Patents

Literature

113results about How to "Realize continuous mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-purity hydrogen peroxide preparation

InactiveCN1439600AMeet the requirements of cleaning agentsSolve the problem of relying on importsIon-exchange column/bed processesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSemiconductor chipCleansing Agents

A process for preparing high-purity hydrogen peroxide from the aqueous solution of industrial hydrogen peroxide includes such steps as contacting with strong-alkaline macroreticular anionic exchange resin, contacting with strong-acidic macroreticular cationic exchange resin, contacting with mixed ionic exchange resin, and filtering via microfilter membrane. Its advantages are colourless, no order, high stability and purity, and low cost. It can be used as detergent for semiconductor chip.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

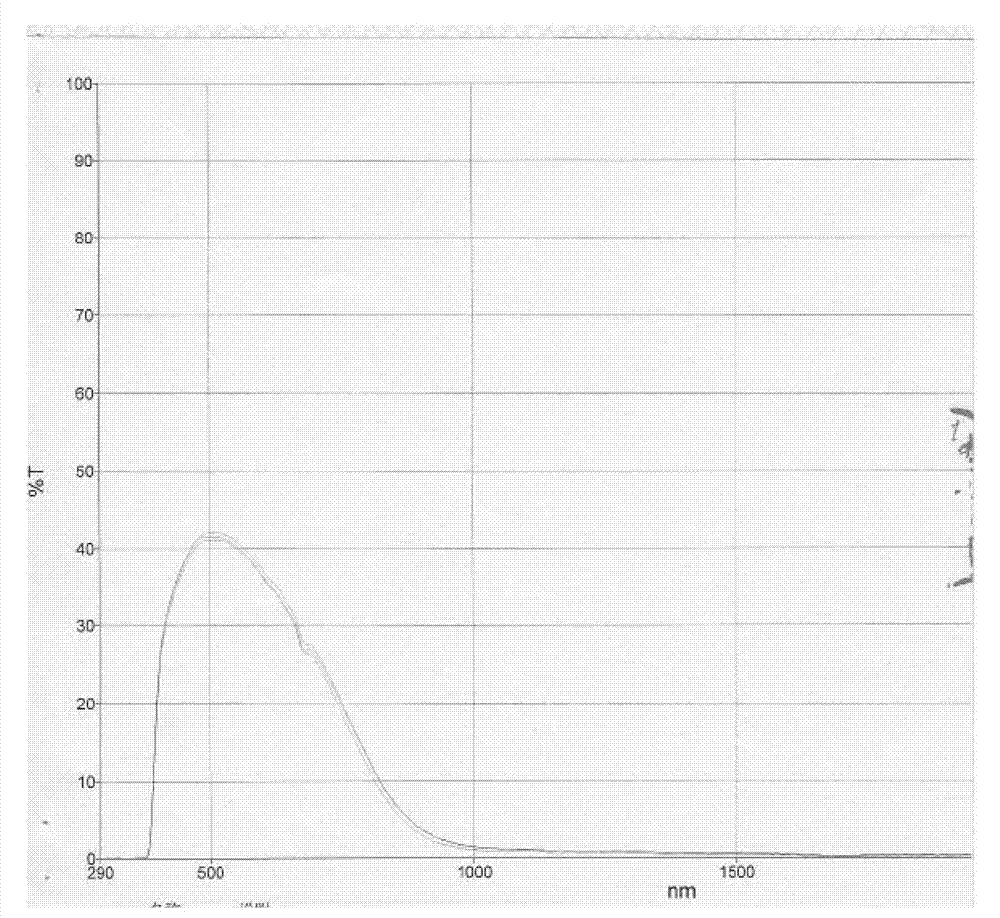

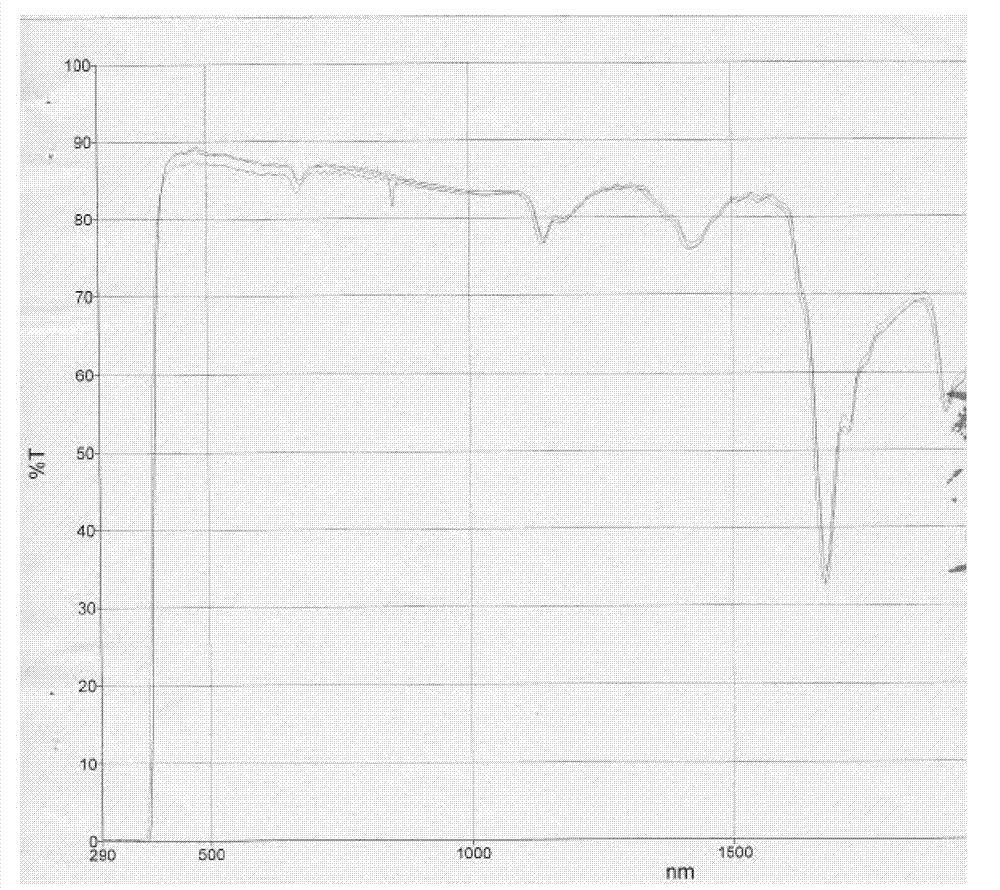

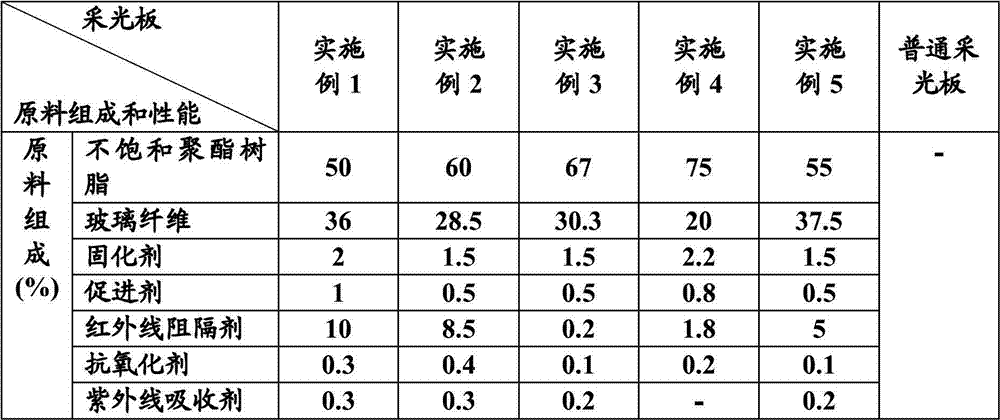

Low thermal radiation type fiber reinforced composite for lighting, daylighting panel and preparation method thereof

ActiveCN102816425AImprove insulation effectGood mechanical propertiesSynthetic resin layered productsInfraredGlass fiber

The invention relates to a low thermal radiation type fiber reinforced composite for lighting, a daylighting panel and a preparation method thereof. The composite comprises 50-80% of unsaturated polyester resin (UPR), 18-45% of glass fibers, 0-1% of an assistant, 1.0-2.5% of a curing agent, 0.3-1.0% of an accelerator and 0.1-10% of an infrared barrier, wherein the assistant is one or more of an antioxidant, an ultraviolet light absorber and a light stabilizer, and the infrared barrier is a nanometer oxide capable of absorbing or blocking infrared rays. Through reasonable design of the formulaof the low thermal radiation type fiber reinforced composite for lighting, blocking of infrared rays can be effectively achieved on the premise that the lighting rate completely satisfies using requirements.

