Industrial continuous type microwave reactor

A microwave reactor and continuous technology, applied in the field of industrialized continuous microwave reactors, can solve problems such as inability to industrialize large-scale production, and achieve the effects of realizing industrialized large-scale production, reducing energy consumption and environmental pollution, and reducing investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

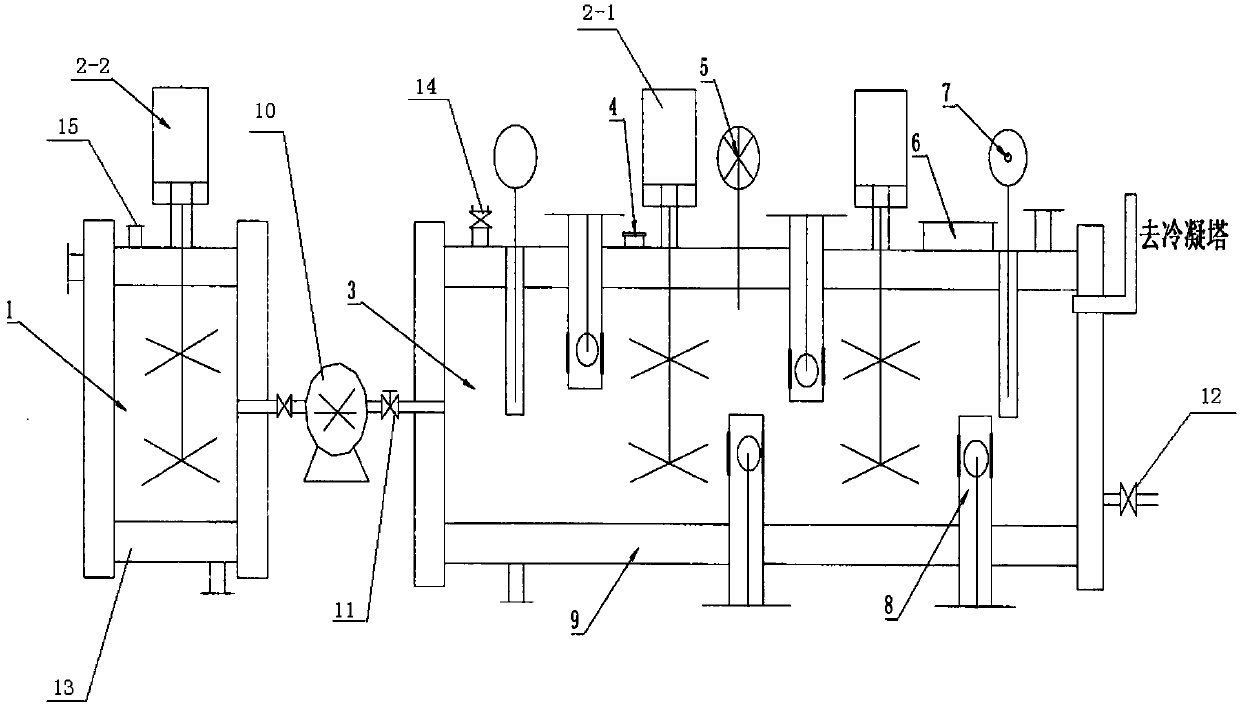

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] see figure 1 , the present invention includes a mixing chamber 1 and a reaction chamber 3; and the right side of the mixing chamber 1 communicates with the left side of the reaction chamber 3 through a pipe.

[0021] 1. The top of the mixing chamber 1 is provided with a feed port 15 for adding raw materials. The top of the mixing chamber 1 is also provided with a mixing and stirring device 2-2 extending into the mixing chamber 1. The mixing and stirring device 2- 2 is connected with the mixing speed regulating motor used to control the stirring speed of the mixing and stirring device; the mixing and stirring device 2-2 can fully mix the materials in the mixing chamber 1, so as to facilitate the full reaction in the reaction chamber. At the same time, a mixing chamber cooling jacket 13 is installed on the outside of the mixing chamber, and the mixing c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com