Full-automatic swiftly moving and spraying type bowl washing machine

A fully automatic and dishwasher technology, which is applied to tableware washing machines/rinsing machines, cleaning equipment, household utensils, etc. It can solve the problems of not being able to install drying and disinfection devices, and powerful jet cleaning in place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

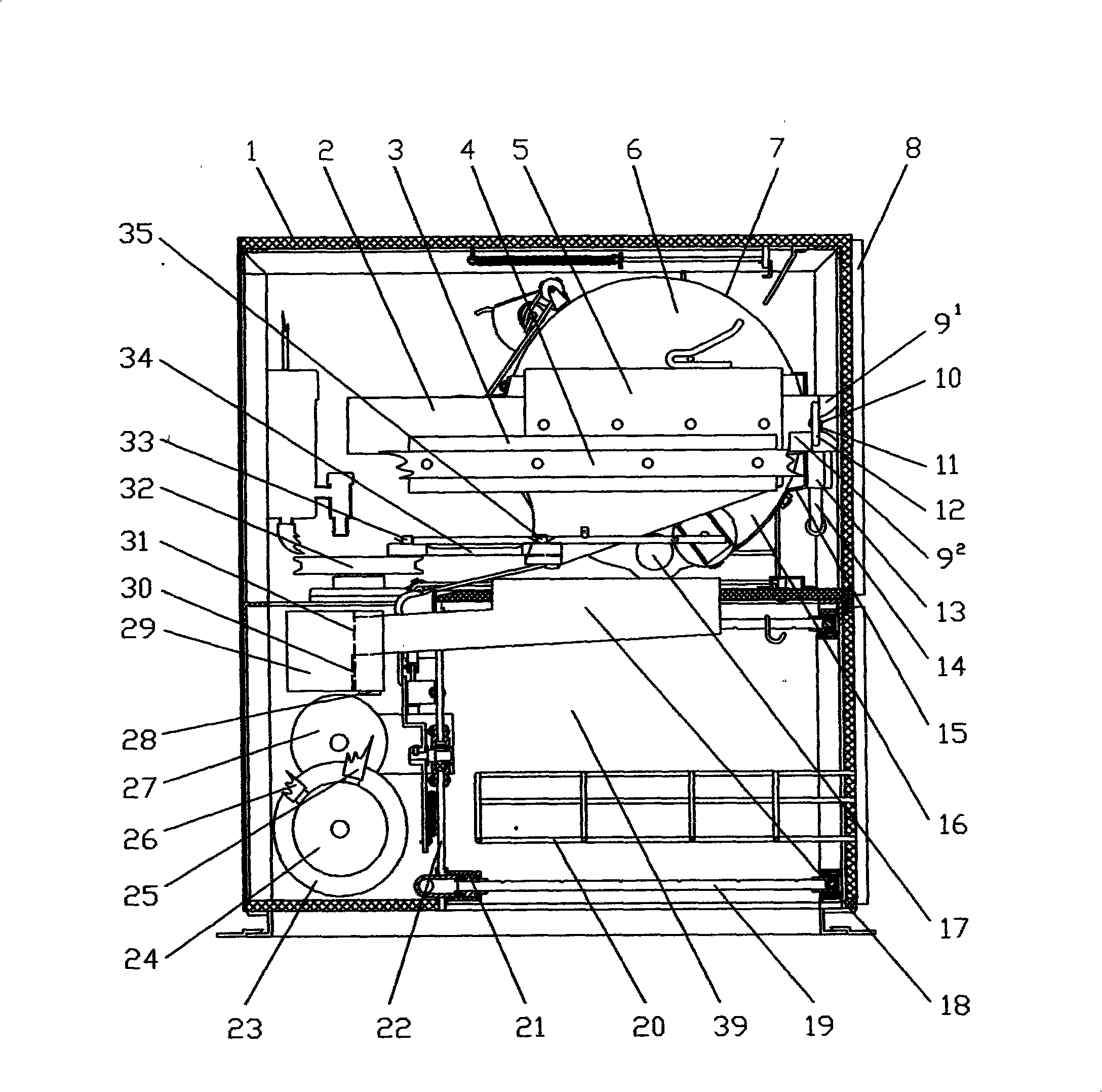

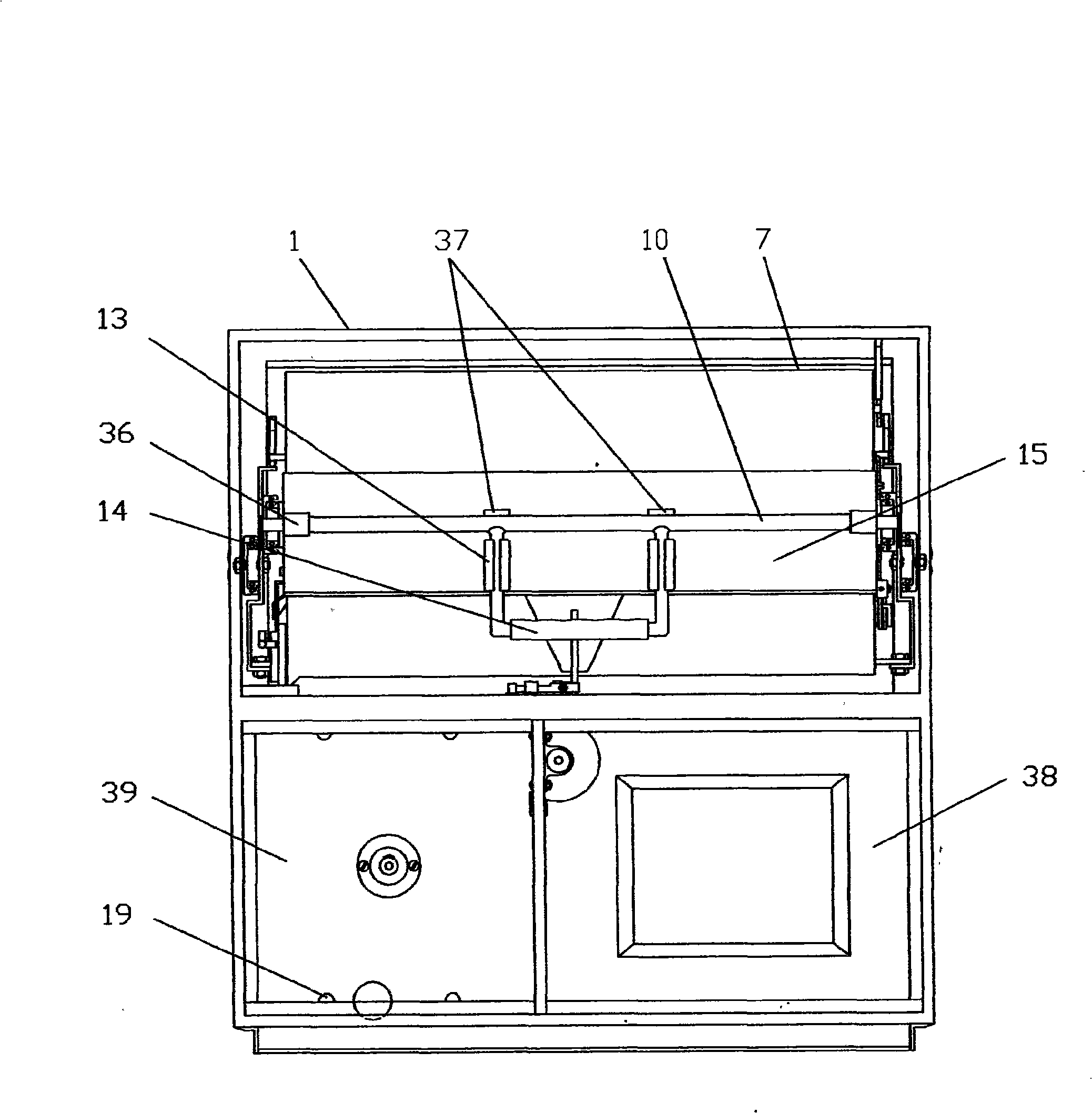

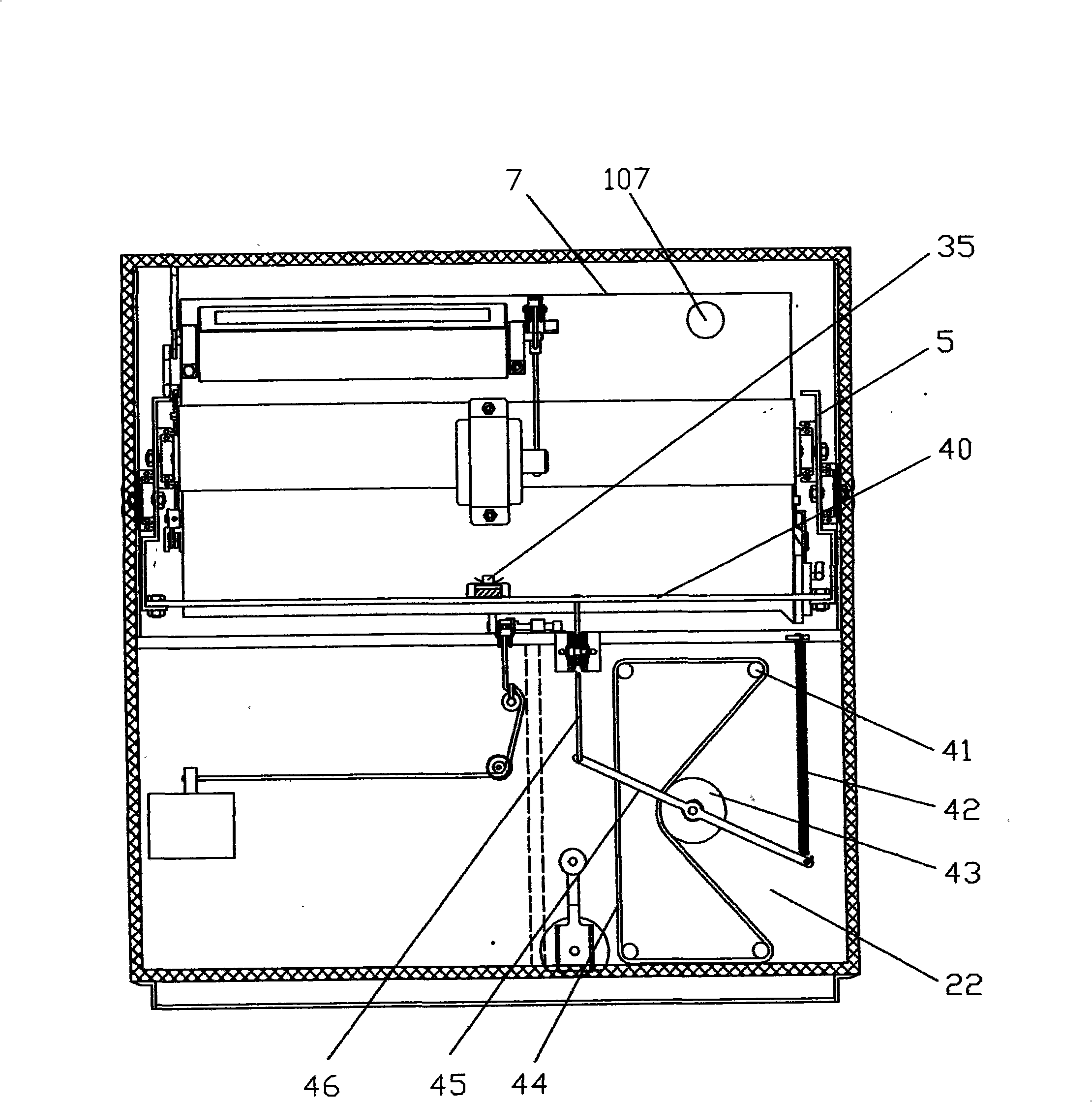

[0032] The body of a fully automatic spray-trent dishwasher is divided into a Trent automatic washing room, a spray washing room, a storage room, a power room, and an automatic device for electric connection and non-electric connection. (refer to Figure 1-3 ) A cylindrical washing tank (7) composed of a tank cover (6) and a water tank (16) is provided in the Trent washing room, and an automatic fastening bowl device is provided in the cavity of the washing tank (7), which automatically Closely fasten the chopsticks box of dish device and automatic scrubbing chopsticks (116), be provided with self-rotating ozone generator 1 (131), self-control type water level detector, automatic swing type drainage valve (17) and The water inlet (107) electromagnetic valve device and the non-electrically connected automatic device for opening, closing and fastening of the tank cover (6). Embodiment 1, the two ends of the washing tank (7) are respectively fastened to the inside of the slide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com