Owner:SUZHOU MORE V COMPOSITE MATERIAL

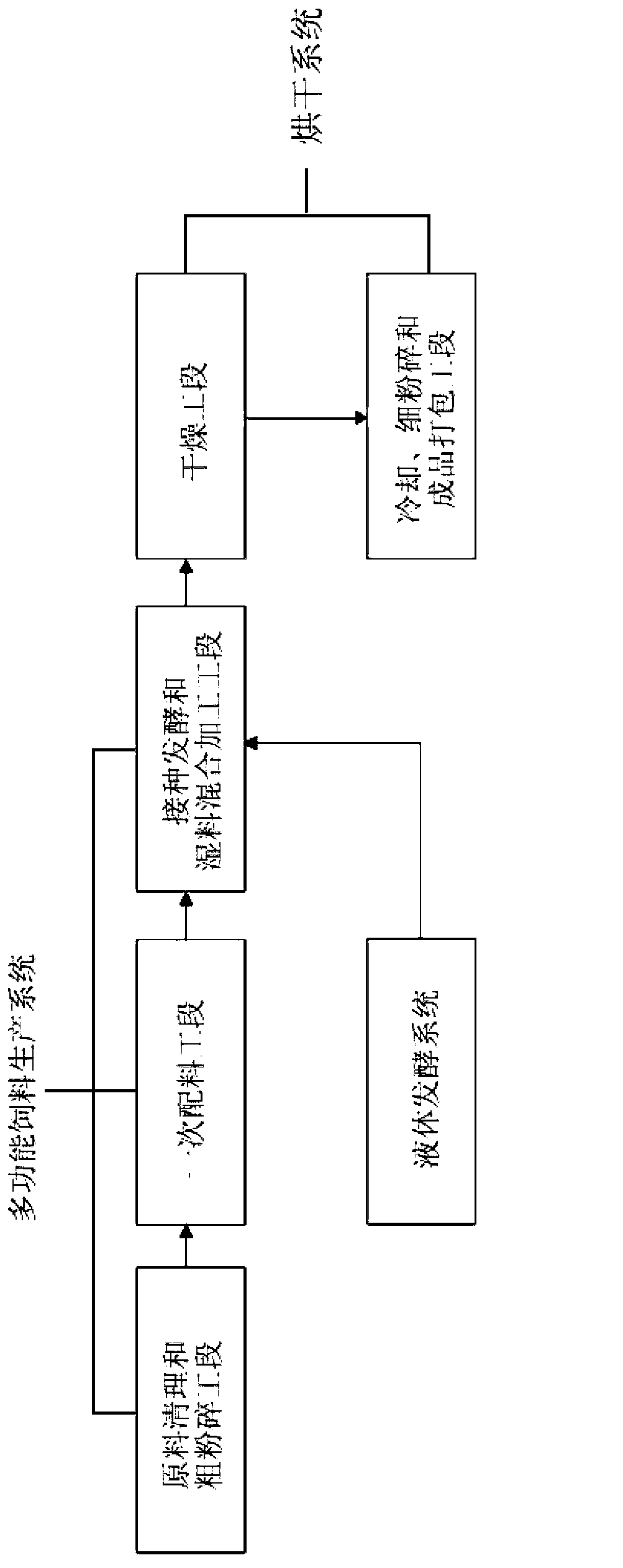

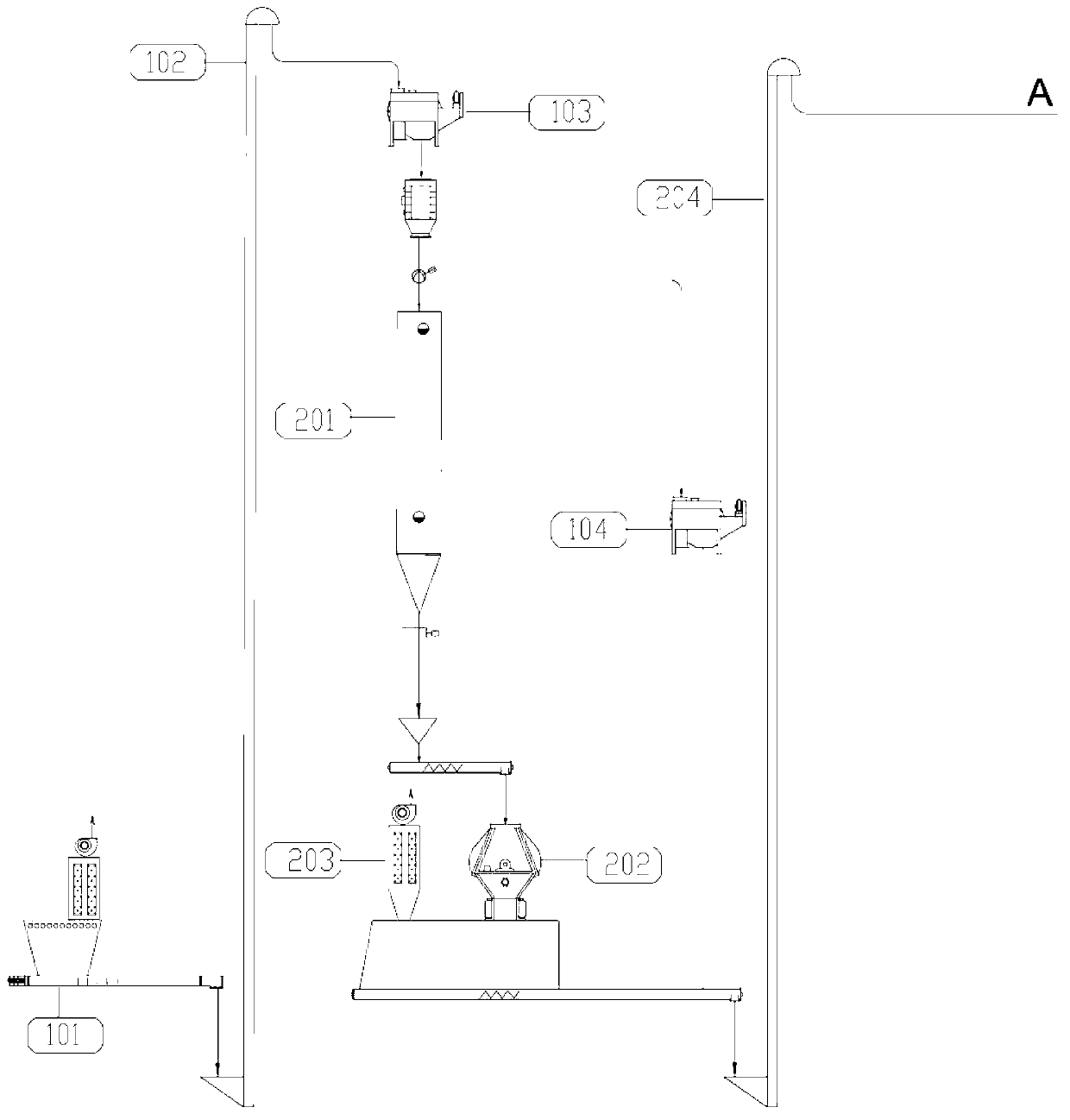

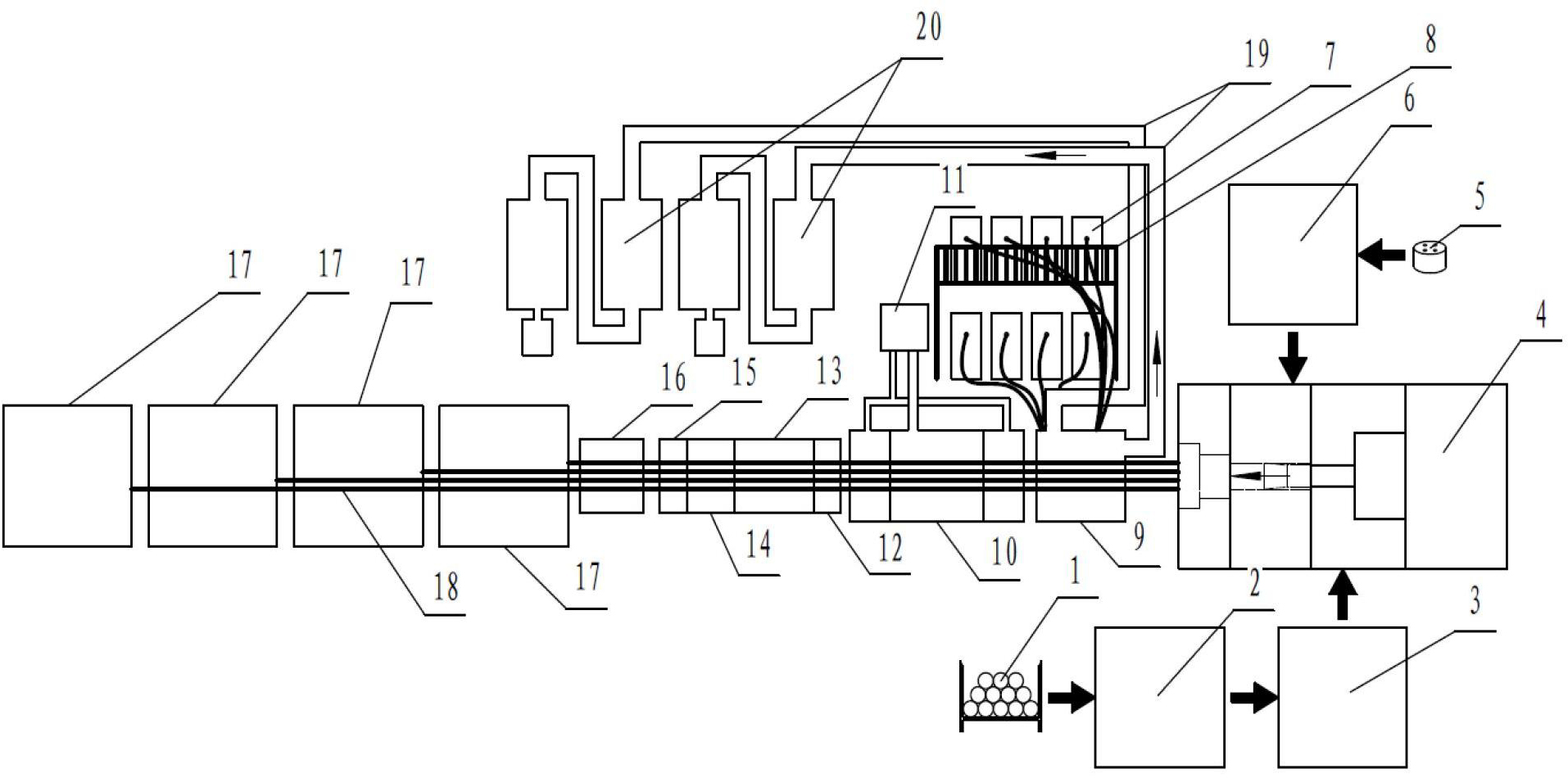

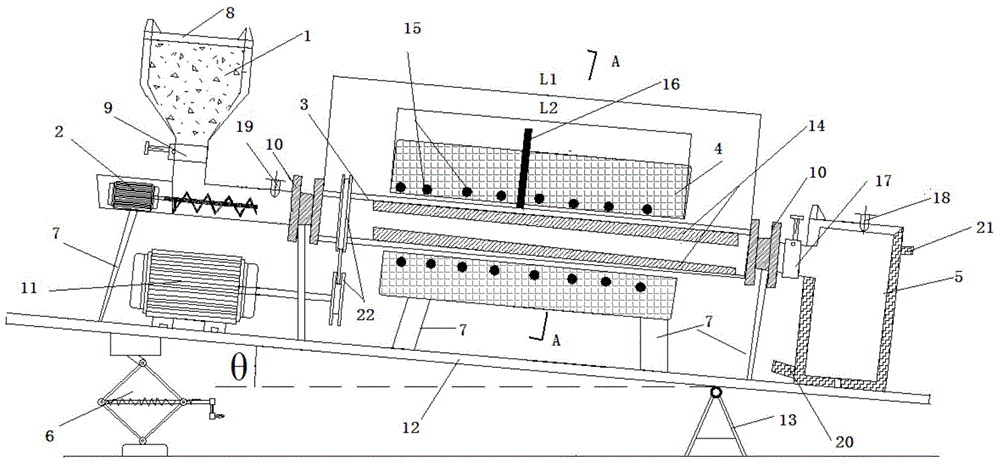

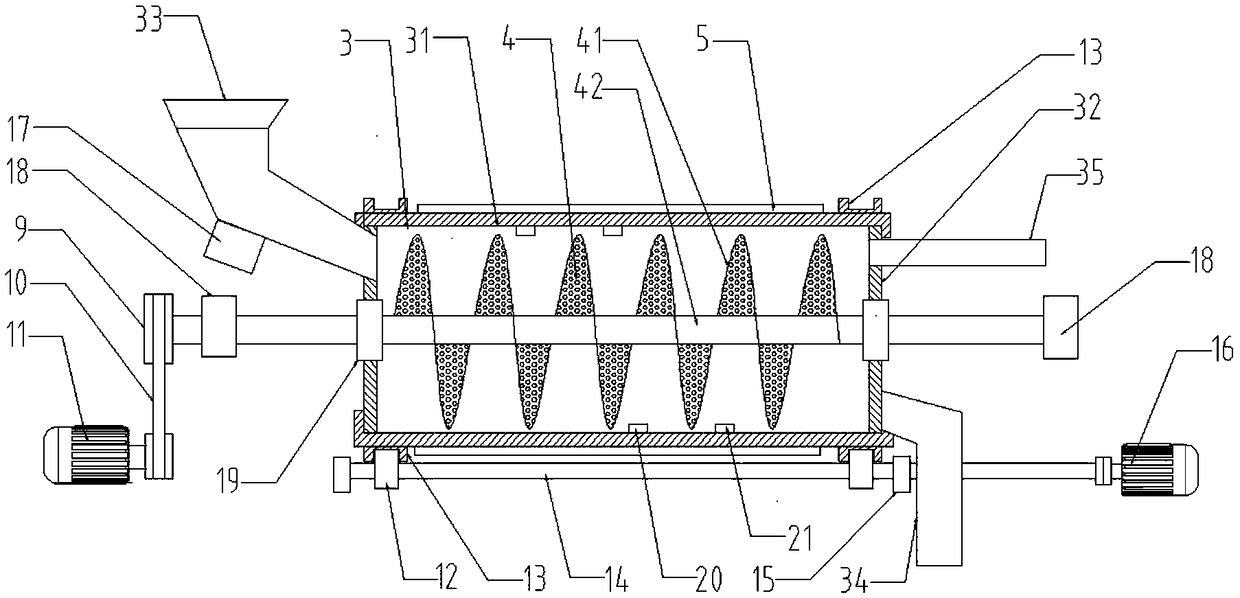

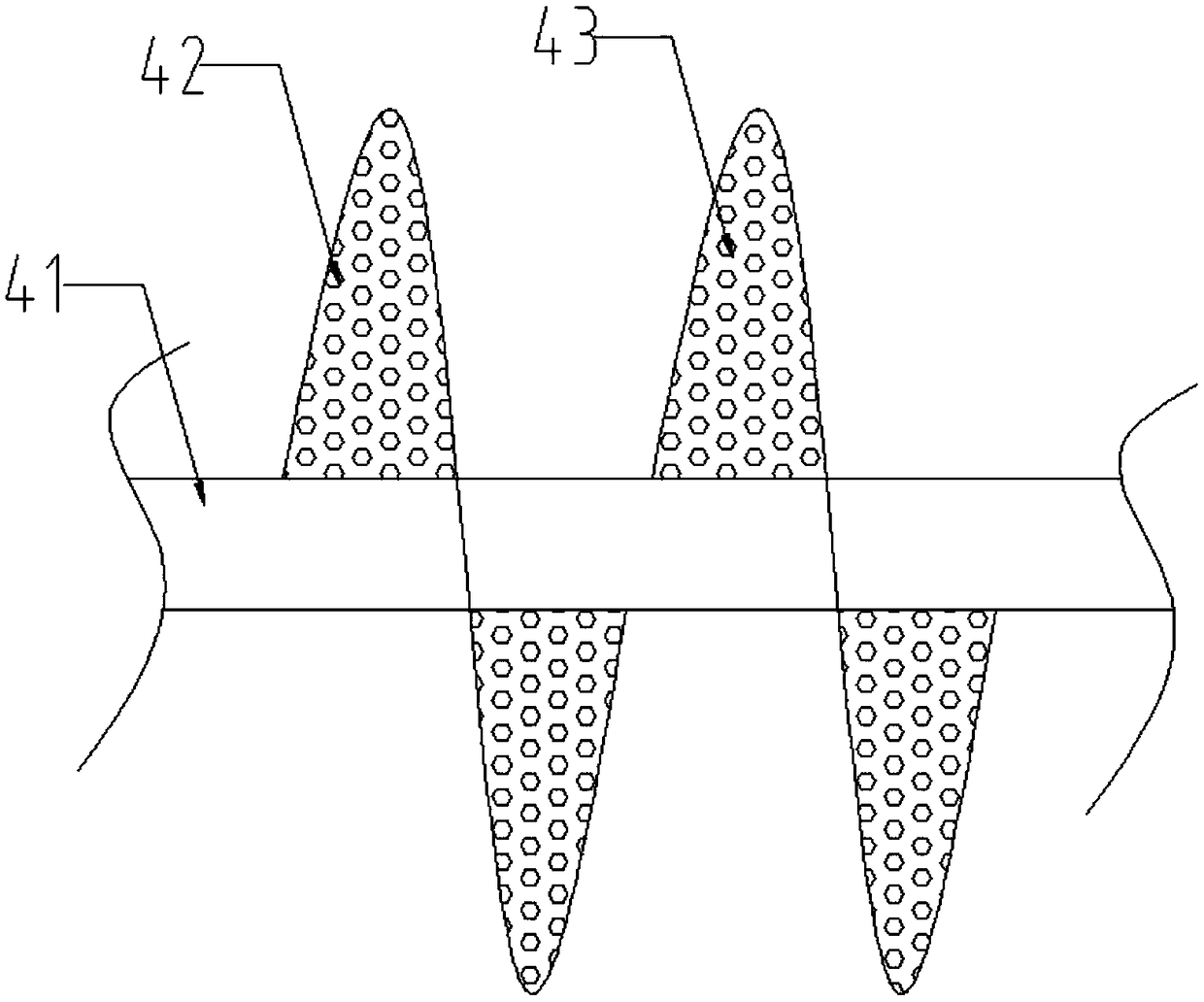

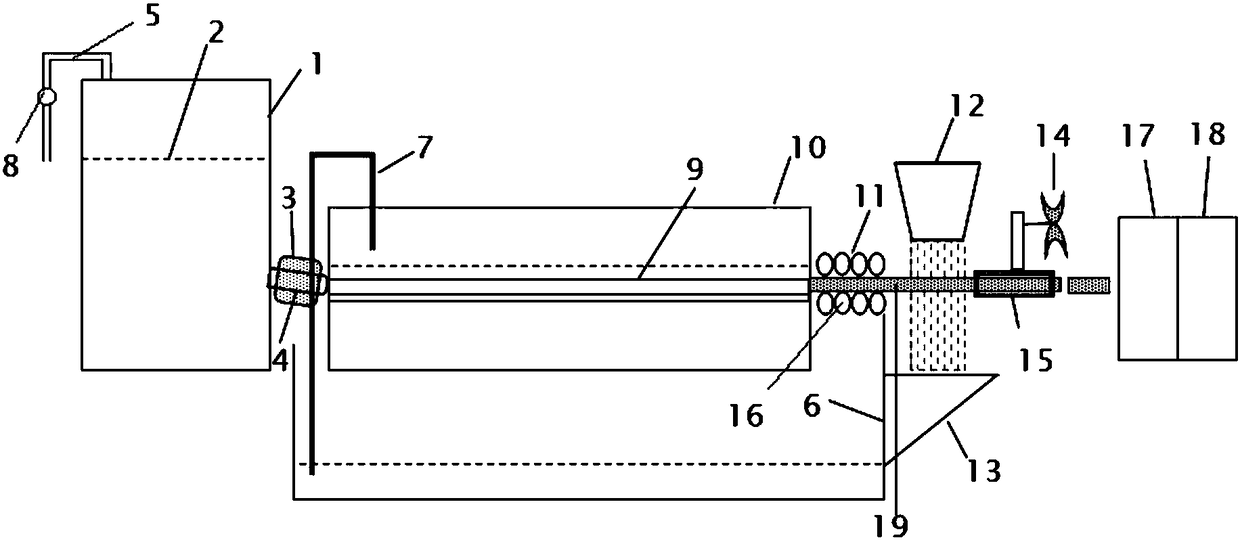

Production device and method of biological feeds

ActiveCN103126042ARealize continuous mass productionPrevent rustFeeding-stuffWork performanceAutomation

The invention provides a production device of biological feeds. The production device is composed of a multifunctional feed production system, a liquid fermentation system and a drying system, the multifunctional feed production system further comprises a raw material clearing and coarse grinding working section, a primary burdening working section and an inoculation fermentation and wet material mixing production working section, and the drying system further comprises a drying working section and a cooling, refine smashing and end product packing working section. The feed production device and a method are high in automation and mechanization degree, stable in working performance, high in work efficiency and simple and convenient to operate and achieve industrialization and large-scale production of probiotic fermented feeds.

Owner:张有聪

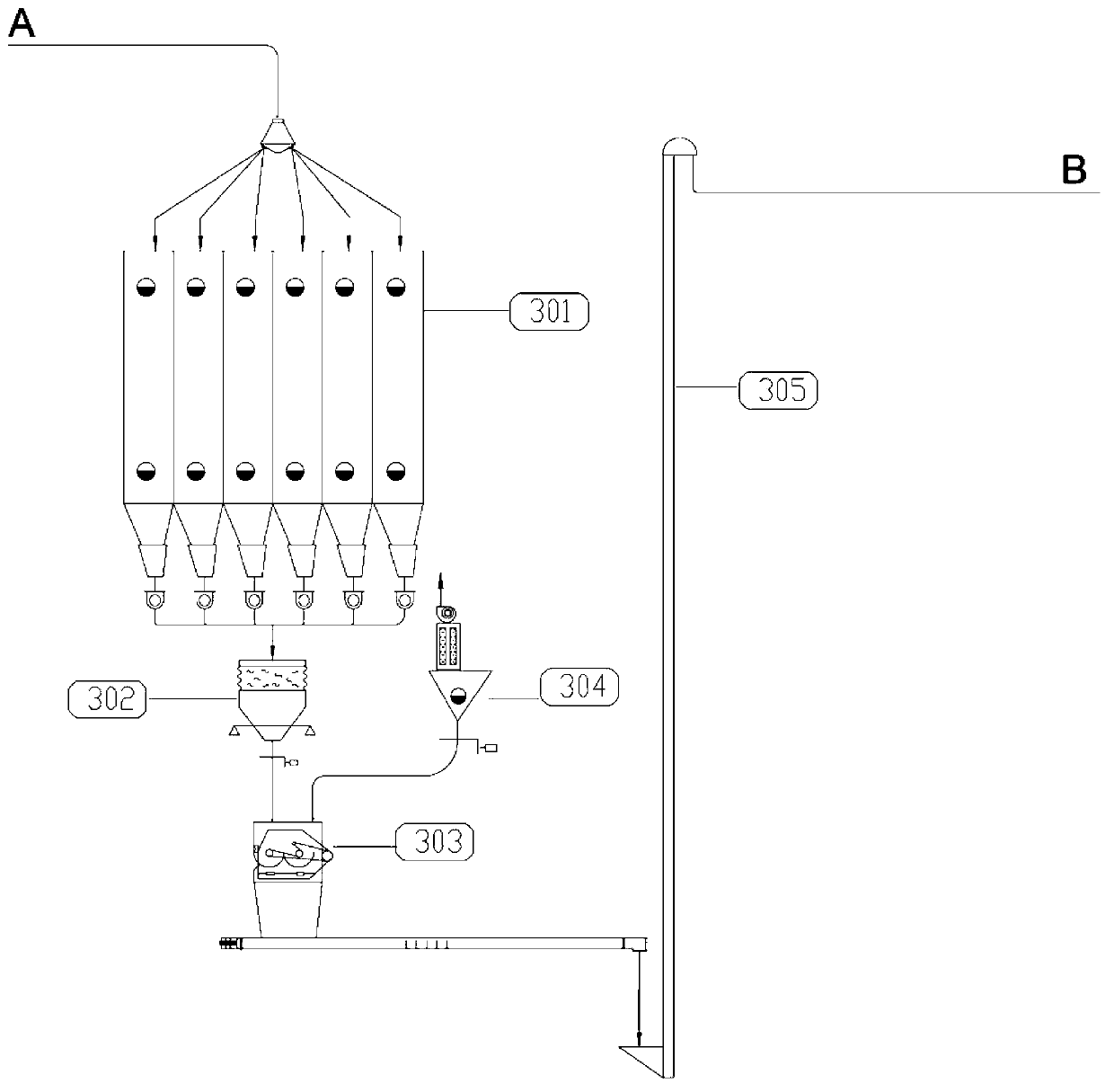

Process for casting ball iron flywheel by iron model sand covering

InactiveCN103143675ASimple processOvercome inherent weaknessesFoundry mouldsMoulding machinesFlywheelCasting

The invention discloses a process for casting a ball iron flywheel by iron model sand covering. The process is characterized by comprising the steps of die assembly for an iron model and a die, sand covering modeling, solidifying, drawing, die assembling, accumulating sprues, molten iron smelting and processing, casting, cooling, die opening, and cast and die cleaning. According to the process for casting the ball iron flywheel by the iron model sand covering, the process for clay sand is simplified, the inherent defects of the clay sand are overcome, free-dead-head production of the ball iron flywheel is achieved, process product yield is improved, and continuous volume production is achieved.

