Patents

Literature

91results about How to "Full drying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparing method of low-cost oxide ceramic shell for titanium alloy precision casting

A low-cost oxide ceramic mould for the precise casting of Ti-alloy is prepared through preparing paint and wax mould of casting, immersing the wax mould in paint for 10-20 min, leveling the paint, uniformly applying the white electro-corundum powder to the paint layer of wax mould, drying, and high-pressure dewaxing.

Owner:HARBIN INST OF TECH

Method for coating plastic molded article

ActiveCN101528362AGood adhesionImprove water resistancePretreated surfacesCoatingsWater basedMetallurgy

Disclosed is a method for coating a plastic molded article which enables to form a three-layer coating film which is composed of a water-based primer, a water-based base coating and a clear coating and excellent in adhesion to the plastic molded article, water resistance and durability even when a low-temperature baking is carried out at a temperature not more than 100 DEG C in a three-coat one-bake system.

Owner:KANSAI PAINT CO LTD +1

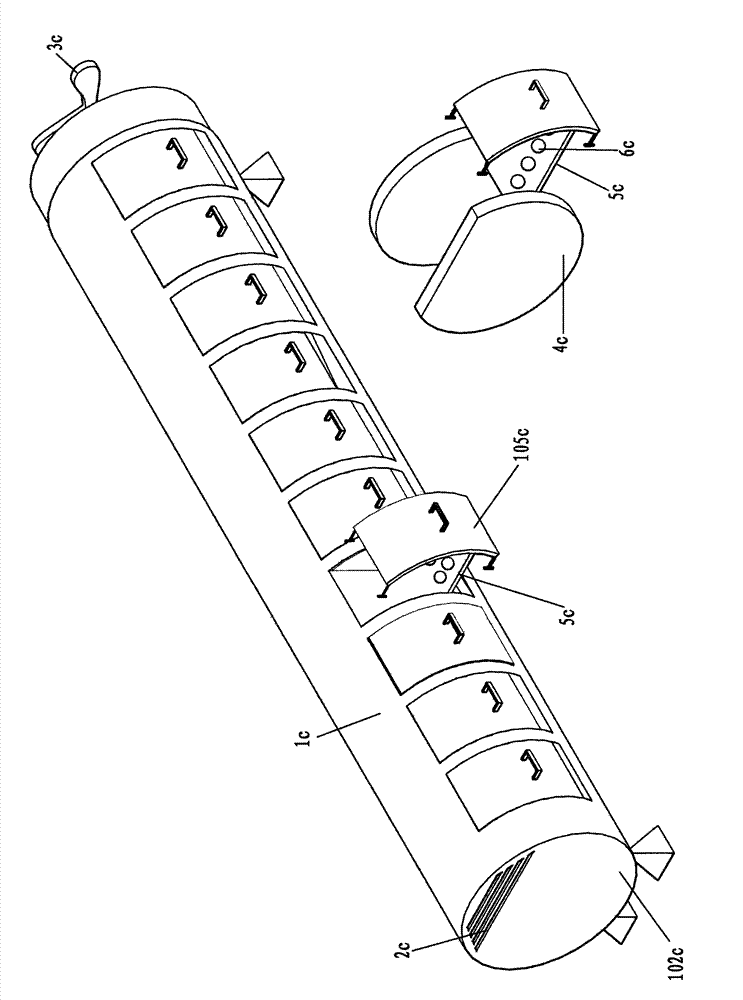

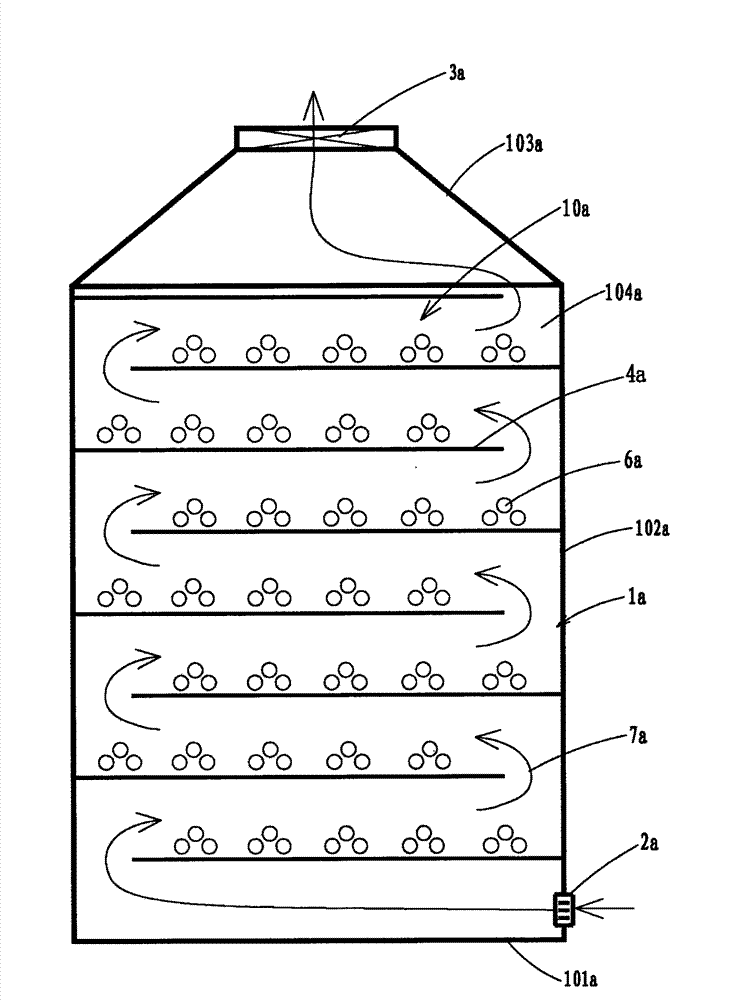

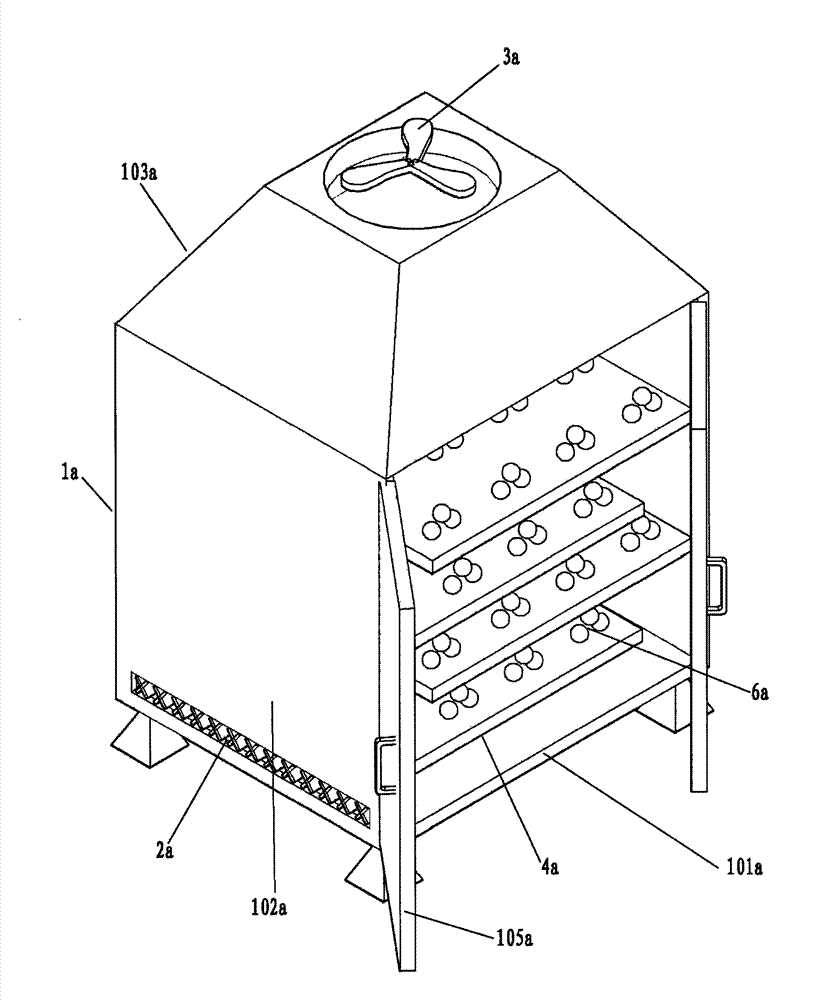

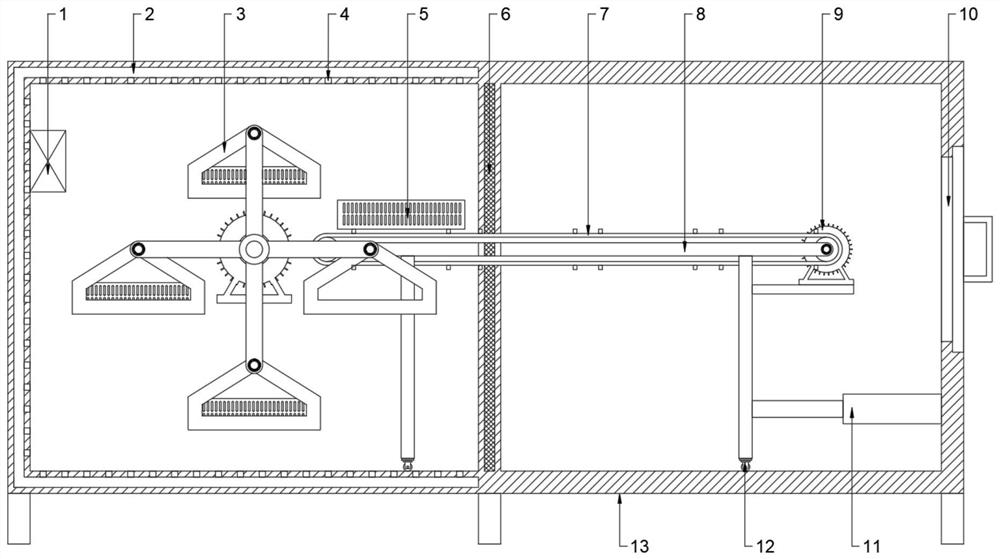

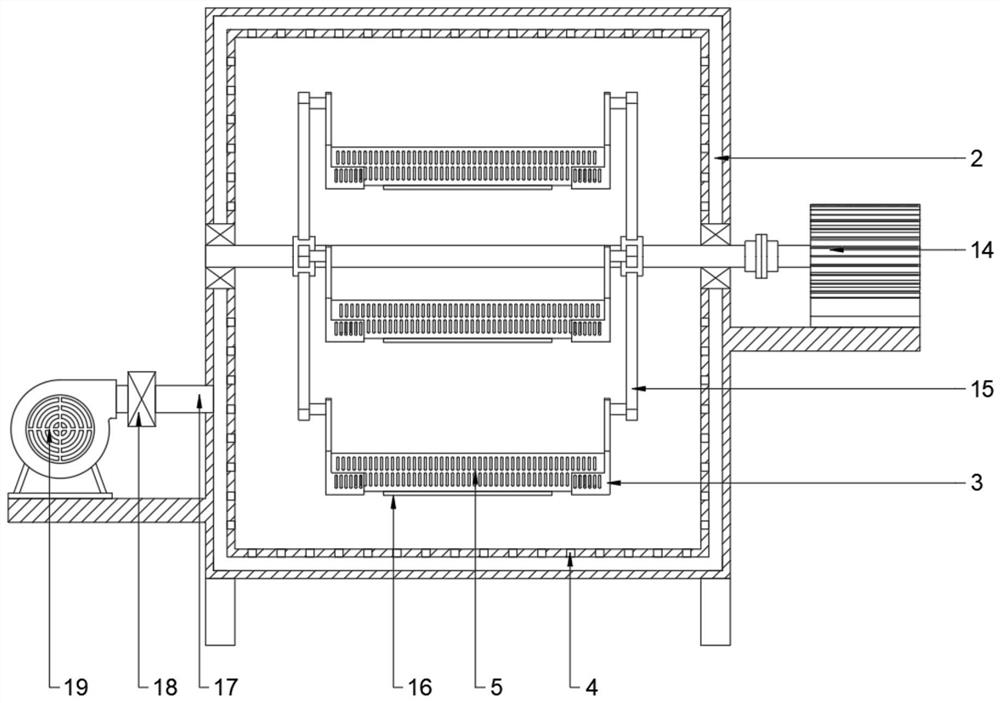

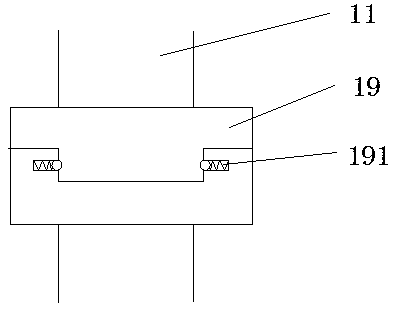

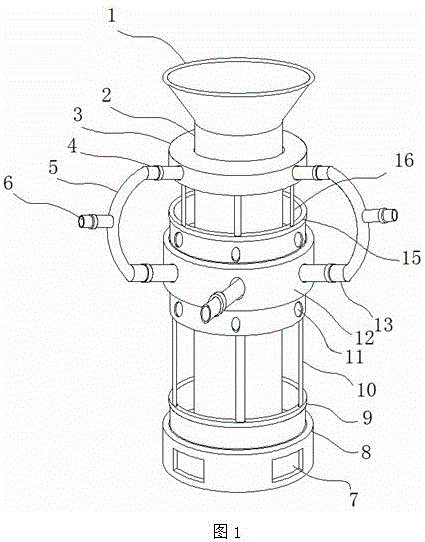

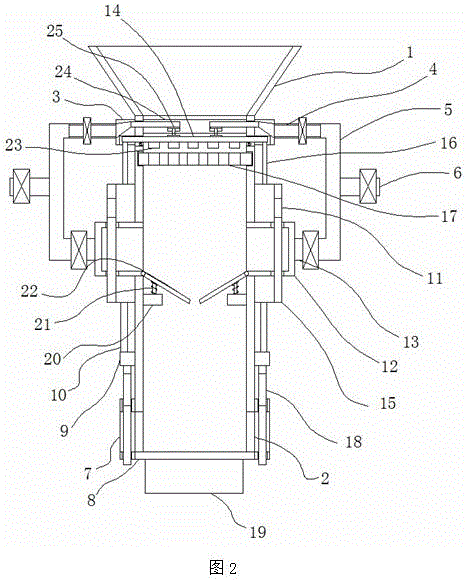

Drying apparatus

InactiveCN102818437AUniform temperature distributionDry evenlyDrying chambers/containersDrying machines with local agitationEngineeringAirflow

The invention discloses a drying apparatus, comprising a cavity body formed by the enclosing of a housing and provided with a cavity, wherein a plurality of separation plates are arranged at intervals in the cavity body, thus the cavity of the cavity body is separated into a plurality of space units for containing materials to be dried; each separation plate or one end of each separation plate is provided with a ventilation hole through which the space units are communicated to form an air flow passage; the housing is provided with at least one air inlet communicated with the cavity of the cavity body; and at least one exhaust fan is arranged in the position of a space unit that is not provided with the air inlet. The cavity of the cavity body is separated into a plurality of space units for containing the materials to be dried; the air flow passage among the space units is still long even though the outline dimension of the whole apparatus is small; the temperature in the whole cavity body is uniformly distributed, thus a space for fully drying is provided for the materials to be dried in the space units, a good drying effect can be obtained, and especially clothes can be dried in a uniform and non-deformed manner; and meanwhile, as different materials can be placed in the same apparatus, different requirements can be met, and convenience can be provided.

Owner:曾庆义

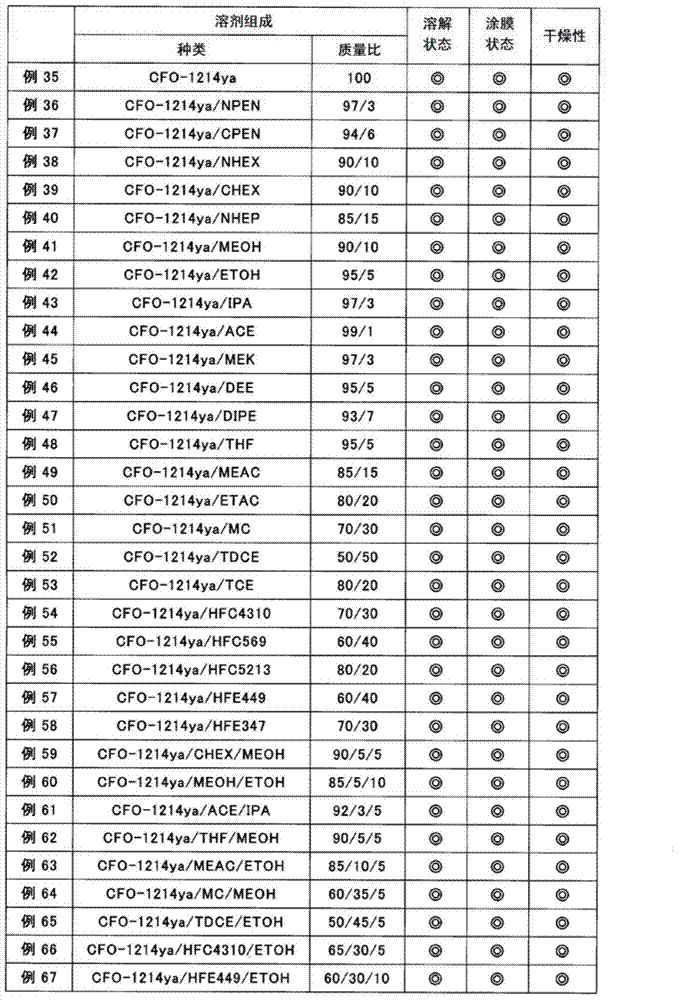

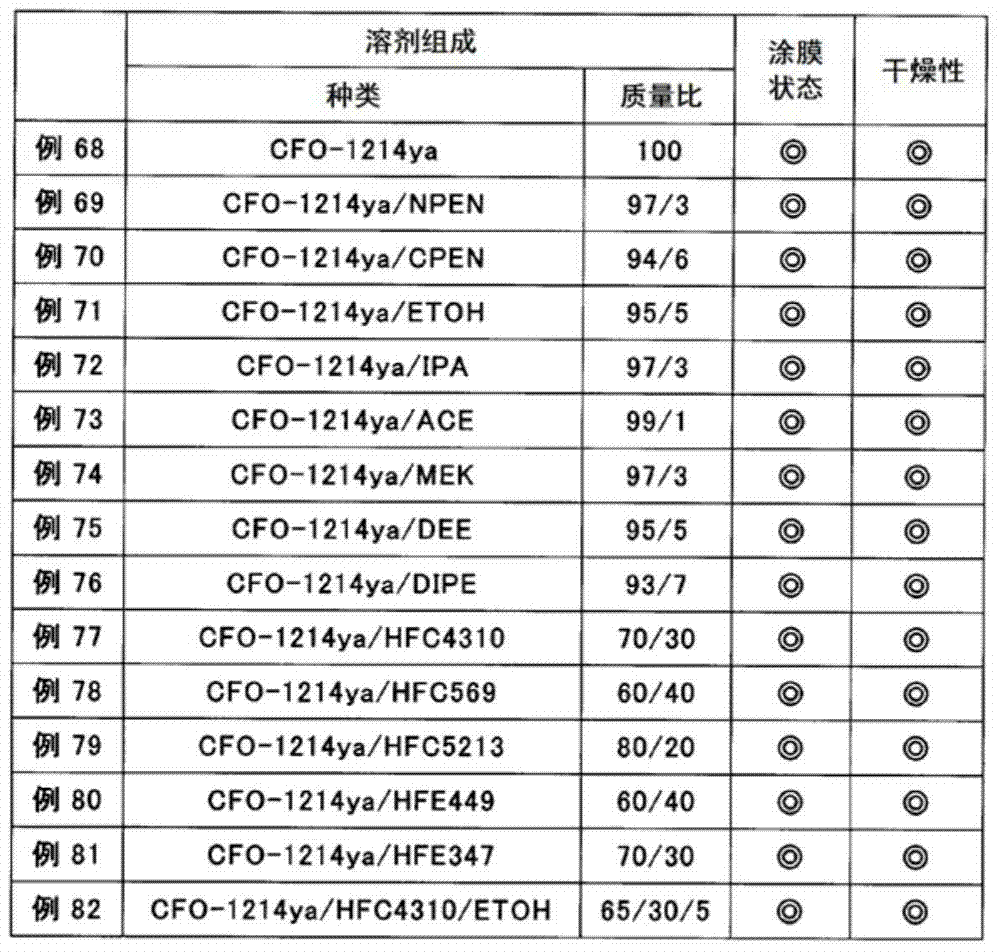

Lubricant solution and method for producing article provided with lubricant coating film

InactiveUS20150037505A1Not to damageImprove solubilitySnowboard bindingsWork treatment devicesSolubilitySolvent

To provide a lubricant solution which does not impair the global environment, which provides an excellent solubility of a lubricant, which has a sufficient drying property and with which a uniform lubricant coating film can be formed, and a method for producing an article provided with a lubricant coating film, using the lubricant solution.A lubricant solution which is a solution of a lubricant, wherein the solvent is a solvent containing 1,1-dichloro-2,3,3,3-tetrafluoro-1-propene. A method for producing an article provided with a lubricant coating film, which comprises applying the lubricant solution to an object to be coated, and evaporating the solvent to form a lubricant coating film on the object.

