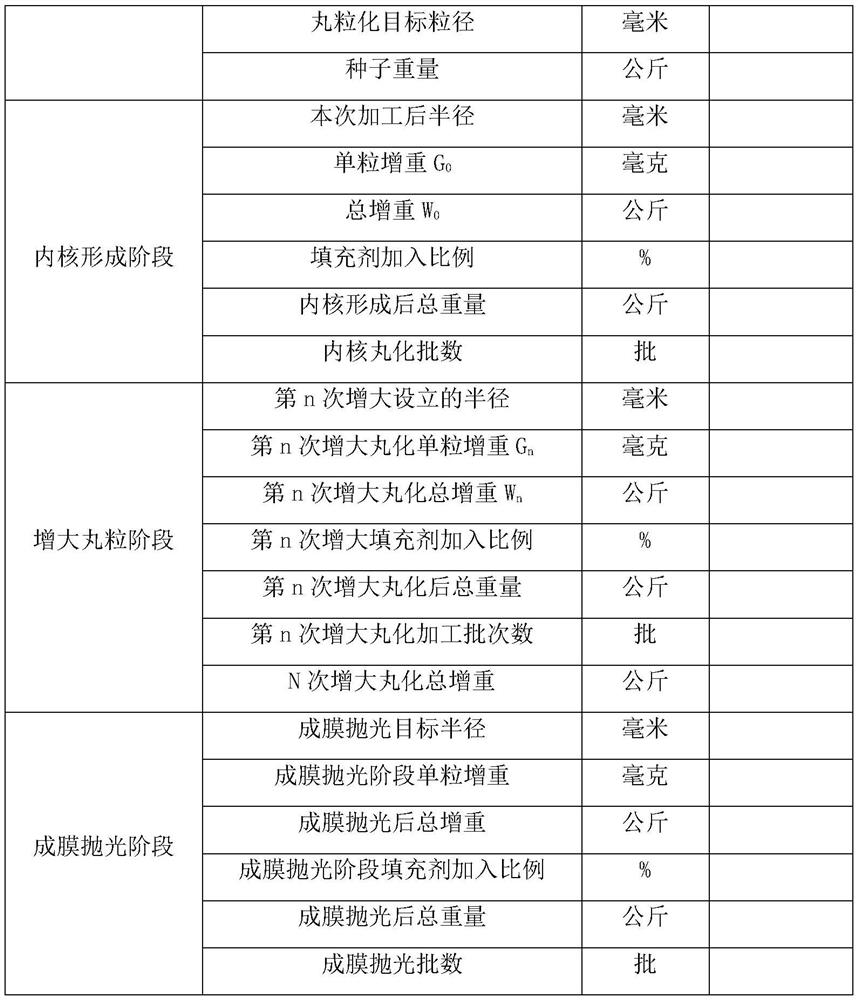

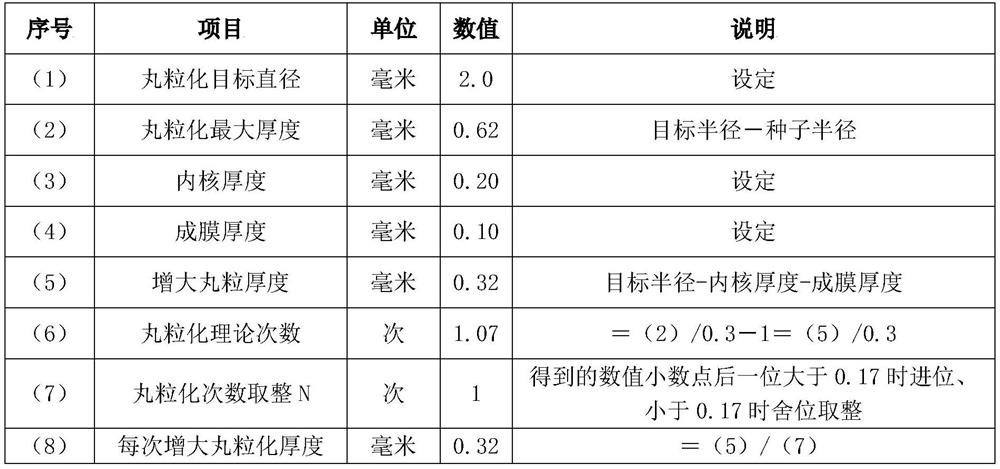

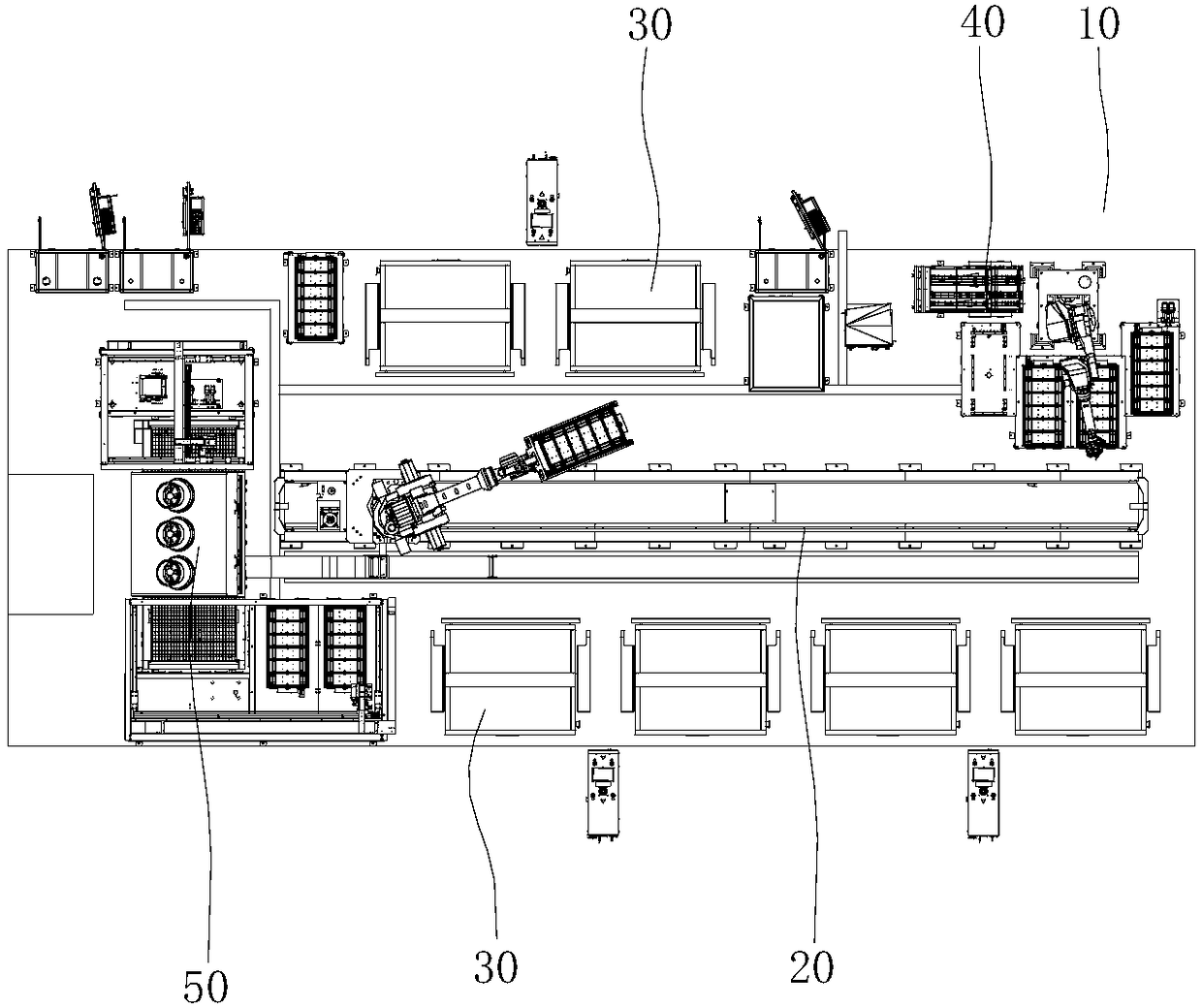

Small-particle seed high-rate pelleting coating material and coating method thereof

ActiveCN114009177ANot easy to reuniteShorten germination timeMagnesium fertilisersOrganic fertilisersSodium polyacrylateFertilizer

