Pushing type dynamic continuous preparing method for My(CXN1-X) powder and sintering device

A push type, powder technology, applied in the dynamic continuous preparation method of carbonitride powder and sintering device field, can solve problems such as difficulty in ensuring uniformity of temperature, limitation of wide application, large range of product composition and particle size distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

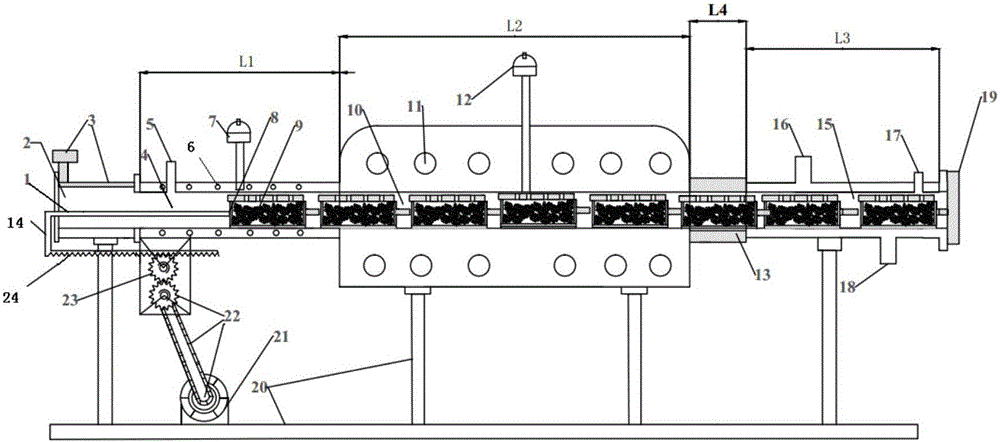

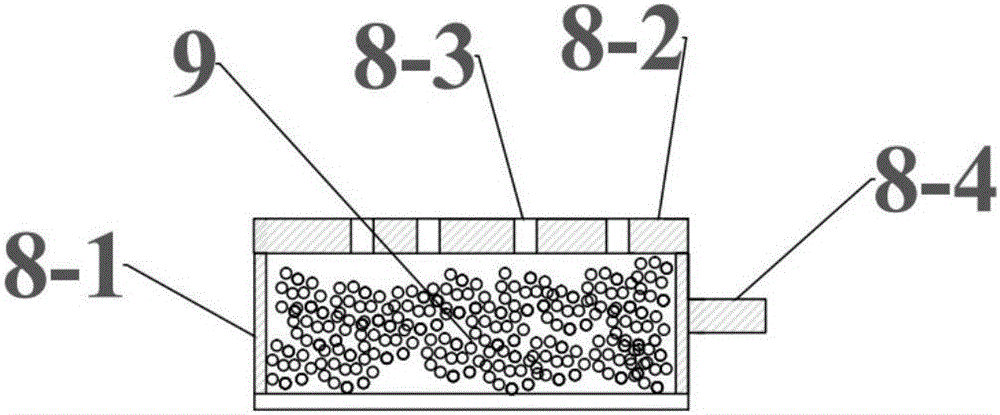

[0048] The structure of the push-type dynamic continuous sintering device in this embodiment is as follows figure 1 , figure 2 As shown, the feeding chamber 2, the preheating chamber 4, the reaction chamber 10, the heat insulation chamber 13, the cooling chamber 15, and the reaction boat 8 loaded with raw material powders and reaction products are sequentially connected and communicated to push the push rod for the movement of the reaction boat. 1. The driving mechanism that can make the push rod do reciprocating linear motion is composed of the supporting frame 13 supporting the feeding chamber 2, the preheating chamber 4, the reaction chamber 10, the heat insulation chamber 13, the cooling chamber 15 and the driving mechanism;

[0049]The top of the feeding chamber 2 is provided with a feeding port and is equipped with a cover plate 3 covering the feeding port, and the end of the feeding chamber is provided with a push rod inlet and outlet hole; the wall of the preheating c...

Embodiment 2

[0061] In this embodiment, the difference between the push type dynamic continuous sintering device and the sintering device described in Embodiment 1 is that the length L1 of the preheating chamber 4 is 2 m, the length L2 of the reaction chamber 10 is 2 m, and the length L3 of the cooling chamber 15 It is 3m, and the length L4 of heat insulation chamber 13 is 0.6m, and the heat device of preheating chamber and reaction chamber is infrared heating device, and the heat insulation plate covering boat body is made by graphite.