Owner:ASAHI GLASS CO LTD

Vibration damping composition

ActiveUS20090048357A1Good vibration reduction effectSuppressing sagging of a vibration damping coating filmNon-rotating vibration suppressionCoatingsFoaming agentEmulsion

To provide a vibration damping composition: excellent in vibration damping property and thermal drying property in a wide temperature range; and sufficiently suppressing sagging of a vibration damping coating film on the vertical surface; and therefore useful for vibration damping materials of various structures.A vibration damping composition comprising an emulsion for vibration damping materials, a foaming agent, and an inorganic pigment, wherein the emulsion for vibration damping materials comprises a particle having a core part formed from an acrylic copolymer (A) and a shell part formed from an acrylic copolymer (B), and at least one of the acrylic copolymers (A) and (B) is prepared by copolymerizing a monomer component comprising methacrylic acid.

Owner:NIHON TOKUSHU TORYO CO LTD +1

Vibration damping composition

ActiveUS8664286B2Good vibration reduction effectSuppressing sagging of a vibration damping coating filmNon-rotating vibration suppressionFoundry mouldsEmulsionFoaming agent

To provide a vibration damping composition: excellent in vibration damping property and thermal drying property in a wide temperature range; and sufficiently suppressing sagging of a vibration damping coating film on the vertical surface; and therefore useful for vibration damping materials of various structures.A vibration damping composition comprising an emulsion for vibration damping materials, a foaming agent, and an inorganic pigment, wherein the emulsion for vibration damping materials comprises a particle having a core part formed from an acrylic copolymer (A) and a shell part formed from an acrylic copolymer (B), and at least one of the acrylic copolymers (A) and (B) is prepared by copolymerizing a monomer component comprising methacrylic acid.

Owner:NIHON TOKUSHU TORYO CO LTD +1

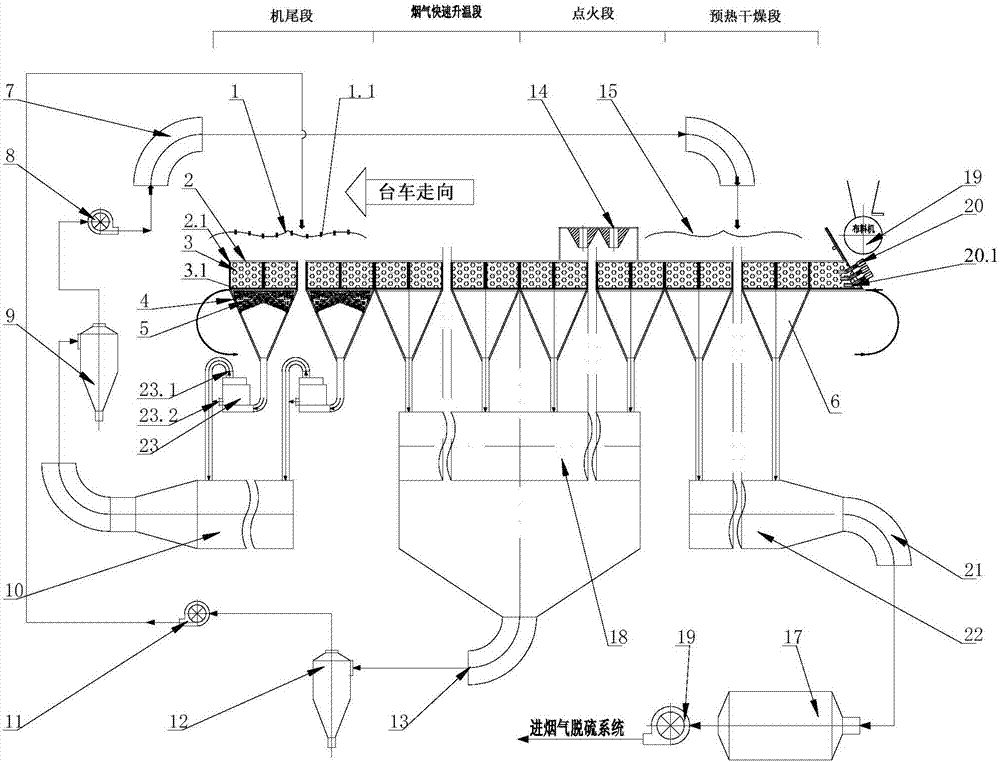

NOx emission reduction system based on ignition and sintering of dry mixture

ActiveCN107314677AFully warm upFull drying effectFurnace typesWaste heat treatmentFluidized bedFlue gas

The invention discloses a NOx emission reduction system based on ignition and sintering of a dry mixture. According to the technical scheme, the system comprises a sintering machine; bellows are arranged below trolleys of the sintering machine; the sintering is sequentially divided into four areas including a preheating and drying section, an ignition section, a flue gas quick-heating section and a tail section in the advancing direction of the trolleys; the bellows below the tail section are connected through fluidized bed reactors, a high-temperature flue gas main flue, a high-temperature flue gas dust remover, a high-temperature flue gas circulating fan and a high-temperature flue gas circulating pipe sequentially with a high-temperature circulating flue gas cover located above the preheating and drying section. With the system, the pollution emission amount is small, the recovery rate of waste heat of sintering flue gas is high, no outsourced denitration catalyst is used, and generation of NOx in the flue gas is effectively reduced.

Owner:武汉钢铁有限公司 +2

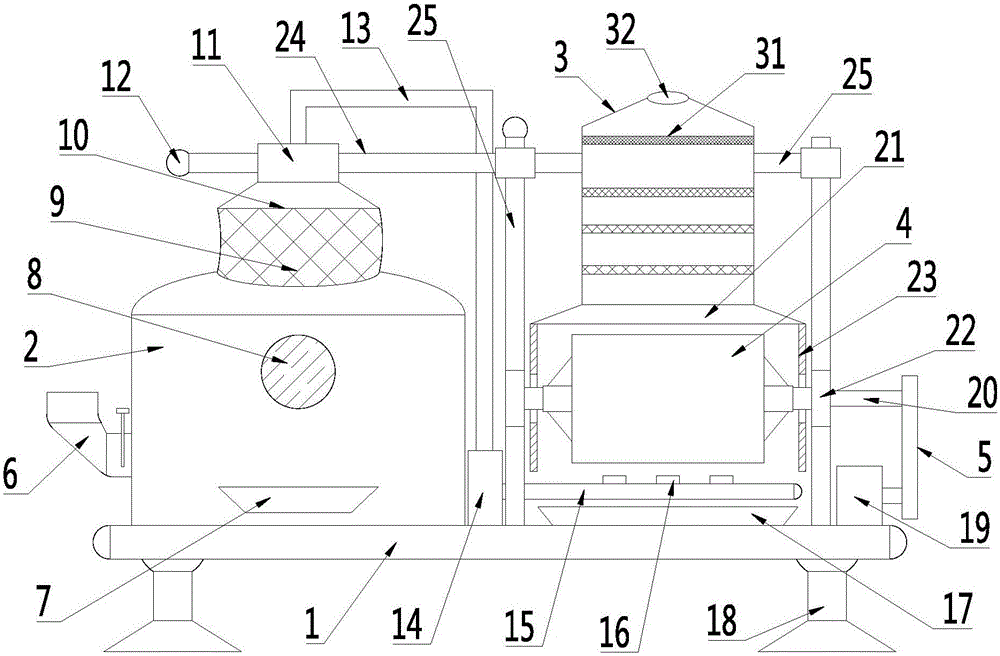

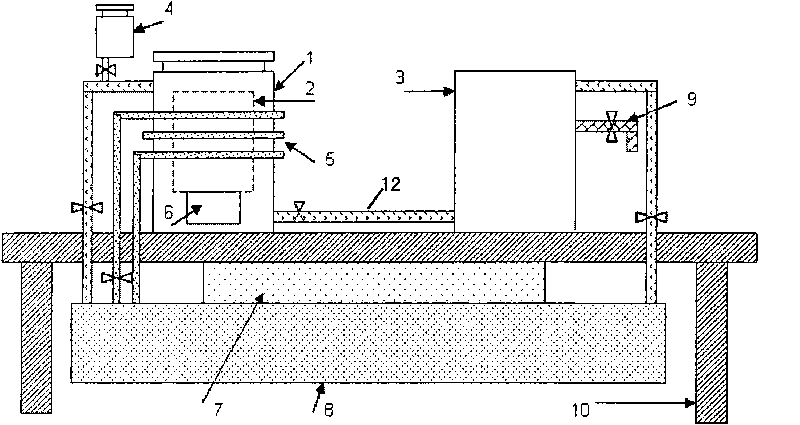

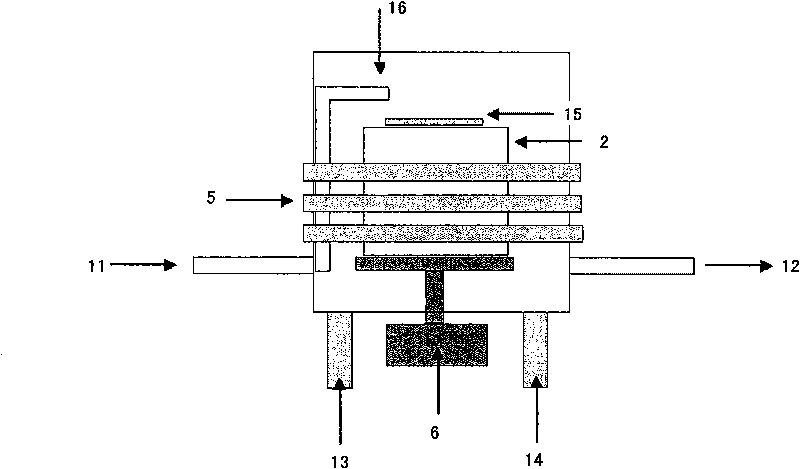

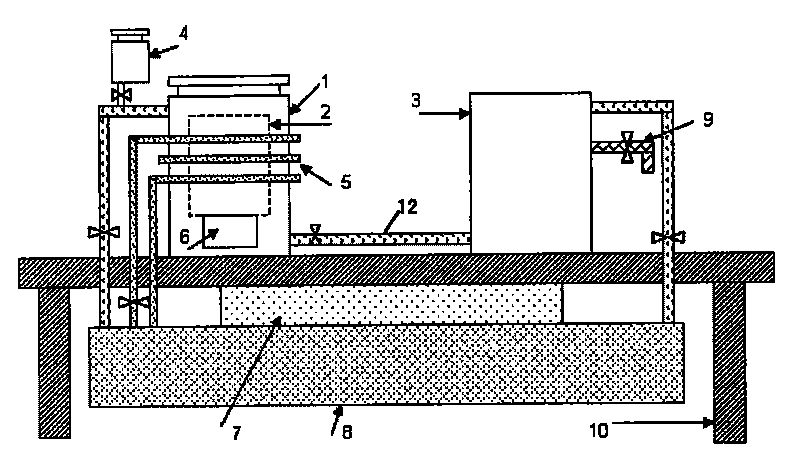

Industrial-boiler flue gas waste heat recycling device

ActiveCN106500517AImproved drying and preheatingSimple device structureIncreasing energy efficiencyWaste heat treatmentProcess engineeringCoal

The invention discloses an industrial-boiler flue gas waste heat recycling device which comprises a base, an industrial boiler, a flue gas filter tank, a coal preheating tank and a soot collecting tank. The flue gas filter tank and the coal preheating tank are arranged between stand columns installed on the base separately, a second dust hood is fixedly installed on the lower portion of the flue gas filter tank, the upper portion of the second dust hood communicates with the lower portion of the flue gas filter tank, and the coal preheating tank is rotationally connected with the two stand columns through rolling bearings; and an exhaust pipeline is arranged under the coal preheating tank, the exhaust pipeline communicates with a suction pipeline through a negative pressure fan, the exhaust pipeline is located over the soot collecting tank, the coal preheating tank comprises an enclosing plate, a movable cover, side plates and a rotating rod, and multiple filter screens are fixedly installed in the flue gas filter tank from top to bottom in sequence. The industrial-boiler flue gas waste heat recycling device is simple in structure, reasonable in design, capable of effectively utilizing waste heat of flue gas in the boiler for drying and preheating coal and improving the burning efficiency of the coal and high in practicability.

