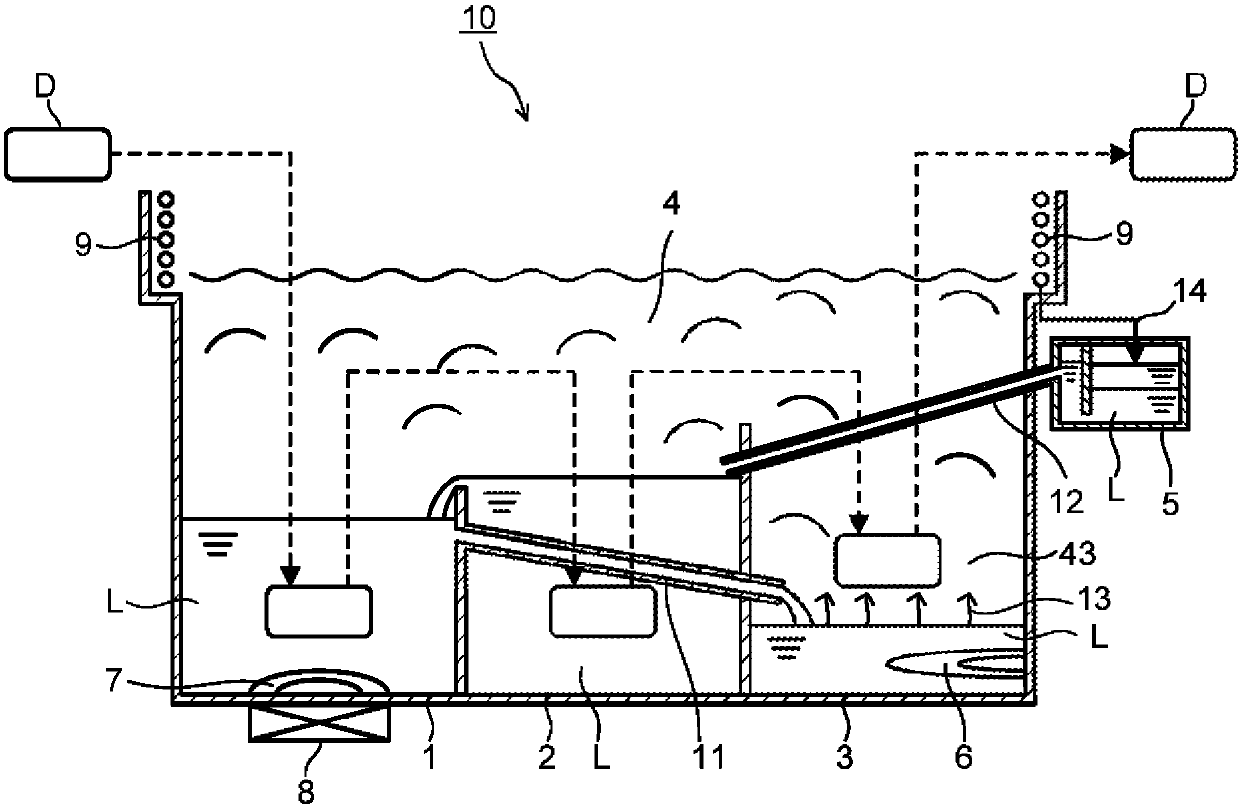

Solvent composition, cleaning method, coating film formation method, heat transfer medium, and heat cycle system

A technology of solvent composition and film coating, which is applied in the preparation of detergent mixture composition, detergent composition, non-surface active detergent composition, etc., can solve the problems that have not been recorded, and achieve excellent stability and cleanability Excellent, excellent solubility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

