Device for drying water purifying filter material particles

A filter material and granule technology, which is applied in the field of water purification filter material production equipment, can solve the problems of slow drying speed of materials, crushing of granules, and affecting product quality, and achieve the effects of fast drying speed, avoiding loss, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

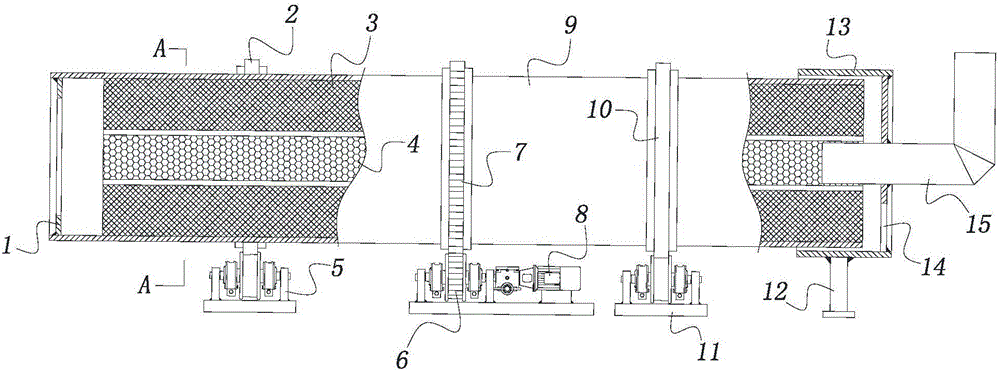

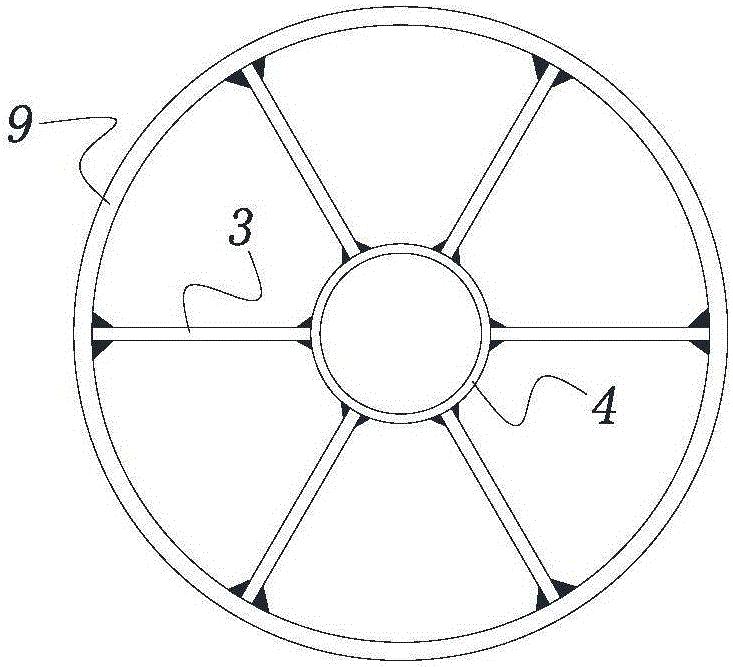

[0012] See figure 1 with figure 2 , the present invention includes a slightly inclined straight roller 9, a ring gear 7 is fixedly installed in the middle of its outer wall, and a first annular track 2 is fixedly installed between the head end on its outer wall and the ring gear 7. A second annular track 10 is fixedly installed between the tail end on the outer wall and the ring gear 7 . The inclination of the straight cylinder 9 is set between 3% and 6%.

[0013] It also includes the first supporting wheel 5 fixedly installed on the ground, the driving device and the second supporting wheel 11, the first supporting wheel 5 cooperates with the first circular track 2, the second supporting wheel 11 cooperates with the second circular track 10, and drives The device includes a reducer 8 and a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com