Device for drying footwear

A drying device and footwear technology, which is applied to household cleaning devices, cleaning and application of boots and shoes, etc., can solve the problems of shortened service life, low heat utilization rate, low drying efficiency of shoes, etc. High utilization rate and good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

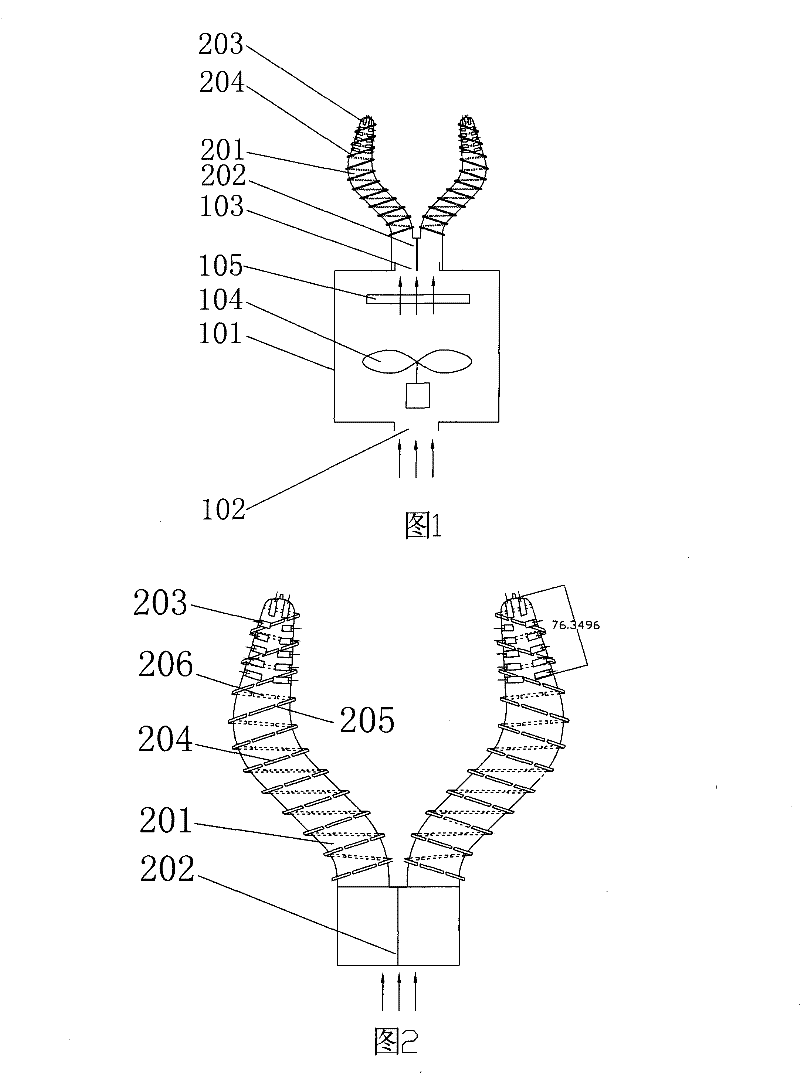

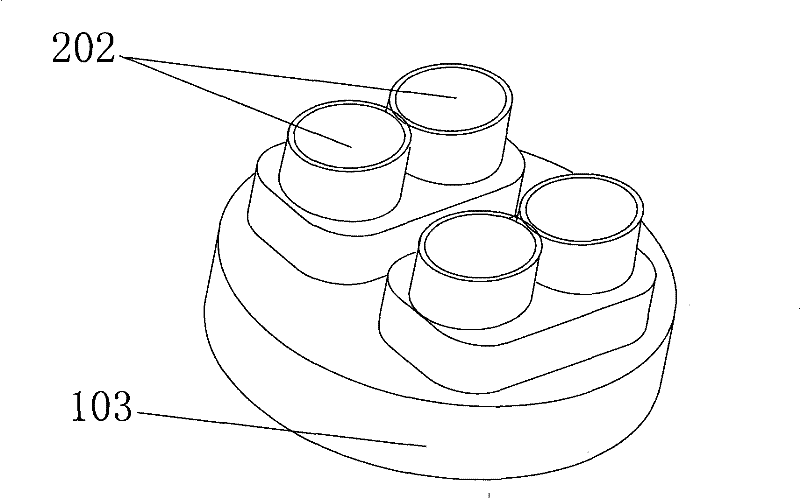

[0040] Embodiment 1 is a form of shoe body bracket with good air duct characteristics and excellent heating and drying performance. Due to the use of spiral air ducts, air circulates in the channel between the outer surface of the shoe body and the inner surface of the shoe cavity. It flows through, so that the hot air can heat the shoe cavity more fully and evenly, and it is far better than the form of comprehensive air supply on the sole for discharging the same amount of humidity or achieving the same humidification effect, such as Figure 5 , the ordinate is the highest water vapor partial pressure in the shoes, and the abscissa is the drying time. The heating curve by adopting the comprehensive air supply form of the sole is I, and the heating and drying curve adopting embodiment 1 is II. As can be seen from this figure, In the initial stage of heating, the humidity in the shoes is the same, and curve I reaches the water vapor partial pressure P0 that is considered dry thr...

Embodiment 2

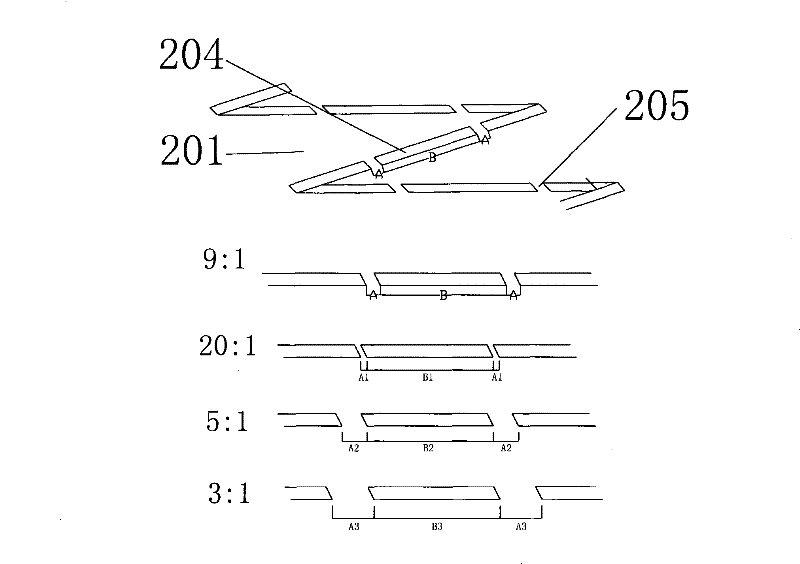