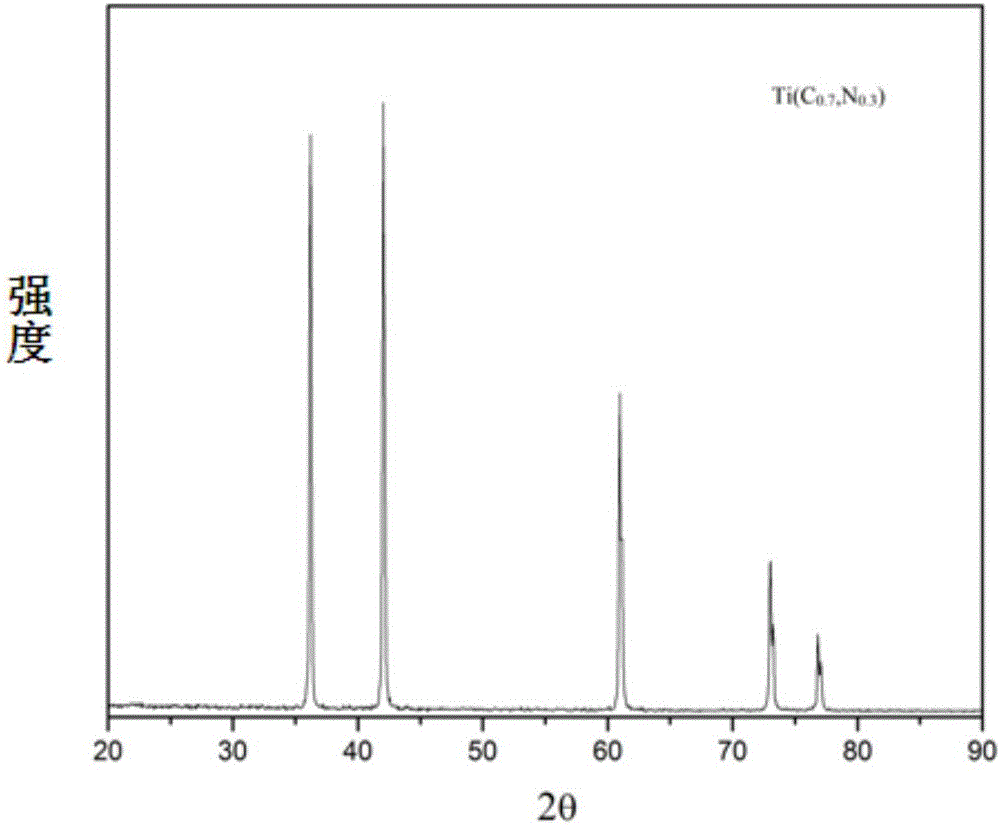

[0062] In this example, Ti(C 0.3 ,N 0.7 ) The push-type dynamic continuous preparation method process steps of the powder are as follows:

[0063] (1) Ingredients

[0064] The raw materials are nano TiO, micron carbon black powder, according to Ti(C 0.3 ,N 0.7 ) The chemical formula of the powder and the chemical reaction between the raw materials used are used to calculate the molar percentage of each raw material:

[0065] TiO powder: carbon black ...

Embodiment 3

[0071] In this embodiment, the difference between the push-type dynamic continuous sintering device and the sintering device described in Embodiment 1 is that the length L1 of the preheating chamber 4 is 2 m, the length L2 of the reaction chamber 10 is 3 m, and the length L3 of the cooling chamber 15 The length L4 of the heat insulation chamber 13 is 0.6m, and the thermal devices of the preheating chamber and the reaction chamber are induction heating devices.

[0072] In this example, Ti(C 0.9 ,N 0.1 ) The push-type dynamic continuous preparation method process steps of the powder are as follows:

[0073] (1) Ingredients

[0074] The raw materials are nano TiO, micron carbon black powder, according to Ti(C 0.9 ,N 0.1 ) The chemical formula of the powder and the chemical reaction between the raw materials used are used to calculate the molar percentage of each raw material:

[0075] TiO 2 Powder: activated carbon powder = 1:2.8

[0076] (2) mixing and drying (with embod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com