Owner:BRIGHT THERMAL EQUIP CO LTD

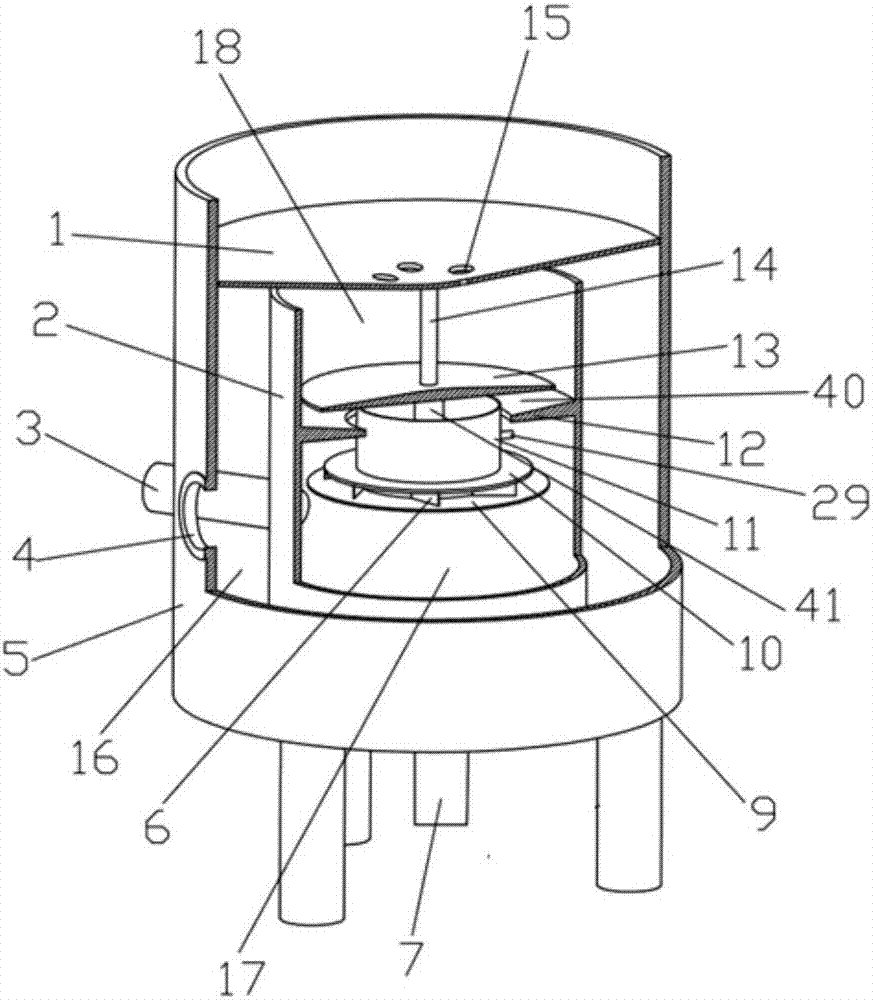

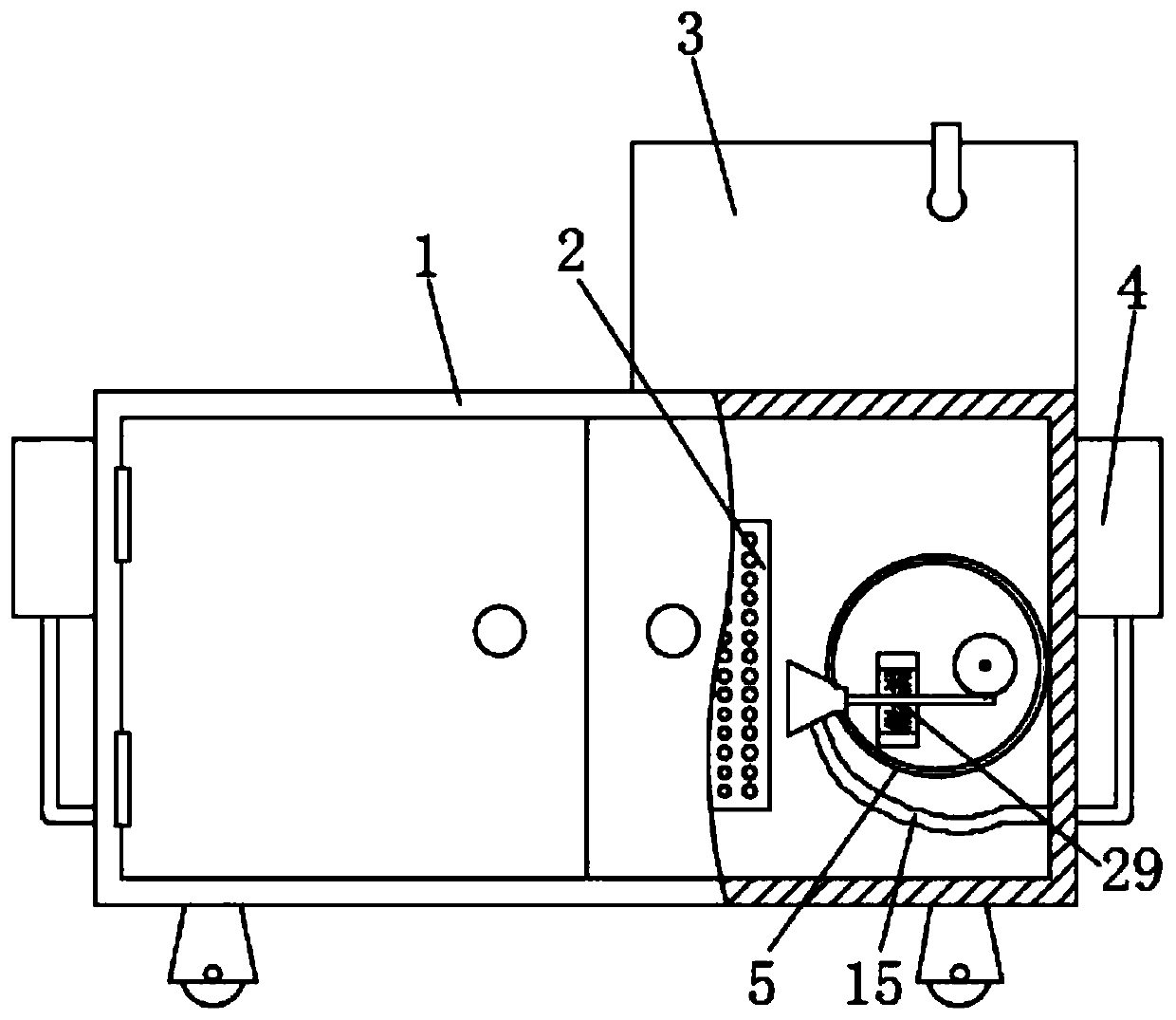

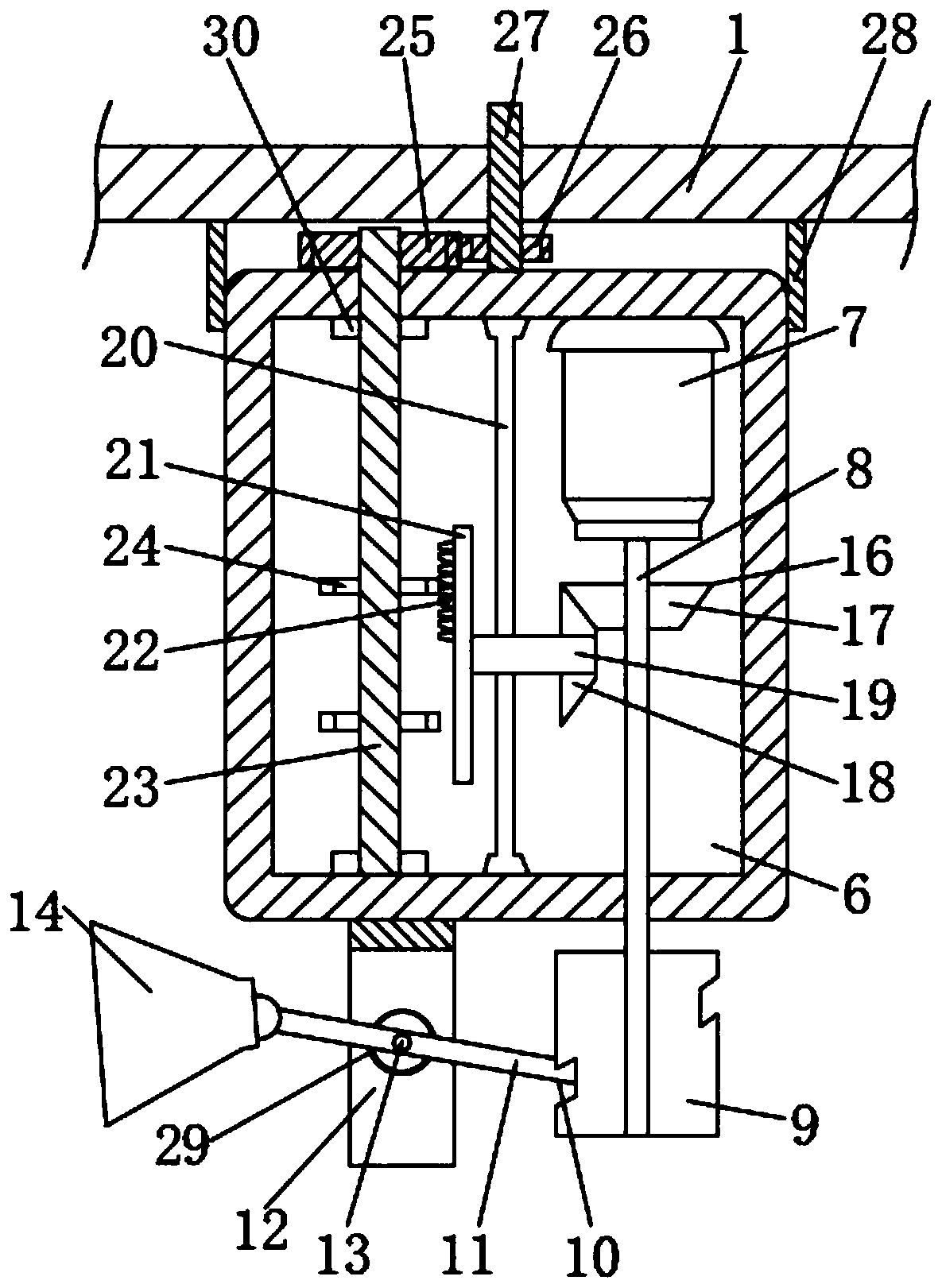

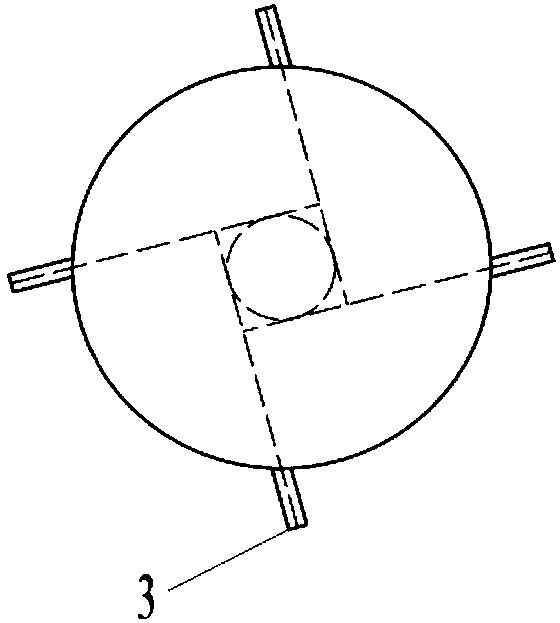

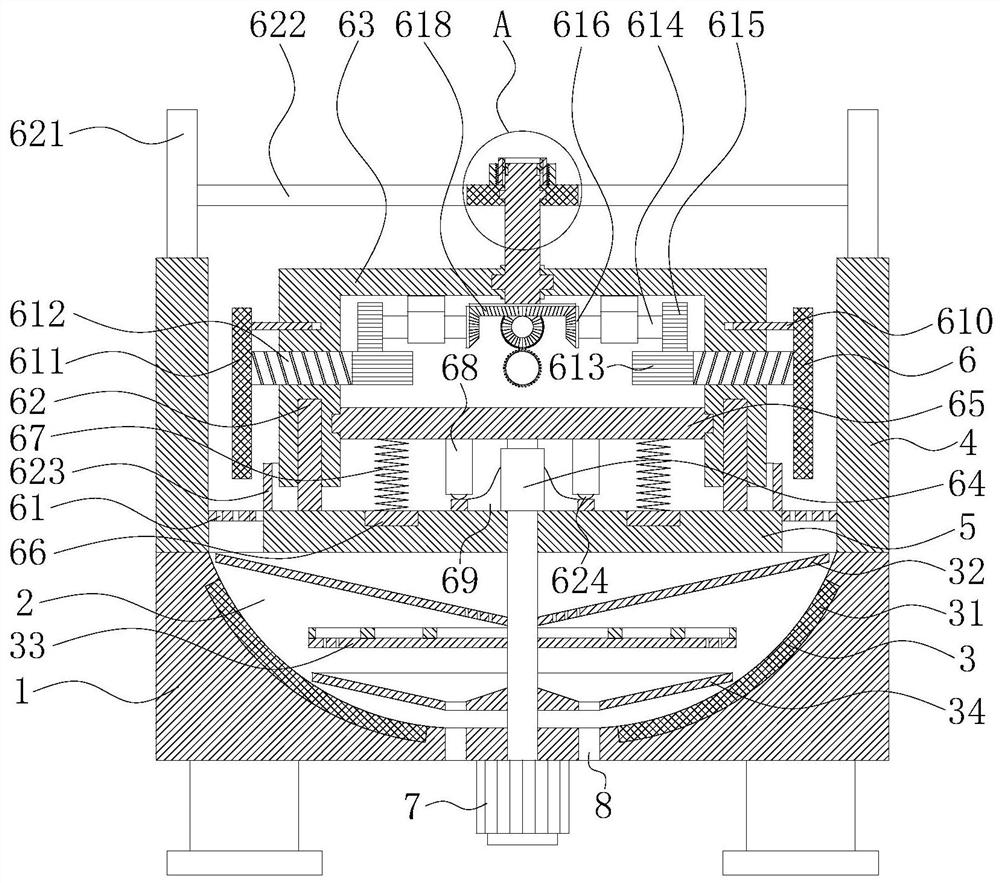

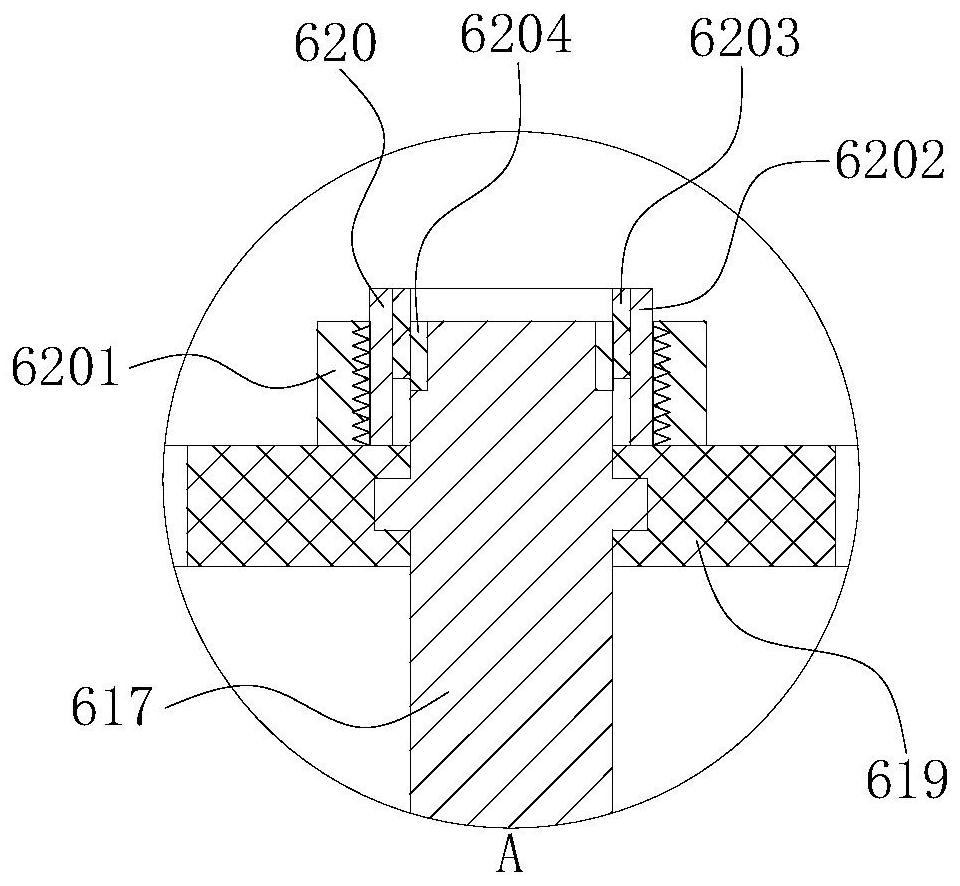

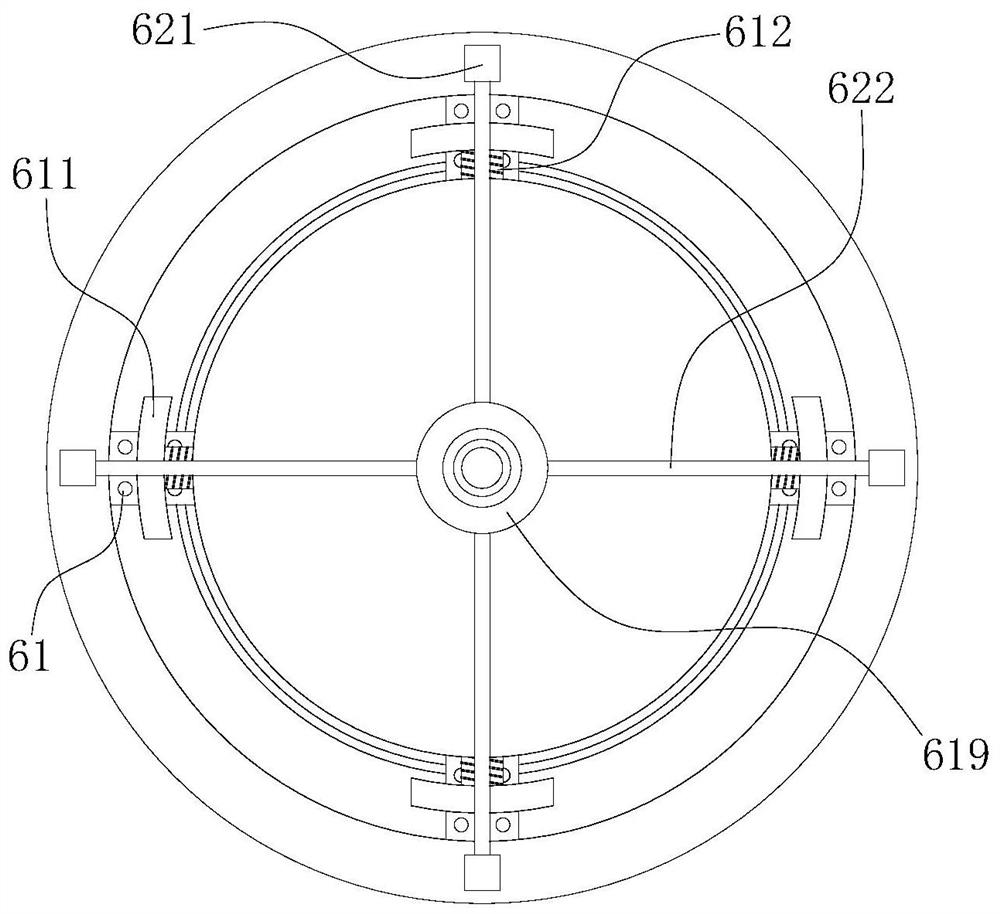

Semiconductor carbon dioxide supercritical sweeping and cleaning machine

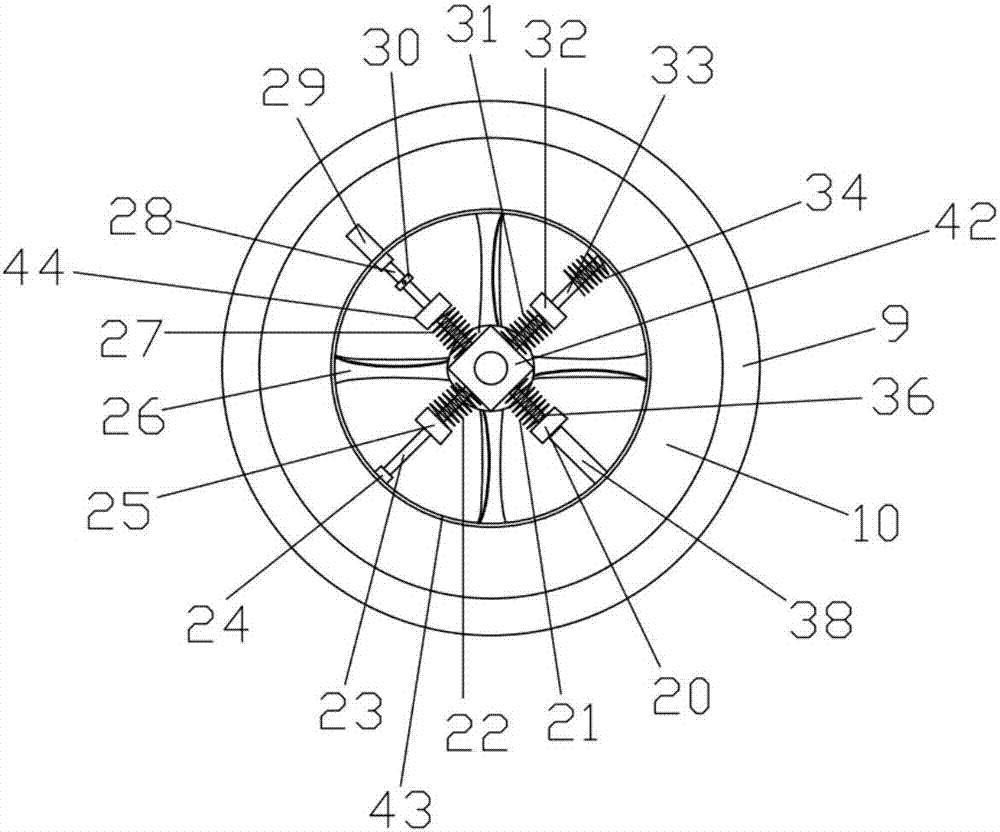

InactiveCN101740337AFully cleanedFull drying effectSemiconductor/solid-state device manufacturingCleaning processes and apparatusSupercritical dryingFine structure

The invention discloses a semiconductor carbon dioxide supercritical sweeping and cleaning machine. A cleaning cavity is internally provided with a magnetic-driven rotating device. Carbon dioxide supercritical fluid has no surface stress, low glutinousness as well as strong diffusivity and dissolving capacity, thereby being capable of performing effective clean and supercritical drying for fine structures on silicon wafers. The semiconductor carbon dioxide supercritical sweeping and cleaning machine has the main structure of the cleaning cavity, and can achieve an ideal cleaning effect by additionally arranging the magnetic-driven rotating structure and a matched nozzle in the design. The development and manufacture of the semiconductor carbon dioxide supercritical sweeping and cleaning machine can greatly promote the development of the semiconductor cleaning technology.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