The invention provides a small-particle seed high-rate pelleting coating material and a coating method thereof. The coating material comprises a filling agent, an adhesive, an auxiliary agent, a coloring agent and a functional auxiliary agent; the filling agent is a mixture obtained by taking 100 parts by weight of 200-325-mesh vermiculite powder as a base material, adding 2-10 parts by weight of potassium carbonate, 0-15 parts by weight of bentonite and 0-20 parts by weight of diatomite and mixing by using a high-speed mixer; the adhesive is a mixture obtained by mixing and stirring 1-3 parts by weight of a high-viscosity hydroxypropyl methyl cellulose aqueous solution with the concentration of 3 wt%, 1-3 parts by weight of a sodium polyacrylate aqueous solution with the concentration of 7 wt%, 3-5 parts by weight of a polyvinyl alcohol aqueous solution with the concentration of 8 wt% and 10-15 parts by weight of water at the temperature of 20-40 DEG C until emulsification; the auxiliary agent comprises 200-mesh talcum powder and a film-forming agent in a mass ratio of 1: 1; and the functional auxiliary agent comprises one or a combination of a microbial fertilizer, a trace element fertilizer and a water-retaining agent. The problems that large-rate pelleting of small-particle seeds is difficult or the pelleting effect is poor, and the seed bud rate is affected are solved.

