Tumble dryer for fruit and vegetable drying

A flip-type dryer technology, applied in applications, food processing, food science, etc., can solve problems such as lack of flipping effect, insufficient drying, and reduced efficiency, so as to achieve energy-saving effect, sufficient drying effect, and simple and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

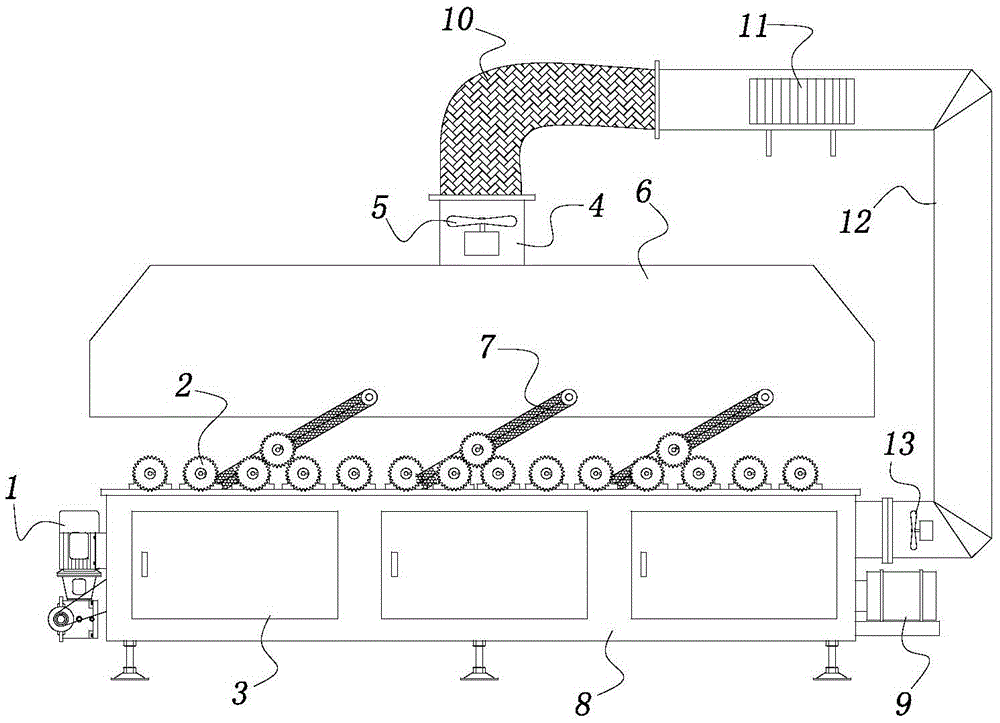

[0012] See figure 1 , the present invention includes a box body 8 with an open top, a hot air blower 9 is fixedly connected to its side wall, and its hot air outlet is connected to the inner cavity of the box body 8, and dry hot air is continuously supplied to the box body 8.

[0013] The top edges of the front side wall and the rear side wall of the box body 8 are respectively provided with a plurality of driving gears 2 arranged at equal intervals and support shaft rollers arranged at equal intervals, and the side walls of the box body 8 are provided with drive gears 2 Rotating reducer 1.

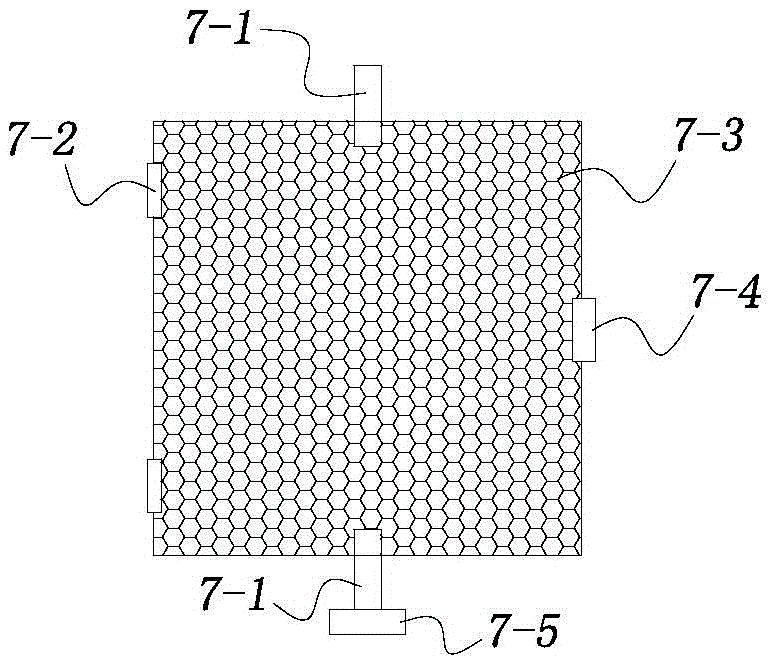

[0014] Also includes clamping screen 7 for clamping the raw material, see figure 2 , the clamping screen 7 includes two screen plates 7-3, the two are connected by a hinge 7-2 on one side edge, and a lock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com