Owner:LUOYANG NEW FIRE ENERGY SAVING TECH PROMOTION

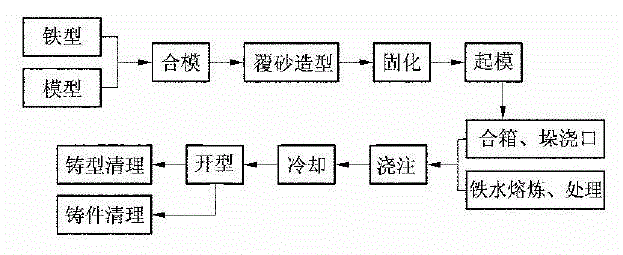

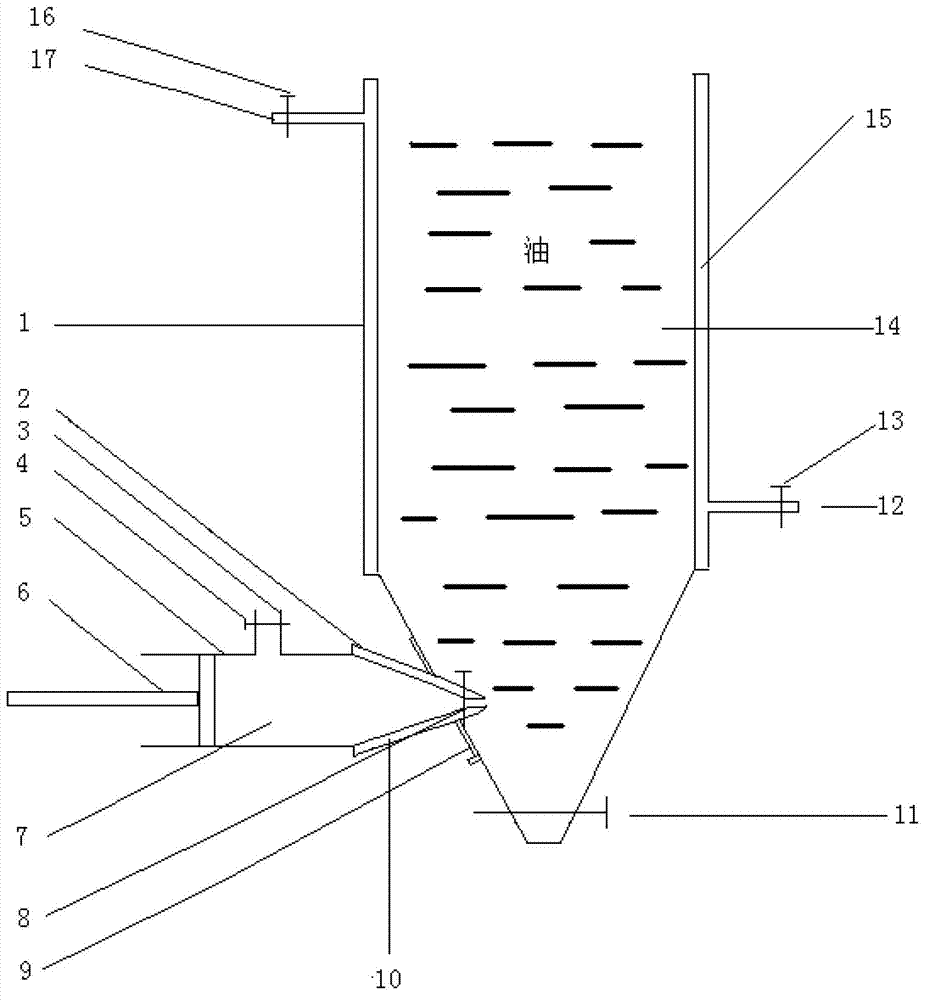

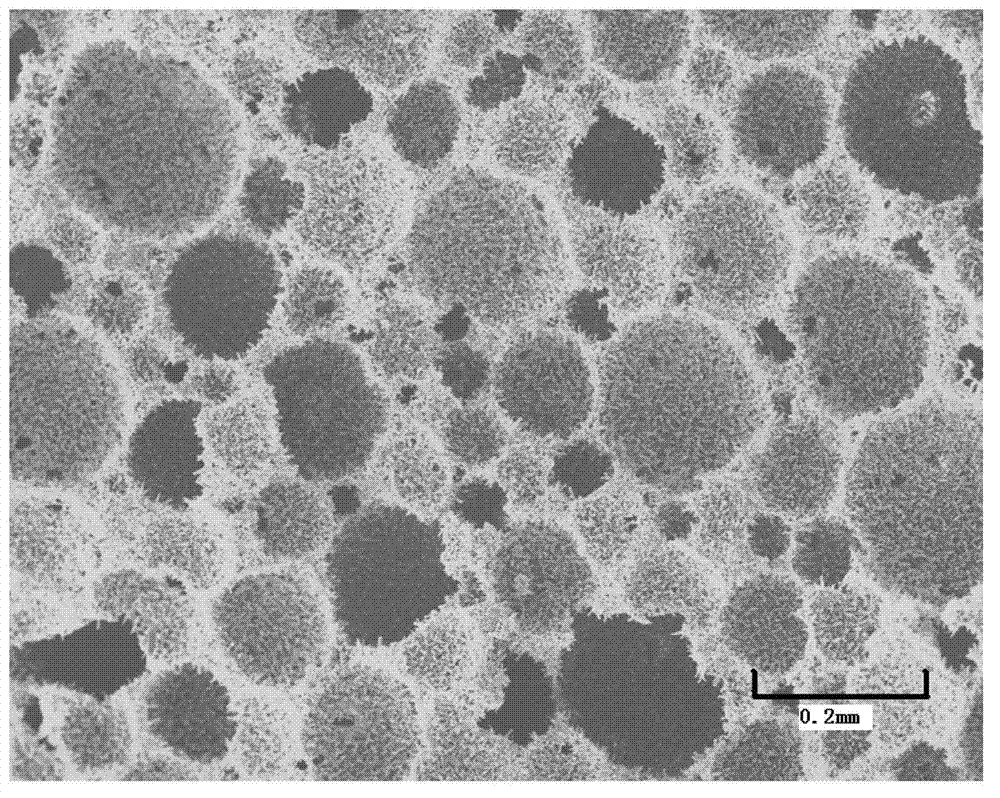

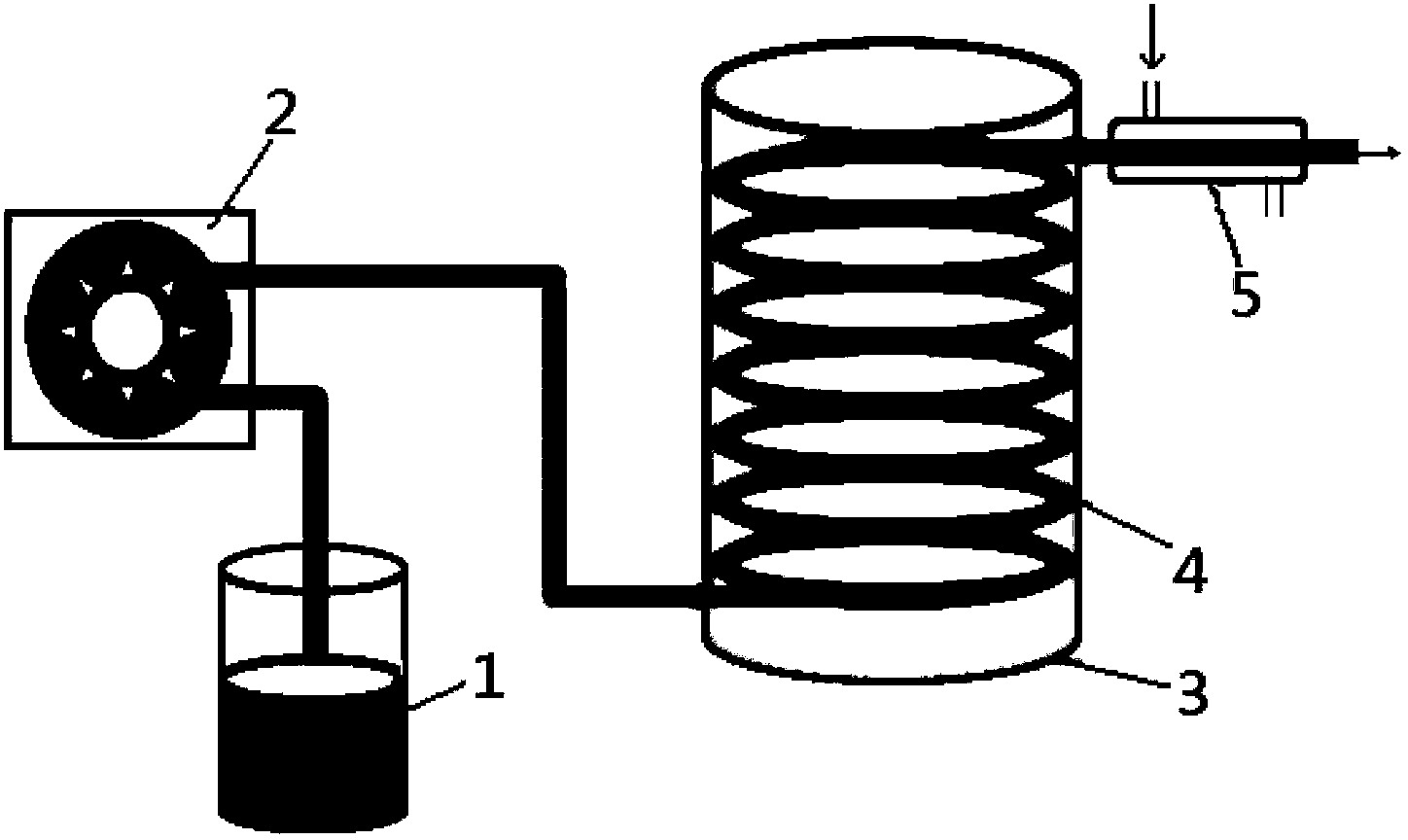

Method and device for preparing porous ceramic micro beads

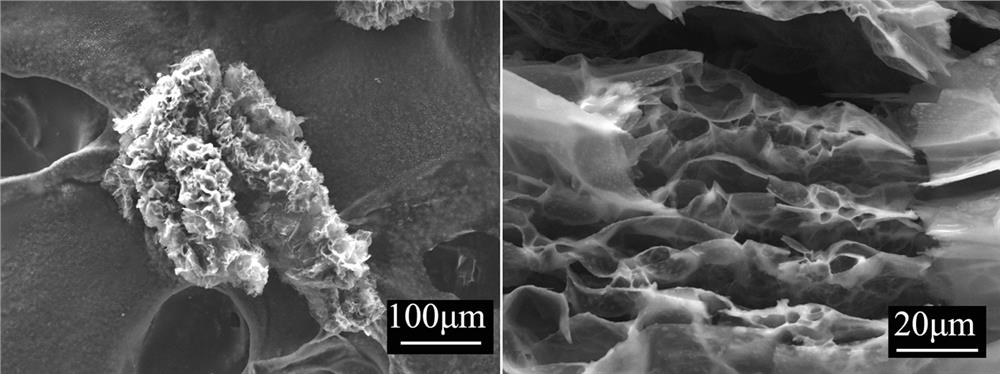

The invention discloses a method and a device for preparing porous ceramic micro beads. The method comprises the following steps of: mixing an organic monomer and a crosslinking agent with water according to a certain proportion for dissolving, adding ceramic powder and a dispersing agent into a solution, and performing ball milling to obtain a ceramic suspension with high solid phase content and low viscosity; adding a foaming agent, an initiator and a catalyst into the suspension for stirring to obtain water-based stable foam ceramic slurry; and continuously injecting the water-base slurry into an oily medium of a certain temperature by using the device for preparing the porous ceramic micro beads to form foam slurry spheres, floating and curing into porous ceramic micro bead blanks in the oily medium, collecting, cleaning, drying and sintering to obtain a porous ceramic micro bead product. The invention further discloses a device for preparing the porous ceramic micro beads. The device comprises a micro bead forming tower and an injection gun, and can be used for realizing continuous automatic injection and generation of spheres. The device has universality, and can be used for realizing large-scale continuous production of porous ceramic micro beads which are of different systems and are 0.3-4.0 millimeters in diameter.

Owner:TSINGHUA UNIV

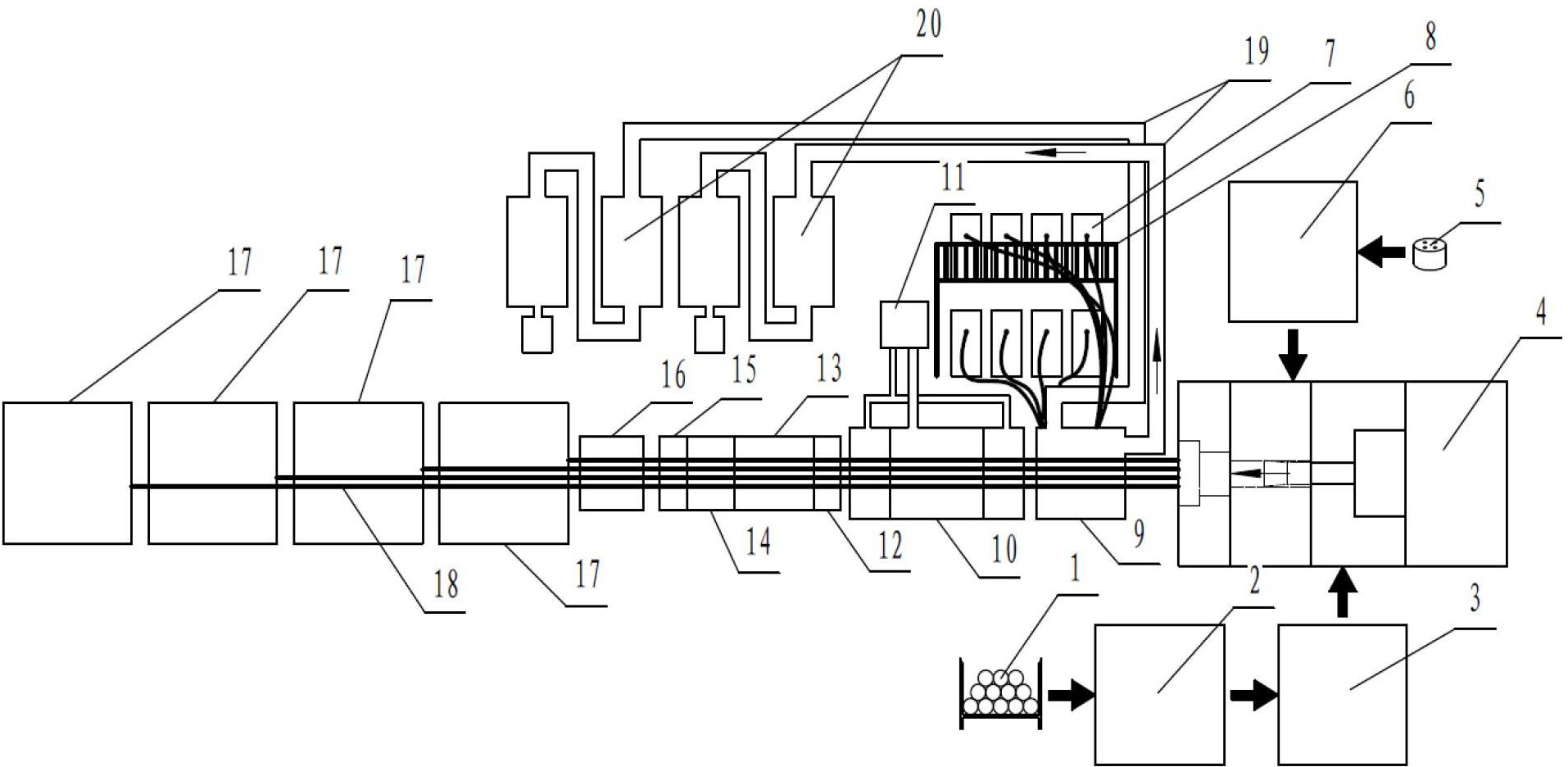

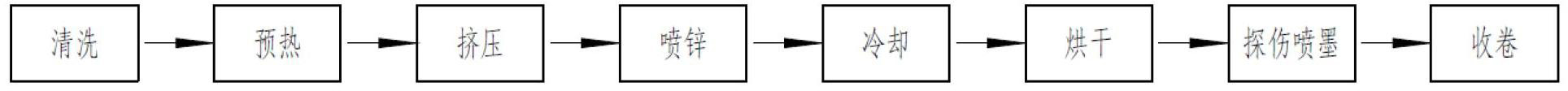

Technology for continuously extruding coils by aluminum and aluminum alloy parallel flow pipes

ActiveCN102641912AHigh degree of automationIncrease productivityDrying using combination processesMolten spray coatingZincHot blast

The invention discloses a technology for continuously extruding coils by aluminum and aluminum alloy parallel flow pipes, which comprises the following steps of: (1) cleaning, (2) preheating, (3) extruding, (4) zinc spraying, (5) cooling, (6) drying, (7) flaw detection ink jetting, and (8) rolling. The technology integrates continuous extrusion, zinc spraying, cooling, drying, flaw detection, flaw marking, rolling and other processes, has high automation degree, stable process and quality, and high production efficiency, and the continuous batch production is successfully realized; the disqualified part of the product is more thoroughly marked; the drying of the product adopts a double-level drying process of a cold knife and hot blast tunnel drying equipment; and the production process is environmental-friendly and safe.

Owner:江苏亚太航空科技有限公司

Copper-chromium alloy powder continuous producing method

The invention discloses a copper-chromium alloy powder continuous producing method. The copper-chromium alloy powder continuous producing method comprises the following steps that (1) 0.7-40% of chromium by the weight ratio and the balance copper are charged into a ceramic crucible to be melted and stirred through electromagnetic induction; (2) metal liquid is atomized and broken into a lot of fine liquid drops, induction heating is conducted on a flow guide nozzle, the molten liquid flows out from the flow guide nozzle at the bottom of the ceramic crucible, and the atomization powder making process is repeated; and (3) the fine liquid drops are solidified into spherical and sub-spherical particles in the flying process and then screened into metal powder with various particle sizes. According to the copper-chromium alloy powder continuous producing method, heating melting is conducted through electromagnetic induction, electromagnetic induction stirring is adopted, rapid gas atomization is adopted, thus, copper-chromium alloy forms the small liquid drops and is quickly cooled, and the situation that copper is separated from chromium at the solid state is avoided.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

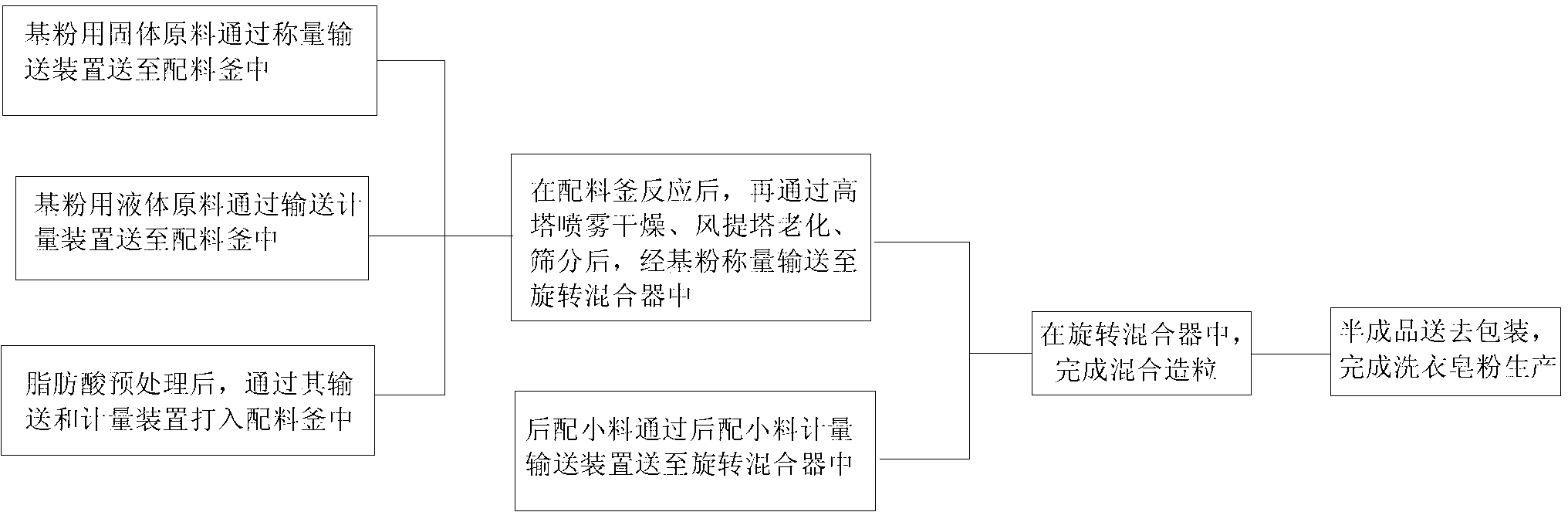

Laundry soap powder slurry, preparation method thereof and industrial production technology of laundry soap powder

ActiveCN103074182AUniform dispersion and adhesion stateLow viscositySurface-active non-soap compounds and soap mixture detergentsDetergent powders/flakes/sheetsWork in processLaundry

The invention discloses laundry soap powder slurry, a preparation method thereof and an industrial production technology of laundry soap powder. The industrial production technology mainly comprises the steps of: 1) directly adopting fatty acid and liquid alkali to conduct neutralization reaction in a batching kettle of a front preparation system to participate in slurry preparation, 2) allowing the slurry after technical optimization treatment to be capable of smoothly entering a high-tower powder spraying system through a high pressure pump to produce base powder, and 3) adding the base powder and other post preparation raw materials, continuously and evenly mixing with a screw mixer, preparing a semifinished product of the laundry soap powder, conveying to a powder bin with a conveyor belt, and packaging into a finish product. According to the technology, high-tower powder spraying equipment is adopted for production, and no other additional special device is added. Compared with the laundry soap powder produced by the original technology (adding powdered to granular sodium aliphatate during post preparation), the produced laundry soap powder has the characteristics of uniform dispersion and adhesion of sodium aliphatate, short product solution time, low agglomeration resistance and good liquidity, and automatic packaging and continuous mass production of the soap powder can be realized.

