Post-harvest drying method for American ginseng

A drying method and technology of American ginseng, which is applied to the dryer of static materials, local stirring dryer, drying and other directions, can solve the problem of increasing the loss, damage and deterioration of American ginseng, high equipment configuration requirements and cost, and unsatisfactory drying effect, etc. To improve the quality of medicinal materials, increase the content of active ingredients, and facilitate the promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

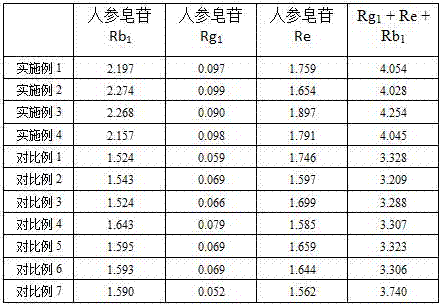

Embodiment 1

[0027] A method for postharvest drying of American ginseng, the steps comprising:

[0028] 1) Pretreatment: the harvested fresh ginseng, remove the soil, fibrous roots, and rinse;

[0029] 2) Classification: remove the diseased plants, and classify according to the unit weight of the plant: the first grade is more than 55 grams, the second grade is 30-55 grams, and the third grade is less than 30 grams;

[0030] 3) Ultraviolet irradiation: put the American ginseng plants graded in step 2) under 5 kJ•m -2 Irradiation under ultraviolet light: the irradiation time is 3.5 hours for the first grade, 3 hours for the second grade, and 2.5 hours for the third grade;

[0031] 4) Drying: put the American ginseng plants treated in step 3) in the air at 25-30°C for 24 hours;

[0032] 5) NO fumigation: place the American ginseng plants treated in step 4) into a plastic container with an internal temperature of 25-30°C, with a flow rate of 20-50 uL·L -1 •min -1 Pass NO, fumigate for 2 h...

Embodiment 2

[0037] A method for postharvest drying of American ginseng, the steps comprising:

[0038] 1) Pretreatment: the harvested fresh ginseng, remove the soil, fibrous roots, and rinse;

[0039] 2) Classification: remove the diseased plants, and classify according to the unit weight of the plant: the first grade is more than 55 grams, the second grade is 30-55 grams, and the third grade is less than 30 grams;

[0040] 3) Ultraviolet irradiation: put the American ginseng plants graded in step 2) under 5 kJ•m -2 Irradiation under ultraviolet light: the irradiation time is 4 hours for the first grade, 3 hours for the second grade, and 2.5 hours for the third grade;

[0041] 4) Drying: put the American ginseng plants treated in step 3) in the air at 25-30°C for 70 hours;

[0042] 5) NO fumigation: place the American ginseng plants treated in step 4) into a plastic container with an internal temperature of 25-30°C, with a flow rate of 20-50ul•••L -1 •min-1 pass NO, fumigate for 1h; th...

Embodiment 3

[0046] A method for postharvest drying of American ginseng, the steps comprising:

[0047] 1) Pretreatment: the harvested fresh ginseng, remove the soil, fibrous roots, and rinse;

[0048] 2) Classification: remove the diseased plants, and classify according to the unit weight of the plant: the first grade is more than 55 grams, the second grade is 30-55 grams, and the third grade is less than 30 grams;

[0049] 3) Ultraviolet irradiation: put the American ginseng plants graded in step 2) under 5 kJ•m -2 Irradiation under ultraviolet light: the irradiation time is 4 hours for the first grade, 4 hours for the second grade, and 4 hours for the third grade;

[0050]4) Drying: place the American ginseng plants treated in step 3) in the air at 25-30°C for 48 hours;

[0051] 5) NO fumigation: place the American ginseng plants treated in step 4) into a plastic container with an internal temperature of 25-30°C, with a flow rate of 20-50ul•••L -1 •min -1 Pass NO, fumigate for 2.5h;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com