Ceramic blank drying device for ceramic processing

A ceramic processing and drying device technology, which is applied in the direction of drying gas arrangement, drying chamber/container, drying solid materials, etc., can solve the problems of high labor intensity, lack of feeding device, and low work efficiency, so as to improve drying efficiency and improve Conveying efficiency, enhanced drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

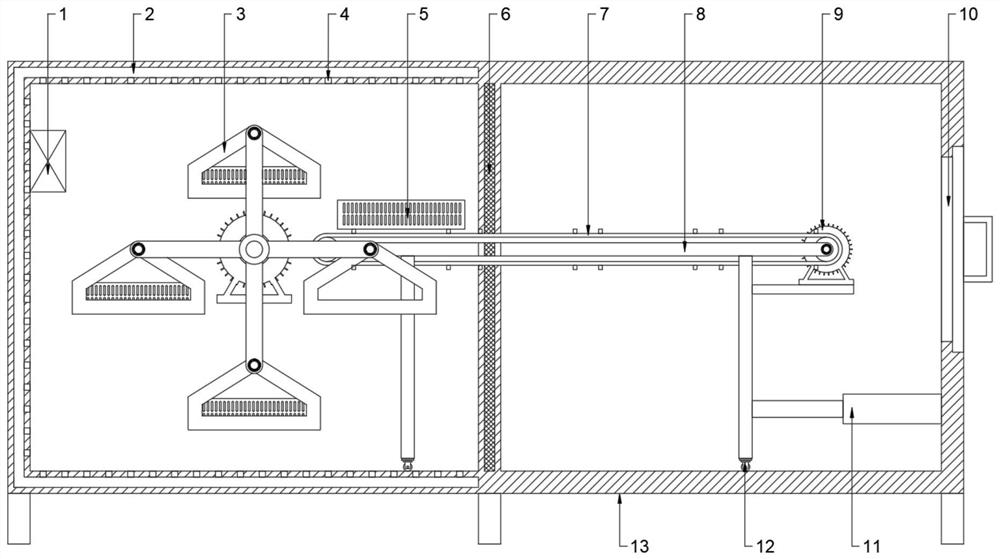

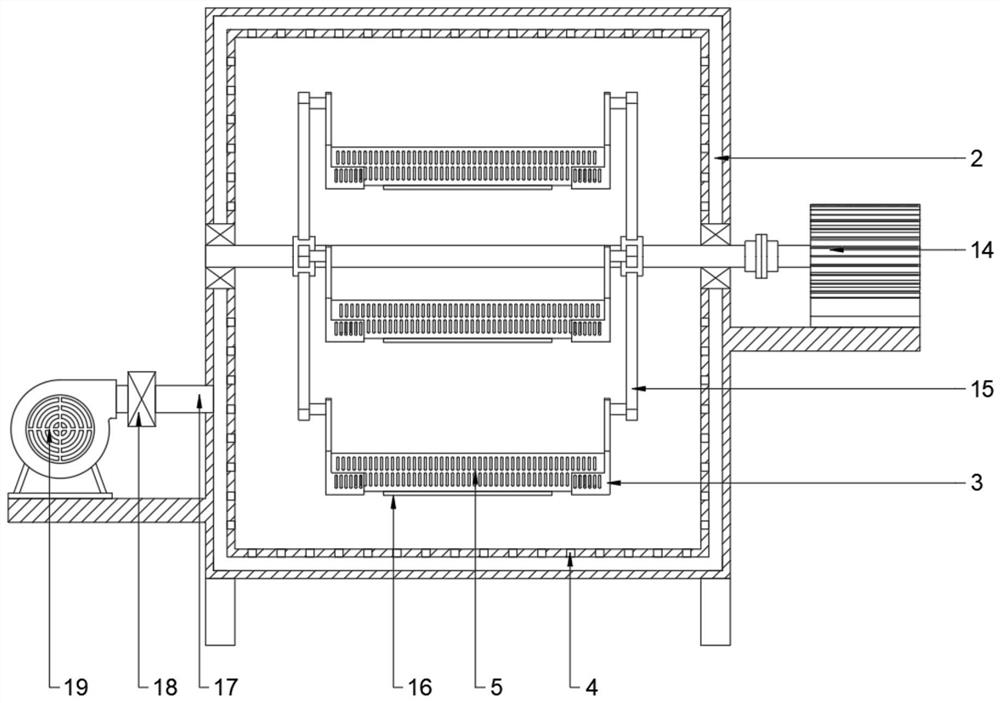

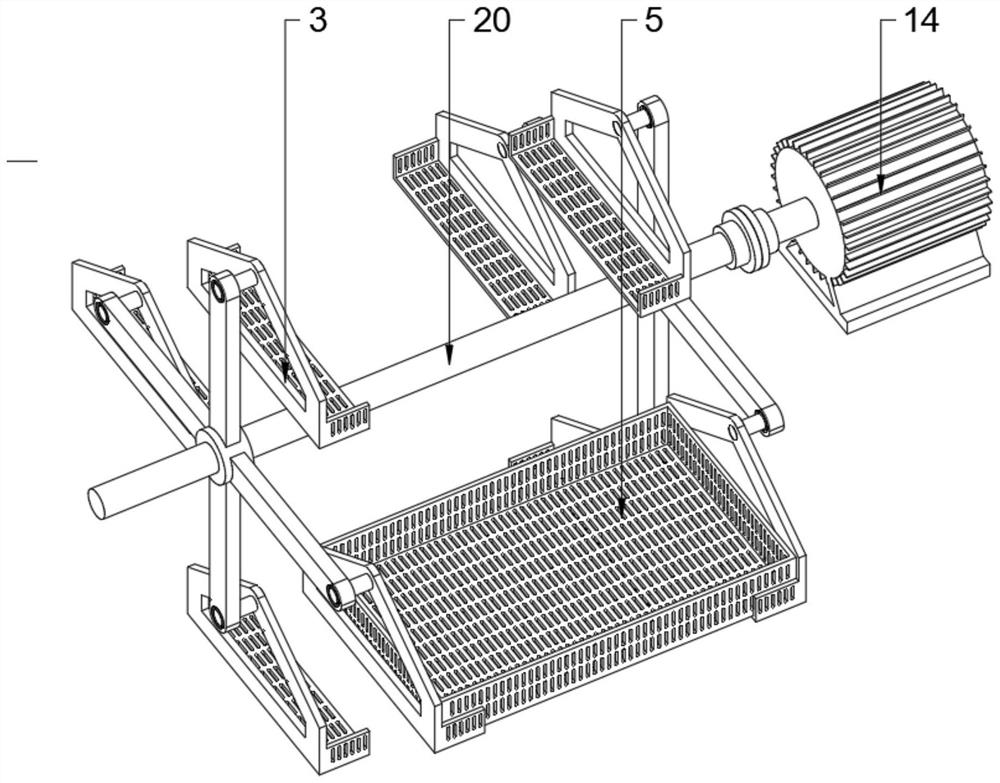

[0026] see Figure 1~6 , in the embodiment of the present invention, a porcelain blank drying device for ceramic processing, including a box body 13 and a drying assembly arranged inside the box body 13, the inside of the box body 13 is provided with an electric sliding door 6 and through the electric sliding door 6 The inside of the box body 13 is divided into a drying chamber and a material delivery room, and a material delivery assembly is provided inside the delivery room; the delivery assembly includes a conveyor belt 7, a walking frame 8 and a telescopic rod 11, and the conveyor belt 7 is rotatably mounted on On the walking frame 8 and set in linkage with the feeding motor 9 fixedly installed on the walking frame 8, the walking frame 8 is arranged at the bottom of the box body 13 and is fixedly connected with the telescopic rod 11, and the telescopic rod 11 is far away from the side of the walking frame 8. One end is fixedly arranged on the side wall of the box body 13, ...

Embodiment 2

[0035] see figure 1 , in the embodiment of the present invention, a porcelain blank drying device for ceramic processing, in order to accurately control the drying temperature and duration of different materials, and enhance the drying effect, on the basis of embodiment 1, a temperature detection device is installed inside the drying chamber 1. The temperature detection device 1 is fixedly installed on the side wall of the drying chamber and electrically connected with the heater 18; the temperature detection device 1 detects the drying temperature of the material in time, and when the temperature is too high, the temperature detection device 1 controls the heating The device 18 is closed to reduce the temperature in the drying chamber. When the temperature is too low, the temperature detection device 1 controls the heater 18 to turn on and heat to a certain temperature to increase the temperature in the drying chamber; the temperature detection device 1 can also be used for dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com