Owner:GUANGZHOU LIBY

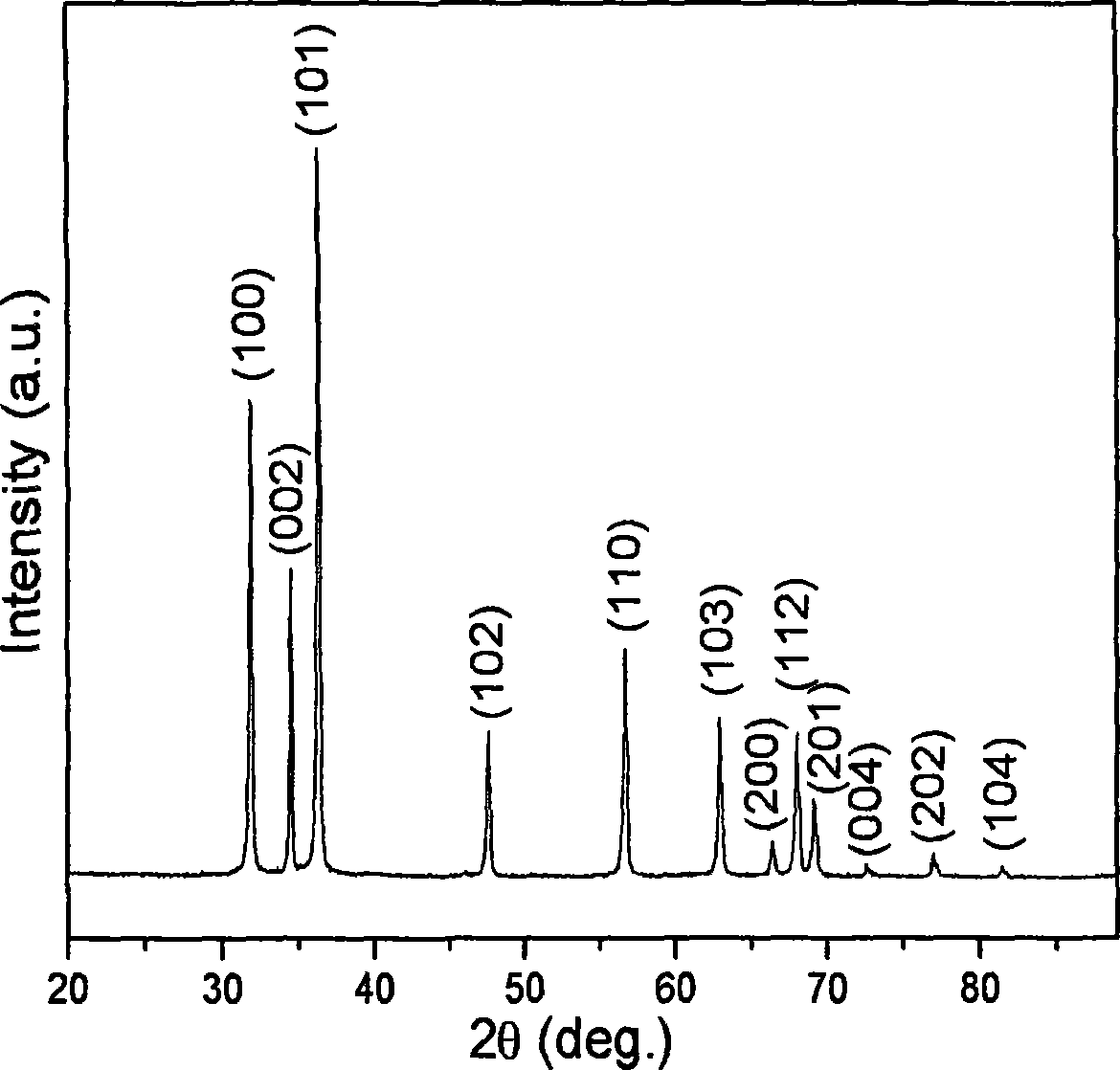

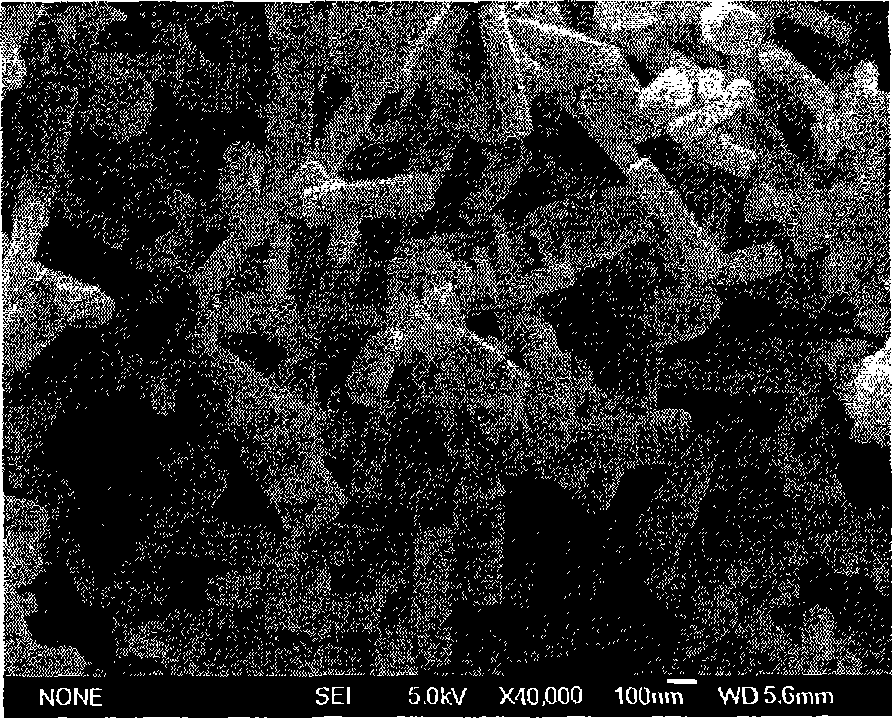

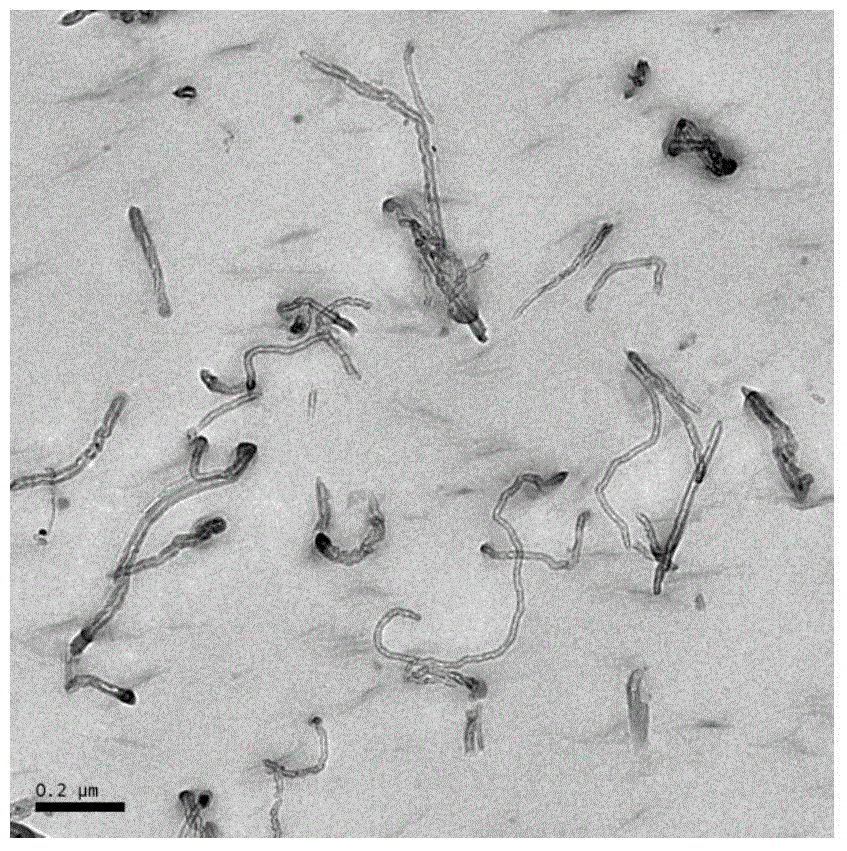

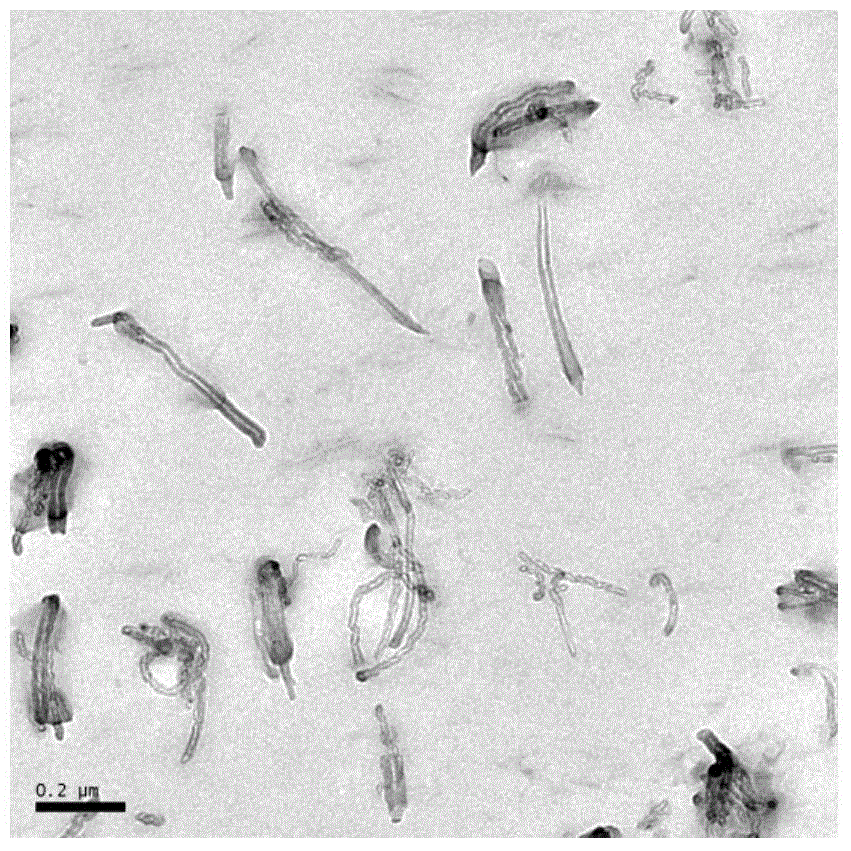

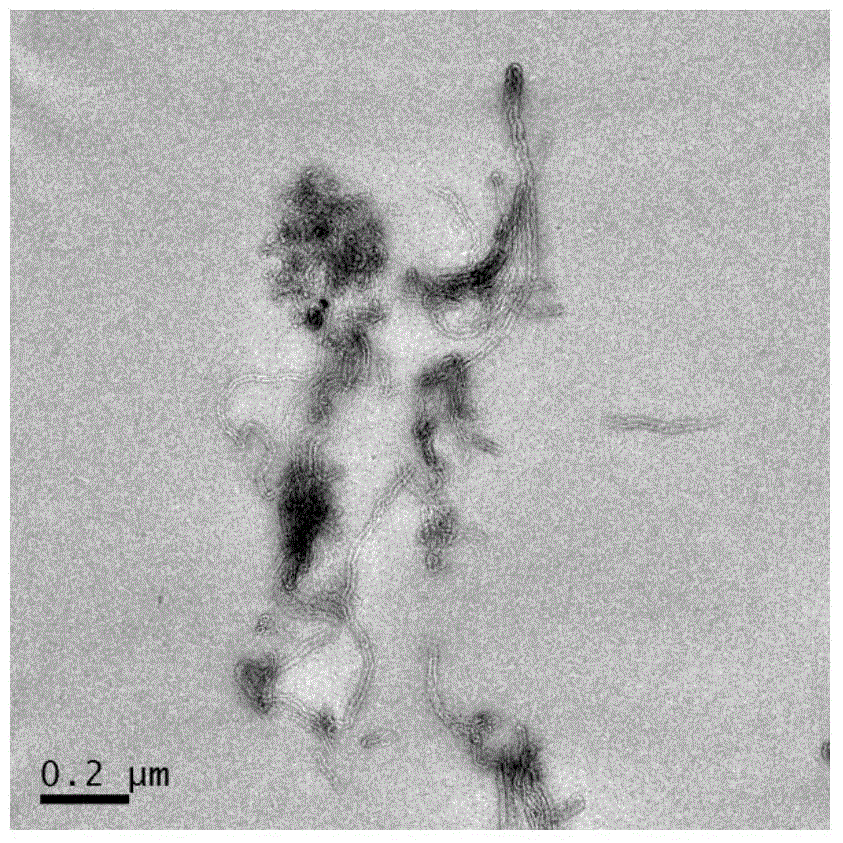

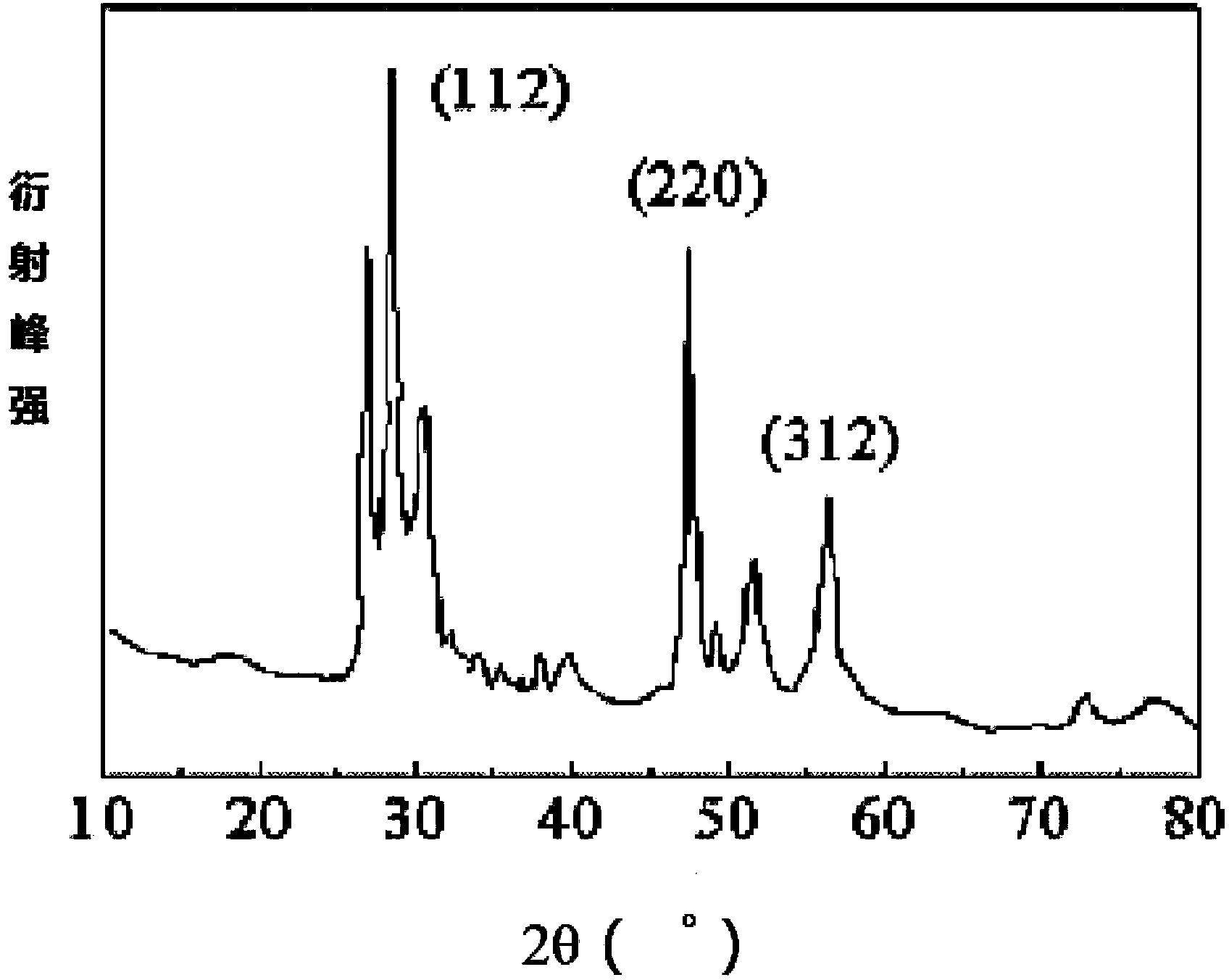

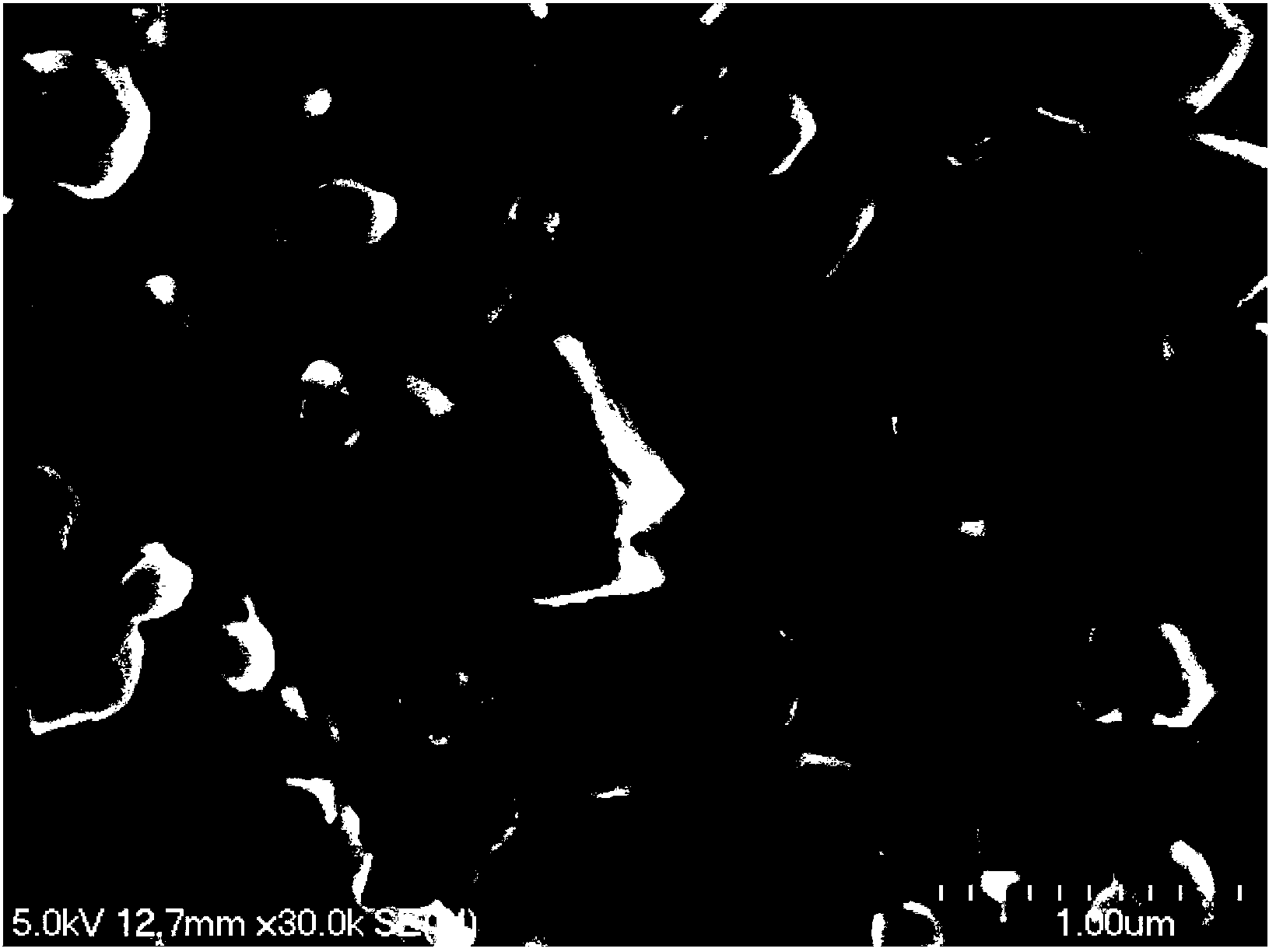

Preparation of transient metal doped nano zinc oxide crystal whisker

InactiveCN101498034ANo pollution in the processWide range of raw materialsPolycrystalline material growthZinc oxides/hydroxidesZinc hydroxideGas phase

The invention relates to a method for preparing nanometer zinc oxide whiskers doped with transitional mental. Zinc powder, zinc oxide, alkaline zinc carbonate or zinc hydroxide, and the like are used as zinc predecessors, and metal and metal chloride are used as doped element predecessors. After being mechanically mixed, the zinc predecessors and the doped element predecessors are added to plasma arcs to have a gas phase reaction after high-frequency induction plasma is instantaneously gasified at a high temperature, and then the uniformly doped nanometer zinc oxide whiskers are obtained by appearance control in a condensing process. The method is characterized by being applied to the doping of various elements and having high doping content and strong suitability, and the prepared nanometer zinc oxide whiskers are uniformly doped and have controllable appearance. The invention has short technological process and high yield and can continue mass production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

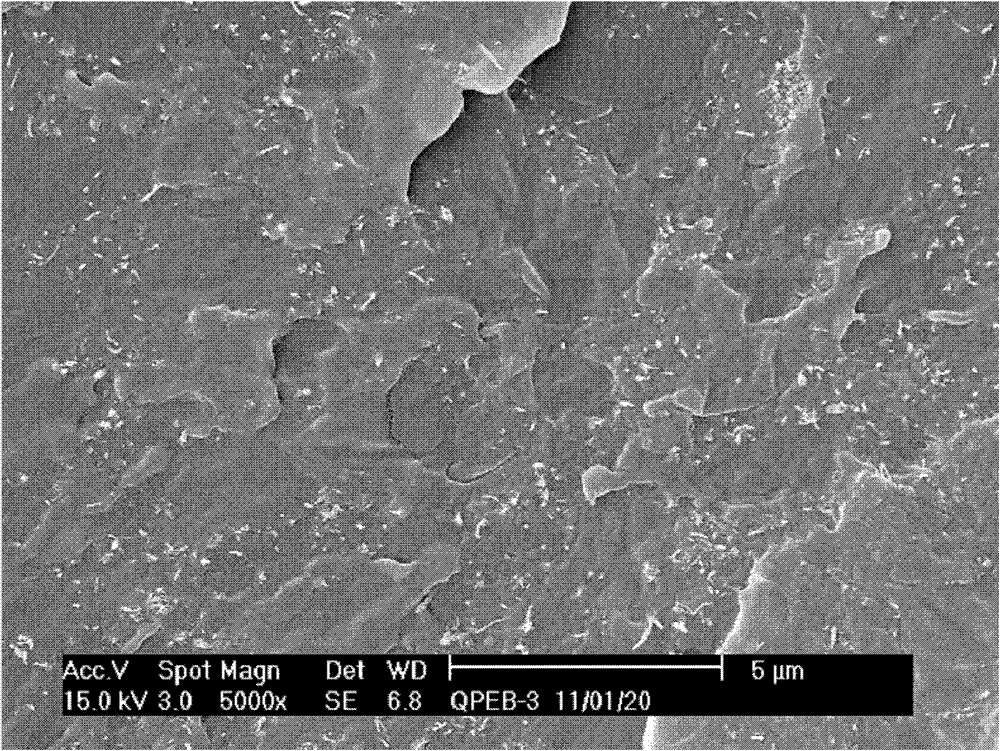

Carbon nanotube / polylactic acid conductive composite material and preparation method thereof

The present invention relates to the field of polymer materials, and further relates to a carbon nanotube / polylactic acid conductive composite material and a preparation method thereof. The carbon nanotube / polylactic acid conductive composite material contains the following groups in blending: 100 parts by weight of polylactic acid and 0.5-10 parts by weight of a modified carbon nanotube conductive powder; the material can also include 0.2-4.0 parts by weight of a non-ion surface active agent, can also further comprise 0.03-0.05 part by weight of an antioxidant. The method of the invention is simple in operation process and suitable for continuous mass production. The obtained carbon nanotube / polylactic acid conductive composite material has good carbon nanotube dispersion, improved aggregation phenomena, good anti-antistatic and conductive properties, and biodegradability and biological compatibility, and can be applied to the fields of electronics, communication and bio-engineering.

Owner:CHINA PETROLEUM & CHEM CORP +1

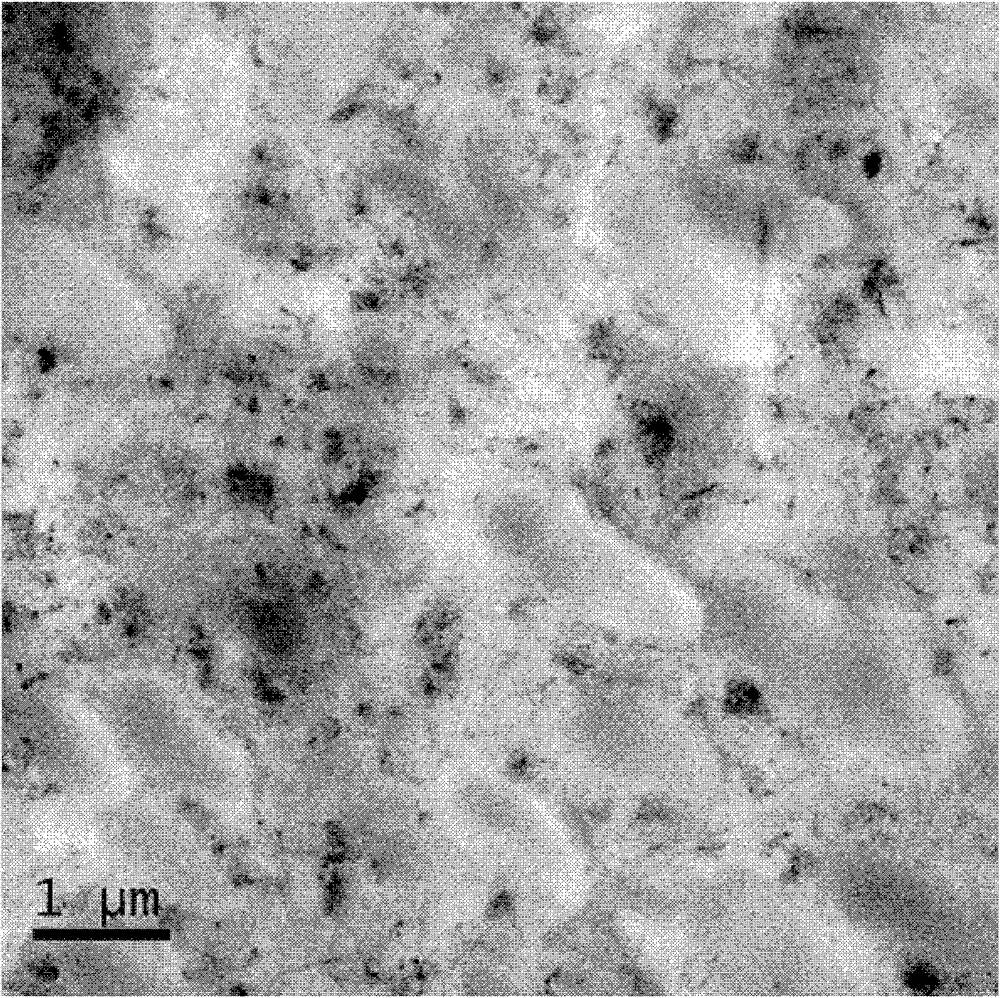

Carbon nanotube/polyolefin conductive composite material and preparation method

The invention discloses a carbon nanotube / polyolefin conductive composite material and a preparation method. The composite material is blended by the following components: 100 parts by weight of polyolefin resin (1) and polyolefin resin (2); and 0.5-4 parts by weight of carbon nanotube, wherein the weight ratio of the polyolefin resin (1) to the polyolefin resin (2) is (90-50):(10-50). The method comprises melt blending of the components according to the using amounts to prepare the carbon nanotube / polyolefin conductive composite material. The carbon nanotube / polyolefin conductive composite material of the invention can effectively reduce the adding amount of carbon nanotube, is simple in preparation process, can greatly improve the material conductivity with few adding amount, and can realize mass continuous production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for continuous preparation of copper zinc tin sulfur film

The invention discloses a method for continuous preparation of a copper zinc tin sulfur (CZTS) film. The method comprises the preparation steps of: preparation of a reaction precursor solution, continuous preparation of CZTS nanocrystals, purification of the CZTS nanocrystals, blending of a CZTS ink, coating drying and selenation sulfurization annealing treatment. Specifically, the means of continuous preparation of the CZTS nanocrystals makes the continuous and mass preparation of the CZTS film come true, and the preparation is free of the problems of uneven heating and limited heat and mass transfer. At the same time, the selenation sulfurization annealing treatment endows the prepared film with high photoelectric conversion efficiency and strong stability. And the method has the advantages of simple operation and low cost, thus being suitable for marketing production.

