Lubricant solution and method for producing article provided with lubricant coating

A technology for lubricants and solutions, applied in lubricating compositions, devices for coating liquids on surfaces, coatings, etc., can solve problems such as the adverse effects of the ozone layer, and achieve the effects of good solubility, simple manufacture, and sufficient drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0110] [Example 1] Manufacture of CFO-1214ya

[0111] The method of Example 1 of International Publication No. 2010 / 074254 was repeatedly implemented to obtain a total of 3900 g of 1,1-dichloro-2,3,3,3-tetrafluoro-1-propene (CFO-1214ya).

[0112] Specifically, 3 g of tetrabutylammonium bromide, 83 g (1.485 moles) of potassium hydroxide, and 180 g of water were added as a phase transfer catalyst to a glass reactor with an inner volume of 1 L equipped with a serpentine condenser cooled to 0° C. , 609g (3 moles) of the product name "ASAHIKLIN AK225" (Asahi Glass Co., Ltd. (Asahi Glass Co., Ltd.), a mixture of HCFC-225ca of 48 mole % and HCFC-225cb of 52 mole %), slowly heated up while stirring, React at 45°C for 1 hour. After the reaction, the organic phase was separated from the crude reaction liquid separated into two phases of an organic phase and an aqueous phase, and the organic phase was distilled in a distillation column with a tank volume of 1 L and a capacity of 10 theo...

example 2

[0115]The solvent formed from CFO-1214ya obtained in Example 1 was mixed with the product name "Krytox (registered trademark) GPL102" (manufactured by DuPont, fluorine oil) as a fluorine-based lubricant to make the content of the fluorine-based lubricant 0.5 Mass % lubricant solution.

[0116] Next, the obtained lubricant solution was applied to the surface of an aluminum vapor-deposited plate obtained by vapor-depositing aluminum on an iron plate with an average thickness of about 0.4 mm, and air-dried at 19 to 21° C. A lubricant coating film is formed on the board surface.