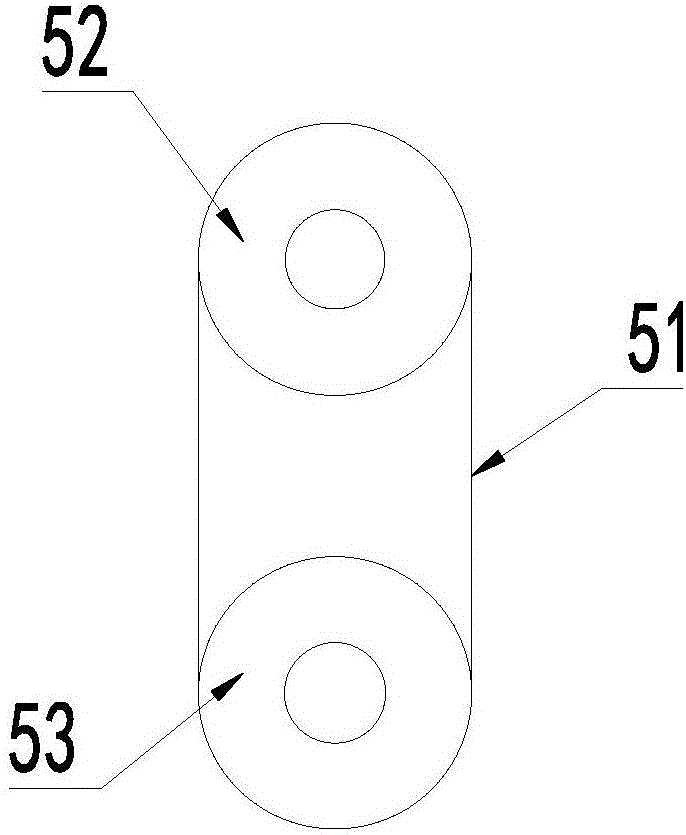

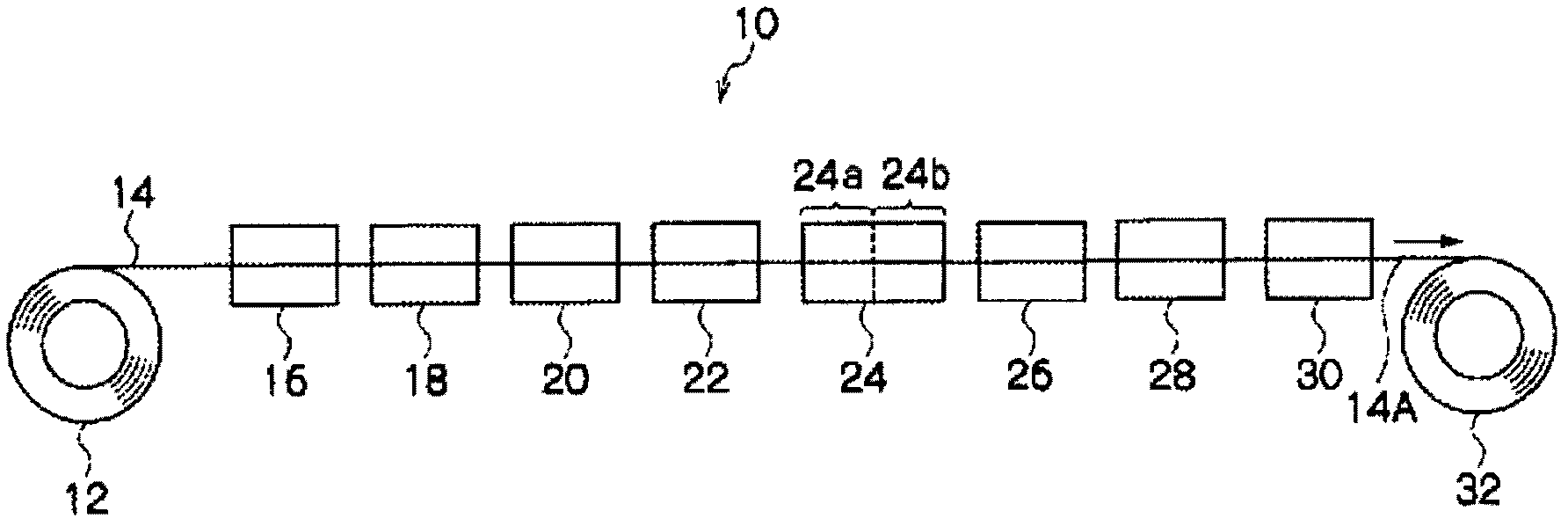

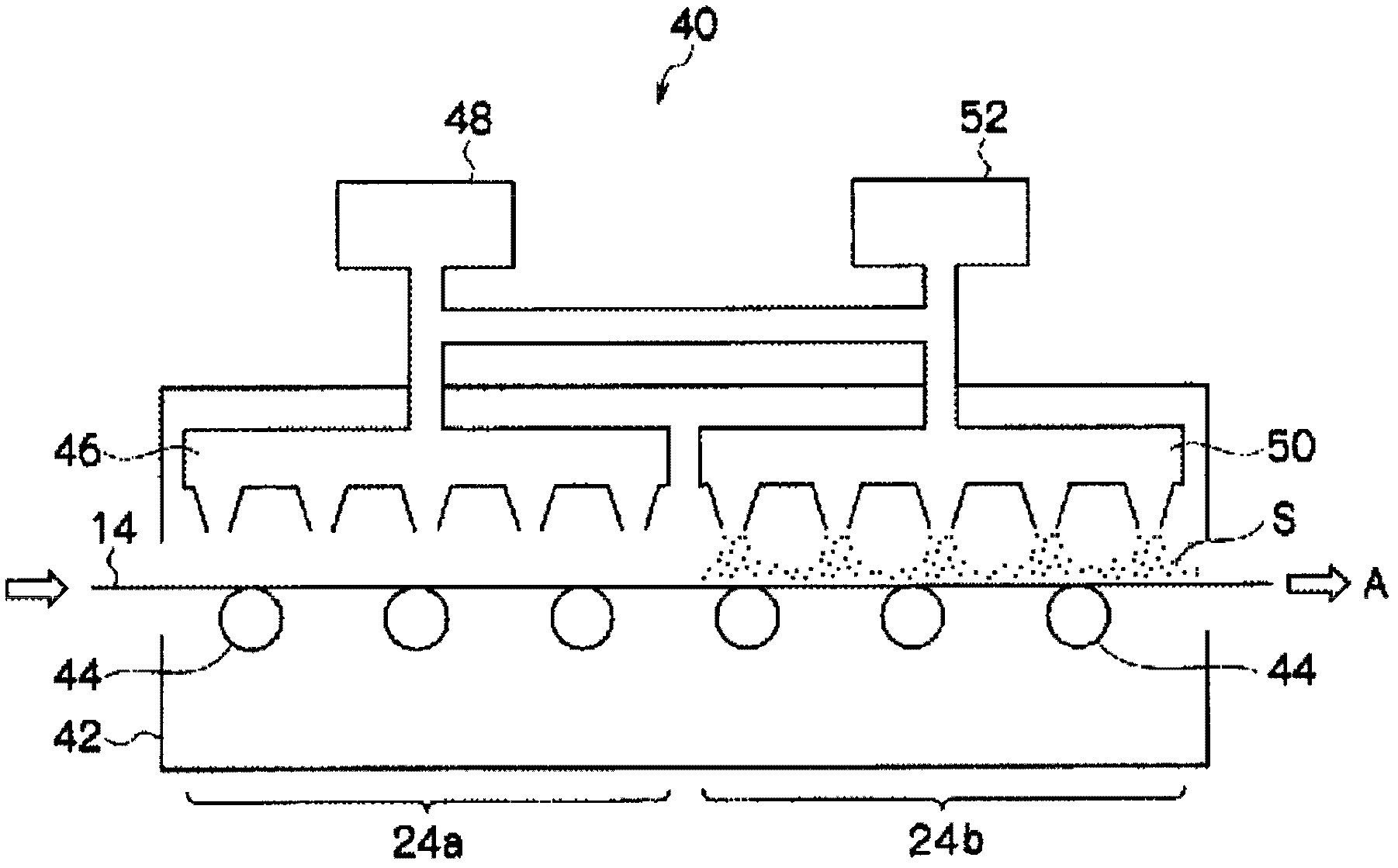

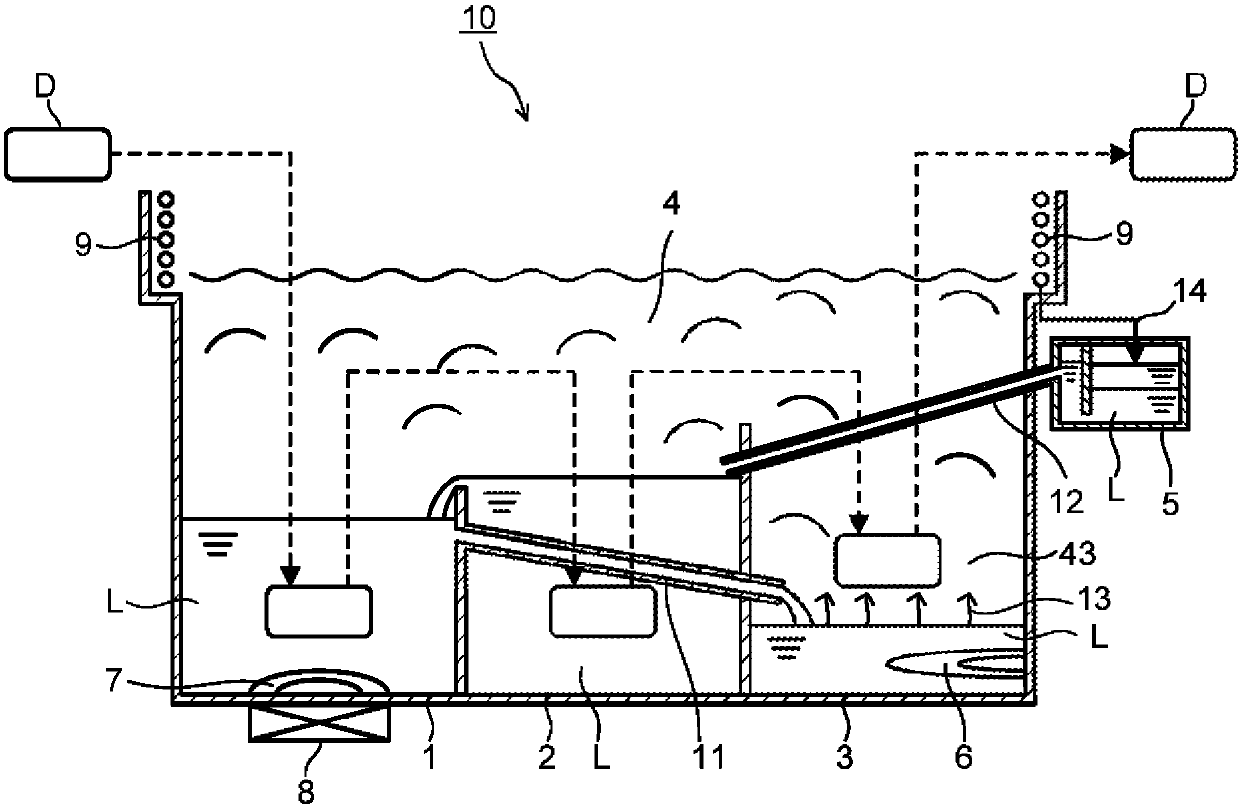

Immersion type grooved circulating water cooling plant for wire rods

ActiveCN103014584AQuality assuranceSolve the lack of cooling capacityHot-dipping/immersion processesWire rodCooling effect

The invention discloses an immersion type grooved circulating water cooling plant for wire rods. The plant comprises a circulating cooling and drying device which is arranged on a position adjusting device, and the position adjusting device is arranged on a pedestal provided with a strip aperture. The invention has the following beneficial effects: the structure of the plant is compact, space is saved, special tools like a pump is not needed for promoting flowing of water, cost is saved, and a uniform cooling effect is obtained at the same time; the immersion type grooved circulating water cooling plant is economic, simple and practical and guarantees surface quality of a wire rod; an air drying box enables a wiped wire rod to undergo thorough cooling and drying; a wire rod is cooled in the manner of grooved circulating water immersion and then totally cooled and dried by using a wiping device and an air-cooled drying device, and uniform and rapid cooling is realized; the plant has the advantages of a simple and compact structure, a small volume and low cost and can be easily used together with other matching equipment.

Owner:西部超导材料科技股份有限公司

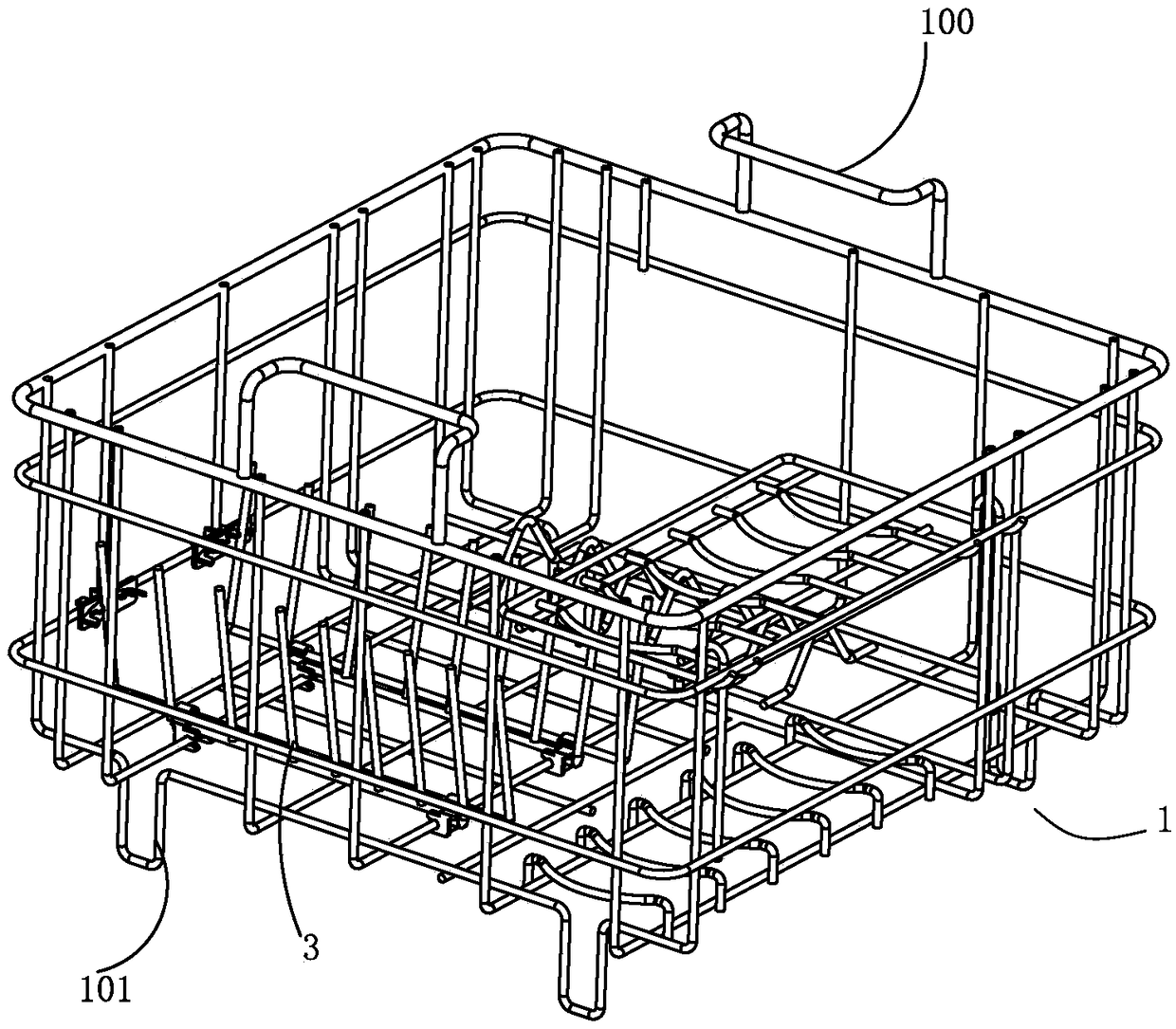

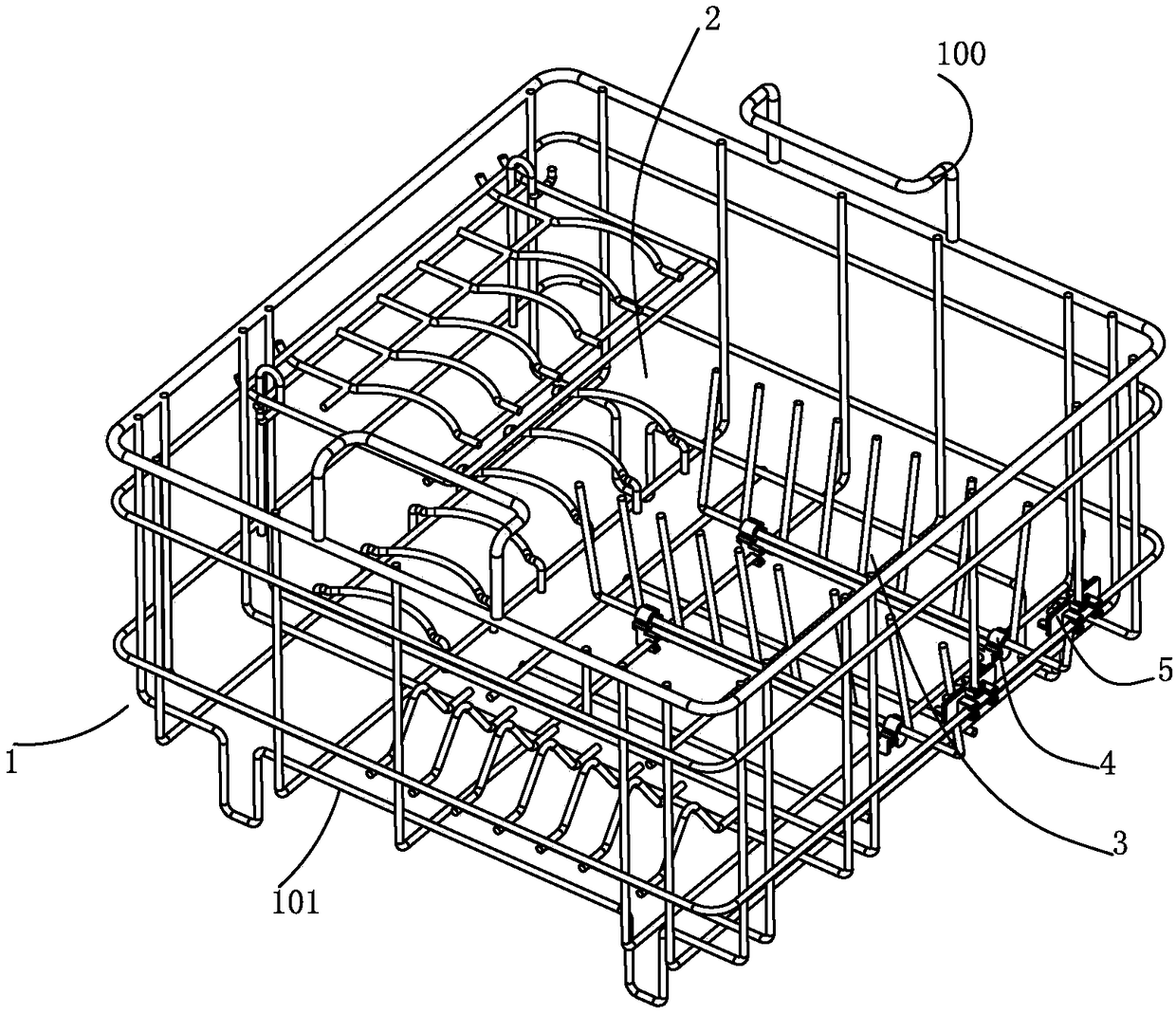

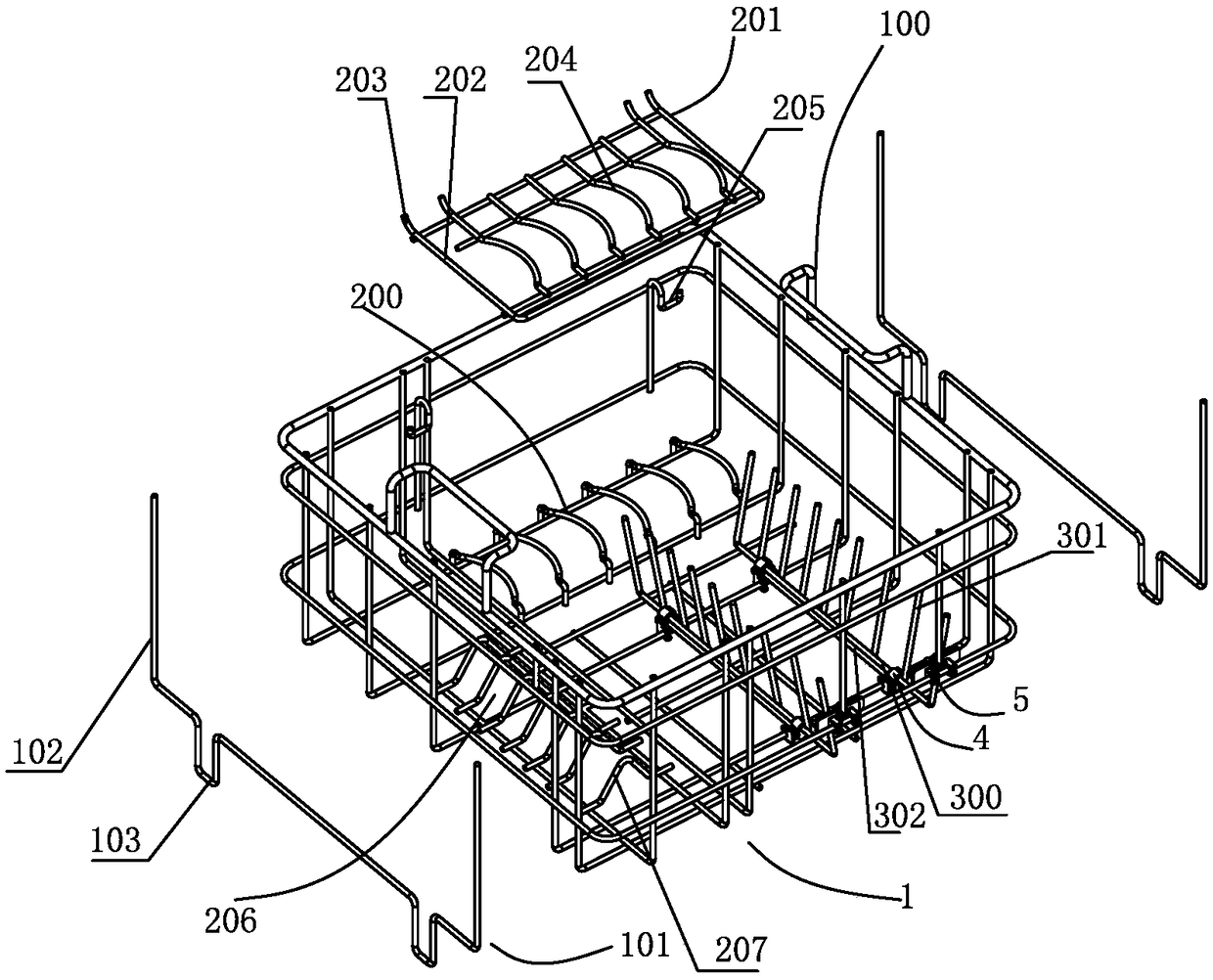

Bowl basket of sink dish-washing machine and sink dish-washing machine adopting bowl basket

PendingCN108968863ASimple structureEasy to useTableware washing/rinsing machine detailsInterior spaceRack unit

The invention discloses a bowl basket of a sink dish-washing machine and the sink dish-washing machine adopting the bowl basket. The bowl basket comprises a bowl basket body, wherein the bowl basket body has accommodating space with the open top, handles are arranged on the top of the bowl basket body, and at least two groups of support legs are arranged on the bottom of the bowl basket body; a bowl rack unit and a plate rack unit are arranged in the accommodating space of the bowl basket body, the plate rack unit comprises two plate rack bodies which are arranged side by side, the two plate rack bodies are rotatably connected to the inner bottom wall of the accommodating space, each plate rack body comprises a rotation rod and a plurality of baffle rods fixedly connected to the rotation rod and distributed at intervals along the length direction of the rotation rod, and space for placing a plate is arranged between each two adjacent baffle rods; and two angle adjusting mechanisms corresponding to the two plate rack bodies are arranged on the inner side wall of the accommodating space. The bowl basket of the sink dish-washing machine is simple in structure, convenient to use, and flexible in adjustment, no noises exist, and the inside space can be sufficiently utilized.