Owner:徐东

Method for producing ultra-low-carbon steel by duplex process

InactiveCN101463410ARealize continuous mass productionImprove continuous casting production capacitySlab casterSlag

The invention provides a method for producing ultra-low carbon steel using a duplex process, comprising converter smelting, RH vacuum processing and slab continuous casting. The method is characterized in that when the converter tapping is finished, the initial quality transforming treatment is carried out on top slag, LF secondary refining is added after the RH vacuum processing, and the final quality transforming treatment is carried out on the top slag; a slab caster with medium thickness is adopted for the continuous casting. With reasonable technical design, the method for producing ultra-low carbon steel using the duplex process can eliminate the problems of the nozzle clogging caused by aluminium oxide and high inclusion defect incidence during the production of the caster with medium thickness, realize the continuous large-scale production of the ultra-low carbon steel on a non-traditional conticaster, further lower the production cost and improve the continuous casting production capability for the ultra-low carbon steel.

Owner:ANGANG STEEL CO LTD

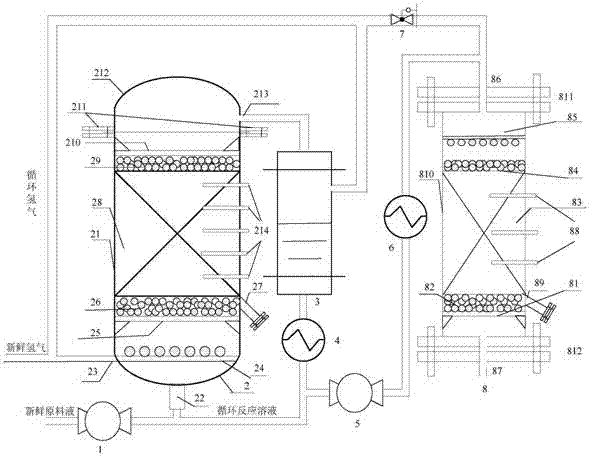

External circular reaction device suitable for hydrogenation exothermic reaction

ActiveCN103566837AControl the average operating temperatureUniform reaction temperaturePreparation by hydrogenationChemical/physical processesReaction temperatureExothermic reaction

The invention discloses an external circular reaction device suitable for hydrogenation exothermic reaction. The external circular reaction device mainly comprises a first-stage hydrogenation reactor, a second-stage hydrogenation reactor, a hydrogen circulation loop and a liquid circulation loop. The liquid circulation loop in the reaction device is used for mixing a part of reacted solution and a fresh raw material solution, so that the concentration of raw materials in the reactor is reduced, the bed temperature rise generated by a heat release effect caused by hydrogenation is relieved, and the temperature inside the first-stage hydrogenation reactor is effectively controlled. A way that the raw material solution and hydrogen flow up in parallel is adopted in the first-stage hydrogenation reactor, a liquid phase is used as a continuous phase, and a catalyst is soaked into a reaction liquid, so that the reaction temperature of a catalyst bed keeps constant, meanwhile, the overhigh local temperature of a reaction site on the surface of the catalyst is avoided, furthermore, the occurrence of polymerization reaction of organic matters on the surface of the catalyst is effectively inhibited, the carbon deposition quantity on the surface of the catalyst is low, and the service life of the catalyst is remarkably prolonged. The external circular reaction device disclosed by the invention is suitable for continuously producing succinic anhydride by using maleic anhydride through catalytic hydrogenation and preparing 1- 4-butanediol by using butynediol through hydrogenation.

Owner:SHANXI UNIV

Welding method for ferri-chromium-aluminum cold-rolled thin plate during continuous production of cold line

ActiveCN104227253AAchieve continuous annealing productionAvoid lostWelding/soldering/cutting articlesWelding apparatusThin slabSpot welding

The invention discloses a welding method for a ferri-chromium-aluminum cold-rolled thin plate during continuous production of a cold line, and belongs to the field of welding methods. The method for realizing welding by three steps comprises: (1) spot welding by a machine; (2) electric welding by a worker; (3) welding of stacking sheets. A ferri-chromium-aluminum material is welded by the three-step method, so that stability and reliability of welding are guaranteed, and continuous annealing and acid pickling production of the cold-rolled ferri-chromium-aluminum material on the cold line is realized.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

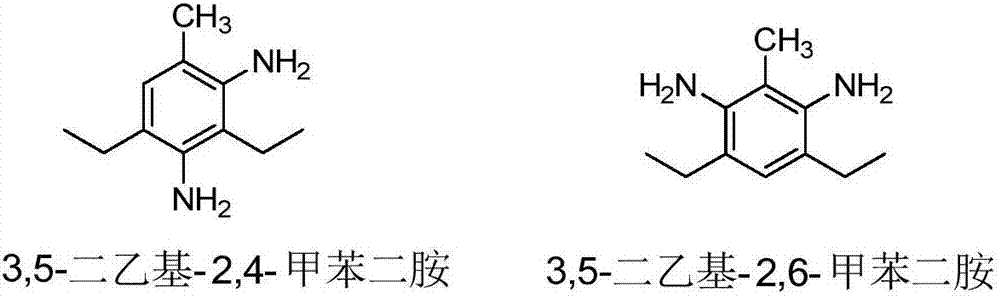

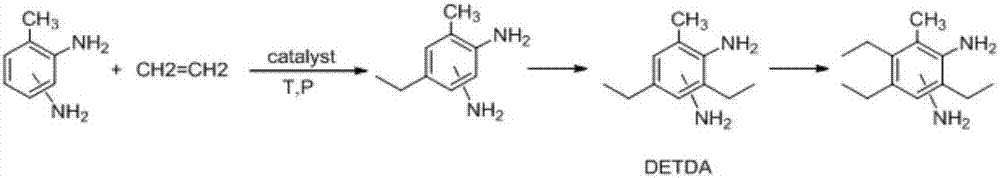

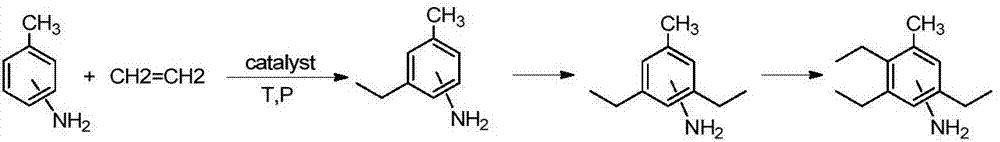

Catalyst for producing diethyltoluene diamine and preparation method and application of catalyst

ActiveCN107999089AHigh activityHigh selectivityAmino preparation from aminesCatalyst activation/preparationAlkyl transferActive component

The invention discloses a supported catalyst for producing diethyltoluene diamine. The supported catalyst for producing diethyltoluene diamine comprises a modified carrier and a supported active component, wherein the modified carrier contains SiO2 and B2O3 obtained by decomposing a soluble silicon-containing compound and a boron-containing compound through drying and roasting after introducing the soluble silicon-containing compound and the boron-containing compound into the carrier. The invention further discloses a preparation method and application of the catalyst. The catalyst disclosed by the invention is suitable for the alkylation of aromatic amines, especially has extremely high activity and selectivity for continuous production of diethyltoluene diamine with toluenediamine alkylation. The catalyst has a simple preparation process, high economy and better application prospects.

Owner:WANHUA CHEM GRP CO LTD

High-purity hydrogen peroxide preparation

InactiveCN1189387CMeet the requirements of cleaning agentsSolve the problem of relying on importsIon-exchange column/bed processesPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSemiconductor chipCleansing Agents

A process for preparing high-purity hydrogen peroxide from the aqueous solution of industrial hydrogen peroxide includes such steps as contacting with strong-alkaline macroreticular anionic exchange resin, contacting with strong-acidic macroreticular cationic exchange resin, contacting with mixed ionic exchange resin, and filtering via microfilter membrane. Its advantages are colourless, no order, high stability and purity, and low cost. It can be used as detergent for semiconductor chip.

Owner:TIANJIN UNIV OF SCI & TECH

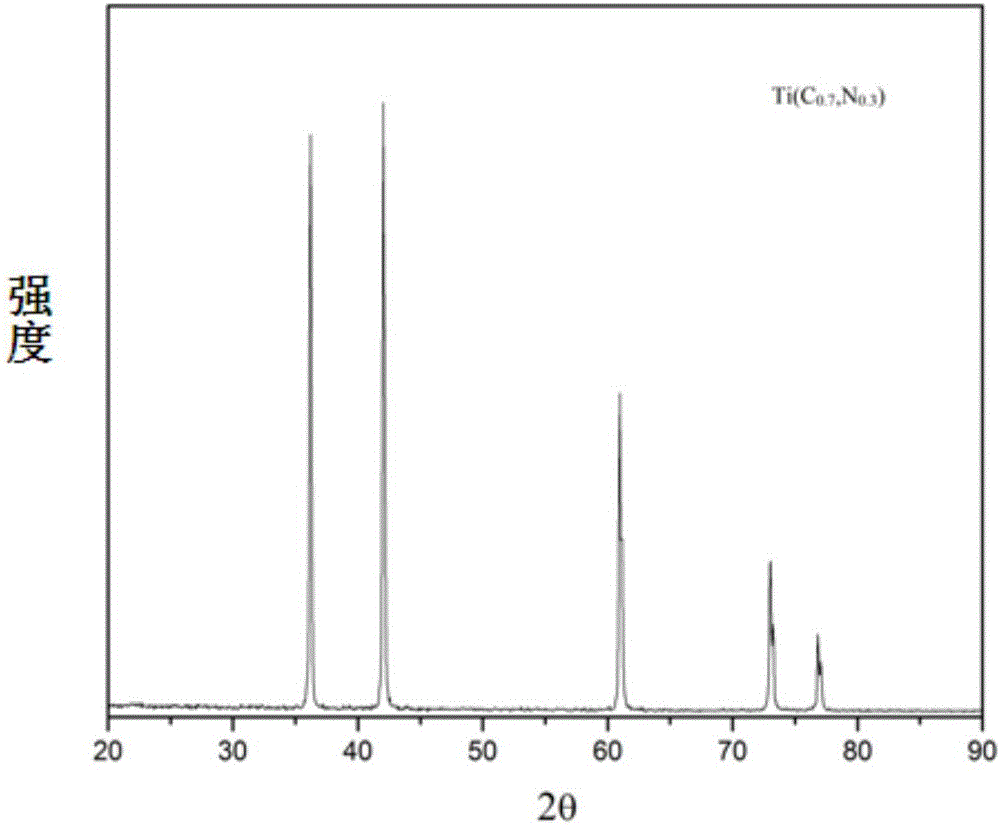

M<y>(C<X>N<1-X>) powder rotary type dynamic continuous preparation method and sintering device

The invention relates to a M<y>(C<X>N<1-X>) powder rotary type dynamic continuous preparation method and a sintering device, wherein in the chemical formula of M<y>(C<X>N<1-X>), M is one of Ti, Cr, V, Ta, Mo, Nb, Zr, Hf, W and Mn, y is 1 or 2, X is greater than or equal to 0.1 and smaller than or equal to 0.9, and the preparation method comprises the following technological steps: (1), compounding, wherein the raw materials comprise compound powder of M and O and a reducing agent; (2), mixing and drying; (3), sintering, in an open system or closed system, a furnace tube is heated under the condition that the furnace tube is in a sloping state in which a discharge opening is lower than a feed opening and a rotation state, when the temperature in the furnace tube reaches the reaction temperature, the powder mixture obtained in step (2) is continuously fed into the furnace tube, the powder mixture, after entering the furnace tube, completes reaction in a manner of performing helical motion through a furnace tube heating area to form a reaction product to falls into a collecting chamber. According to the M<y>(C<X>N<1-X>) powder rotary type dynamic continuous preparation method and the sintering device, provided by the invention, single-phase M<y>(C<X>N<1-X>) powder can be obtained and continuous batch production can be realized.

Owner:SICHUAN UNIV

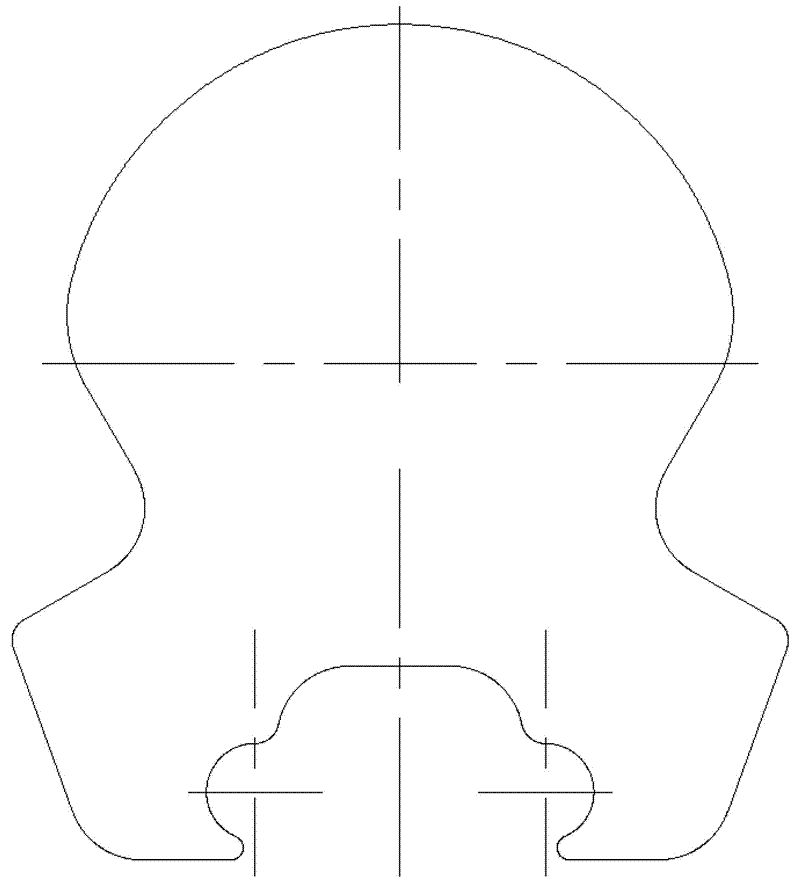

Hot extrusion mold for producing profile for electrified high-speed railway feedback line clamps

InactiveCN102366766ARealize continuous mass productionIncrease productivityExtrusion diesThermodynamicsEngineering

The invention provides a hot extrusion mold for producing a profile for electrified high-speed railway feedback line clamps. The mold core of the hot extrusion mold is of a single-cone integral type, and the inner cavity structure of the hot extrusion mold comprises an inlet region, a sizing region, a cone angle transition region and an outlet region, wherein the sizing region is enlarged conically toward the front face of the mold core to form the inlet region; the cone angle transition region is enlarged transitionally between the sizing region and the outlet region; and the cross-sectional shape and size of the sizing region are uniformly enlarged for 0.3-0.8mm on a single side compared with the shape and size of the profile. The hot extrusion mold provided by the invention is suitable for producing a profile copper product with a complex shape, and is especially suitable for producing various special profiles for electrified high-speed railway feedback line clamps, thereby laying a foundation for the subsequent drawing process, realizing continuous volume production of such products, improving production efficiency, reducing cost and shortening production cycle.

Owner:BAIYIN NONFERROUS GROUP

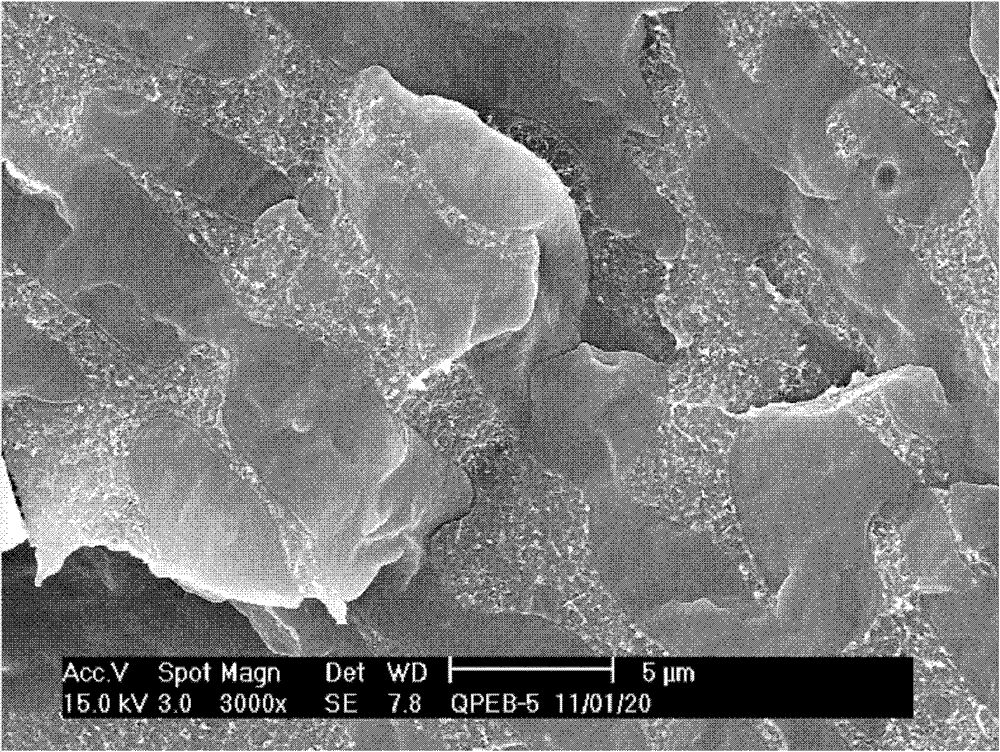

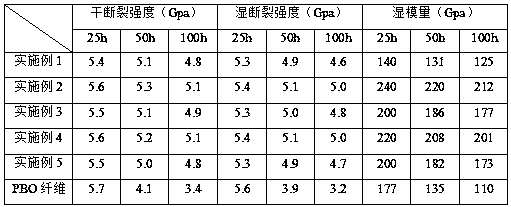

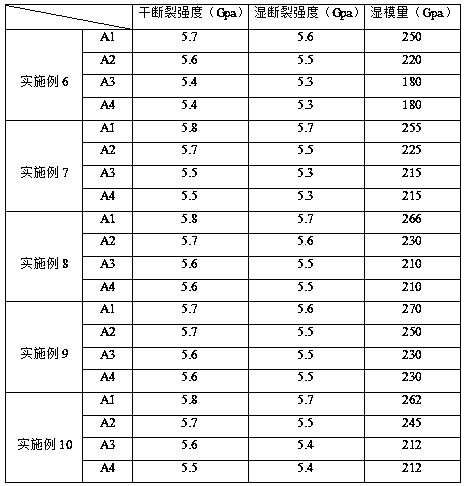

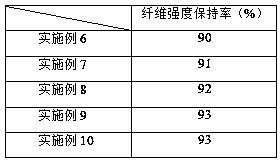

Ultraviolet light-resistant PBO fiber and preparation method thereof

ActiveCN107620204AImproves UV resistanceEnhanced interactionPhysical treatmentFibre typesBreaking strengthFiber

The invention discloses an ultraviolet light-resistant PBO fiber and a preparation method thereof. The ultraviolet light-resistant PBO fiber is prepared from PBO tows sequentially through surface chemical treatment, surface free radical reaction, anti-ultraviolet sizing treatment and drying. The ultraviolet light-resistant PBO fiber has the following parameters: the dry breaking strength is 5.4Gpa-5.6Gpa, the wet breaking strength is 5.2Gpa-5.4Gpa, and the wet modulus is 140Gpa-240Gpa. The ultraviolet light-resistant PBO fiber is prepared by modifying the PBO tows by virtue of the combinationof surface chemical treatment, surface free radical reaction and anti-ultraviolet sizing treatment, the PBO fiber can present relatively good ultraviolet resistance and can furthest preserve the mechanical properties of the PBO fiber, and the integral tensile strength and modules of the PBO fiber are not reduced.