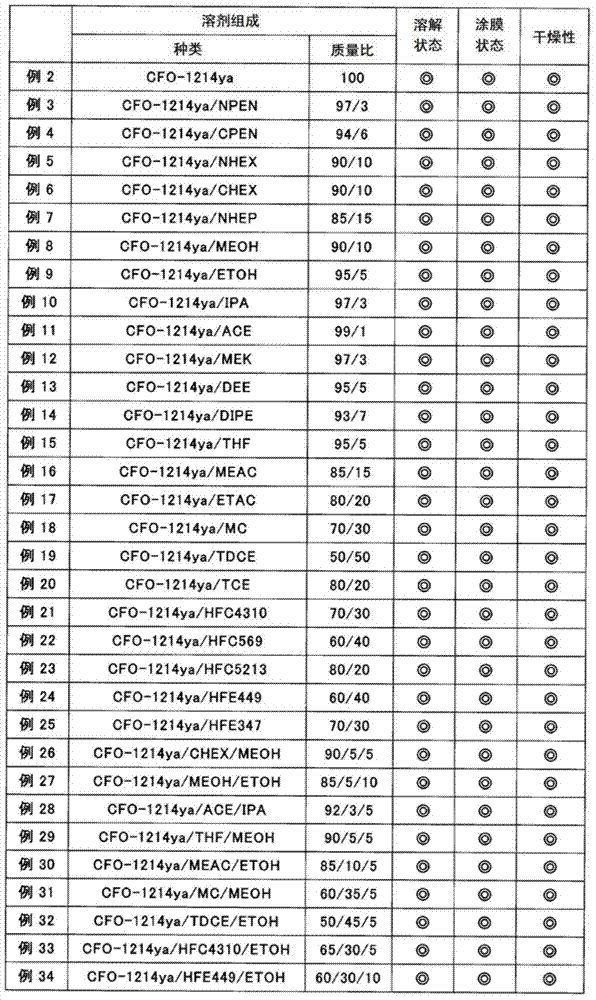

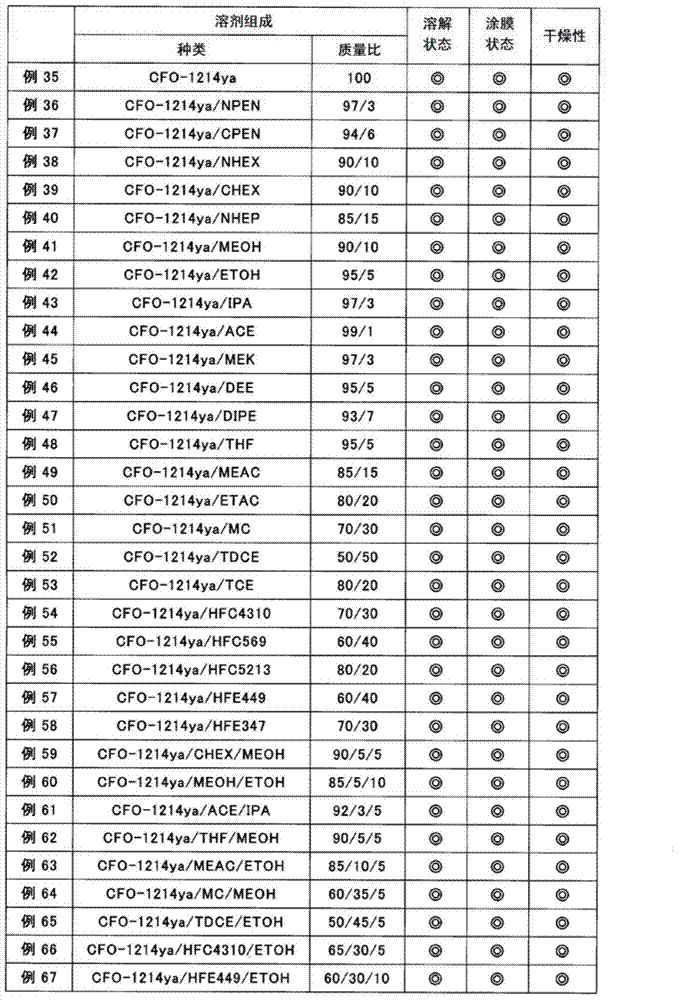

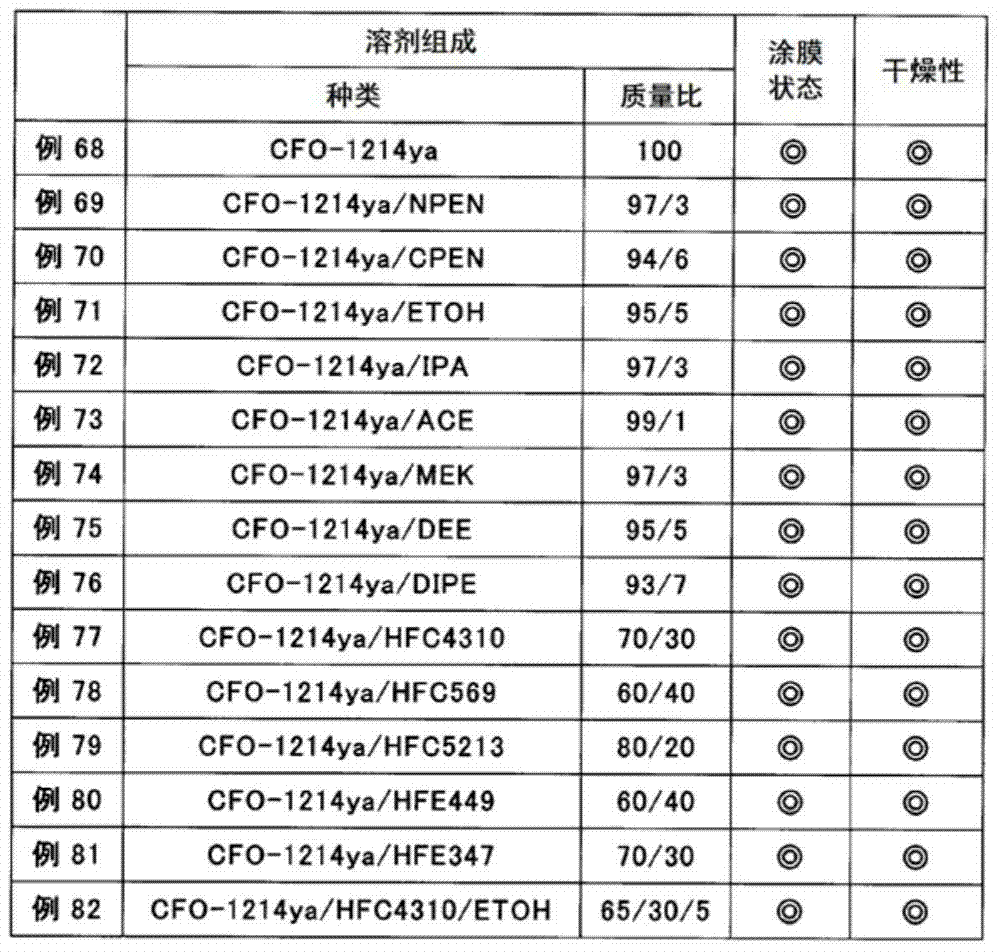

example 3~34

[0118] Lubricant solutions were produced in the same manner as in Example 2 except that the composition of the solvent was changed as shown in Table 1. Then, a lubricant coating film was formed in the same manner as in Example 2.

[0119] Table 1 shows the compositions and evaluation results of the solvents of Examples 2 to 34. The abbreviations in Table 1 have the following meanings.

[0120] CFO-1214ya: 1,1-dichloro-2,3,3,3-tetrafluoro-1-propene.

[0121] NPEN: n-pentane.

[0122] CPEN: cyclopentane.

[0123] NHEX: n-hexane.

[0124] CHEX: Cyclohexane.

[0125] NHEP: n-heptane.

[0126] MEOH: Methanol.

[0127] ETOH: ethanol.

[0128] IPA: isopropyl alcohol.

[0129] ACE: acetone.

[0130] MEK: methyl ethyl ketone.

[0131] DEE: diethyl ether.

[0132] DIPE: diisopropyl ether.

[0133] THF: Tetrahydrofuran.

[0134] MEAC: methyl acetate.

[0135] ETAC: ethyl acetate.

[0136] MC: dichloromethane.

[0137] TDCE: trans-1,2-dichloroethylene.

[0138] TCE: Tric...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com