High-conductivity aluminum-doping zinc oxide nanometer noodles powder and preparation thereof

A technology of aluminum-doped zinc oxide and nanopowder, which is applied in nanostructure manufacturing, zinc oxide/zinc hydroxide, nanotechnology, etc., can solve the problems of poor product crystallinity, expensive equipment, affecting product performance, etc., and achieve electrical conductivity Strong ability, good crystallinity and high reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

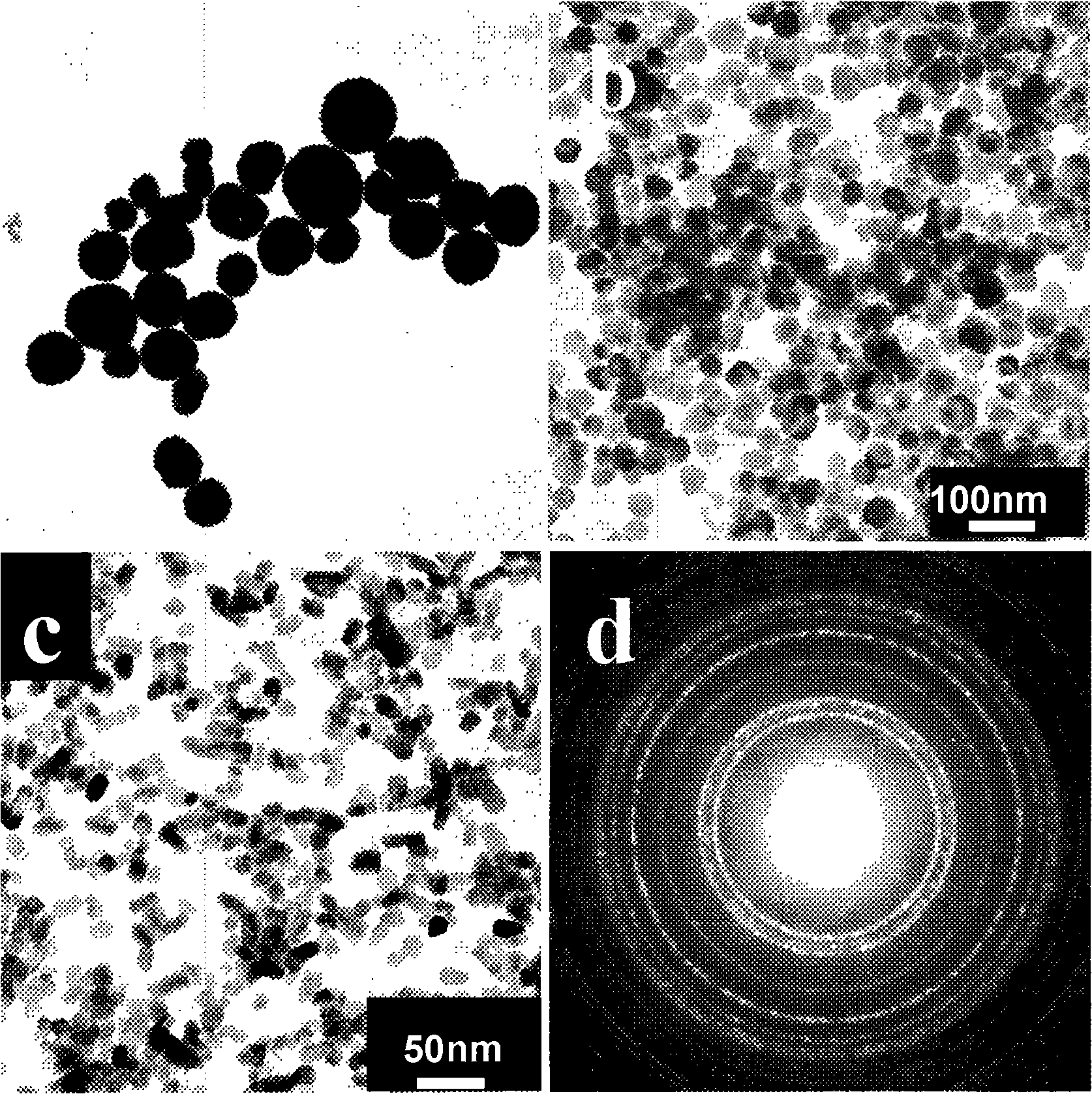

[0019] Example 1: 2.5g of zinc acetate and 0.0872g of aluminum nitrate were added to a 50ml hydrothermal synthesis reaction kettle, and then 40ml of ethanol was added, then the hydrothermal kettle was tightened, placed in an oven, and reacted at 120°C for 12 hours, After the reaction is complete, cool down to room temperature, wash the product three times with deionized water and absolute ethanol, and then dry at 80°C for 12 hours. The obtained white powder is sintered at 600°C for 2 hours in a hydrogen atmosphere, and finally obtains high conductivity. Al-doped ZnO nanopowders. Its morphology is determined by transmission electron micrographs, and the average size of the particles is estimated to be 40nm-50nm in combination with the half-peak width of the XRD diffraction pattern.

[0020] Determination of Volume Resistivity

[0021] Prepare a sufficient amount of sample according to this method, take 2g and pour it into a special mold with a diameter of 10mm, apply a pressur...

Embodiment 2

[0022] Example 2: Add 2.5g of zinc acetate and 0.0872g of aluminum nitrate into a 50ml hydrothermal synthesis reaction kettle, then add 40ml of methanol, finally tighten the hydrothermal kettle, place it in a drying oven, and react at 120°C for 12 hours. After cooling to room temperature, the product was washed three times with deionized water and absolute ethanol, and then dried at 80°C for 12 hours. The obtained white powder was sintered at 600°C for 2 hours in a hydrogen atmosphere to obtain the final conductive powder. , The morphology and volume resistivity measurements are the same as in Example 1, and the particle size of the product is 15nm-25nm and the conductivity is 15Ω·cm.

Embodiment 3

[0023] Example 3: Add 2.5g of zinc acetate and 0.0872g of aluminum nitrate into a 50ml hydrothermal synthesis reaction kettle, then add 40ml of diethylene glycol, and finally tighten the hydrothermal kettle, place it in a drying oven, and heat it at 120°C After reacting at room temperature for 12 hours, after cooling to room temperature, the product was washed three times with deionized water and absolute ethanol, and then dried at 80°C for 12 hours, and the obtained white powder was sintered at 600°C in a hydrogen atmosphere for 2 hours. The final conductive powder was obtained, and its morphology and volume resistivity measurements were the same as in Example 1. The particle size of the product was 300nm-500nm, and its conductivity was 183Ω·cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com