Owner:CHENGDU XINCHEN NEW MATERIAL TECH CO LTD

Economic and environmental friendly technology for manufacturing cardboard paper and straw boards by using straws

InactiveCN102505576ANo pollution in the processHigh glossFibreboardFibrous raw materialsCardboardFiber

The invention discloses an economic and environmental friendly technology for manufacturing cardboard paper and straw boards by using straws, belonging to the field of papermaking methods; the economic and environmental friendly technology sequentially comprises the following steps of: a. smashing crop straws into pieces; b. adding the smashed straws to a grinding and splitting machine to be ground into crude fibers; c. adding water to the crude fibers generated by the grinding and splitting machine, and entering into a pulping machine for producing pulp; d. pressing the paper pulp produced by the pulping machine into the cardboard paper and straw boards; and e. recycling papermaking tail pulp wastewater as water used in the step in the step c. The economic and environmental friendly technology realizes the pollution-free manufacturing of the cardboard paper and the straw boards by using the straws under the condition of very simple working procedures, very little personnel and equipment funds investment, and very low production cost and energy consumption.

Owner:何学信

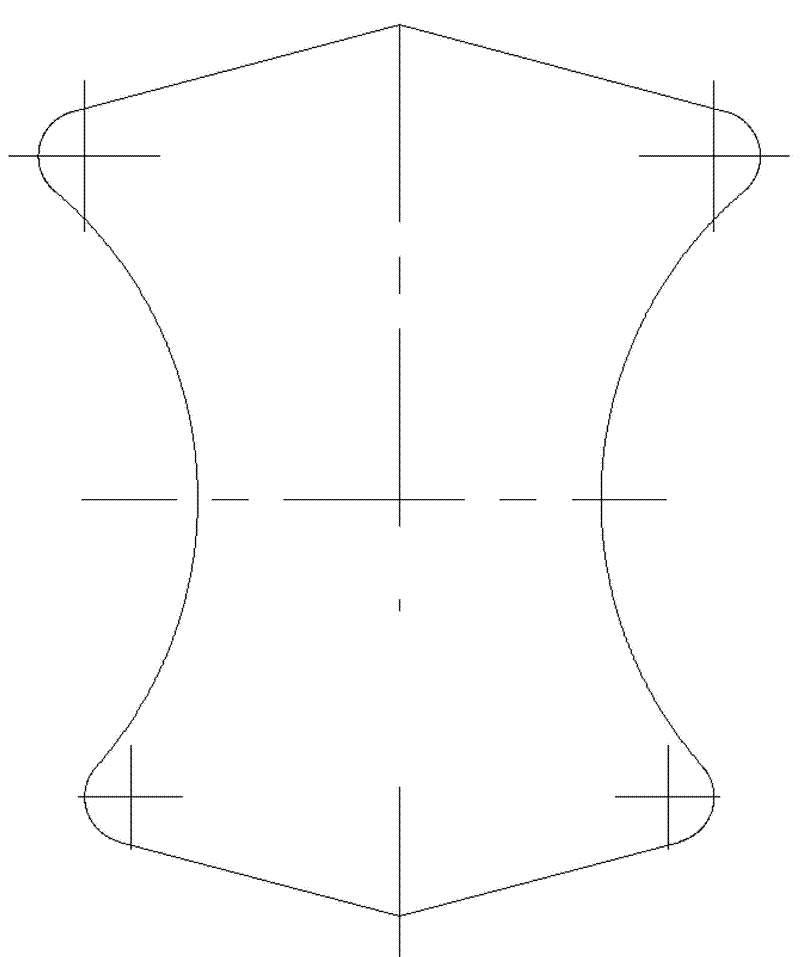

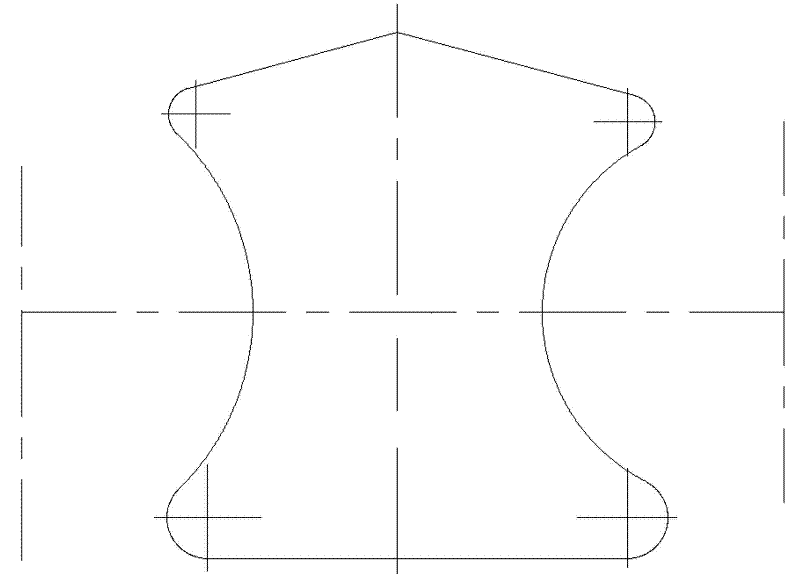

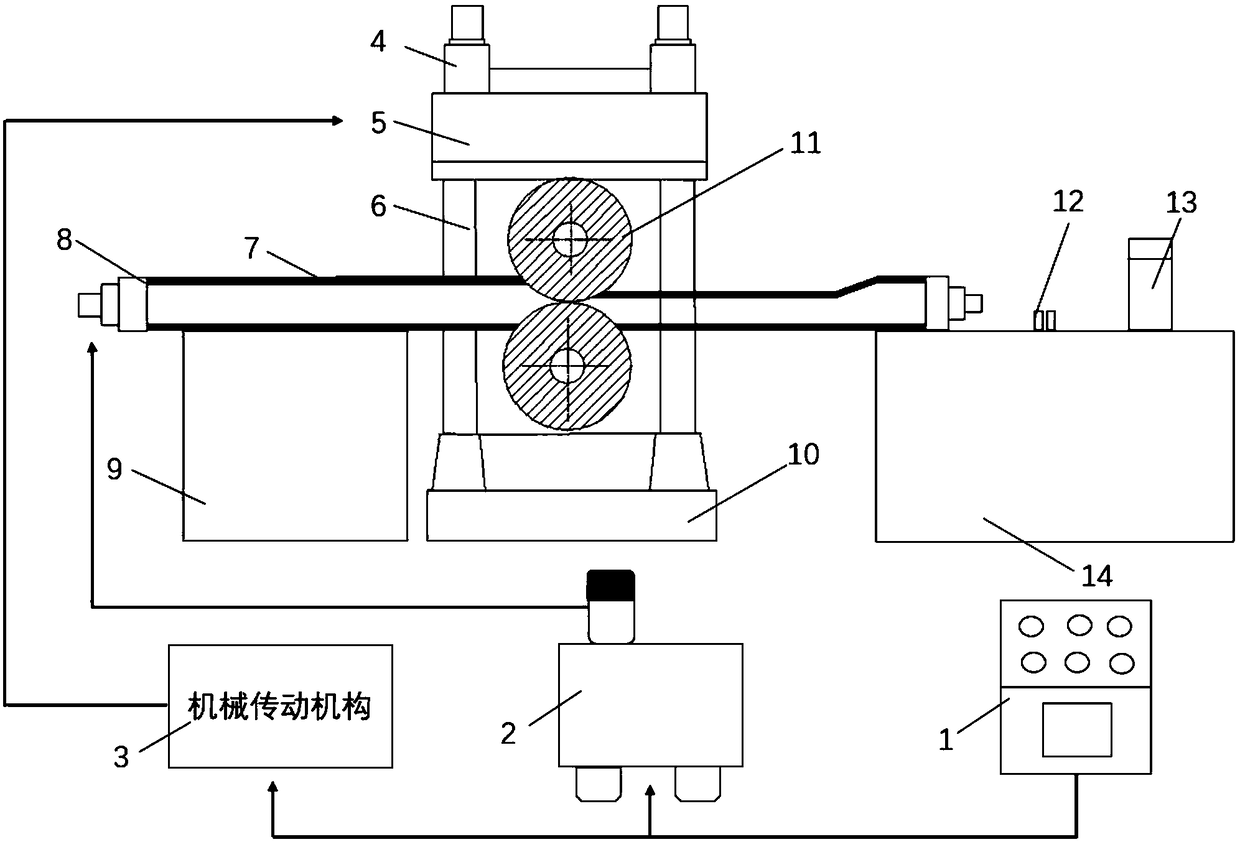

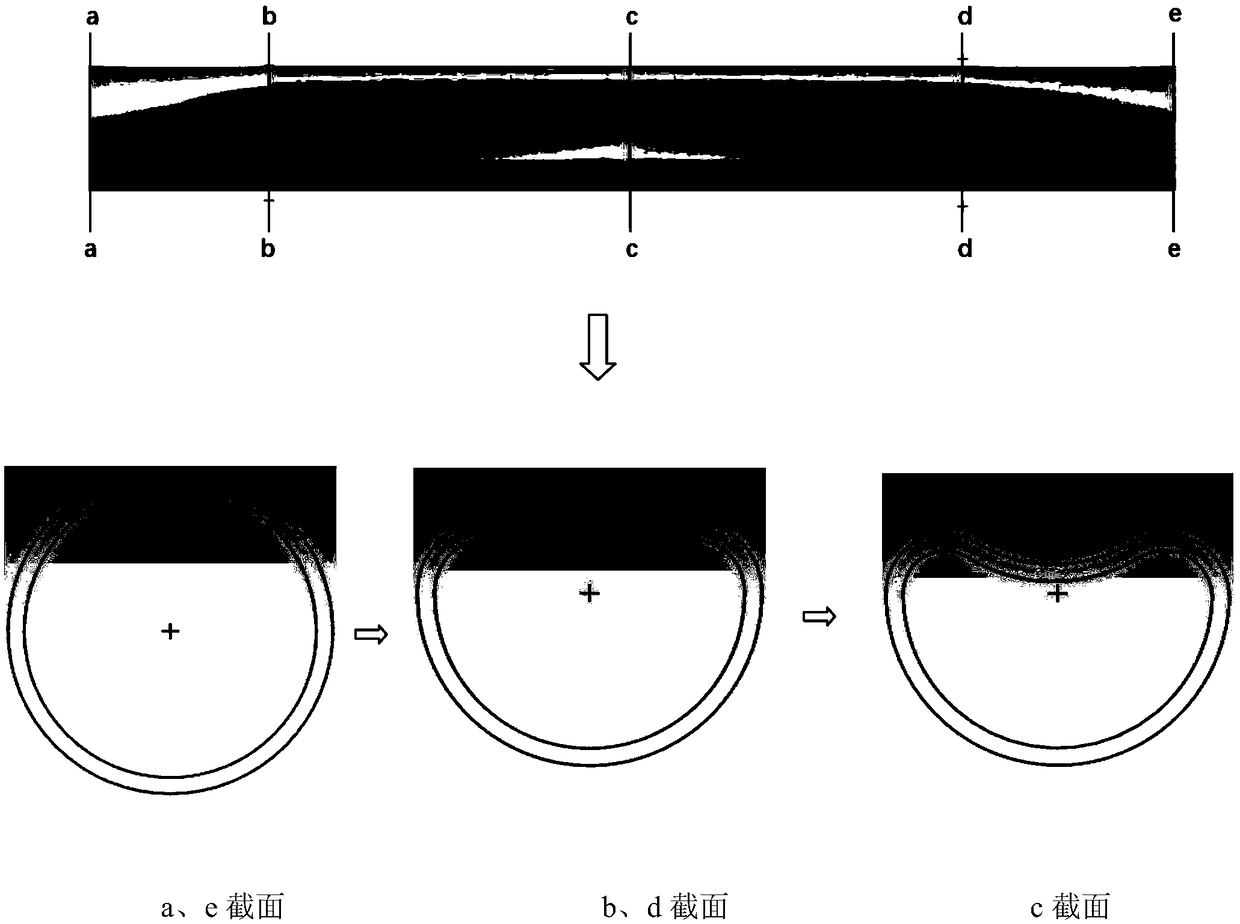

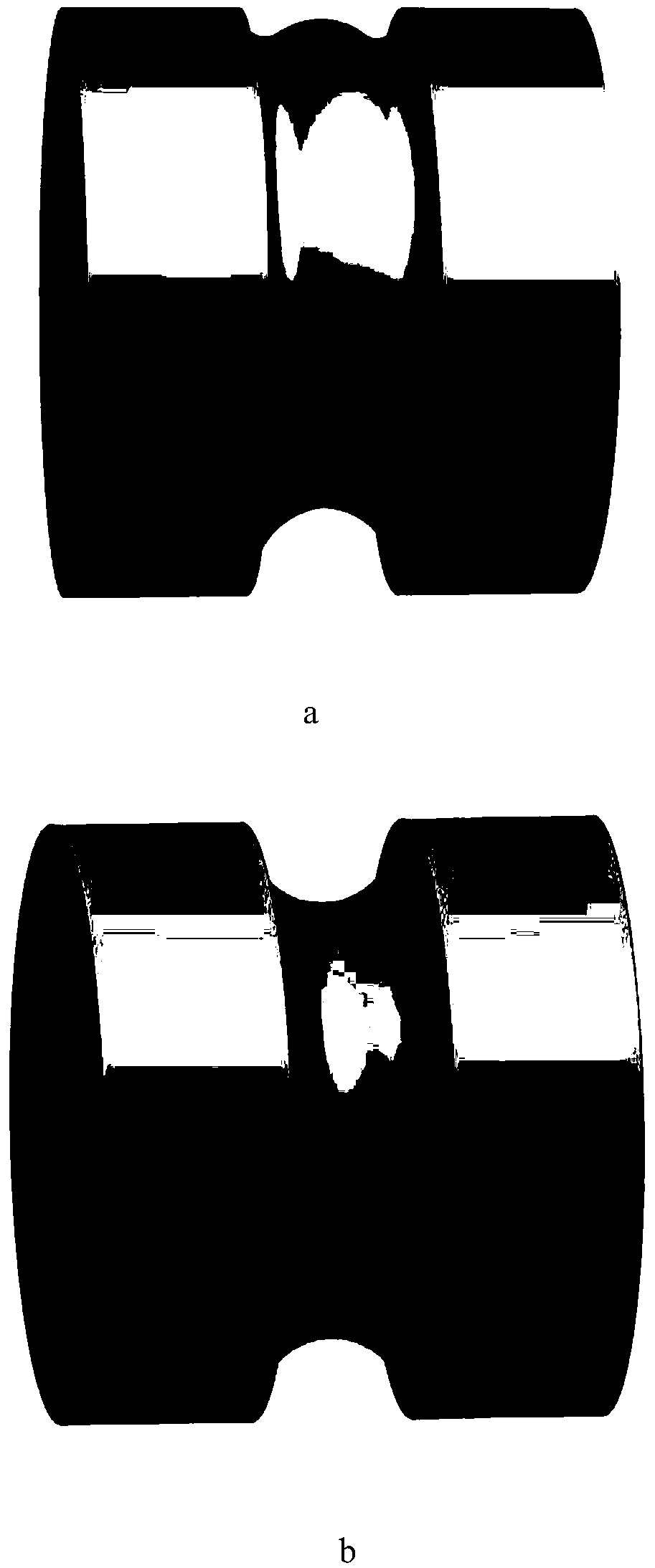

Rolling forming method and device for metal special-shaped variable-section pipe based on hydraulic forming

ActiveCN109174970ALow investment costLess investmentMetal rolling arrangementsFriction effectRolling resistance

The invention discloses a rolling forming method and device for a metal special-shaped variable-section pipe based on hydraulic forming, relates to a metal pipe part forming technology and aims at solving the problems that in an existing method, the investment cost is high, the production efficiency is low, and crumpling and cracking are likely to be generated due to the friction effect. Rollers are obtained, and forming technology parameters in the rolling forming process are determined; the two ends of a pipe blank are sealed and put into grooves of the upper roller and the lower roller; theupper roller is pressed down and is engaged with the lower roller, and certain die combining force is applied; and the pipe is filled with a liquid medium; the rollers rotate according to a preset angle to drive the pipe to move, and needed section characteristics are formed in the roller grooves. By means of the supporting effect of liquid pressure, a rolling technological method is adopted forforming the metal pipe, sliding friction of traditional inner high pressure forming is changed into rolling friction of the rolling technology, meanwhile, the friction direction is changed so that thecondition that friction impedes material flowing can be changed into the condition that friction facilitates material flowing, and the product forming quality is improved.

