Production device and production method of plant polysaccharide cigarette filter tip or filter tip bar

A technology of filter sticks and plant polysaccharides, which is applied in the fields of e-liquid filter elements, tobacco, food science, etc., can solve the problems of industrial production without proposed production process and equipment schemes, chemical residues, and inability to degrade filters, etc., to achieve good adsorption performance and biological Degradability, good quality stability of product batches, and easy scale-up of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

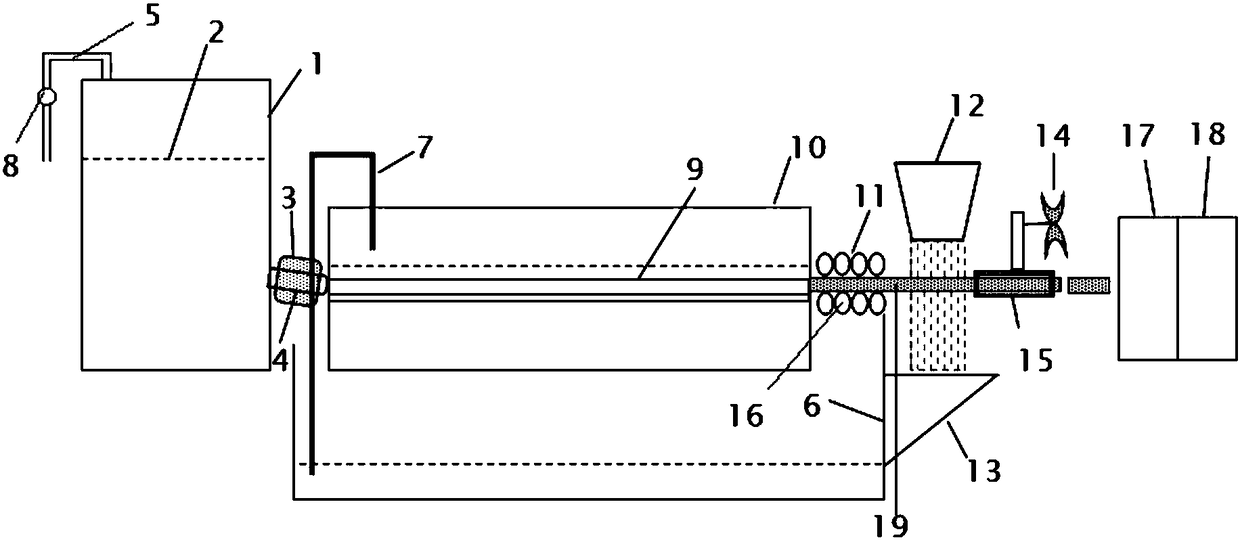

[0043] 1. Add konjac flour, starch, cellulose derivatives, vegetable protein, auxiliary glue, plasticizer, and water into the tank in a mass ratio of 4:50:14:1:4:20:1000, turn on the mixer, At the same time, heat to 65°C and stir the raw materials at a rotation speed of 200rpm to obtain a glue solution;

[0044] 2. Turn on the air to increase the pump and air cooler, use the pressure to squeeze the glue into the inner tube of the liquid guide, so that the glue is cooled at 1°C (the temperature of the refrigerant in the refrigerant sleeve is 1°C) and matured to obtain a stable curing and curing glue;

[0045] 3. Continue to use pressure to squeeze the matured gel into the guide groove, freeze and solidify at -15°C (the temperature of the refrigerant in the pre-freeze solidification chamber is -15°C), control the growth of ice crystals to freeze the matured gel, and obtain a solidification rod 19 , The curing rod 19 continues to move backwards at a uniform speed under the action of ...

Embodiment 2

[0051] 1. Add konjac flour, starch, cellulose derivatives, vegetable protein, auxiliary glue, plasticizer, and water into the tank at a mass ratio of 5:50:14:1:4:25:1000, turn on the mixer, At the same time, heat to 70°C and stir the raw materials at a rotation speed of 200rpm to obtain a glue solution;

[0052] 2. Turn on the air to increase the pump and air cooler, use the pressure to squeeze the glue into the inner tube of the liquid guide, so that the glue is cooled at 1°C (the temperature of the refrigerant in the refrigerant sleeve is 1°C) and matured to obtain a stable curing and curing glue;

[0053] 3. Continue to use pressure to squeeze the matured gel into the guide trough, freeze and solidify at -17°C (the temperature of the refrigerant in the pre-freeze solidification chamber is -17°C), and control the growth of ice crystals to freeze the matured gel to obtain a solidified rod. The curing rod continues to move backwards at a uniform speed under the action of pressure....

Embodiment 3

[0059] 1. Add konjac flour, starch, cellulose derivatives, vegetable protein, auxiliary glue, plasticizer, and water into the tank at a mass ratio of 4:50:14:1:3:30:900, turn on the mixer, At the same time, heat to 65°C and stir the raw materials at a rotation speed of 200rpm to obtain a glue solution;

[0060] 2. Turn on the air to increase the pump and air cooler, use the pressure to squeeze the glue into the inner tube of the liquid guide, so that the glue is cooled at 1°C (the temperature of the refrigerant in the refrigerant sleeve is 1°C) and matured to obtain a stable curing and curing glue;

[0061] 3. Continue to use pressure to squeeze the matured gel into the guide groove, freeze and solidify at -15°C (the temperature of the refrigerant in the pre-freeze solidification chamber is -15°C), control the growth of ice crystals to freeze the matured gel, and obtain a solidified rod. The curing rod continues to move backwards at a uniform speed under the action of pressure. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com