Cylinder spraying and cleaning process

A spray cleaning and process technology, which is applied in the direction of cleaning hollow objects, drying solid materials, cleaning methods and utensils, can solve the problems that cylinder parts cannot achieve the expected cleaning and drying effects, and achieve full cleaning and drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

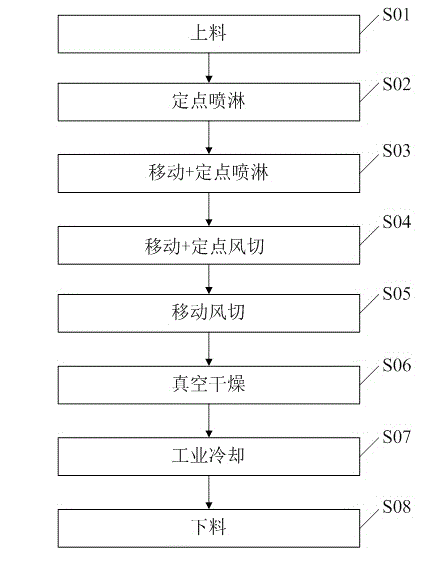

[0031] Such as figure 1 As shown, the embodiment of the present invention provides a cylinder spray cleaning process, including the following steps:

[0032] S01, feeding

[0033] Place the workpieces to be cleaned on the stainless steel conveyor network, and the conveyor chain network automatically transports the workpieces sequentially. Among them, the workpieces can be cylinder parts, for example, the workpieces can be automobile engine cylinders, cylinders and crankcases, etc.;

[0034] S02, fixed-point spraying

[0035] When the workpiece in step (1) enters the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com