[0043] In this embodiment, the length of the air outlet part accounts for 1 / 6 of the length of the shoe body bracket. Compared with Embodiment 1, the range of the air outlet is reduced, and the wind speed of the air outlet is relatively increased, but the air volume is reduced; The ratio of the length to the interval length is B1:A1=20, the air leakage is small, and the wind speed in the air duct is high; the angle θ1 between the air duct surrounded by the long strip support points and the vertical direction is 103 degrees, and the wind direction is clockwise , the number of turns of the air duct rotation is large, and the wind speed at the air outlet is small. Due to the long flow of the air duct, only a small air volume is needed to meet the drying demand, the power requirements for the fan and the air heater are small, and the drying efficiency is high, which is a preferred embodiment suitable for home use.

Embodiment 3

[0045] In this embodiment, the length of the air outlet part accounts for 2 / 5 of the length of the shoe body bracket. Compared with Embodiment 1, the scope of the air outlet has been expanded, and the air outlet speed has been relatively reduced, but the air volume has increased; The ratio of the length to the interval length is B2: A2 = 5 to B3: A3 = 3, the air leakage volume gradually increases, and the mixed flow in the air duct appears; the angle θ3 between the air duct surrounded by the long strip support points and the vertical direction is 52 degrees, the number of turns of the air duct rotation is less, and the air flow is smoother. It is suitable for commercial applications with relatively large drying capacity and high temperature and humidity requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com