Method for preparing hollow nano calcium carbonate by utilizing ultrasonic aerosol

A nano-calcium carbonate and aerosol technology, which is applied in the direction of calcium carbonate/strontium/barium, nanotechnology, inorganic non-active ingredients, etc., can solve the problems of low carbon dioxide utilization rate, high power consumption, low cost performance, etc., and achieve carbonization reaction and Sufficient dehydration and drying, accelerated production rate, and good water absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

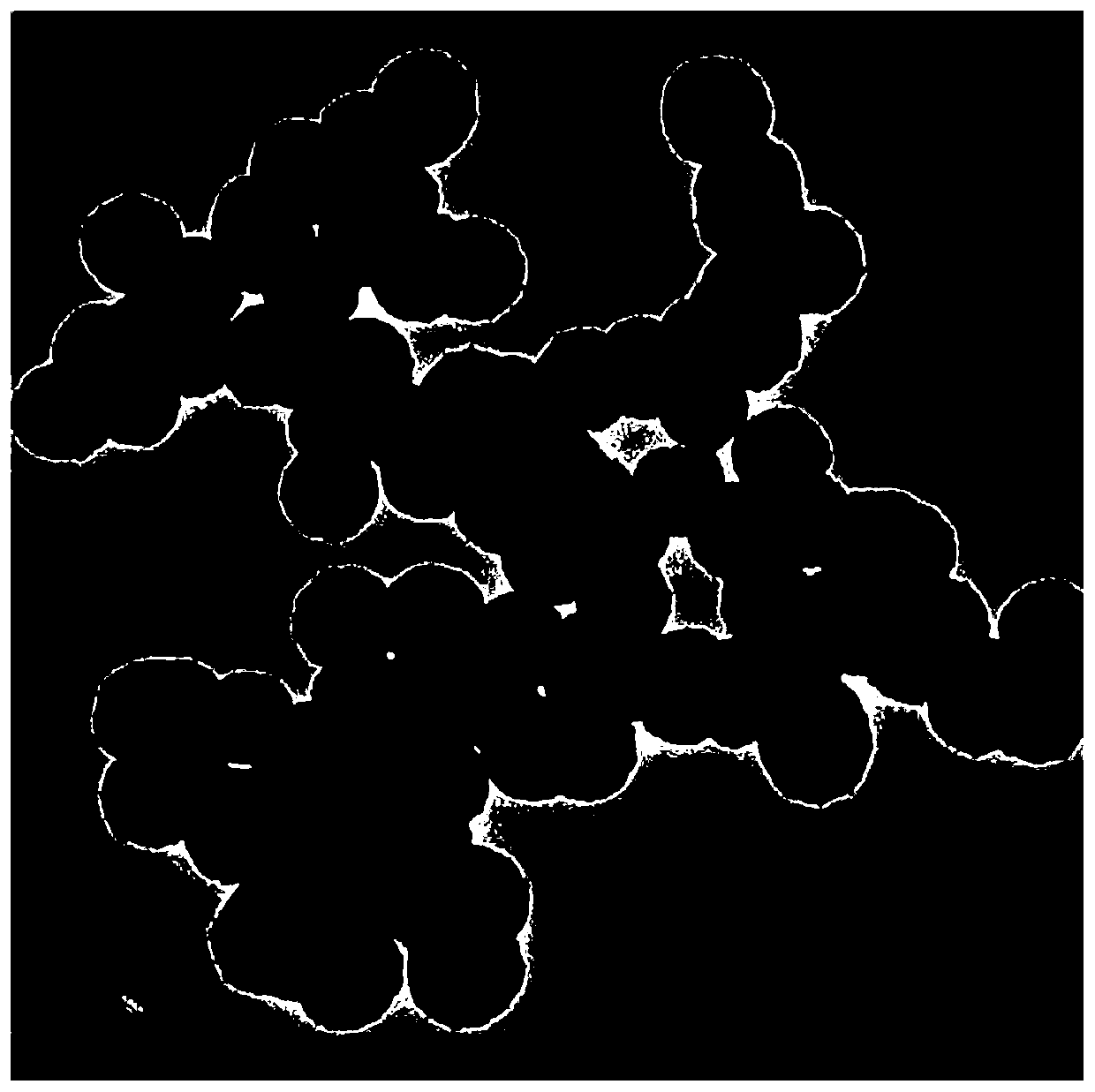

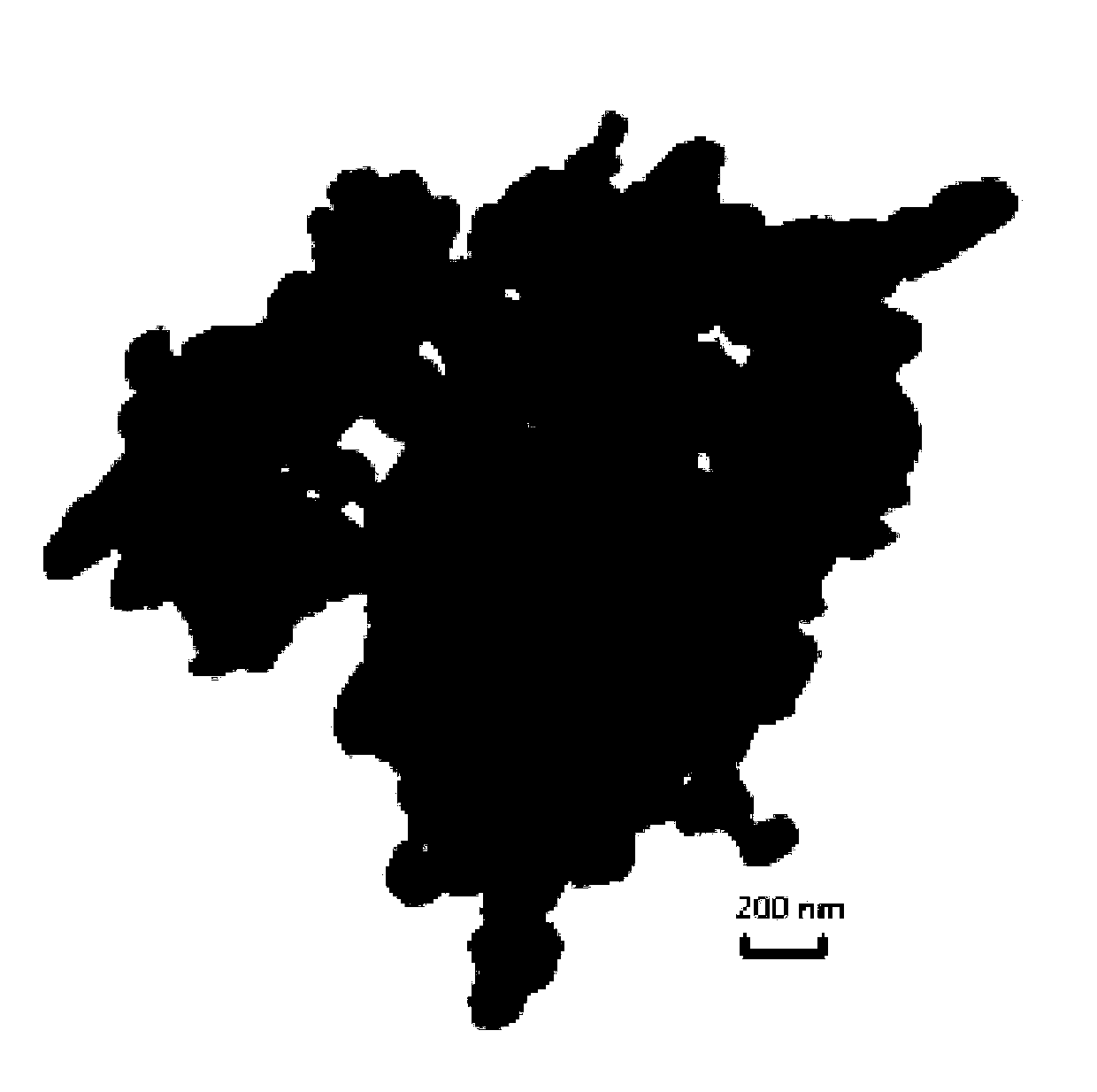

Image

Examples

Embodiment 1

[0034] See Figure 4 , a device for preparing hollow nano-calcium carbonate by ultrasonic aerosol method, comprising a gas source device 1, a drying device 2, a flow control device 3, a heating device 4, an ultrasonic aerosol device 5, the outlet end of the gas source device 1 It communicates with the inlet end of the drying device 2, the outlet end of the drying device 2 communicates with the inlet end of the flow control device 3, and the outlet end of the flow control device 3 communicates with the inlet end of the heating device 4 , the outlet end of the heating device 4 communicates with the inlet end of the ultrasonic aerosol device 5 . Preferably, the drying device 2 is used to place a desiccant or the drying device is a freeze dryer; the gas source device 1 is provided with a pressure reducing valve. Further, the ultrasonic aerosol device 5 is provided with an ultrasonic transducer 6 .