Owner:北京万成缘农业科技有限公司 +1

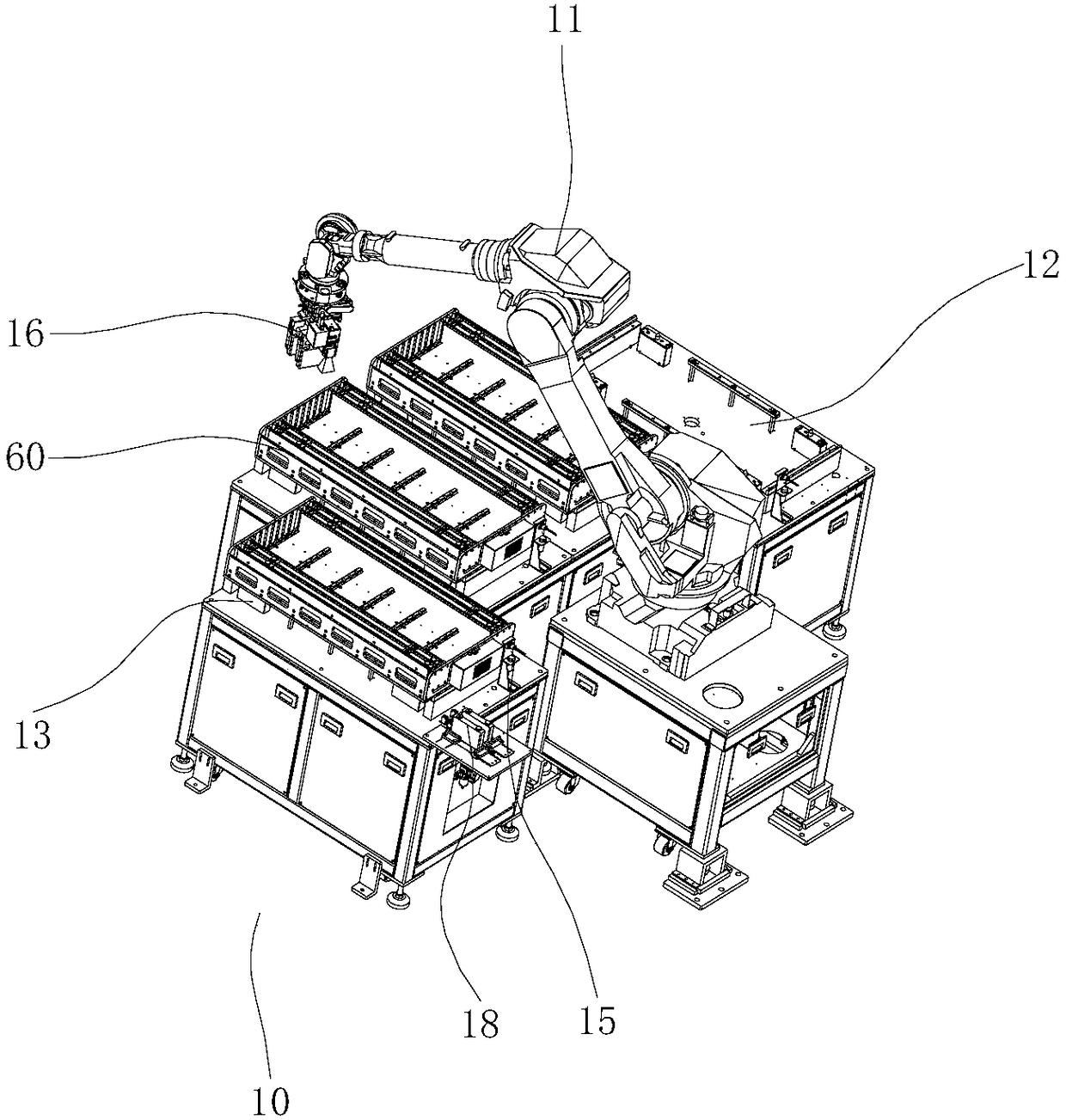

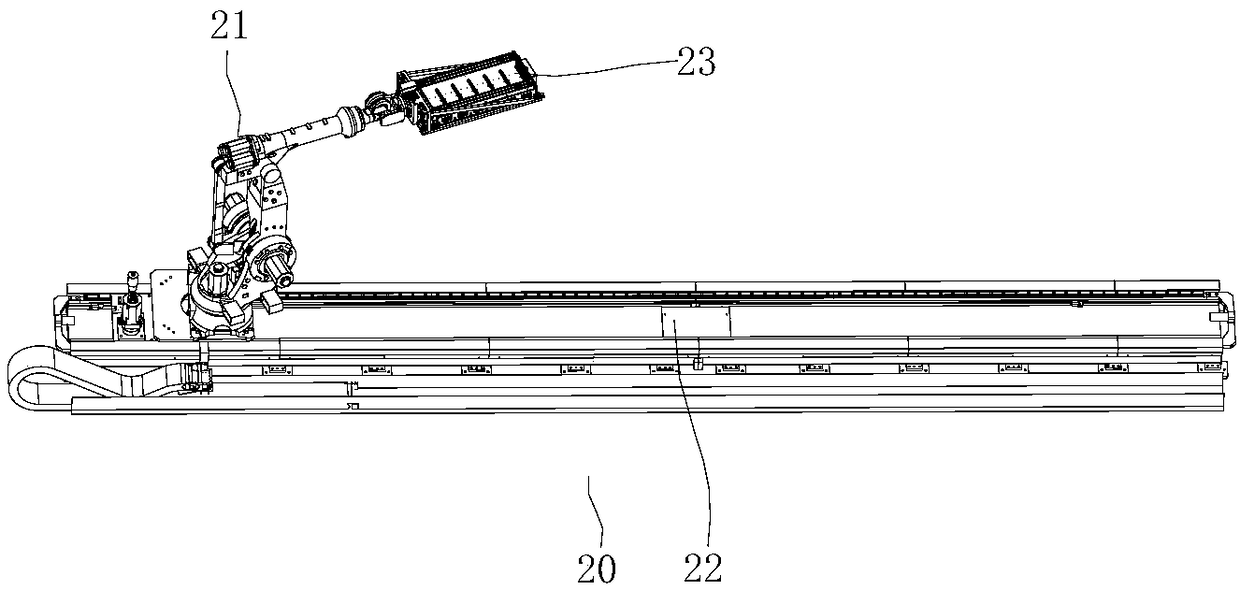

Full-automatic battery drying and cooling system

PendingCN108344294AImprove production efficiency and production safetyRealize automatic drying and coolingSecondary cellsDrying solid materialsAfter treatmentEngineering

The invention discloses a full-automatic battery drying and cooling system. The system comprises a loading module, a detecting module, a carrying module, a drying module and a cooling module; the loading module cooperates with the detecting module and the carrying module; the carrying module cooperates with the drying module and the cooling module; and batteries are conveyed into the drying modulefor drying through the carrying module after loading through the loading module, are conveyed into the detecting module for detection through the carrying module after treatment, and are conveyed into the cooling module for cooling through the carrying module. Through cooperation of the loading module, the detecting module, the carrying module, the drying module and the cooling module, automaticdrying and cooling of the batteries are realized; and compared with traditional manual taking and feeding of the batteries and natural cooling, the full-automatic battery drying and cooling system candry and cool the batteries efficiently, reliably and safely, so that the production efficiency and the production safety in the battery production process are greatly improved.

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com