Washing machine

A washing machine and laundry technology, which can be applied to other washing machines, washing machines with containers, control devices of washing machines, etc., can solve problems such as damage to laundry, and achieve the effect of preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

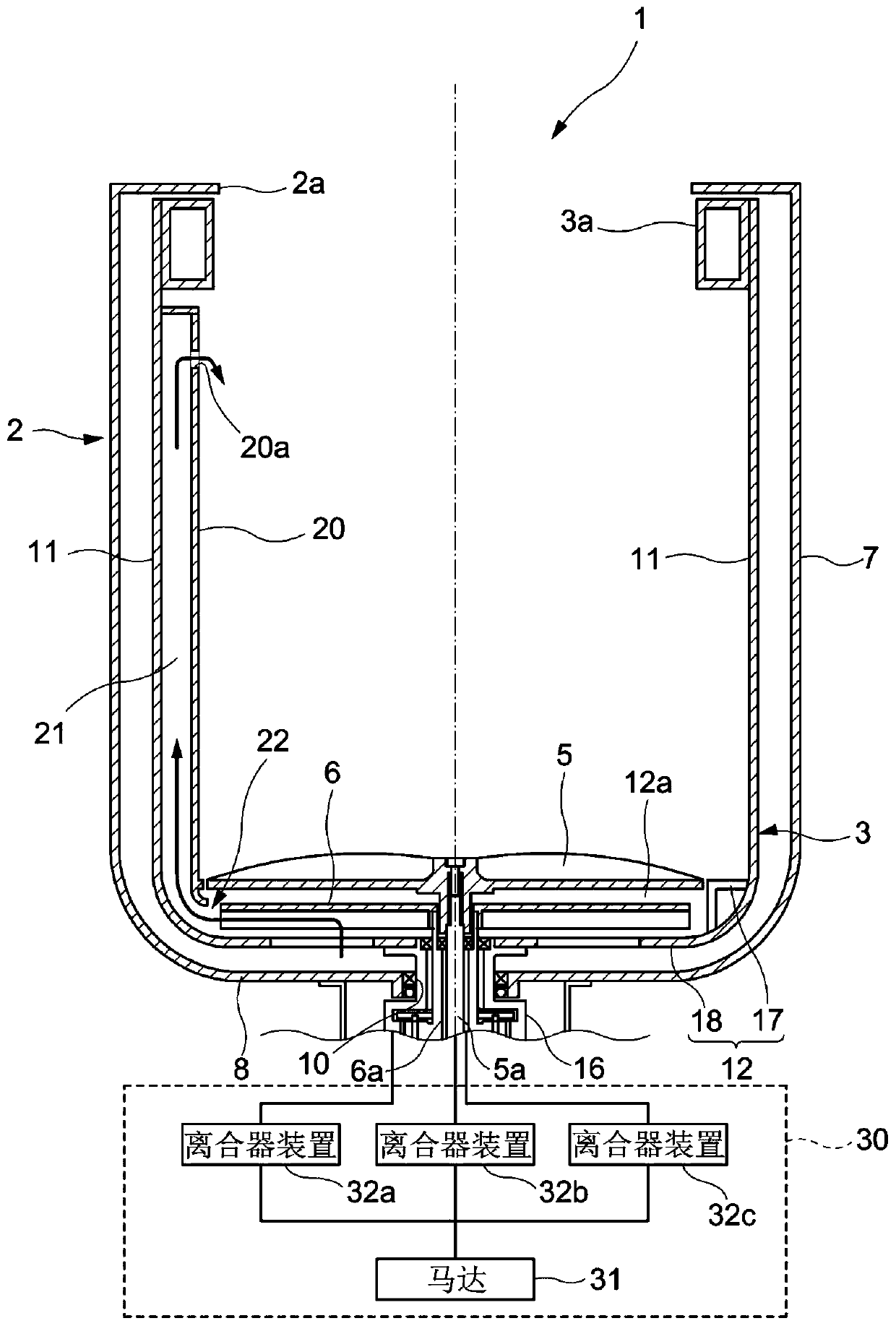

[0039] Hereinafter, a vertical washing machine 1 according to an embodiment of the present invention will be described with reference to the drawings. figure 1 It is a schematic sectional view of the vertical washing machine 1 which concerns on embodiment of this invention.

[0040] Vertical washing machine 1 (hereinafter, sometimes referred to as washing machine 1) has a cabinet (not shown) as the main body of the washing machine. Inside the cabinet, a bottomed cylindrical outer tub 2 is formed by a plurality of suspension rods not shown. suspension support.

[0041] The tub 2 integrally has a cylindrical side wall 7 extending in the vertical direction, and a bottom wall 8 closing the lower end of the side wall 7 . An opening 2 a is formed at the upper end of the tub 2 by the upper edge of the side wall 7 . A through hole 10 is formed at the center of the bottom wall 8 . Washing liquid (water or fresh water mixed with detergent) is stored in the outer tub 2 from the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com