Owner:HARBIN INST OF TECH

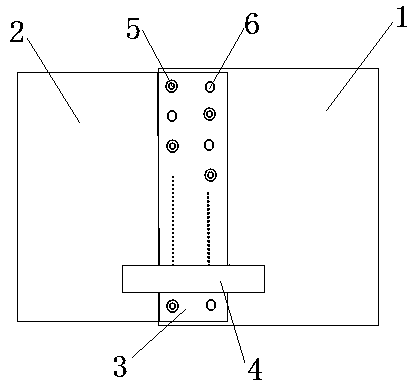

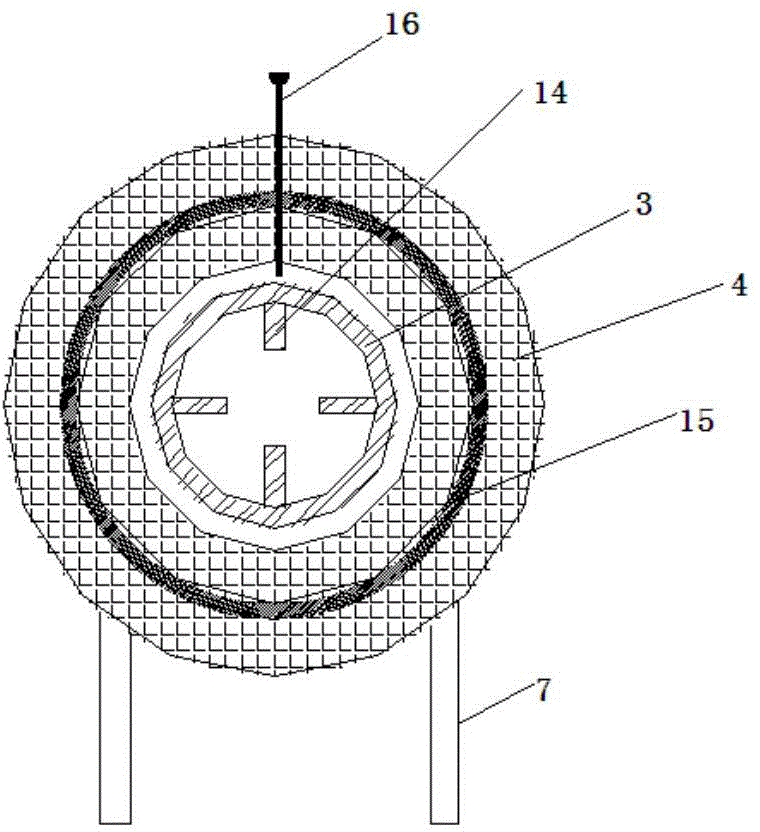

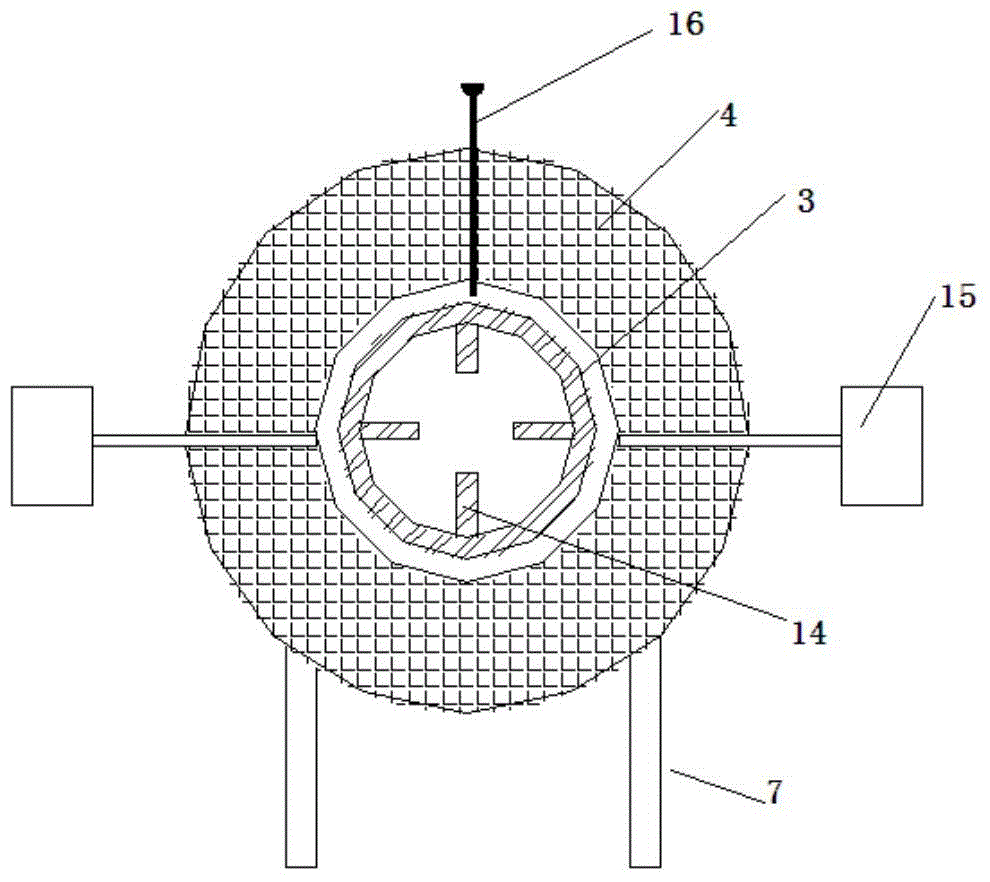

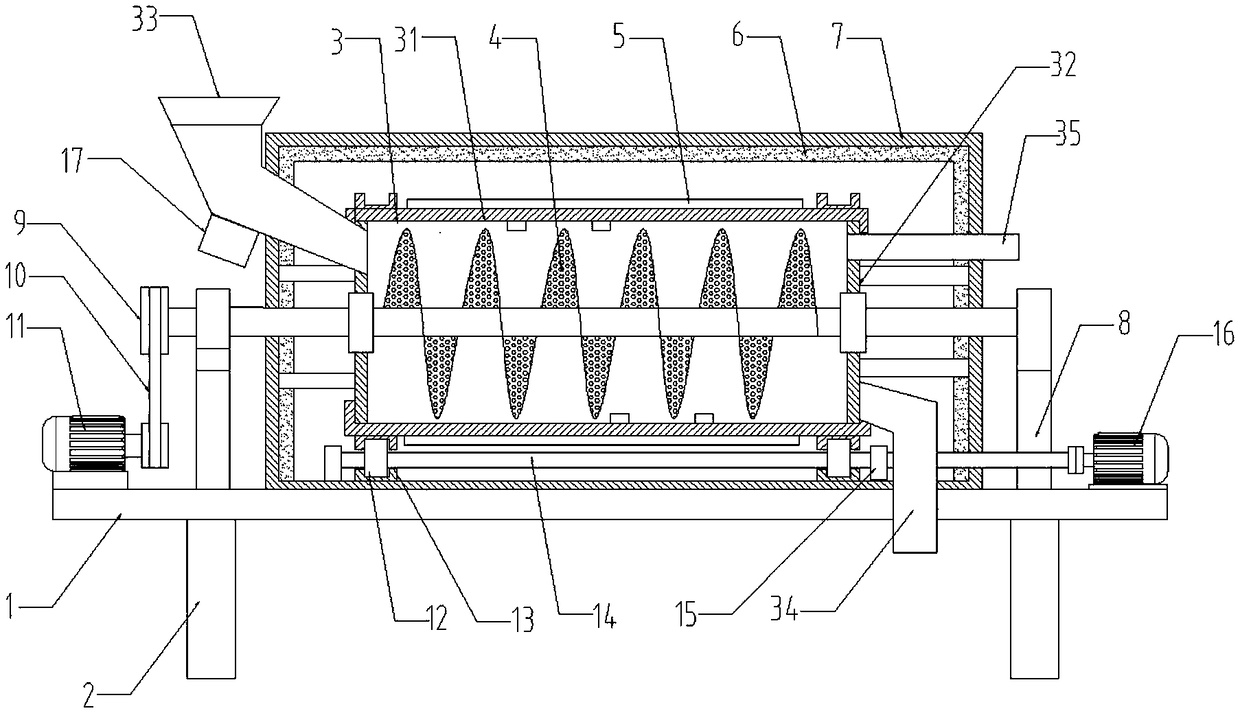

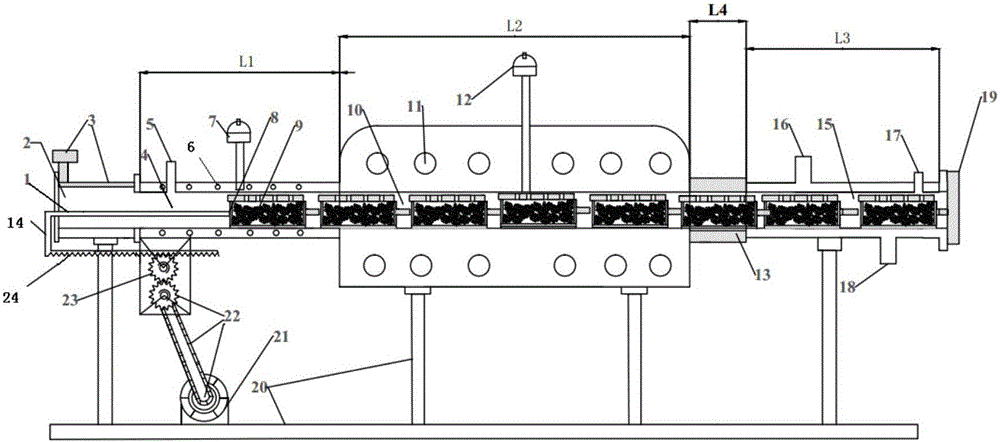

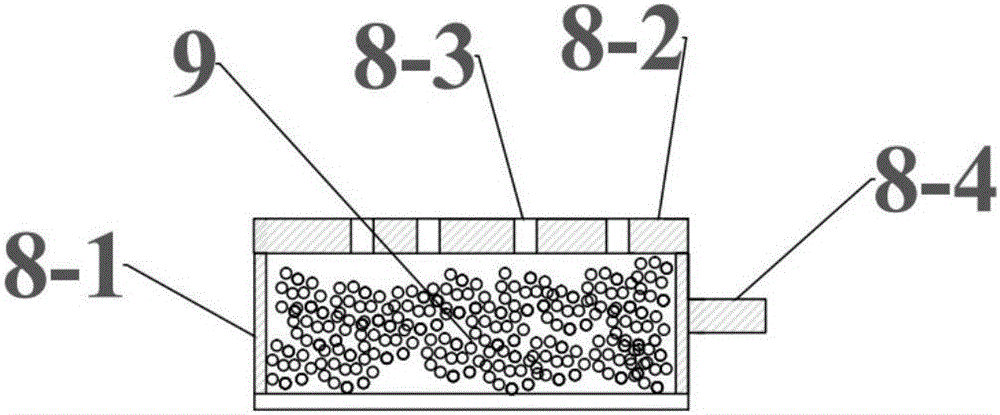

Tea leaf drying device

InactiveCN109303124ARealize continuous mass productionIncrease productivityPre-extraction tea treatmentThermal insulationCoupling

The invention discloses a tea leaf drying device and belongs to the technical field of tea leaf production equipment. The tea leaf drying device comprises a bracket and a drying cylinder; the outer part of the drying cylinder is provided with a thermal insulation cylinder; the thermal insulation cylinder is internally provided with a thermal insulation layer and is installed on the bracket; the drying cylinder is internally provided with a screw feeder; the screw feeder is driven by a first motor; the drying cylinder comprises a cylinder body and a side plate; the side plate is fixedly connected with the inner wall of the thermal insulation cylinder; the outer surface of the cylinder body is provided with an electric heating plate; the lower part of the cylinder body is provided with rolling wheels; the rolling wheels are arranged on a rotary shaft; and the right end of the rotary shaft is fixedly connected with an output shaft of a second motor through a coupling. The tea leaf dryingdevice provided by the invention continuously feeding tea leaves to a discharge funnel while drying the tea leaves, performs continuous drying and automatic discharge, realizes tea leaf continuous batch production and improves the production efficiency; a helical blade rotates to perform stir-frying on the tea leaves, and rotation of the drying cylinder body improves the stir-frying effect of thetea leaves, so that drying of the tea leaves is uniform, the roasting efficiency is improved, and the quality of the tea leaves is ensured; and with the thermal insulation cylinder, the heat loss is reduced, and energy consumption is lowered.

Owner:尹领

Pushing type dynamic continuous preparing method for My(CXN1-X) powder and sintering device

The invention discloses a pushing type dynamic continuous preparing method for My(CXN1-X) powder. In the chemical formula My(CxN1-x), M is one of Ti, Cr, V, Ta, Mo, Nb, Zr, Hf, W and Mn, y is 1 or 2, and x is larger than or equal to 0.1 but smaller than or equal to 0.9. The preparing method includes the steps that firstly, burdening is conducted; secondly, mixing and drying are conducted; thirdly, sintering is conducted, wherein nitrogenous gas is injected into a cooling room, a reaction room and a preheating room with the gas flow speed of 0.1-8 L / min, the temperature of the preheating room is increased to the preheating temperature, the temperature in the reaction room is increased to the reaction temperature, the cooling room is in the working state, and afterwards, reaction boats loaded with mixed powder are put into a feeding room successively at certain intervals and are intermittently pushed towards a discharging port at a constant speed. The invention further provides a pushing type dynamic continuous sintering device. The single-phase My(CxN1-X) powder can be obtained, and continuous batched production is achieved.

Owner:SICHUAN UNIV

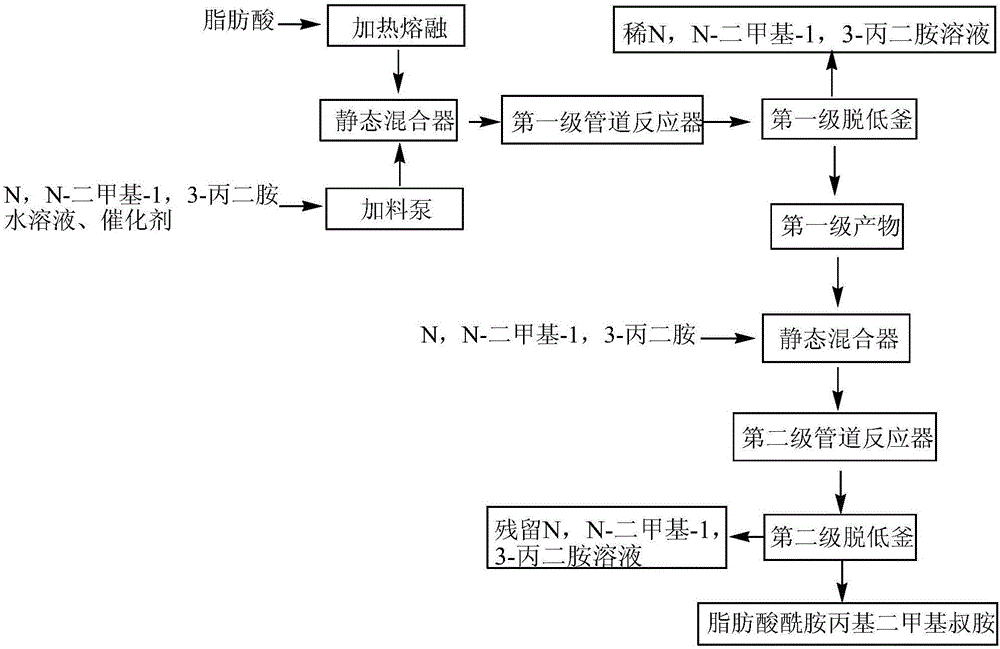

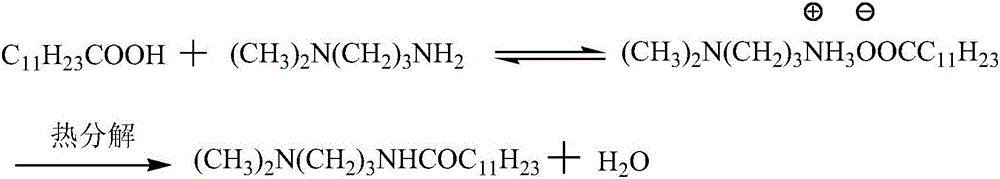

Preparing method for fatty acid amide propyl tertiary amine

ActiveCN106278922AHigh synthesis efficiencyReduce energy consumptionOrganic compound preparationCarboxylic acid amide separation/purificationBoiling pointTwo step

The invention relates to a preparing method for fatty acid amide propyl tertiary amine. Preparation is carried out with pipeline reactors and devolatiligation equipment. The preparing method comprises the following steps that fatty acid, an N,N'-Dimethyl-1,3-propyldiamine aqueous solution and a catalyst are mixed and then enter the first pipeline reactor for a reaction; then a reaction product is put into a first devolatiligation kettle, and low-boiling-point substances are removed; then, the product obtained after devolatiligation is mixed with a small amount of pure N,N'-dimethyl-1,3-propyldiamine and then enters the second pipeline reactor for a reaction; finally, the product is put into a second devolatiligation kettle, low-boiling-point substances are removed, and fatty acid amide propyl tertiary amine is obtained. According to the preparing method, the pipeline reactors and a two-step method are adopted for synthesizing fatty acid amide, the synthesizing efficiency is greatly improved, the synthesizing time can be shortened to be 4 h or shorter, the conversion rate of fatty acid can reach 98% or above, and energy consumption is greatly reduced; besides, the preparing method is convenient to control and safe, and continuous mass production can be achieved.

Owner:GUANGZHOU TINCI MATERIALS TECH

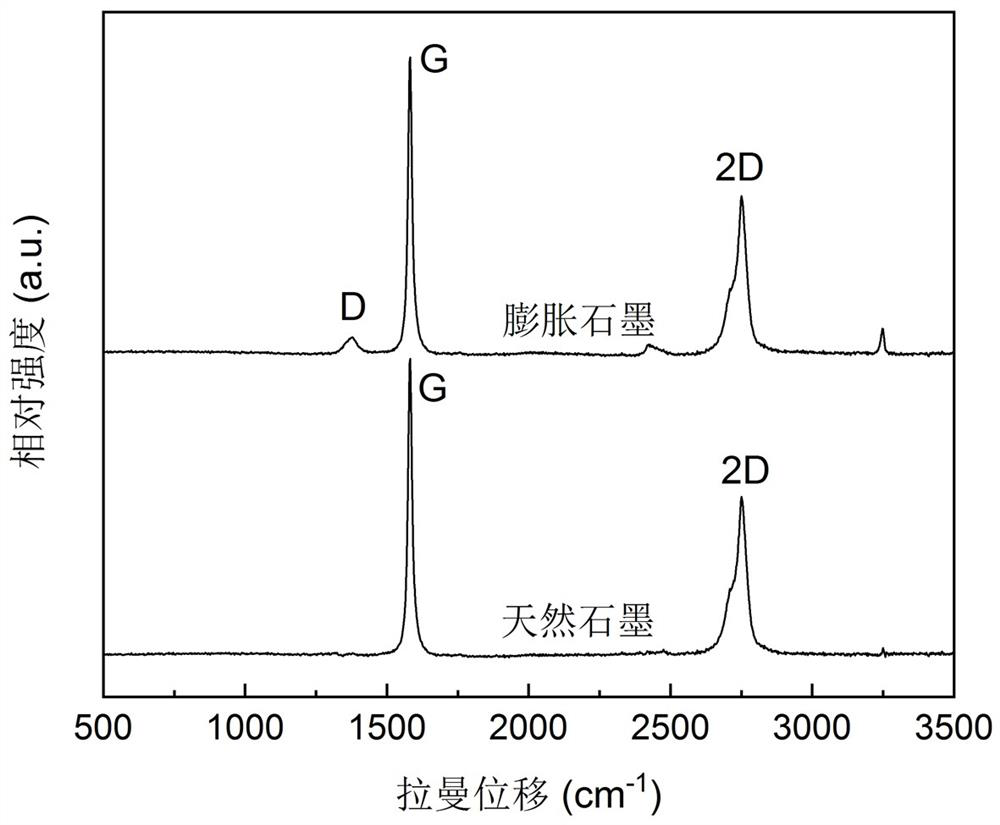

Natural flake graphite normal-pressure low-temperature expansion method

InactiveCN112194125AReduce consumptionSimple processCarbon compoundsMetallic materialsOxidizing agent

The invention provides a natural flake graphite expansion method which is simple and convenient in process and low in energy consumption, directly obtains expanded graphite with the expansion volume of not less than 300mL / g at normal pressure and low temperature (less than 100 DEG C), and belongs to the technical field of inorganic non-metallic materials. The method comprises the following specific steps: 1) putting 50-325 mesh natural flake graphite into a beaker, adding an intercalating agent and an auxiliary agent, and uniformly stirring by using a glass rod; and 2) dropwise adding an oxidant solution, standing, heating to 55-95 DEG C, keeping the temperature for 0.5-3 h, cooling, and washing until a filtrate is neutral to obtain the expanded graphite with the expanded volume of not less than 300mL / g. The method has the advantages of low chemical reagent consumption, easy treatment of waste liquid, low energy consumption, and realization of continuous large-scale production.