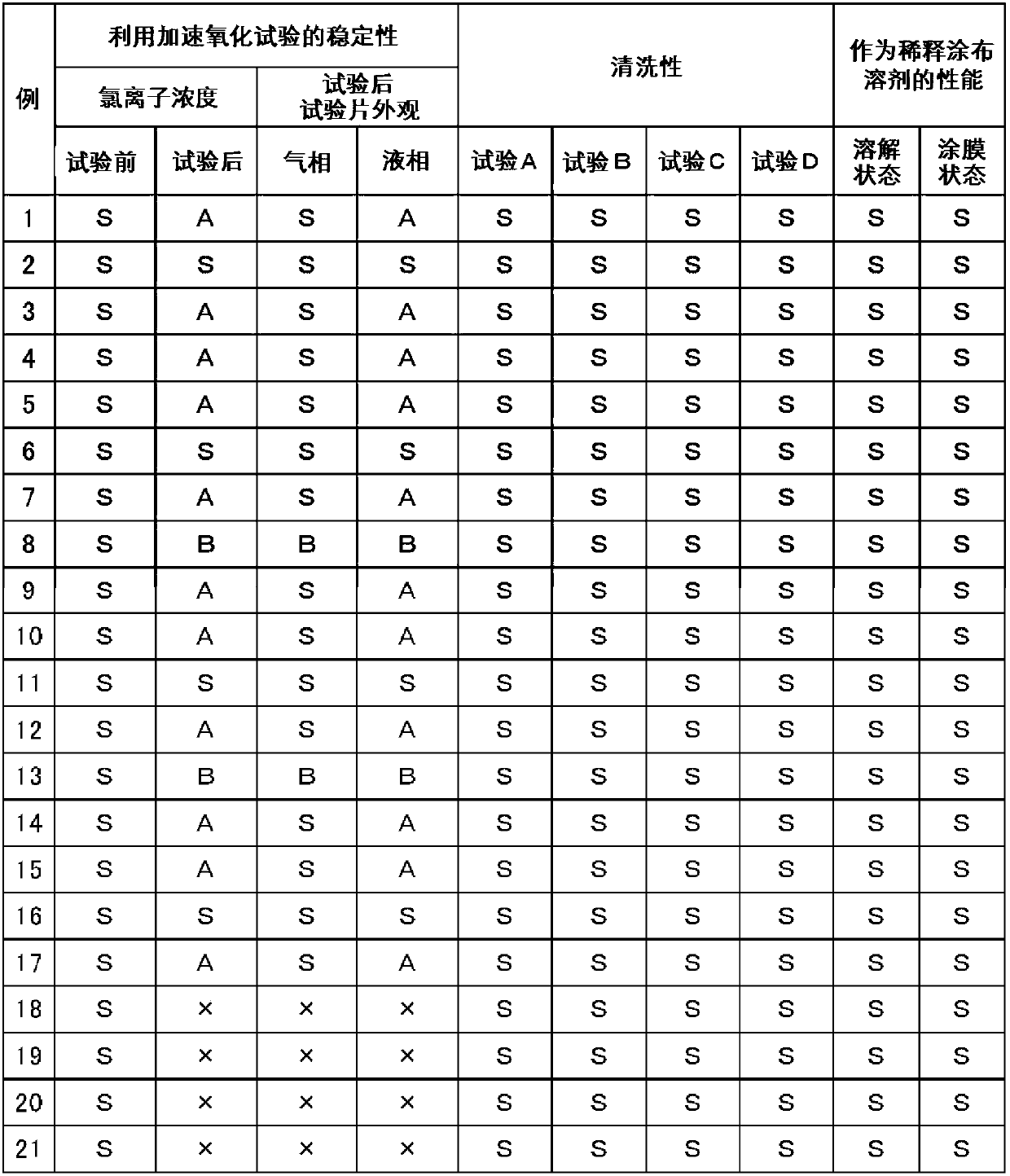

[0133] Hereinafter, the present invention will be described in detail through examples. The present invention is not limited to these embodiments. Examples 1-17 are examples of the solvent composition of the present invention, and examples 18-21 are comparative examples.

manufacture example

[0134] (Manufacturing example: Manufacturing of HCFC-244ca)

[0135] A 2-liter four-necked flask equipped with a stirrer, a Dimuro cooler, and a glass distillation tower filled with Raschig rings (the number of plates measured is 5 layers) is charged with 1204g (9.12 mol) 2,2,3,3-tetra Fluoropropanol (TFPO) and 12g (0.17 mole) of N,N-dimethylformamide (DMF). 1078 g (9.12 mol) of thionyl chloride was dropped, and the mixture was stirred at normal temperature for 12 hours. The reactor was heated to 100°C, and reactive distillation was carried out using a reflux timer under the condition that the ratio of reflux time / distillation time was 5 / 1. The distilled HCFC-244ca was neutralized with a 20% by mass aqueous potassium hydroxide solution. The recovered HCFC-244ca (purity 100%) was 979 g (6.50 mol).

[0136] (Production example: Production of HCFO-1233yd and 1-chloro-3,3-difluoro-1-propyne)

[0137] Using 2000 g of HCFC-244ca as a raw material, 19.9 g of tetra-n-butylammonium chlori...

example 1~17

[0138] (Examples 1-17: Production of solvent composition (Example))

[0139] Using the above-obtained HCFO-1233yd (Z), HCFO-1233yd (E) and the mixture (X), according to the content ratio shown in Table 1, 100 g of HCFO-1233yd (Z) and / or HCFO-1233yd ( E) Solvent composition with 1-chloro-3,3-difluoro-1-propyne as a stabilizer. The values of HCFO-1233yd(Z), HCFO-1233yd(E) and 1-chloro-3,3-difluoro-1-propyne shown in Table 1 are relative to the content of HCFO-1233yd and 1-chloro-3 The content ratio (mass%) of each component to the total content of 3-difluoro-1-propyne. In addition, the solvent compositions of Examples 1 to 17 are solvent compositions composed only of HCFO-1233yd and 1-chloro-3,3-difluoro-1-propyne.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com