[0035]The structure of the device in this implementation is simple and easy to o...

Embodiment 2

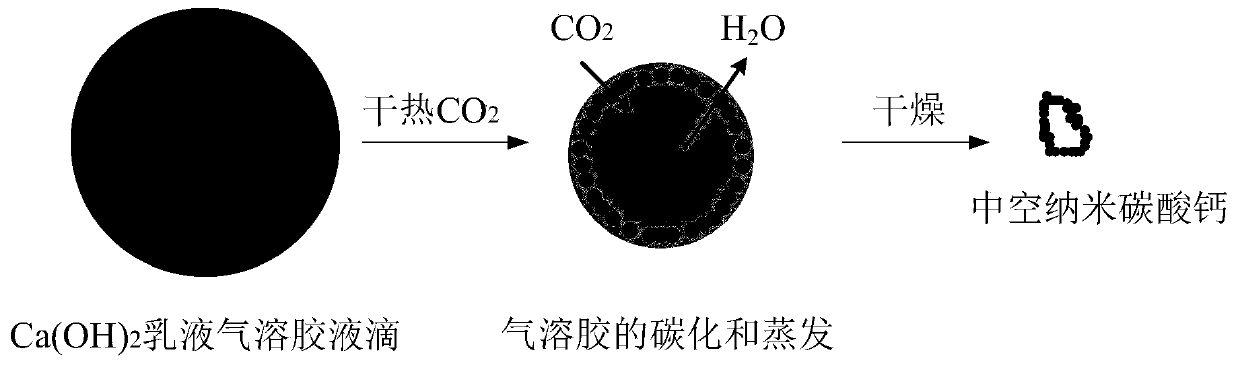

[0052] A kind of method utilizing ultrasonic aerosol to prepare hollow nano-calcium carbonate, comprises the steps:

[0053] 1) Drying of carbon dioxide: depressurize the carbon dioxide in the carbon dioxide gas source to maintain the air pressure at 1.5 MPa, pass it into the drying device to remove the moisture in the carbon dioxide gas, and obtain dry carbon dioxide gas for future use;

[0054] 2) metering of carbon dioxide: pass the dried carbon dioxide gas into the metering device in step 1) to measure and control the flow;

[0055] 3) Carbon dioxide heating: pass the carbon dioxide gas through the metering device into the heating device, heat the carbon dioxide gas to a temperature of 55°C, and set it aside;

[0056] 4) Carbonization of calcium hydroxide droplets: the carbon dioxide gas after heating in step 3) is passed in the ultrasonic aerosol generating device, and the concentration of 0.25% calcium hydroxide emulsion is formed with the mass percentage placed in the u...

Embodiment 3

[0063] A kind of method utilizing ultrasonic aerosol to prepare hollow nano-calcium carbonate, comprises the steps:

[0064] 1) Drying of carbon dioxide: depressurize the carbon dioxide in the carbon dioxide gas source to maintain the air pressure at 3MPa, pass it into the drying device to remove the moisture in the carbon dioxide gas, and obtain dry carbon dioxide gas for future use;

[0065] 2) metering of carbon dioxide: pass the dried carbon dioxide gas into the metering device in step 1) to measure and control the flow;

[0066] 3) Carbon dioxide heating: pass the carbon dioxide gas through the metering device into the heating device, heat the carbon dioxide gas to a temperature of 70°C, and set it aside;

[0067] 4) Carbonization of calcium hydroxide droplets: the carbon dioxide gas heated in step 3) is passed into the ultrasonic aerosol generating device, and the concentration of 0.5% calcium hydroxide emulsion with the mass percentage placed in the ultrasonic aerosol g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com