Owner:NINGBO MEIGAO KITCHENWARE CO LTD

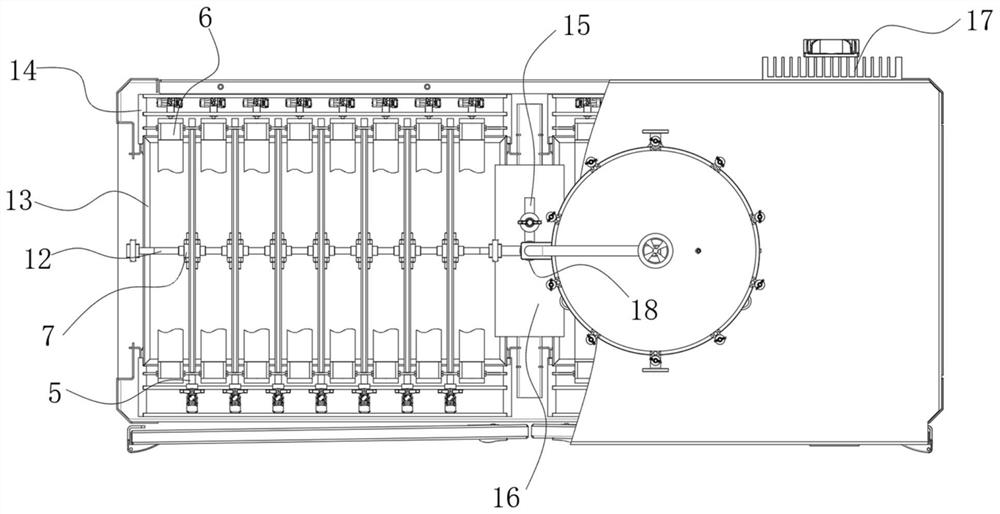

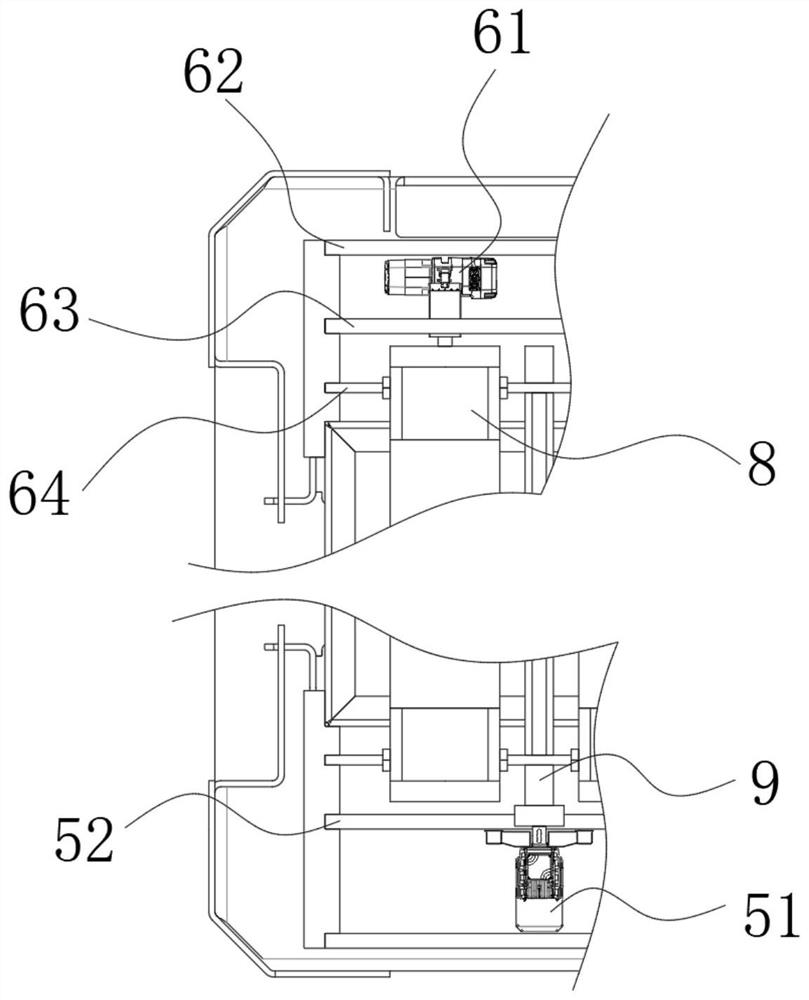

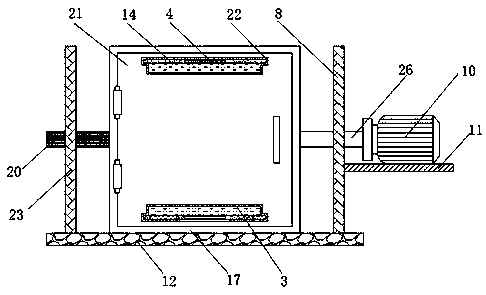

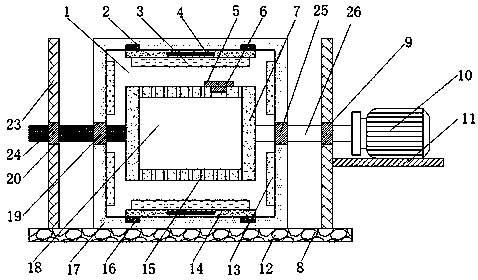

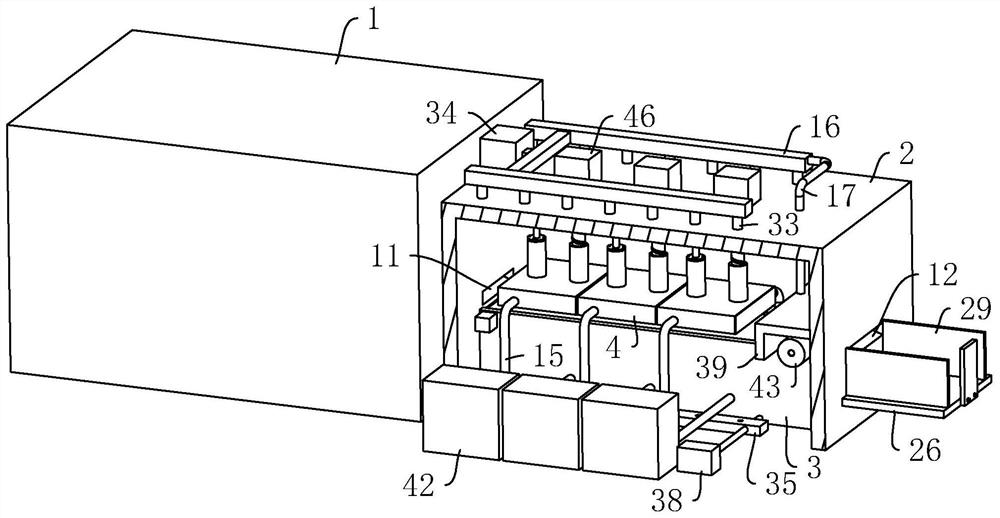

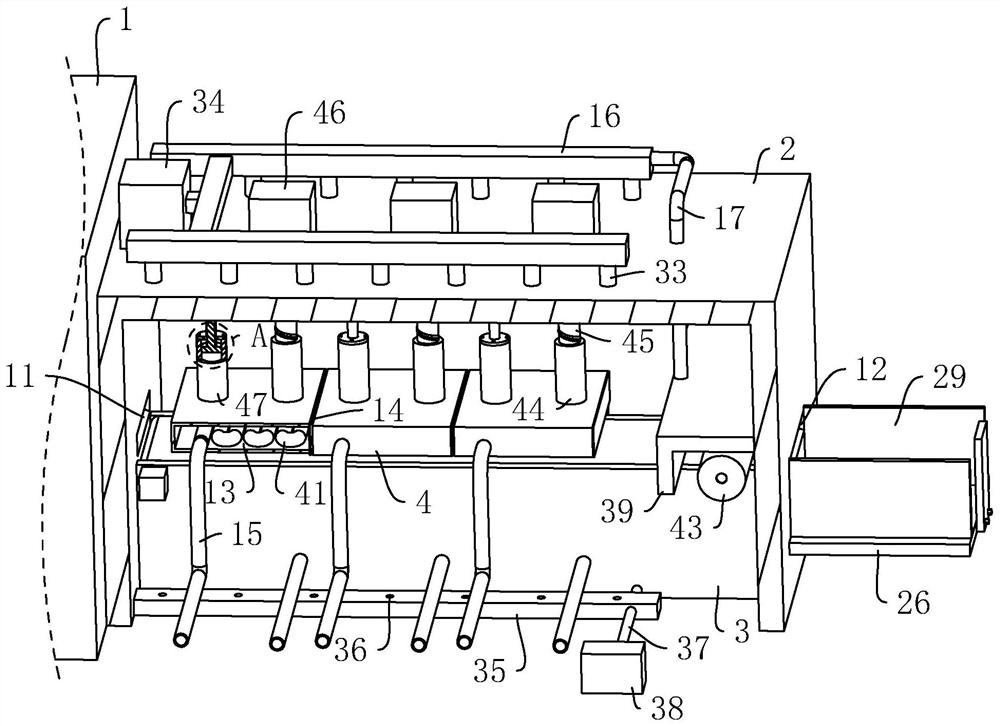

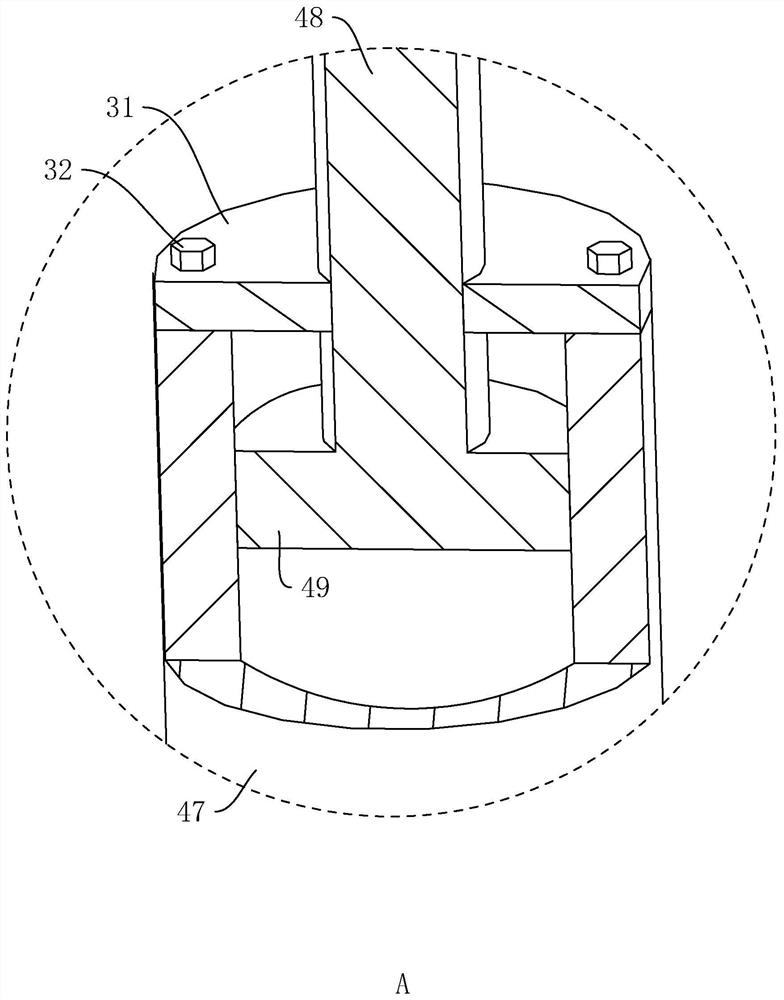

Ceramic blank drying device for ceramic processing

ActiveCN112344692APrecise deliveryEvenly heatedDrying gas arrangementsDrying chambers/containersElectric machineryEngineering

The invention discloses a ceramic blank drying device for ceramic processing, the device comprises a box body and a drying assembly arranged inside the box body, the interior of the box body is divided into a drying chamber and a material conveying chamber, the material conveying assembly is arranged inside the material conveying chamber, the material conveying assembly comprises a conveying belt,a traveling frame, a telescopic rod, a material conveying motor and a tray, the drying assembly comprises an object supporting device and a heating device, the object supporting device comprises a transmission shaft, a transmission frame, a tray frame and a transmission motor, and the heating device is arranged outside the box body and communicates with a drying channel. According to the ceramicblank drying device for ceramic processing, the conveying belt with a limiting groove, the tray with a limiting block and the traveling frame are adopted and cooperate with the telescopic rod, so thataccurate conveying of materials is achieved; the transmission motor is used for driving the tray to rotate through the transmission shaft and the transmission frame, so that the materials are uniformly heated, and the drying effect is enhanced; and a fan, a heater and an air pipe are adopted and cooperate with the drying channel provided with air outlet holes, so that, the drying quality is guaranteed.

Owner:泰州水冶新材料科技有限公司

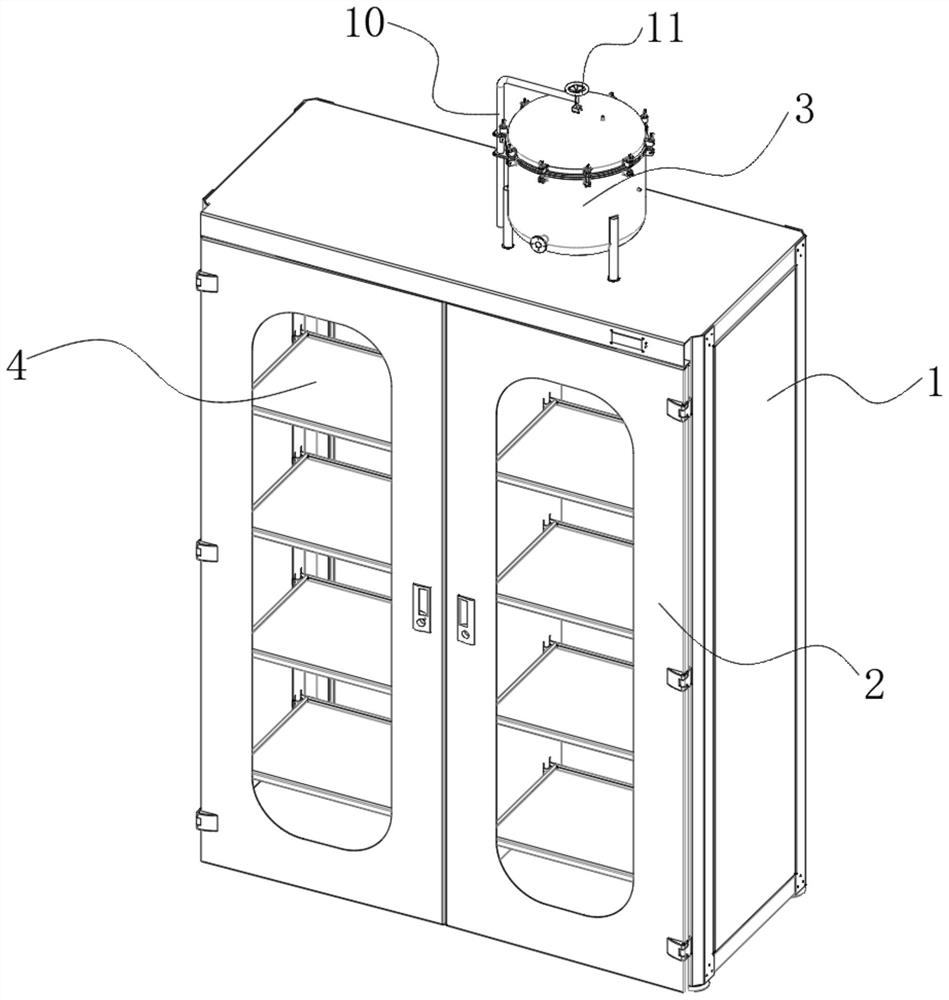

Financial management file storage device with moisture-proof and anti-corrosion functions

ActiveCN112806734AImprove efficiencyAvoid scratchesBook cabinetsDispersed particle separationProcess engineeringControl valves

The invention discloses a financial management file storage device with moisture-proof and anti-corrosion functions. The financial management file storage device comprises a file cabinet, a door frame, a drying tank, a main supporting frame and storage chambers, the interior of the file cabinet is divided into a left storage space and a right storage space by the main supporting frame, the storage chambers are vertically installed in the left storage space and the right storage space, and the storage chambers are of a stacked structure; the drying tank is fixedly installed on the file cabinet, two sets of rotatable door frames are arranged in front of the file cabinet, and a humidity and heat monitoring device is further installed on the rear side face of the file cabinet and used for detecting the indoor air drying degree. A control valve at the upper end of the drying tank regulates and controls a conveying pipe arranged in the main supporting frame and communicated with the control valve to convey dry gas into the storage chamber, and the dryness of the gas in the file cabinet is regulated and controlled.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

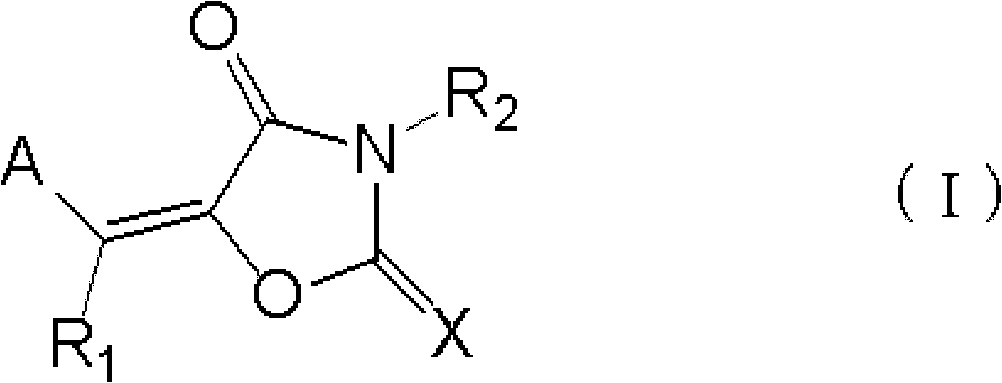

Method for producing planographic printing plate precursor

InactiveCN102548770AFull drying effectImprove the development effectPlate printingFoil printingImage recordingRecording layer

Owner:FUJIFILM CORP

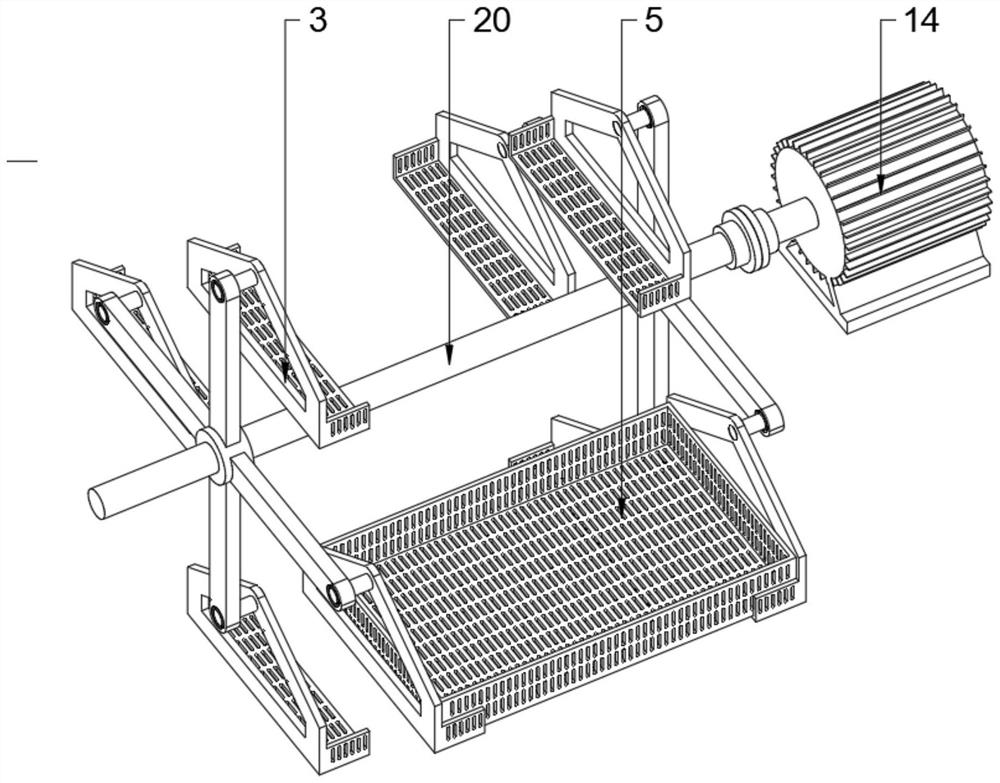

Drying machine for pesticide production

InactiveCN108716820AEasy maintenanceStable jobDrying solid materials without heatDrying machines with non-progressive movementsAgricultural engineeringRaw material

The invention discloses a drying machine for pesticide production. The drying machine for pesticide production comprises a base body, wherein a first support rod is fixedly connected to the left sideof the upper surface of the base body; a first bearing is fixedly embedded to the middle of the first support rod; a second support rod is fixedly connected to the right side of the upper surface of the base body; a second bearing is fixedly embedded to the middle of the second support rod; a support plate is fixedly connected to the right side surface of the second support rod; a motor is fixedlyconnected to the upper surface of the support plate; a drying machine body is fixedly connected to the middle of the upper surface of the base body; a door is fixedly hinged to the front surface of the drying machine body through a hinge; plate pulling ports are formed in the upper part and the lower part of the front surface of the door; and a first cavity is arranged in the drying machine body.According to the drying machine for pesticide production, the drying machine can be conveniently repaired and maintained, the working stability of the drying machine is realized, the drying machine is prevented from shaking during working, and pesticide raw materials can be dewatered.

Owner:WUXI JIABAO PESTICIDE & PHARMA

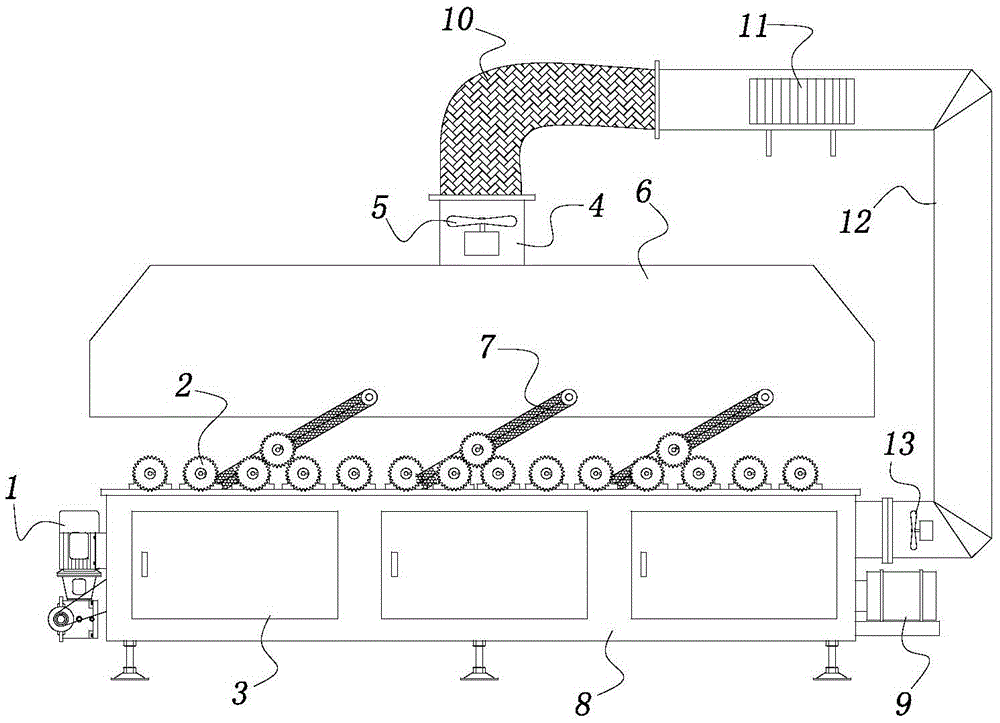

Tumble dryer for fruit and vegetable drying

The invention relates to an overturn type drying machine used for drying vegetables and fruits. The overturn type drying machine comprises a box body with an open top end, a clamping screen mesh, an elevating cover and a return air duct with a moisture exhausting device, wherein a hot-air blower is fixedly connected to the side wall of the box body; the hot air outlet of the hot-air blower is communicated with the inner cavity of the box body; a plurality of driving gears which are arranged at equal intervals and a plurality of supporting shaft rollers which are arranged at equal intervals are arranged on the top edge of each of the front side wall and the rear side wall of the box body; the clamping screen mesh is used for tightly clamping raw materials and comprises two screen mesh plates which are connected in a hinged manner on one side edges and connected by adopting a lock buckle on the other sides; a rotating shaft is arranged in the middle of each of the front side edge and the rear side edge of one of the screen mesh plates; a driven gear is arranged at the end part of the rotating shaft on one of the two sides; the elevating cover is arranged on the box body in a buckling manner; a funnel with a first axial flow fan is arranged at the top of the elevating cover; the upper end of the return air duct is connected to the funnel by adopting a hose, and the lower end of the return air duct is connected to a return air inlet formed in the side wall of the box body.

