Enameled copper wire cleaning device and method of using enameled copper wire cleaning device for cleaning copper wires

A cleaning device and enamelled copper wire technology, applied in the direction of cleaning methods using tools, cleaning methods and utensils, cleaning methods using liquids, etc., can solve problems such as single cleaning means, poor cleaning effect, and affecting the cleaning of copper wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

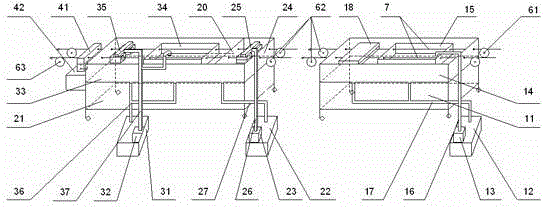

[0033] Now in conjunction with accompanying drawing, describe the present invention in detail.

[0034] Refer to attached figure 1 , an enamelled copper wire cleaning device, including an alkali solution cleaning device, a clear water cleaning device, a soft water cleaning device and a copper wire drying device placed in sequence;

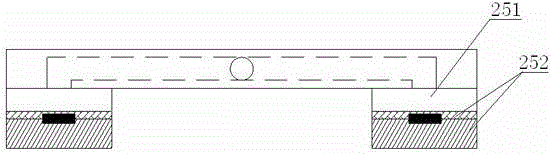

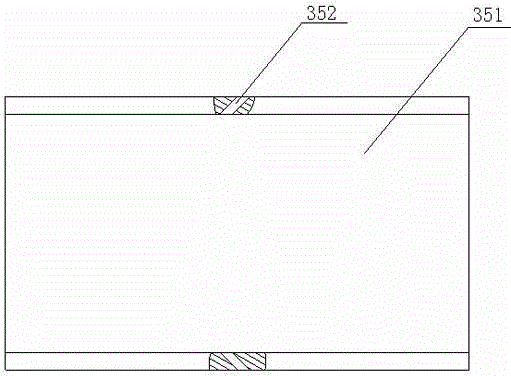

[0035] The lye cleaning device comprises a first frame 11, an lye tank 12 filled with lye with a pH value of 13 to 14, an lye pump 13, an lye storage tank 14, and a copper wire ultrasonic lye cleaning tank 15; The top of a frame 11 is provided with lye storage tank 14, is provided with copper wire ultrasonic lye cleaning tank 15 in lye storage tank 14, and lye tank 12 is provided with lye inlet pipe 16 of lye pump 13 and copper Line ultrasonic lye cleaning tank 15 is connected, and lye tank 12 is connected with lye storage tank 14 by lye return pipe 17; The lye cleaning device also includes cleaning felt 18, and cleaning felt 18 is placed in the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com