Small-particle seed high-rate pelleting coating material and coating method thereof

A coating material and pelletizing technology, applied in the field of agricultural seedling raising, can solve the problems of needing thinning, decreased seed activity, uneven water content, etc. Uniform volume and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

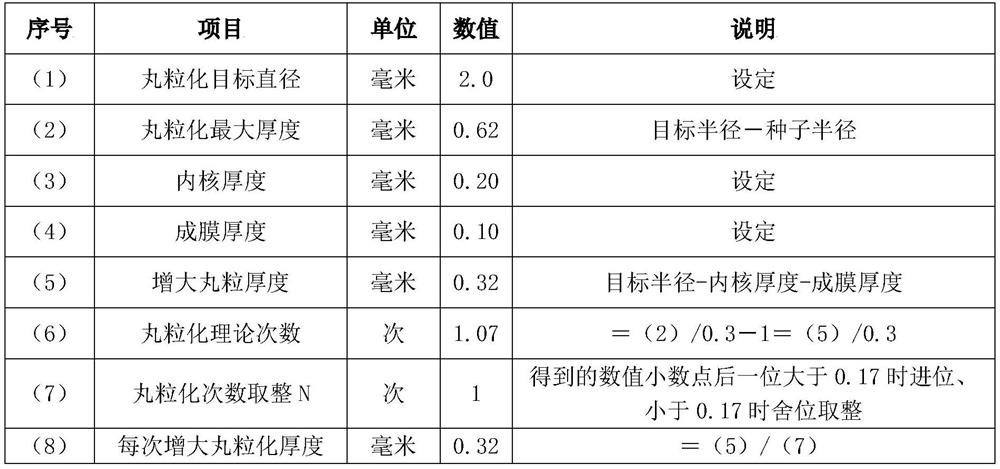

[0124] Embodiment 1: It is required that the dehulled bermudagrass seeds increase to a particle size (diameter) of 2mm, add functional additives, and red coat. The seeds are provided by Beijing Baiqingyuan Animal Husbandry Science and Technology Development Co., Ltd., the seed quantity is 1000g, the purity is >98%, and the germination rate is >85%. .

[0125] 1. Preparation of pelletized coating material

[0126] Preparation of filler: The pelletized filler is composed of vermiculite, potassium carbonate, bentonite and diatomaceous earth, with a mass ratio of 100:10:5:20; 22.62 kg of filler is required for the pellets, and it is taken according to the principle of greater than or equal to With 20 kilograms of 200 mesh vermiculites, 2 kilograms of potassium carbonate, 1 kilogram of bentonite, and 4 kilograms of diatomaceous earth, mix for 10 minutes with a high-speed mixer to obtain 27 kg of fillers, which are left to stand for use;

[0127] Preparation of adhesive: Prepare a...

Embodiment 2

[0161] Example 2: petunia seeds increased to a particle size of 2 mm, without adding any functional additives, and coated in blue. The seeds are 1000g of petunia seeds provided by Beijing Baiqingyuan Animal Husbandry Technology Development Co., Ltd., with a purity of >98% and a germination rate of >85%.

[0162] 1. Preparation of pelletized coating material

[0163] Preparation of fillers: Confirm that the coating materials are vermiculite, methyl carbonate, and bentonite, and prepare them at a mass ratio of 100:2:15. According to the "Method for formulating the pelletization plan" in this example, it can be known that the target pellets need fillers of 65.6 Kilogram, take 60 kilograms of 200 mesh vermiculites, 1.2 kilograms of salt of wormwood, 9 kilograms of bentonites according to the principle of greater than or equal to, mix 10 minutes with a high-speed mixer, obtain filler 70.2kg, leave standstill for use;

[0164] Preparation of adhesive: prepare a total amount of 17.5...

Embodiment 3

[0203] Embodiment 3: celery seed increases to particle size 3.2mm. The seeds are 1500g of celery seeds provided by Beijing Baiqingyuan Animal Husbandry Technology Development Co., Ltd., with a purity of >98% and a germination rate of >85%.

[0204] 1. Preparation of pelletized coating material

[0205] Preparation of filler: choose vermiculite, potassium carbonate, and diatomaceous earth as fillers, with a mass ratio of 100:5:20; according to the "method for formulating pelletization plan" in this example, about 105 kg of filler is needed for pelleting celery seeds. Take 85 kilograms of 200 mesh vermiculites, 4.25 kilograms of potassium carbonate, and 19 kilograms of diatomaceous earth according to the principle of greater than or equal to, and mix for 15 minutes with a high-speed mixer to obtain 108.5kg of fillers, which are left to stand for use;

[0206] Preparation of adhesive: Prepare a total amount of 23.8 kg of adhesive according to the ratio of about 22% of the filler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com