Owner:TIANJIN SHIXINSHIYI FOOD

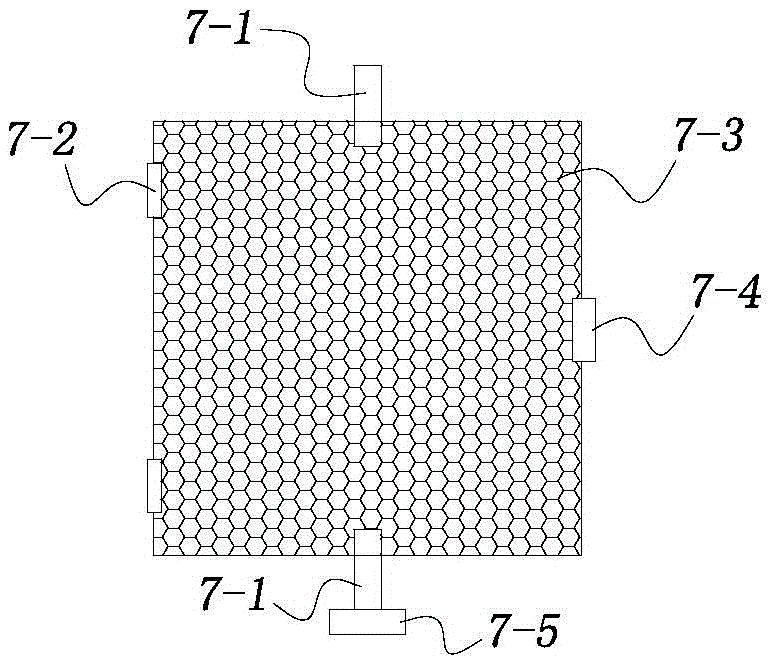

Grain drying and dedusting device and method

ActiveCN107006603ALow costVibrate evenlyGas current separationSeed preservation by dryingVibration amplitudeProtection mechanism

The invention discloses a grain drying and dedusting device and method. The grain drying and dedusting device comprises an outer container of a machine, a first banking plate, a dedusting reaction container, a second blanking plate, a third blanking plate and a fan vibration unit; grains are uniformly blanked and fully dried and de-dusted through multiple layers of blanking plates arranged according to a certain rule, of the device; a vibration device and a fan device are designed into a whole and located at the center of the equipment, so that vibrating and blowing are more uniform; the space is saved; the cost of multiple motors is reduced by adopting a single motor; and the vibration device is provided with a protection mechanism, so that the problem of damage to equipment due to the fact that the fan is over-high in rotating speed and over-large vibration amplitude is effectively solved.

Owner:ANHUI TIANQI FLOUR TECH CO LTD

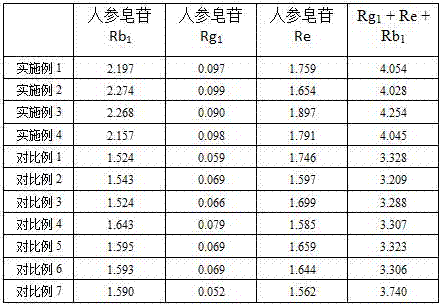

Post-harvest drying method for American ginseng

ActiveCN107233374AAvoid breedingPrevent reproduction, mildewDrying machines with local agitationDrying machines with materials at restAdditive ingredientBULK ACTIVE INGREDIENT

The invention discloses a post-harvest drying method for American ginseng. The post-harvest drying method comprises the following steps: pre-treating, grading, performing ultraviolet radiation, performing air-drying, performing NO fumigation and drying. The product quality of the American ginseng processed by the method is improved while the American ginseng is dried, content of active ingredients in the American ginseng can be greatly increased, color and luster, taste and nutrient ingredients of fresh American ginseng are completely kept, uniform water separation speed and a sufficient drying effect are achieved, and loss, caused by high-temperature heating, of various active ingredients is prevented; the content of the active ingredients of the dried American ginseng is obviously increased, and the content of main components such as ginsenoside is far higher than that by an existing drying method; and moreover, the dried product is uniform in color and luster, is stable in quality, is high in bioavailability, is strong in activity, is high in quality, is low in water content, is good in stability and is long in guarantee period.

Owner:威海市文登区道地参业发展有限公司

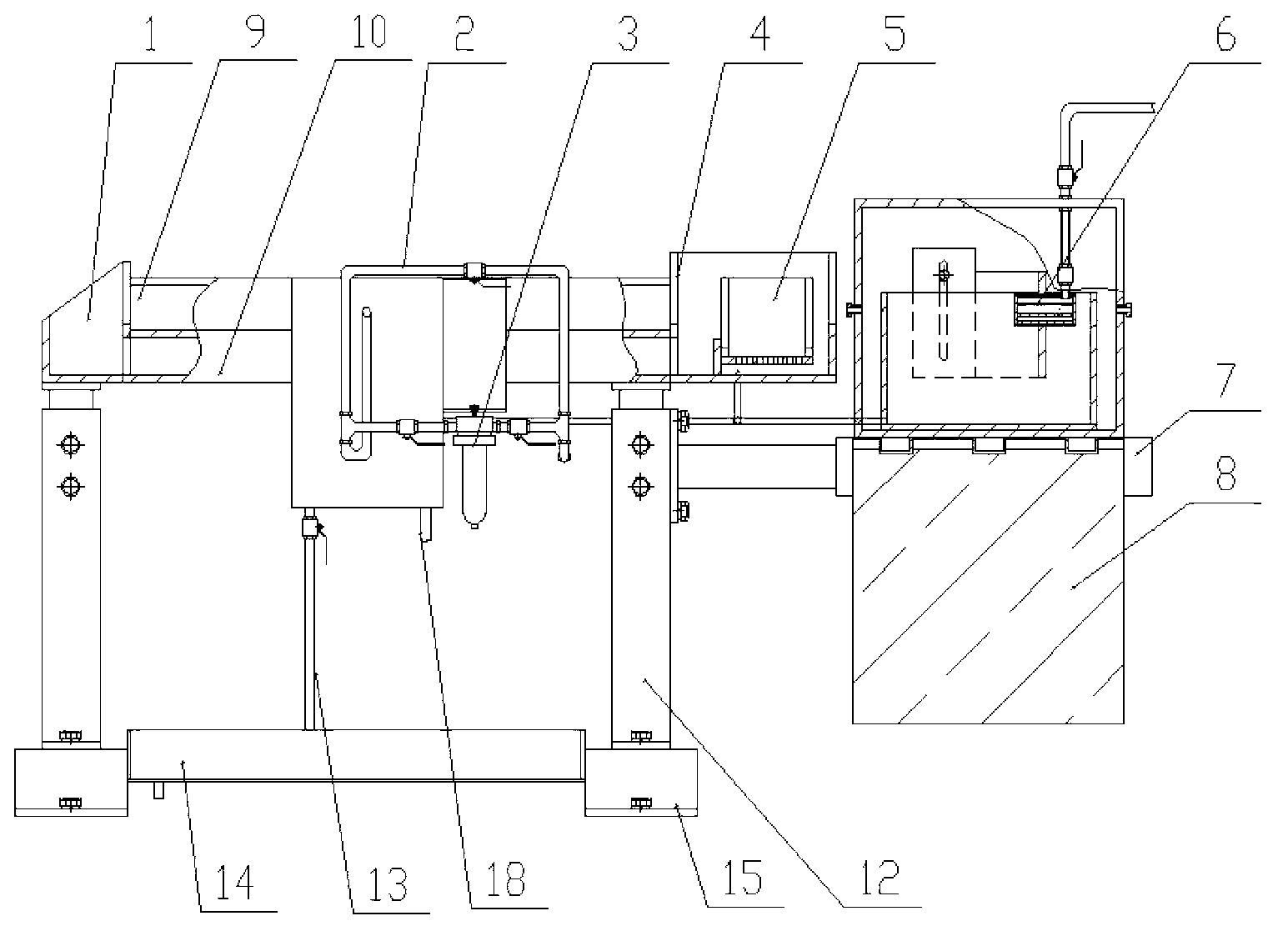

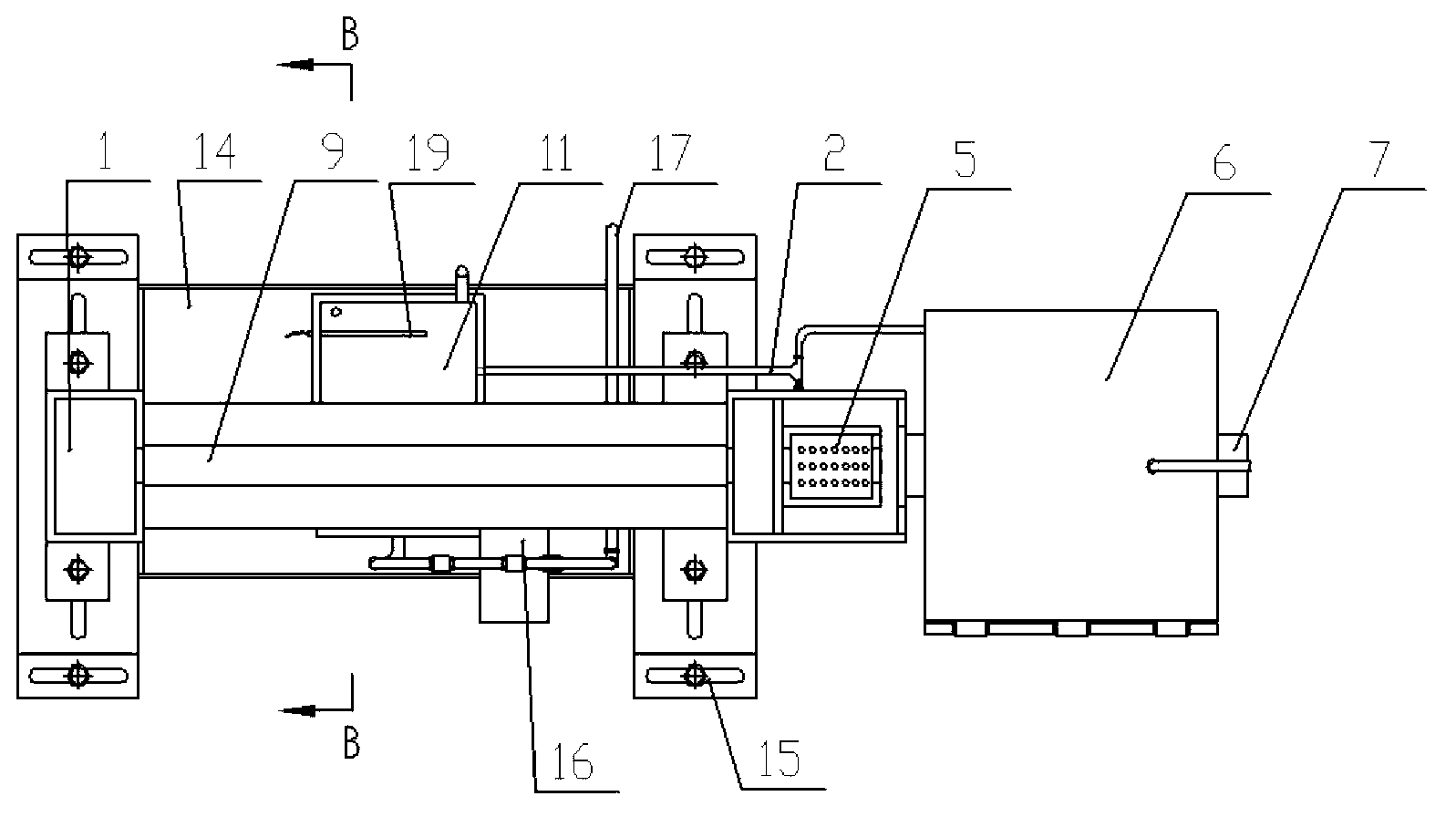

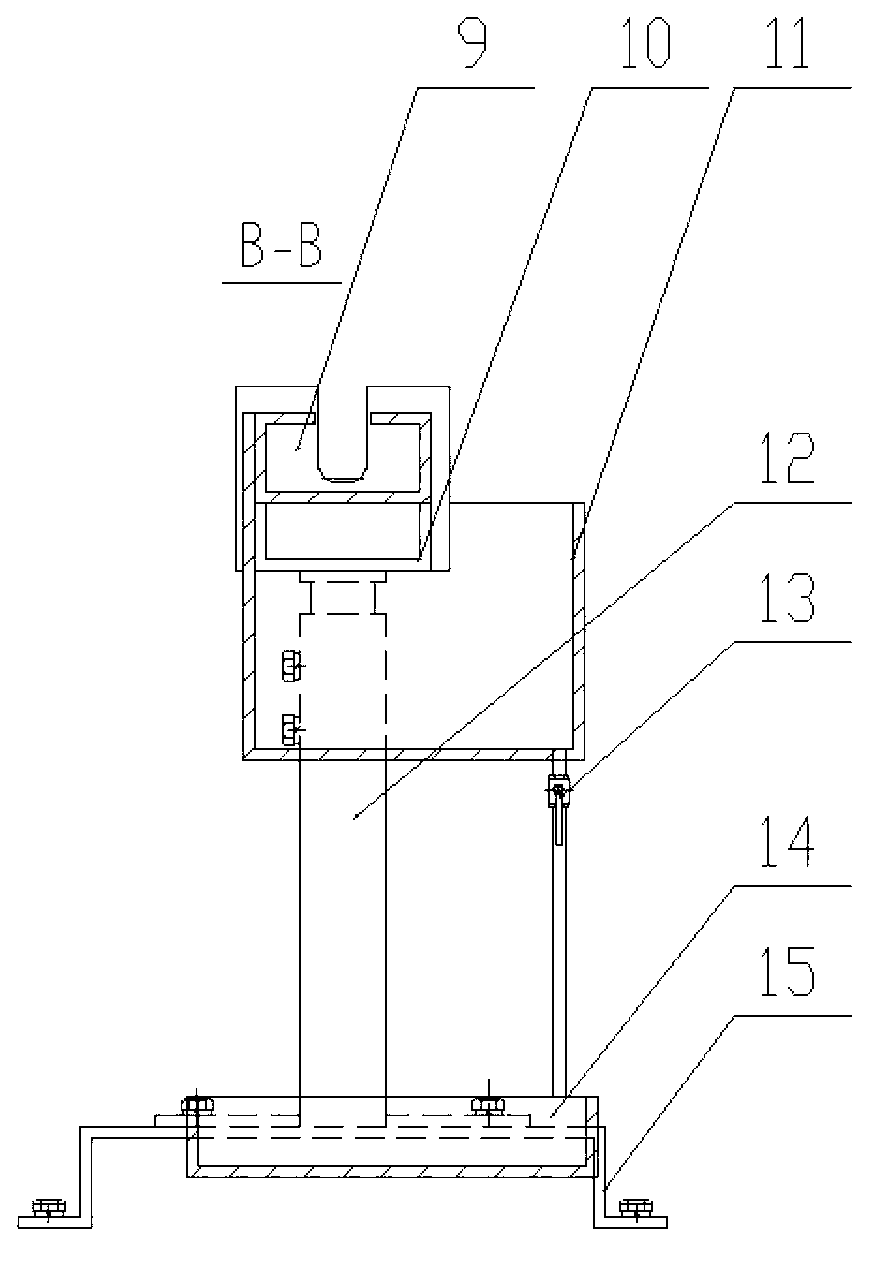

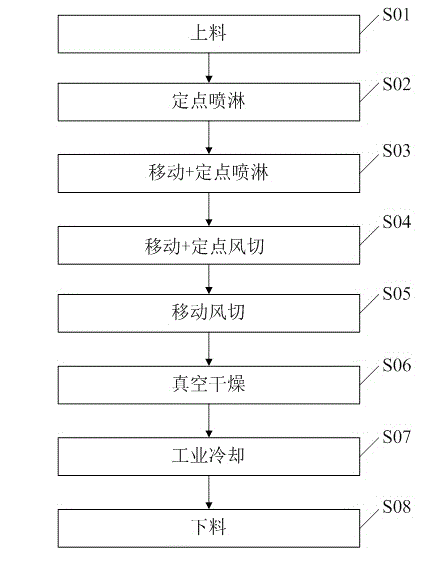

Cylinder spraying and cleaning process

InactiveCN104690054AFully cleanedFull drying effectDrying using combination processesHollow article cleaningPulp and paper industry

The invention relates to the field of industrial cleaning machines and provides a cylinder spraying and cleaning process. The process includes the following steps of (1), feeding; (2), fixed-point spraying; (3), moving spraying and fixed-point spraying; (4), moving wind cutting and fixed-point wind cutting; (5), moving wind cutting; (6), vacuum drying; (7), industrial cooling; (8), discharging. Medicament can be uniformly sprayed on the surface of a workpiece through fixed-point spraying to remove oil stain, the medicament on the surface of the workpiece can be flushed away through moving spraying and fixed-point spraying, most water on the surface of the workpiece can be removed through moving wind cutting and fixed-point wind cutting, the water on the surface of the workpiece can be completely removed through moving wind cutting, the surface of the workpiece and water in a threaded hole of the workpiece can be dried through vacuum drying to completely dry the workpiece, and the workpiece can be cooled through industrial cooling for the convenience of the workpiece to enter the discharging stage. Consequently, the cylinder spraying and cleaning process can realize effect on fully cleaning and drying cylinder-type parts.

