Preparing method for fatty acid amide propyl tertiary amine

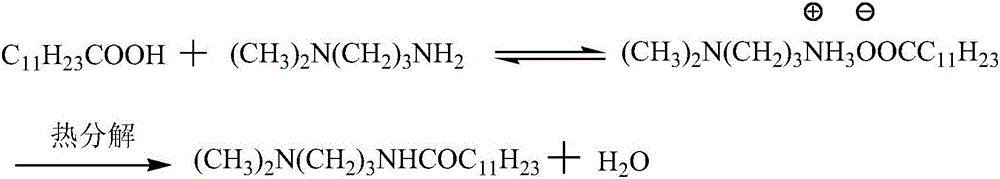

A technology of fatty acid amidopropyl tertiary amine and fatty acid, which is applied in the field of preparation of fatty acid amidopropyl tertiary amine, can solve the problems of long synthesis time and low conversion rate of fatty acid, and achieve the effects of convenient control, improved efficiency, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

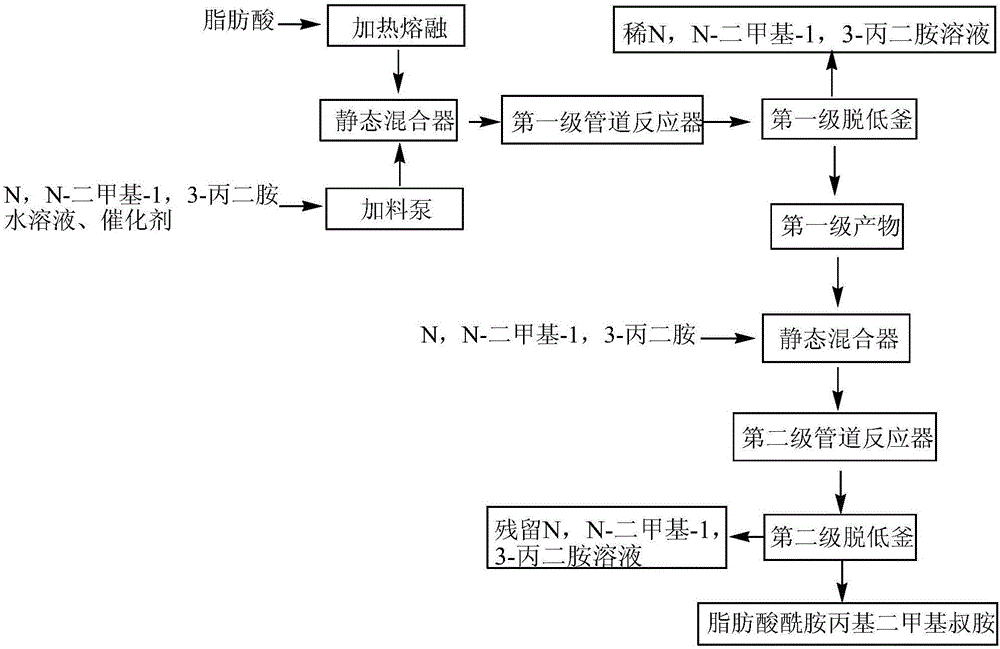

[0035] A kind of preparation method utilizing pipeline reactor to synthesize fatty acid amidopropyl tertiary amine, its preparation process (preparation process is as follows figure 1 shown) as follows:

[0036] Take 600.96g (3mol) of lauric acid, heat up and melt. Take 408.72g (3.6mol) N,N-dimethyl-1,3-propanediamine aqueous solution (purity 90%), 0.101g (100ppm) sodium hydroxide, dissolve sodium hydroxide in N,N-dimethyl Base-1,3-propanediamine. The above materials are mixed in a static mixer, and then enter the first pipeline reactor after mixing, the temperature of the pipeline is raised to 170°C, the initial pressure of the system is adjusted to 0.01MPa, and the reaction stays for 20min. Enter the first low boiler, remove the low boiler, get the first grade product and heated 61.31g (0.6mol) of pure N,N-dimethyl-1,3-propanediamine into the second through a static mixer In the pipeline reactor, the temperature was raised to 170° C., and stayed for 20 minutes, and then e...

Embodiment 2

[0038] A kind of preparation method utilizing pipeline reactor to synthesize fatty acid amidopropyl tertiary amine, its preparation process is as follows:

[0039]Take 600.96g (3mol) of lauric acid, heat up and melt. Take 395.50g (3.6mol) N,N-dimethyl-1,3-propanediamine aqueous solution (purity 93%), 0.093g (100ppm) sodium hydroxide, and dissolve sodium hydroxide in N,N-di Methyl-1,3-propanediamine. The above materials are mixed in a static mixer, and then enter the first pipeline reactor after mixing, the temperature of the pipeline is raised to 180°C, the initial pressure of the system is adjusted to 0 MPa, and the reaction stays for 30 minutes. Enter the first low boiler, remove the low boiler, get the first grade product and heated 61.31g (0.6mol) of pure N,N-dimethyl-1,3-propanediamine into the second through a static mixer The pipeline reactor was heated to 180° C., stayed for 30 minutes, and entered the second de-lowering kettle for the second de-lowering. After the d...

Embodiment 3

[0041] A kind of preparation method utilizing pipeline reactor to synthesize fatty acid amidopropyl tertiary amine, its preparation process is as follows:

[0042] Take 600.96g (3mol) of lauric acid, heat up and melt. 387.21g (3.6mol) N,N-dimethyl-1,3-propanediamine aqueous solution (purity 95%), 0.12g (120ppm) sodium hydroxide, and dissolve sodium hydroxide in N,N-dimethyl Base-1,3-propanediamine. The above materials are mixed in a static mixer, and then enter the first pipeline reactor after mixing, the temperature of the pipeline is raised to 190°C, the initial pressure of the system is adjusted to 0 MPa, and the reaction stays for 30 minutes. Enter the first low boiler, remove the low boiler, get the first grade product and heated 61.31g (0.6mol) of pure N,N-dimethyl-1,3-propanediamine into the second through a static mixer In the pipeline reactor, the temperature was raised to 190° C., and the temperature was kept for 30 minutes. Then, it entered the second de-lowering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com