Owner:HARBIN UNIV OF SCI & TECH

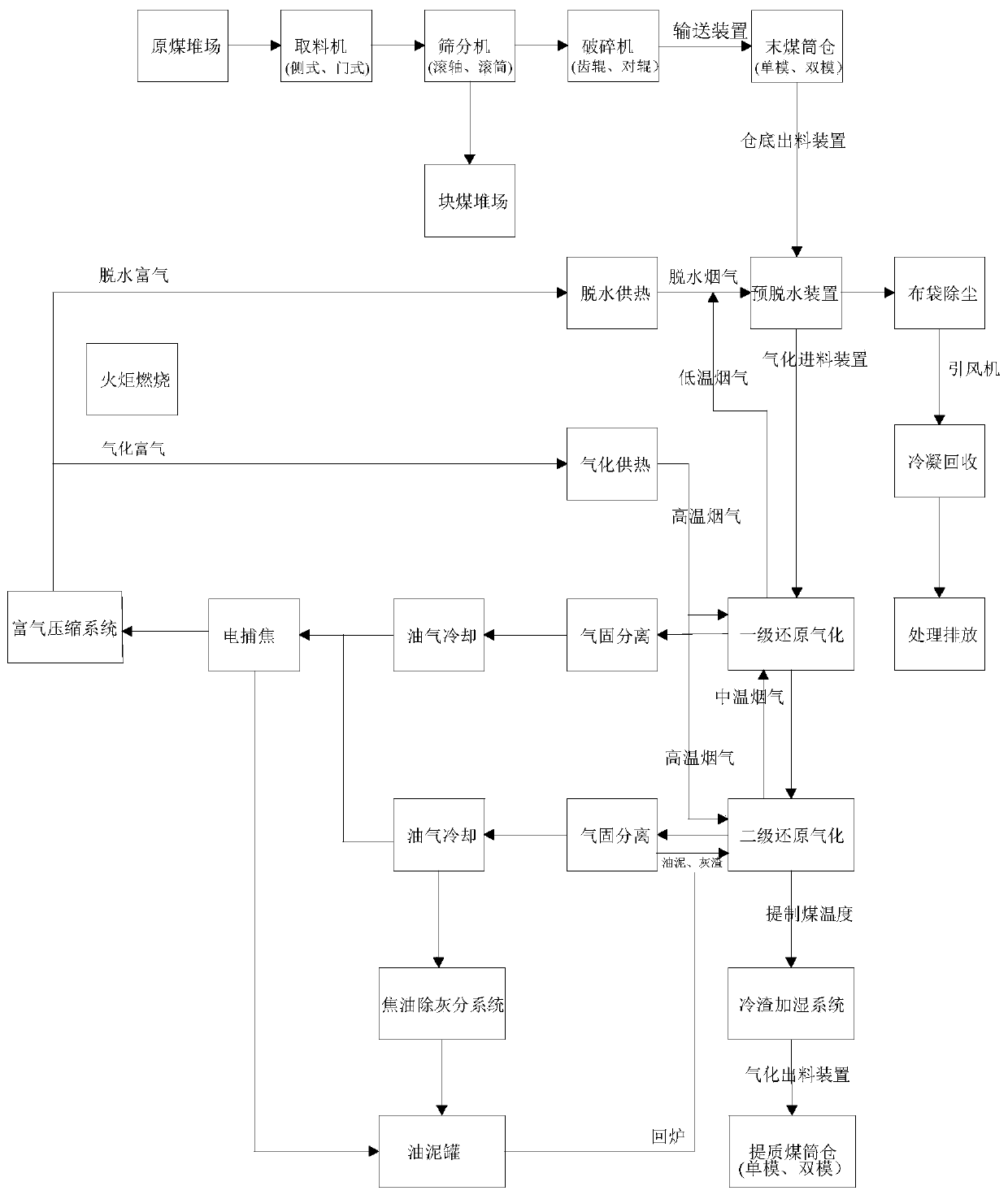

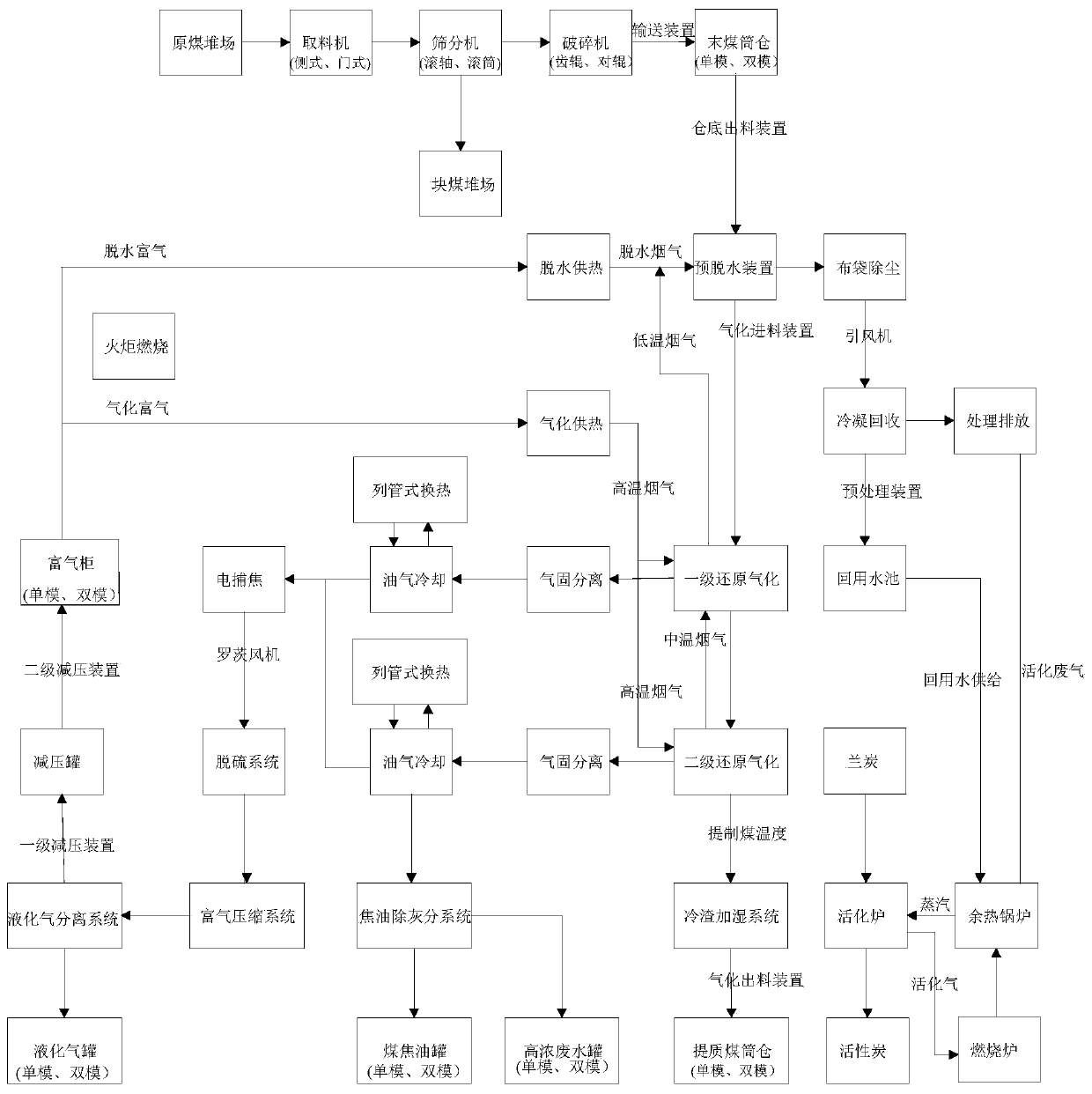

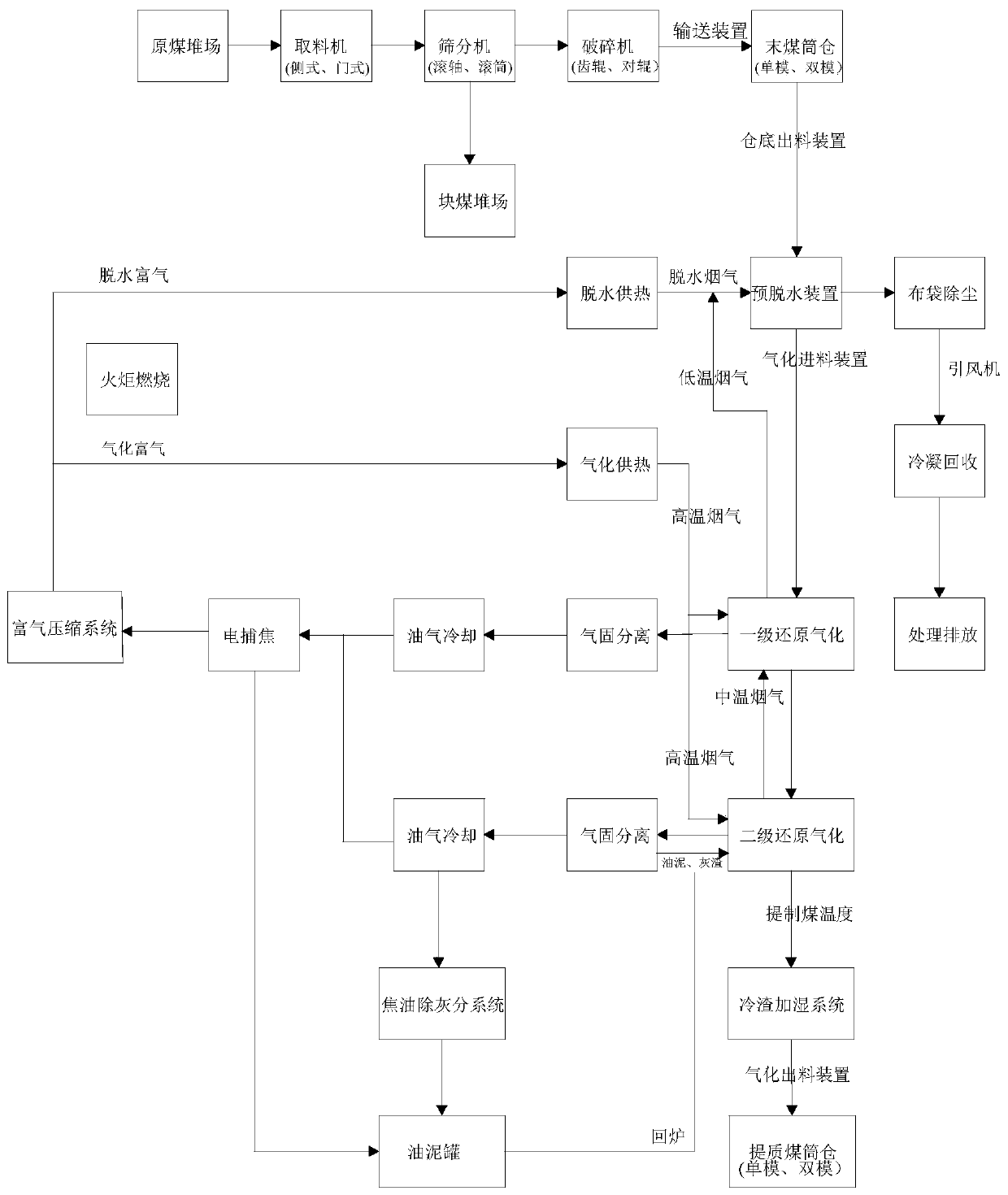

Method for gasification reduction of pulverized coal and separation and recycling of upgraded coal

PendingCN110003929AReduce productionNo lossEnergy inputOven incrustations prevention/removalSlagPulverizer

The invention discloses a method for gasification reduction of pulverized coal and separation and recycling of upgraded coal. The method comprises following steps: 1), raw coal is screened and pulverized by a pulverizer and pulverized coal enters a slack coal silo; 2), the pulverized coal in the slack coal silo is dried, then enters a primary gasification reduction device and a secondary gasification reduction device and is reacted sufficiently, an obtained material enters a cold slag humidification system and then enters an upgraded coal silo through a gasification discharging device, and anupgraded coal product is obtained; 4), ash residues obtained by a gas-solid separation system is conveyed to the secondary gasification reduction device, and oil sludge returns to the a secondary gasification device through an oil sludge conveying device; 5), a non-condensable gas is gasified to supply heat to a reaction system, and dewatered non-condensable gas and flue gas with waste heat supplyheat to a pre-dewatering device to dry a material; 6), flue gas containing dust and steam, which is produced by the pre-dewatering device, is subjected to cloth bag dedusting and condensation recovery successively under the power action of an induced draft fan.

Owner:浙江天禄环境科技有限公司

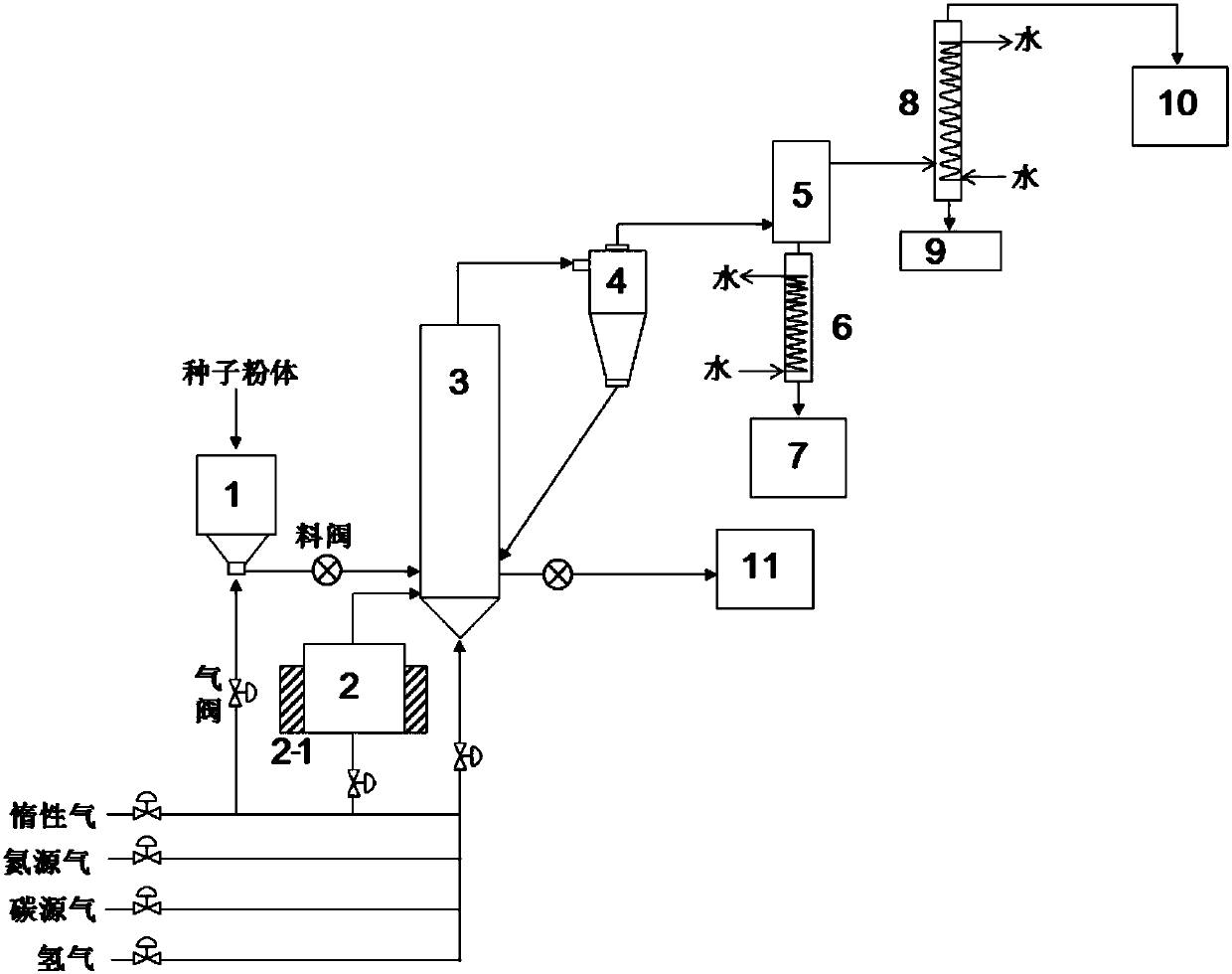

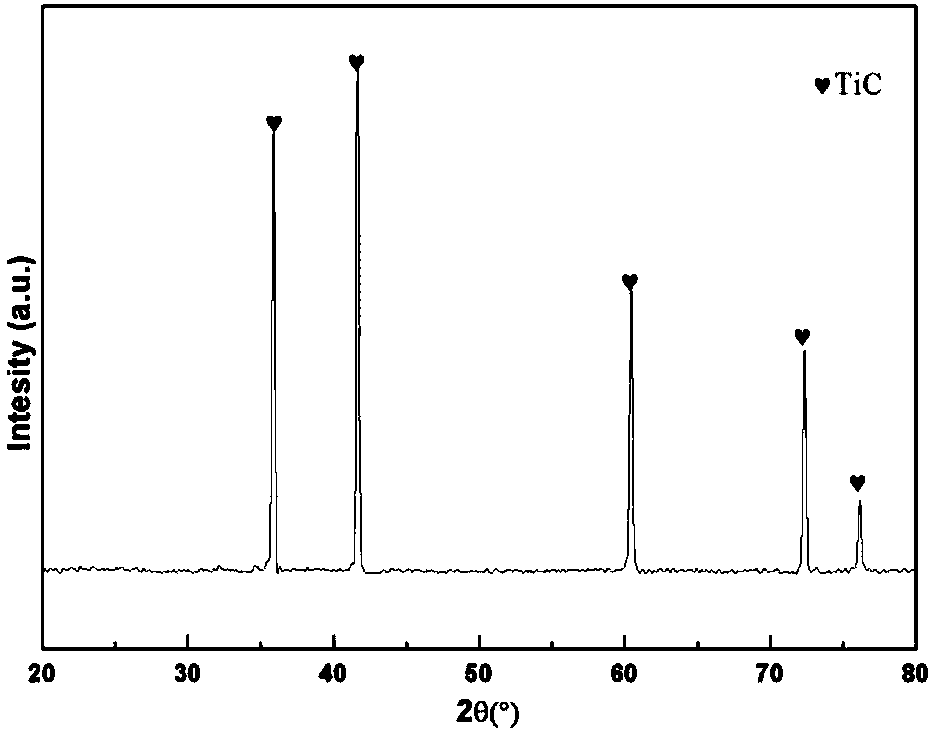

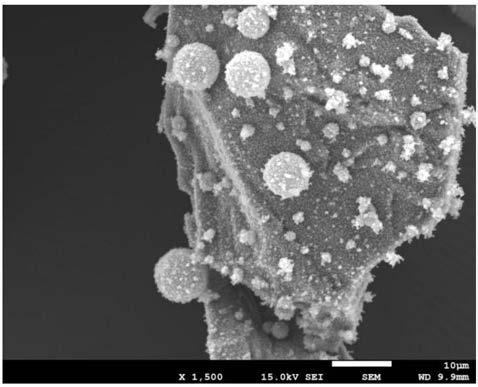

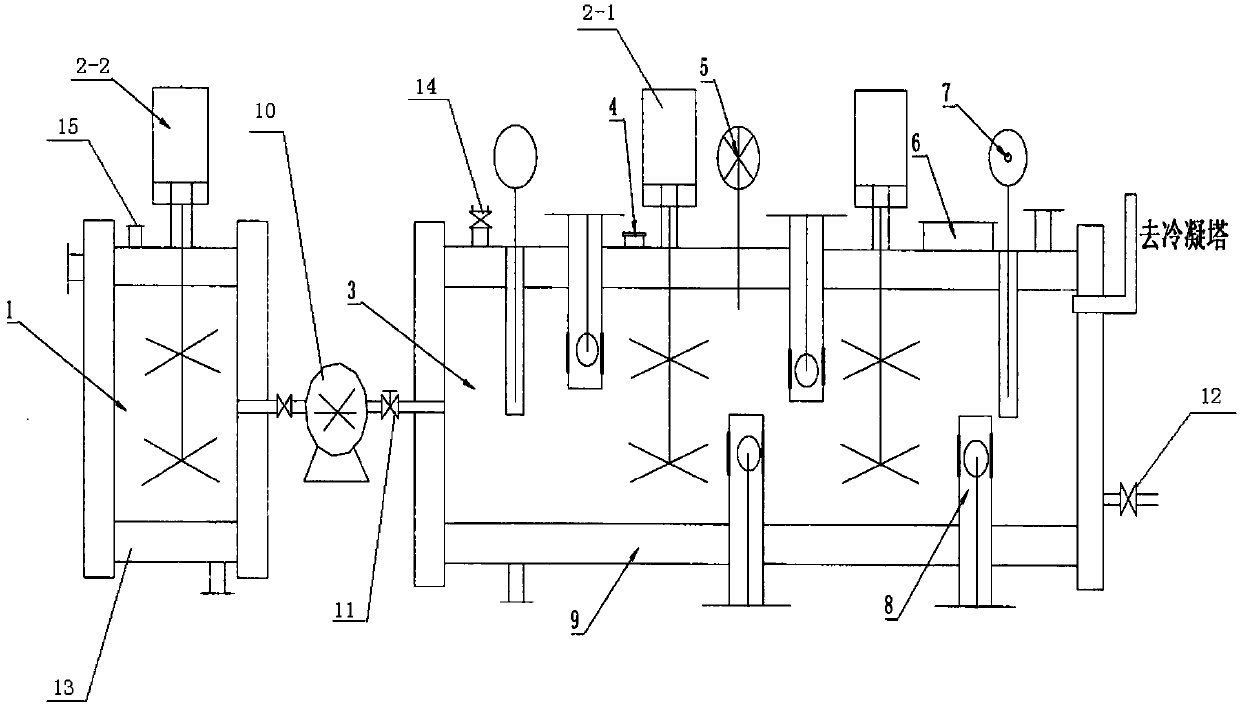

System and method for producing TiN, TiC and TiCN powder

ActiveCN110155965AAchieve recyclingSolve the problem of easy film formationNitrogen compoundsTitanium carbideSocial benefitsFluidized bed

The invention discloses a system and a method for producing TiN, TiC and TiCN powder. Target seed powder is added in a fluidized bed in advance and fluidized by an inert gas, and then the TiN, TiC andTiCN powder are synthesized in the fluidized bed by gaseous TiCl 4 and a nitrogen source or (and) carbon source gas under a certain temperature range. The method solves the problems of low efficiency, easy coating formation and difficult powder formation in a chemical vapor deposition process based on TiCl 4 raw materials, improves the efficiency of preparing the TiN, TiC and TiCN powder, has simple process flow, does not need expensive equipment, can realize continuous batch production of the TiN, TiC and TiCN powder, and has good economic and social benefits.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Industrial continuous type microwave reactor

ActiveCN103623755AReduce investmentReduce consumptionEnergy based chemical/physical/physico-chemical processesRubber materialThermodynamics

The invention relates to an industrial continuous type microwave reactor. The industrial continuous type microwave reactor comprises a material mixing chamber and a reaction chamber which are connected together through a pipeline, wherein a feeding hole is formed in the material mixing chamber, a discharging hole is formed in the reaction chamber, multiple groups of microwave generators stretching into the reaction chamber are arranged in the reaction chamber, each microwave generator assembly consists of an isolation pipe and a microwave generator stretching into the isolation pipe, an opening is formed in each isolation pipe, an isolation plate capable of isolating the corresponding microwave generator from reactants is arranged at each opening, and microwaves pass through each isolation plate. According to the industrial continuous type microwave reactor, the multiple microwave generator assemblies are mounted in the reaction chamber, and the reactants in the reaction chamber are directly influenced by microwave radiation, so that the reaction time can be greatly shortened, the energy consumption can be reduced, the environmental pollution can be alleviated, the production cost can be lowered, the investment on facilities such as boilers of an enterprise can be lowered, and the industrial continuous type microwave reactor can be widely applied to multiple industries of chemical engineering, pharmacy, plastic, rubber, materials and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Production device and production method of plant polysaccharide cigarette filter tip or filter tip bar

ActiveCN108433176ARealize continuous mass productionThe production and processing process is green and environmentally friendlyTobacco smoke filtersFreeze-dryingPolysaccharide

The invention discloses a production device and a production method of a plant polysaccharide cigarette filter tip or filter tip bar. The device comprises a pressurizing mechanism, a mixing tank, a pre-freezing and curing mechanism, a material guide mechanism, a cutting machine, a deep-freezing room and a vacuum freeze-drying room, wherein the mixing tank comprises a tank body and a stirrer; the stirrer is arranged in the tank body; the pre-freezing mechanism comprises a pre-freezing and curing room and a material guide groove, a coolant outer pipe and a liquid guide inner pipe; the coolant outer pipe fixedly sleeves the liquid guide inner pipe; the material guide groove is fixedly arranged in the pre-freezing and curing room; the material guide mechanism comprises multiple pairs of rollermechanisms and a fixed sleeve; each pair of roller mechanisms comprises an upper roller and a lower roller; the upper rollers are arranged above the lower rollers; one end of the liquid guide inner pipe is connected to an outlet of the tank body and the other end is connected to an inlet of the material guide groove; and the pressurizing mechanism is connected to the tank body. The device is simple in structure, and large-scale continuous production can be achieved. The production method, which is achieved on the basis of the device, is convenient and safe to operate.

Owner:WUHAN LICHENG BIOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com