Owner:深圳市利兴隆机电设备有限公司

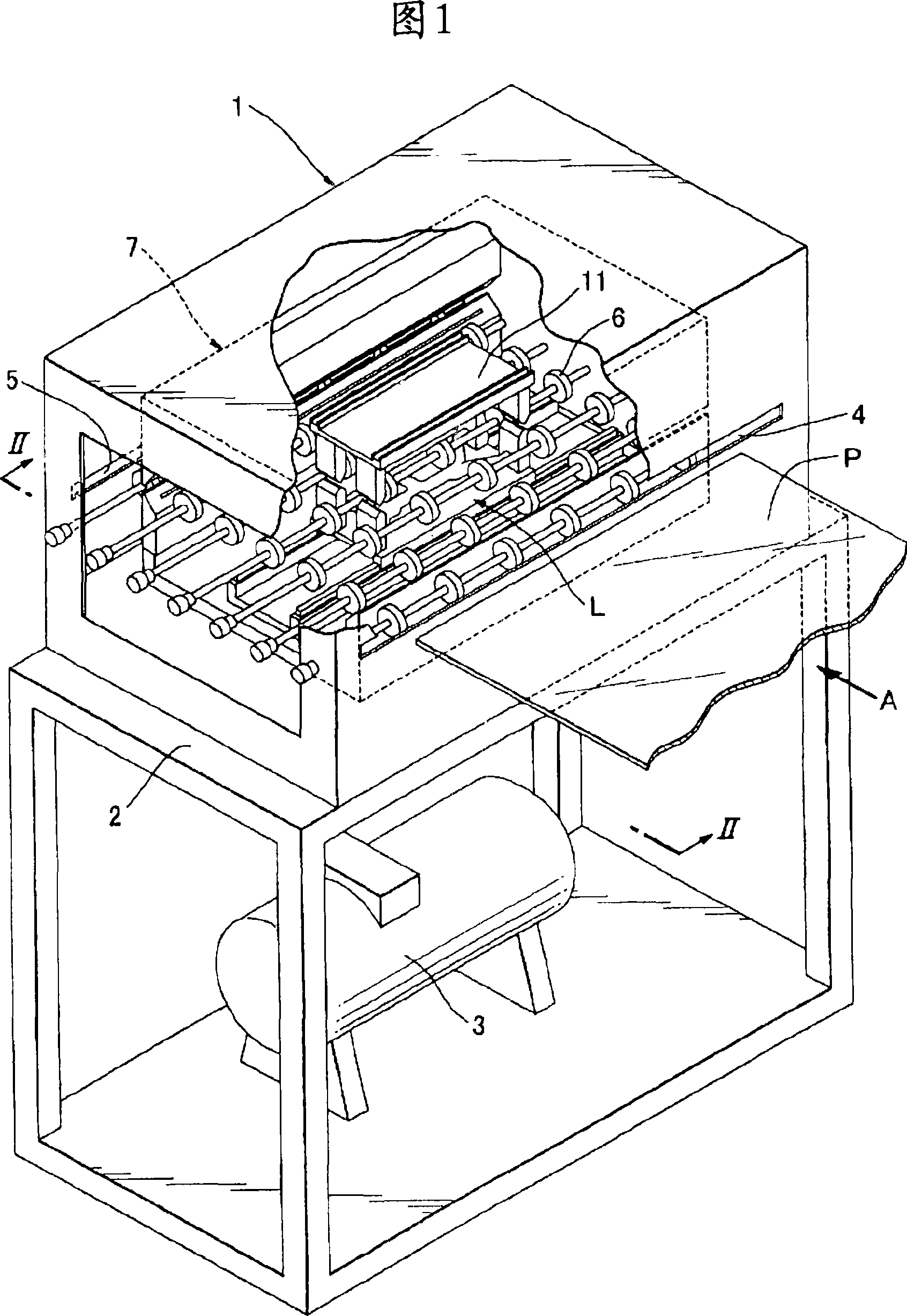

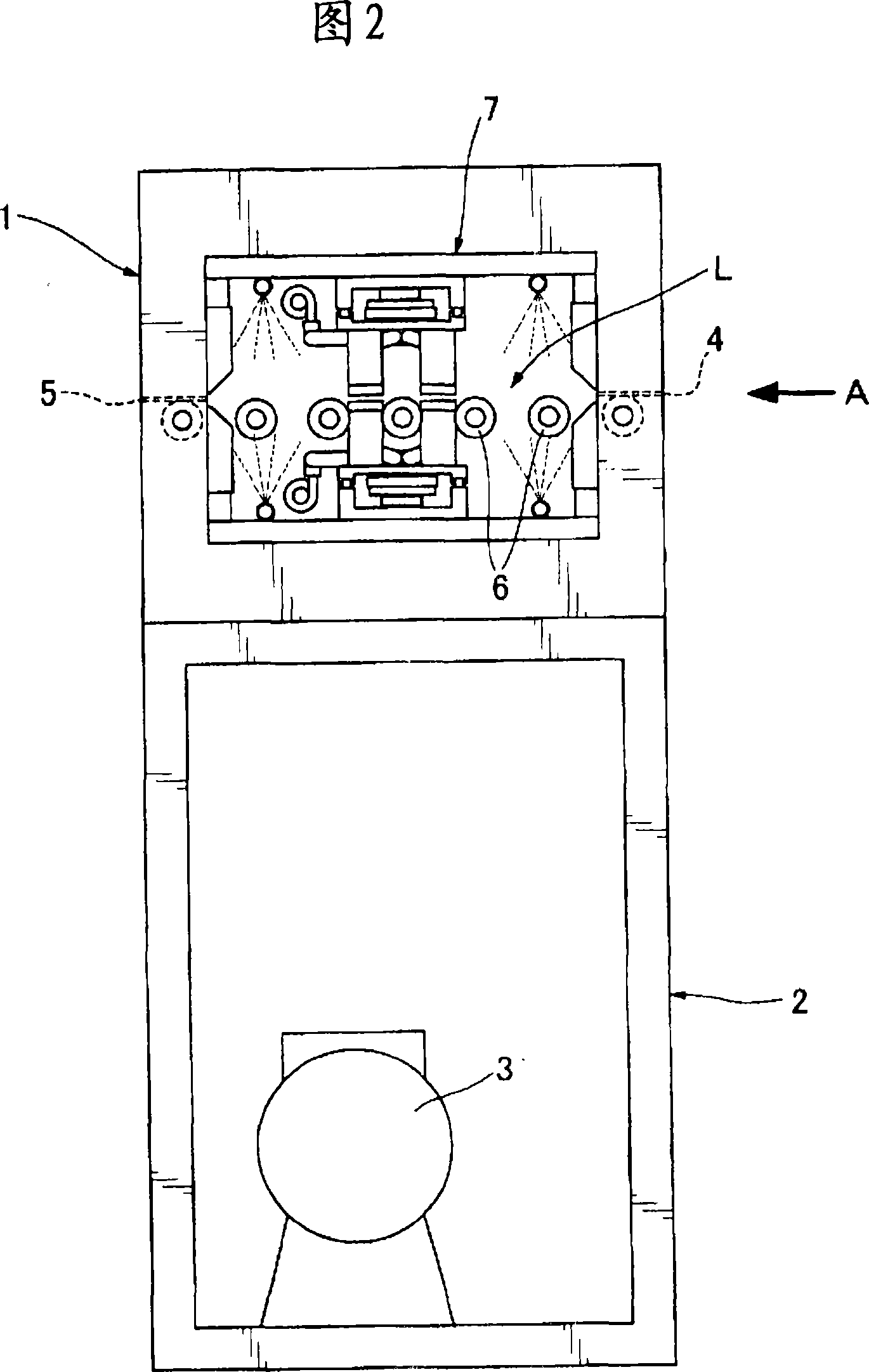

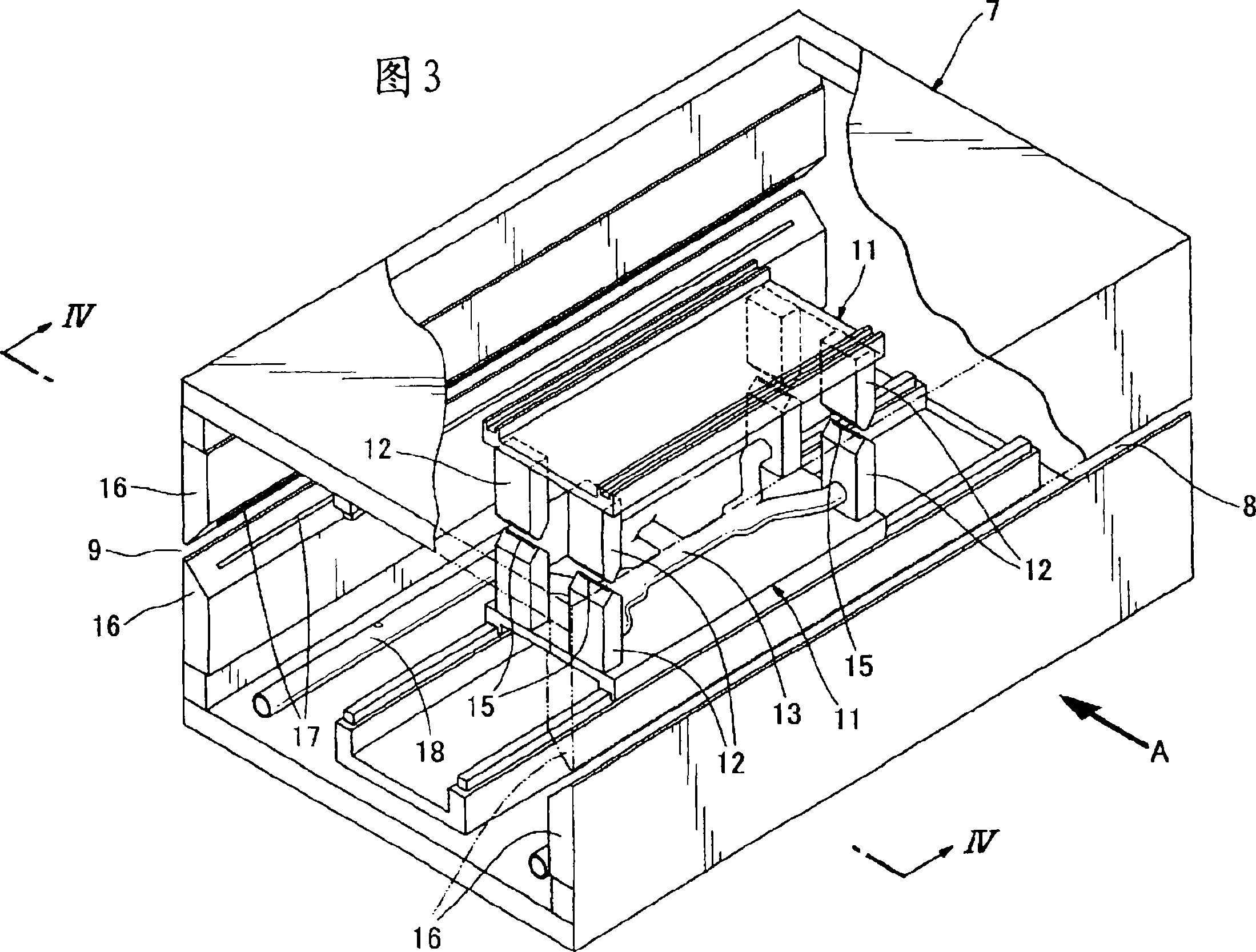

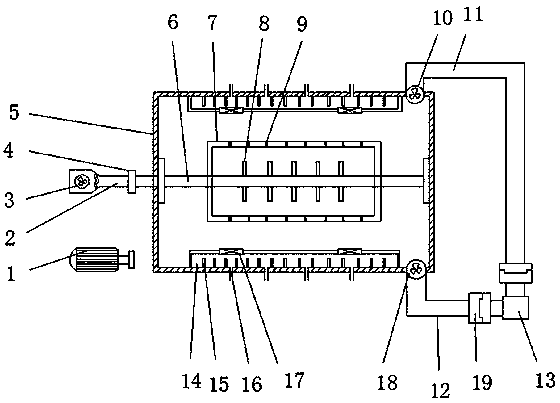

Drying apparatus

InactiveCN101163936AKeep dryFull drying effectDrying gas arrangementsSemiconductor/solid-state device manufacturingSpray nozzleLinear drive

A drying device has a linear drive device for linearly moving, in a drying box, a spray nozzle in a direction orthogonal to a conveyance direction of an object to be washed, and an ejection opening of the spray nozzle is formed as a slit stretching in the conveyance direction. A pair of nozzles is arranged at an inlet and outlet of the drying device, and each nozzle has a slit extended in the direction orthogonal to the conveyance direction, by the width of the object to be washed. Those surfaces of the nozzles that face each other are each inclined from an inner edge to an outer edge so that the distance between the inner edges of the nozzles is greater than the distance between the outer edges.

Owner:KYOWA KAKO KABUSHIKI KAISHA

Novel instrument cleaning and disinfecting device for supply room nursing

InactiveCN111495848ASpray evenlyFull drying effectDrying gas arrangementsCleaning using liquidsNursing careElectric machinery

The invention discloses a novel instrument cleaning and disinfecting device for supply room nursing. The device comprises a disinfecting box, a cabinet door is mounted on the front side of the disinfecting box, a placing box is mounted in the disinfecting box, an air hole is formed in the surface of the placing box, a heating water box is fixedly connected to the upper surface of the disinfectingbox, a drying machine is fixedly connected to the side face of the disinfecting box, an adjusting device is fixedly connected into the disinfecting box, and comprises a columnar shell, the columnar shell carries out limiting rotation in the disinfecting box, a motor is fixedly connected to the inner wall of the columnar shell, and a first shaft is fixedly connected to the front end of an output shaft on the motor. According to the device, through cooperative use of the structure, the problems that in the actual use process, due to the fact that hot air blown out of the drying machine is singlein wind direction, the air cannot be in sufficient contact with medical instruments in the placing box, the drying efficiency of the medical instruments is reduced, and inconvenience is brought to use can be solved.

Owner:李广燕

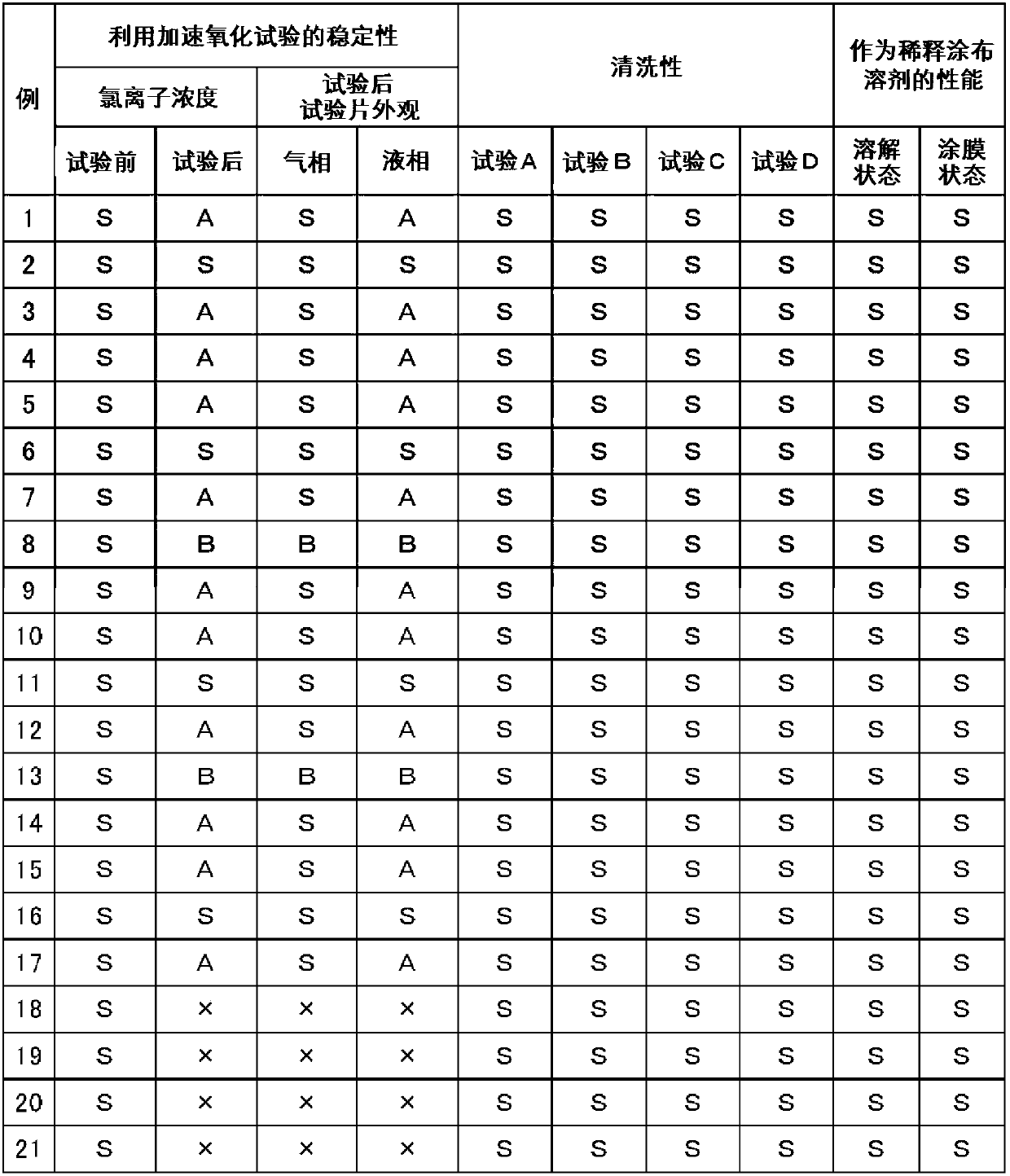

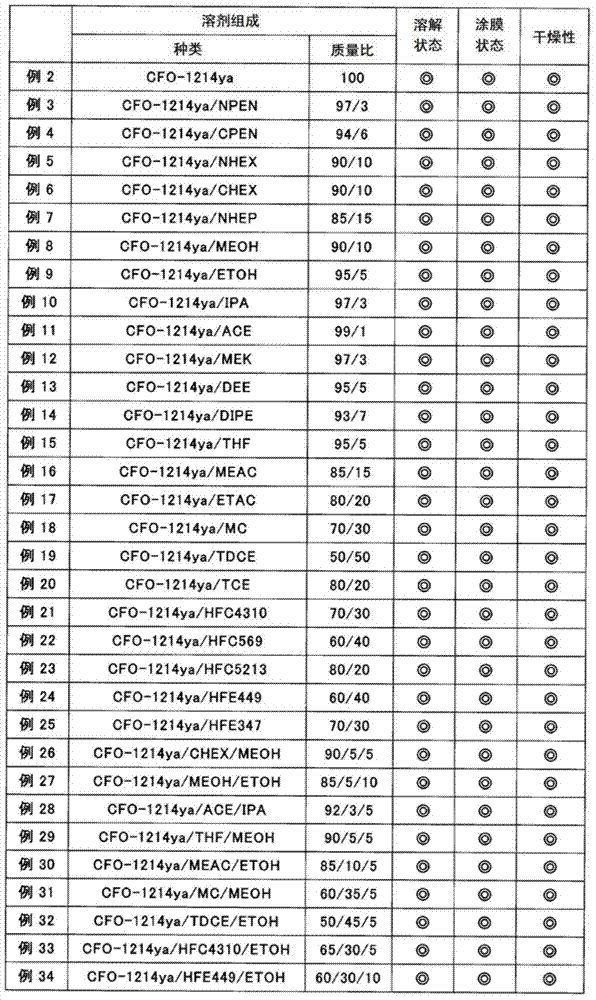

Solvent composition, cleaning method, coating film formation method, heat transfer medium, and heat cycle system

ActiveCN107849500AGood solubilityGood cleaningOrganic chemistryNon-surface-active detergent compositionsVolatile organic compoundSolubility

Provided are: a solvent composition that has an excellent ability to dissolve various organic substances, has excellent cleaning performance and drying properties, does not cause detrimental effects to the global environment, and has superior stability; a cleaning method using the solvent composition; a coating film formation method; a heat transfer medium that includes the solvent composition; and a heat cycle system using the heat transfer medium. A solvent composition that includes 1-chloro-2,3,3-trifluoro-1-propene and 1-chloro-3,3-difluoro-1-propene; a cleaning method in which the solventcomposition is brought into contact with an article to be cleaned; a method in which a non-volatile organic compound is dissolved in the solvent composition to prepare a coating film-forming composition, the coating film-forming composition is applied upon an object to be coated, and thereafter the solvent composition is evaporated to form a coating film comprising the non-volatile organic compound; a heat transfer medium that includes the solvent composition; and a heat cycle system using the heat transfer medium.

Owner:ASAHI GLASS CO LTD

High-quality printing printer

ActiveCN113799482AOverall print quality improvementGood drynessPile receiversPrinting press partsPaper sheetProcess engineering

The invention relates to a high-quality printing printer. The high-quality printing printer comprises a printing body used for independently printing stacked paper one by one; a drying box is arranged at a paper outlet of the printing body; a paper feeding belt is arranged in the drying box; one end of the paper feeding belt is close to the printing body, and the paper feeding belt is used for receiving and conveying the printed paper; a paper stacking device used for stacking printed paper is arranged at a paper outlet in the end, away from the drying box, of the paper feeding belt;a drying plate is arranged at the position, over the paper feeding belt, of the drying box; the drying plate is close to the conveying upper surface of the paper feeding belt; a hot liquid pipe is arranged in the drying plate; the hot liquid pipe communicates with a hot liquid production box which is located outside the drying box and feeds high-temperature liquid into the hot liquid pipe; the hot liquid pipe is arranged in the drying plate in an S shape; the high-temperature liquid in the hot liquid pipe transmits heat to the drying plate; then the drying plate dries the paper; and the effect that the saturation degree of patterns printed on the surface of the paper can be well improved can be achieved.

Owner:桐乡市凯盛印刷股份有限公司

Novel chili pepper drying apparatus

The invention discloses a novel chili drying device, which comprises a box body, the outer upper end surface and the lower end surface of the box body are both provided with air intake pipes, and the inner upper end surface and the lower end surface of the box body are both provided with a heating chamber, The lower end surface of the heating chamber is provided with an electric heating wire, the upper end surface of the heating chamber is provided with a first air blower, the inner center of the box is provided with a drying chamber, and the outer surface of the drying chamber is evenly provided with The first ventilation hole, the inner cavity of the drying chamber is provided with a rotating shaft, the outer surface of the rotating shaft is provided with a disc, the other side of the rotating shaft is fixedly connected with a pulley, and the outer upper end surface of the box is A first exhaust pipe is provided, an exhaust fan is provided at one end of the first exhaust pipe, and a dust collecting device is provided at the other end of the exhaust pipe. The invention is convenient and practical, has better drying effect of peppers, reduces the workload of workers, and improves the drying efficiency of peppers.

