A dryer for fireworks beads and sulphur free propellants

A dryer and propellant technology, applied in dryers, dryers for static materials, drying and other directions, can solve problems such as the inability to recover alcohol, achieve convenient production operations, small equipment footprint, and high safety factor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

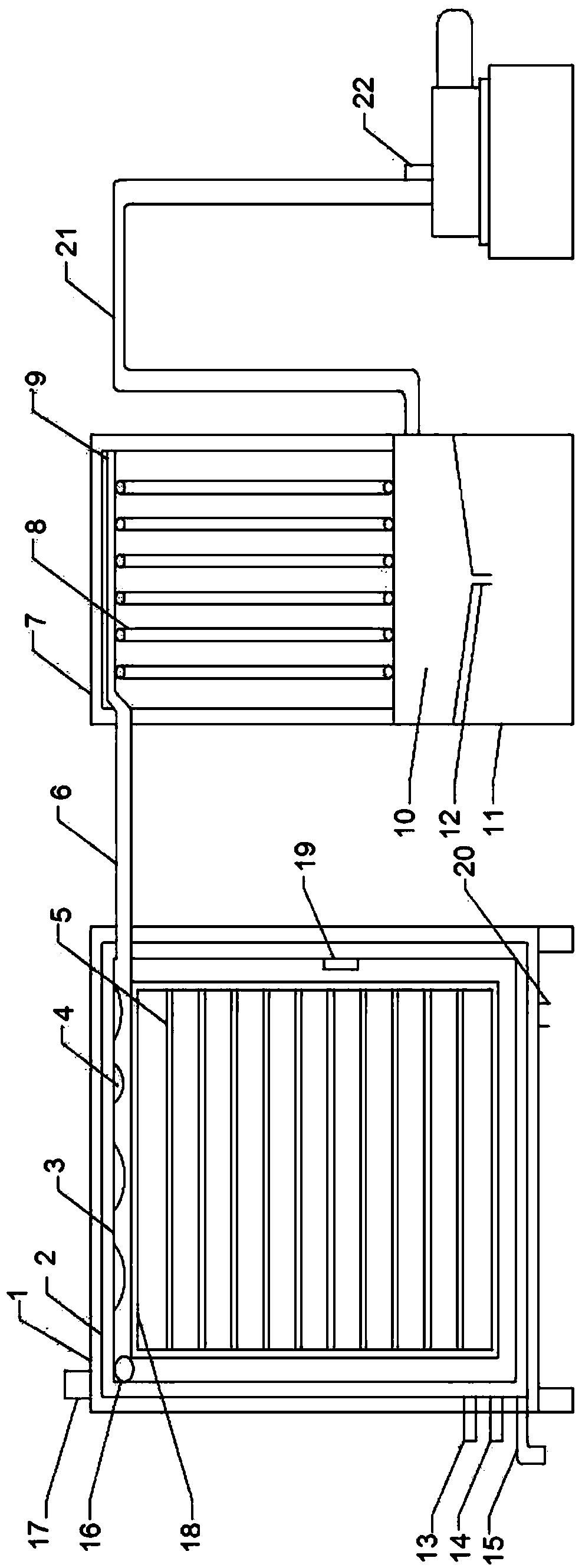

[0036] see figure 1 , a dryer for fireworks bright beads and sulfur-free propellants, including a drying module and an alcohol recovery module connected through a vacuum exhaust pipe, one end 21 of the vacuum exhaust pipe is connected to a water ring vacuum pump unit 22, and the other end is connected to an alcohol At the bottom of the recovery module, another section of vacuum suction pipe is set between the top of the drying module and the alcohol recovery module. After starting the water ring vacuum pump unit, the hot air carrying alcohol gas in the drying module is gradually extracted into the alcohol recovery module. After the alcohol recovery module is cooled, the alcohol in the air is naturally condensed into liquid and deposited in the alcohol reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com