Owner:潍坊金聖铸造材料有限公司

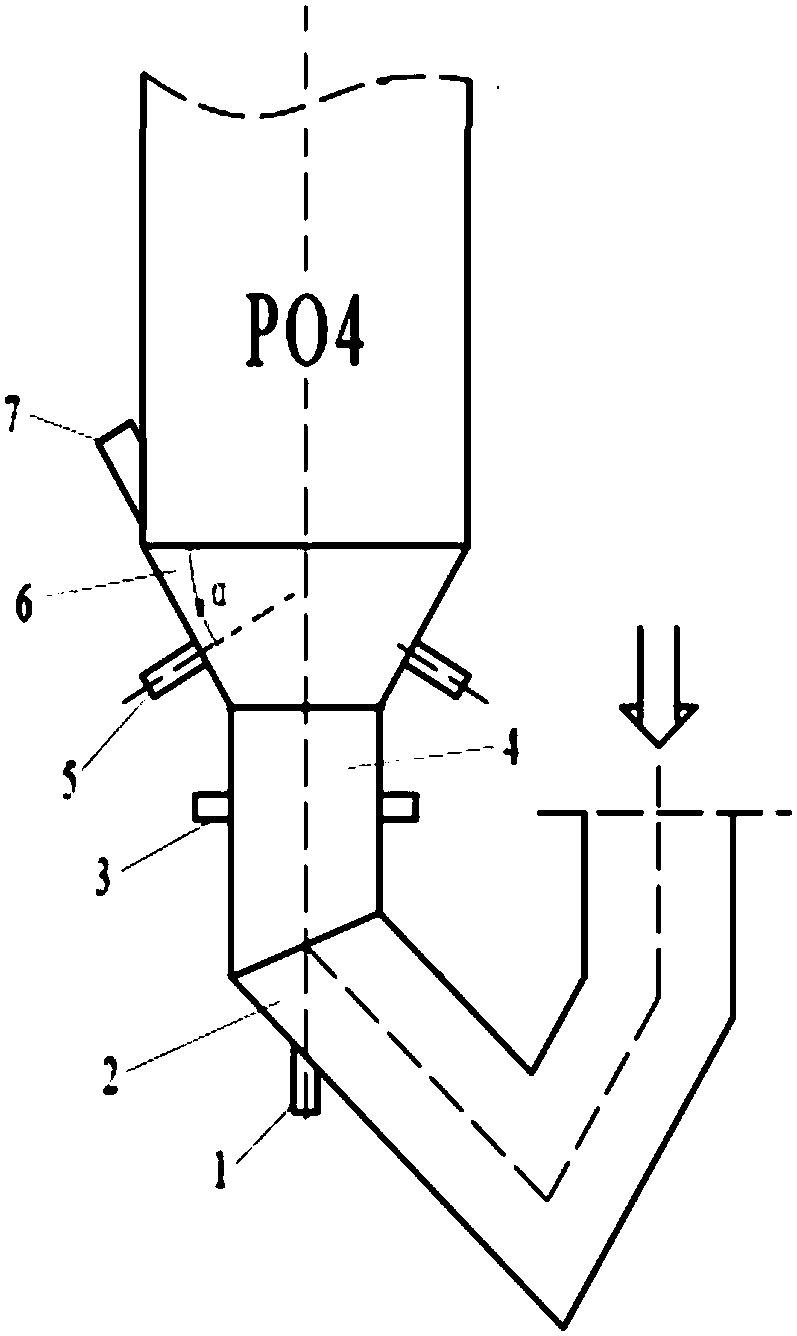

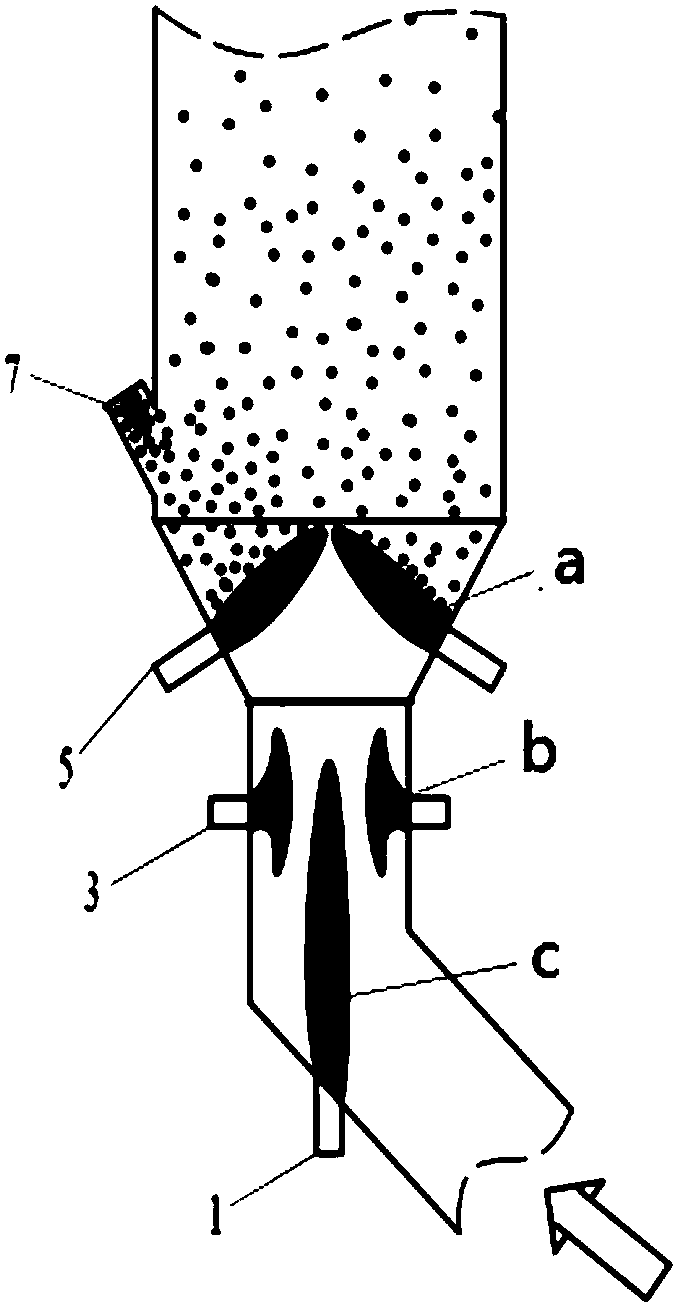

Staged-combustion system of suspension roaster and application thereof

PendingCN107559826AIncrease profitImprove the mixing effectGaseous fuel burnerCombustion systemInstability

The invention discloses a staged-combustion system of a suspension roaster and an application thereof, belonging to the field of roasting. The staged-combustion system comprises a main roaster PO4, amain combustion pipe, an auxiliary gas pipe, a first-stage combustor and a second-stage combustor, wherein the main roaster PO4, the main combustion pipe and the auxiliary gas pipe are connected in sequence; the first-stage combustor is connected to the bottom of the main combustion pipe; the central axis of the first-stage combustor and the central axis of the main combustion pipe coincide; and the second-stage combustor is arranged on the main combustion pipe along a periphery direction and is connected to the main combustion pipe. The staged-combustion system solves the problems existing ina tradition suspension roaster that the insufficient mixing of gas and combustion-supporting gas causes the insufficient combustion of fuel, low utilization rate of fuel and formation of a large amount of high-temperature pollutants, and material dropping causes the flameout of the combustors and the instability of the combustion system. The staged-combustion system has the characteristics of high efficiency, stability and low emission load of pollutants.

Owner:KEDA MAS CLEAN ENERGY +1

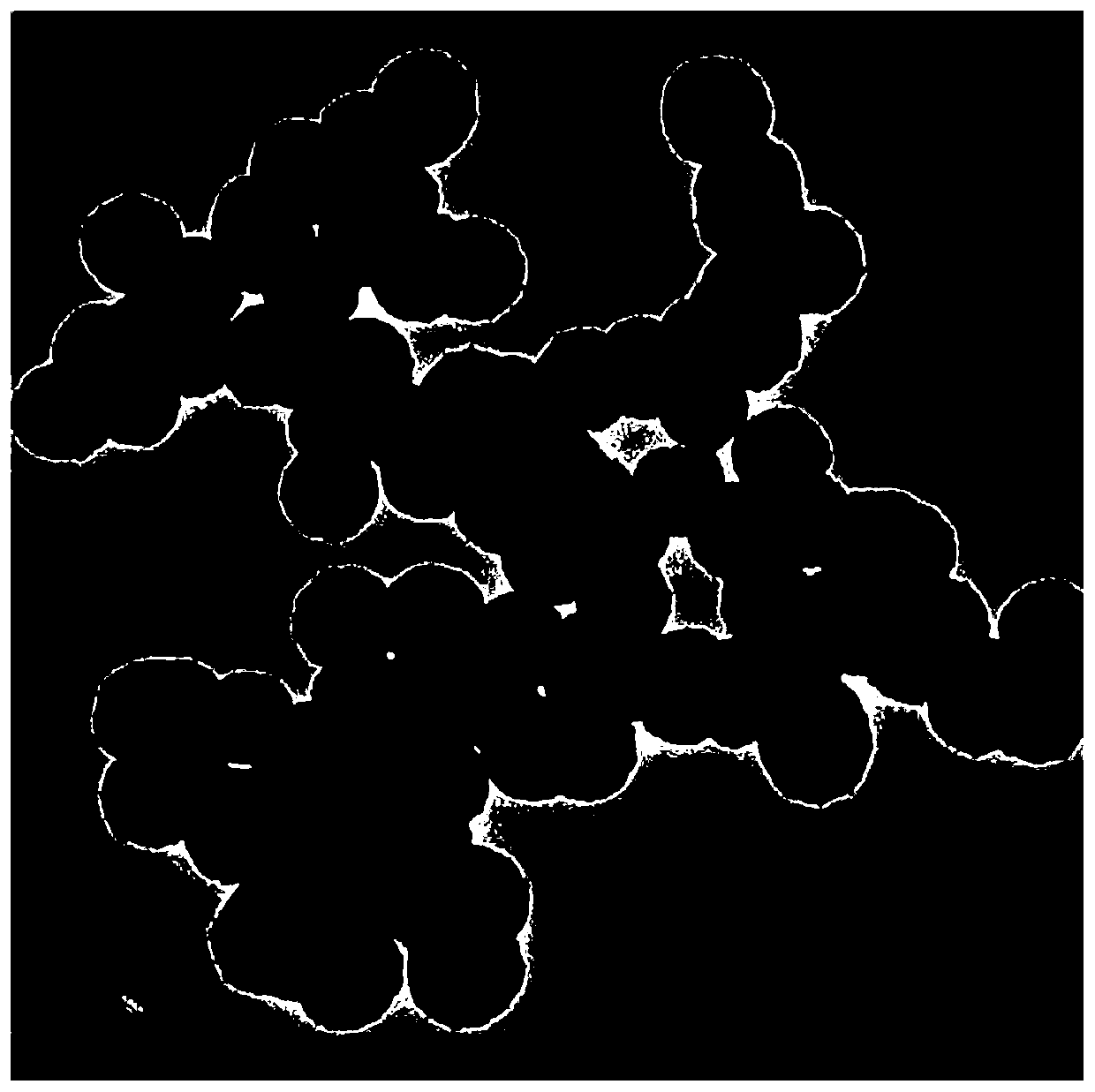

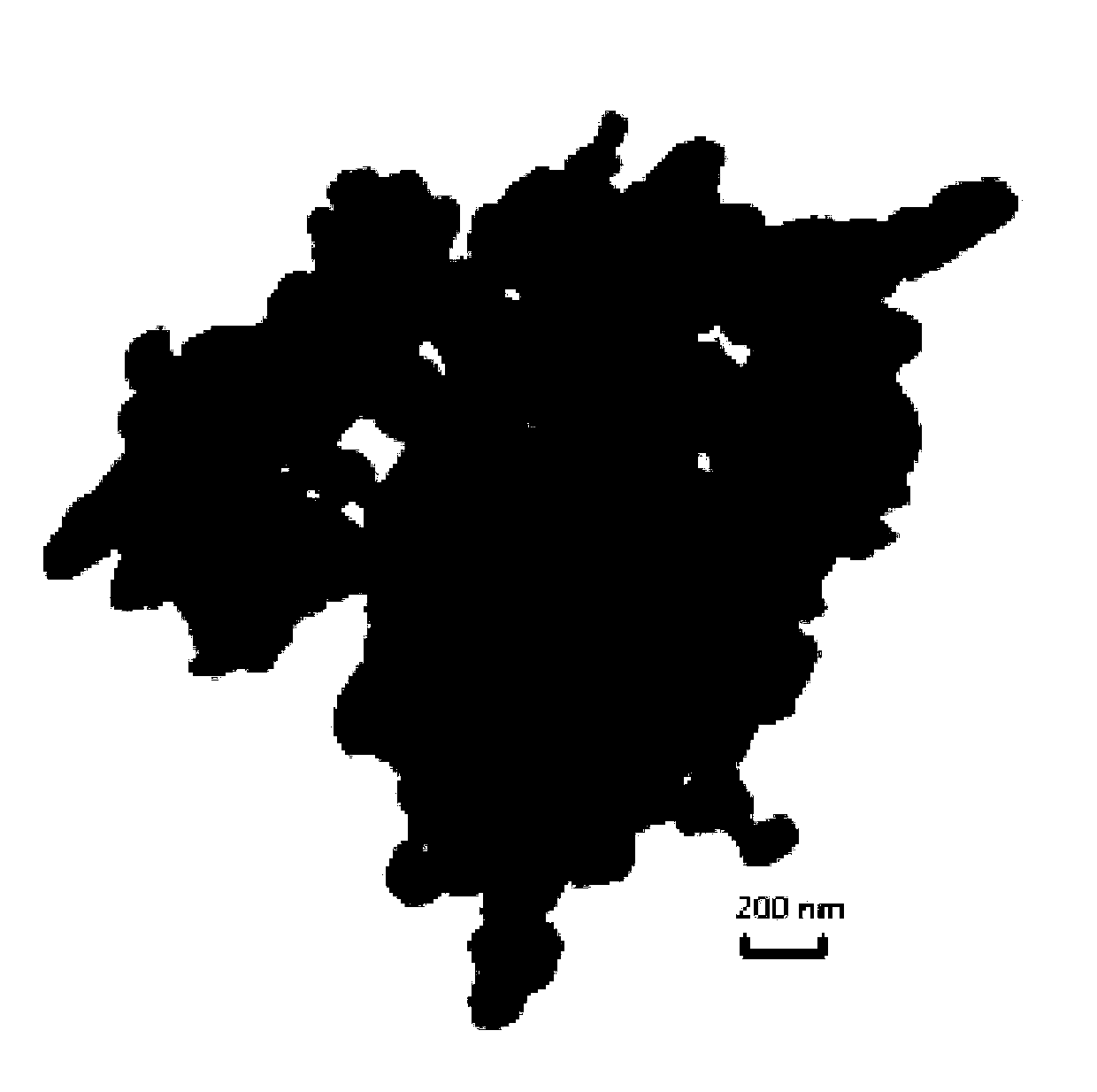

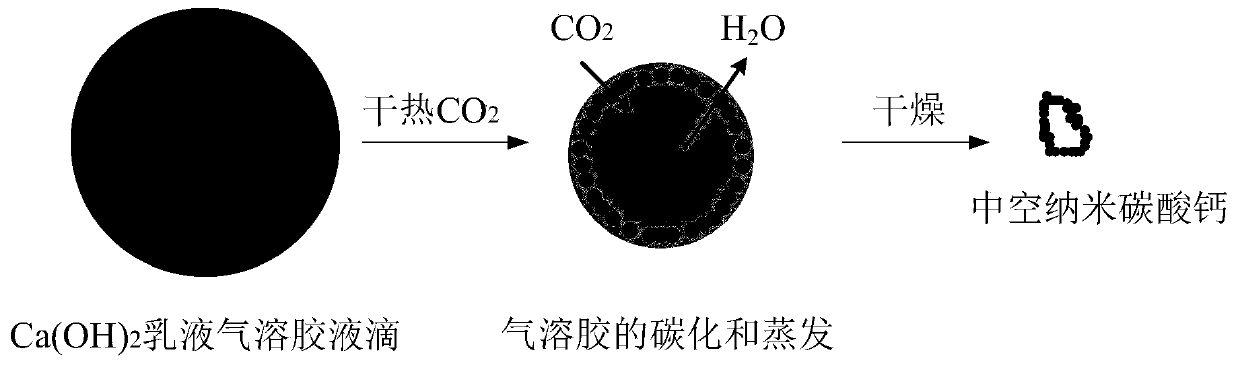

Method for preparing hollow nano calcium carbonate by utilizing ultrasonic aerosol

ActiveCN111017973AImprove water absorptionImprove adsorption capacityCalcium/strontium/barium carbonatesProductsCALCIUM HYDROXIDE SOLUTIONEmulsion

The invention relates to the technical field of preparation of nano hollow materials, in particular to a method for preparing hollow nano calcium carbonate by using ultrasonic aerosol, which comprisesthe following steps: 1) drying carbon dioxide; 2) metering carbon dioxide; 3) heating carbon dioxide; and 4) carbonizing the calcium hydroxide liquid drops. The hollow nano calcium carbonate preparedby the method can be used as a carrier particle for coating other components; in addition, calcium hydroxide emulsion droplets in an ultrasonic aerosol generating device are used for generating calcium hydroxide solution aerosol in a dry heat and excessive carbon dioxide atmosphere; calcium carbonate crystals are generated on the surfaces of the aerosol droplets to form a shell layer, and meanwhile, surface moisture of the calcium hydroxide emulsion droplets is evaporated in the carbonization process, so that the calcium hydroxide emulsion droplets lose water, and finally, hollow nano calciumcarbonate is formed.

Owner:DONGGUAN UNIV OF TECH

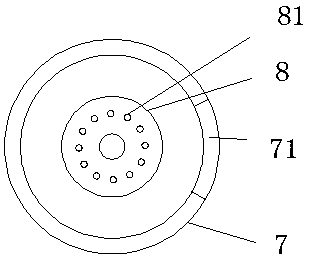

Efficient hot-blast stove for grain dryer

InactiveCN105928349AFully dehumidifyFull drying effectDrying gas arrangementsSeed preservation by dryingEngineeringHot blast

The invention discloses an efficient hot-blast stove for a grain dryer. The efficient hot-blast stove for the grain dryer comprises a stove body, wherein a base is arranged at the lower end of the stove body; a feeding funnel is arranged at the upper end of the base and communicates with the inside of the stove body; a first fixing ring, a second fixing ring and a discharging body are successively arranged on the outer side of the stove body from top to bottom in a surrounding manner; a plurality of first discharging openings are formed in the outer side of the discharging body in a surrounding manner; a second seal plate is arranged on the inner side of the second fixing ring; a first seal plate is arranged on the inner side of the discharging body; a plurality of second discharging openings are formed in the outer side of the first seal plate in a surrounding manner; and the first fixing ring is connected with the second seal plate through a plurality of second connecting rods. By the efficient hot-blast stove for the grain dryer, moisture can be quickly removed from the drying device, by setting hot air provided by the hot-blast stove, the heating process of the traditional dryer is omitted, service time is saved, the overall efficiency of the dryer is improved, and grains are dried in such a circulating manner and then are discharged until water of the grains reaches a specified value.

Owner:ANHUI GUFENG MECHANICAL TECH CO LTD

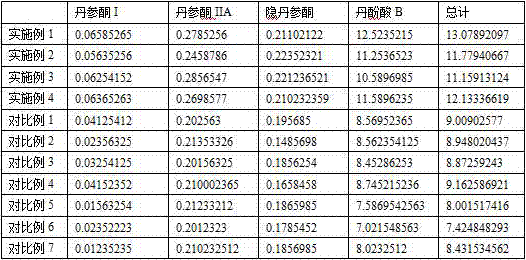

Method for drying harvested red sage root

ActiveCN107184649AQuality improvementHigh activityDrying machines with local agitationDrying machines with materials at restSalvia miltiorrhizaActive ingredient

The invention discloses a method for drying harvested red sage root. The method comprises pretreatment, grading, ultraviolet irradiation, airing, jasmonic acid methyl ester spraying, secondary airing and drying. The method dries the medical red sage root, improves red sage root quality, greatly improves active ingredient content of red sage root, realizes uniform and full drying effects, prevents an active ingredient loss caused by high temperature heating and significantly increases active ingredient content of red sage root after drying.

Owner:山东中平药业有限公司

Lubricant solution and method for producing article provided with lubricant coating

InactiveCN104245907AImprove solubilityFull drying effectPretreated surfacesCoatingsSolubilitySolvent

The purpose of the present invention is to provide: a lubricant solution which does not adversely impact the global environment, has excellent lubricant solubility, and is able to form a uniform lubricant coating that has satisfactory drying properties; and a method for producing an article provided with a lubricant coating in which the lubricant solution is used. A lubricant solution, wherein the solvent comprises 1,1-dichloro-2,3,3,3-tetrafluoro-1-propene. Also, a method for producing an article provided with a lubricant coating, the method being characterized by comprising coating an article to be coated with the lubricant solution, evaporating the solvent, and forming a lubricant coating on the article to be coated.

Owner:ASAHI GLASS CO LTD

Daily fertilization treatment device for agricultural planting

ActiveCN111886990AThe effect of low grindingFull drying effectFertiliser distributersDrying gas arrangementsAgricultural engineeringElectric machinery

The invention belongs to the technical field of agricultural planting, and particularly relates to a daily fertilization treatment device for agricultural planting. The daily fertilization treatment device comprises a base, wherein an accommodating cavity is formed in the base; a drying mechanism is arranged in the accommodating cavity; an annular support tube is vertically and fixedly arranged onthe top surface of the base around the accommodating cavity; a wear-resistant material covers the inner side wall of the support tube; a round separation plate is horizontally and fixedly arranged onthe bottom of the support tube; a grinding mechanism is arranged on the separation plate; a motor is vertically and fixedly arranged on the bottom surface of the base; an output shaft of the motor vertically penetrates through the middle of the base and the middle of the separation plate and extends into the support tube. When the daily fertilization treatment device is used for drying organic fertilizers, the contact time of organic fertilizer particles and hot air in the accommodating cavity is prolonged, so that the sufficient drying effect is achieved on the organic fertilizer particles;the fertilizers can be ground into spherical fine particles; the surface area of the fertilizer particles is increased; the grinding effect is improved; and the organic fertilizer raw materials with great sizes can also be sufficiently ground and dried.

Owner:WEIFANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com