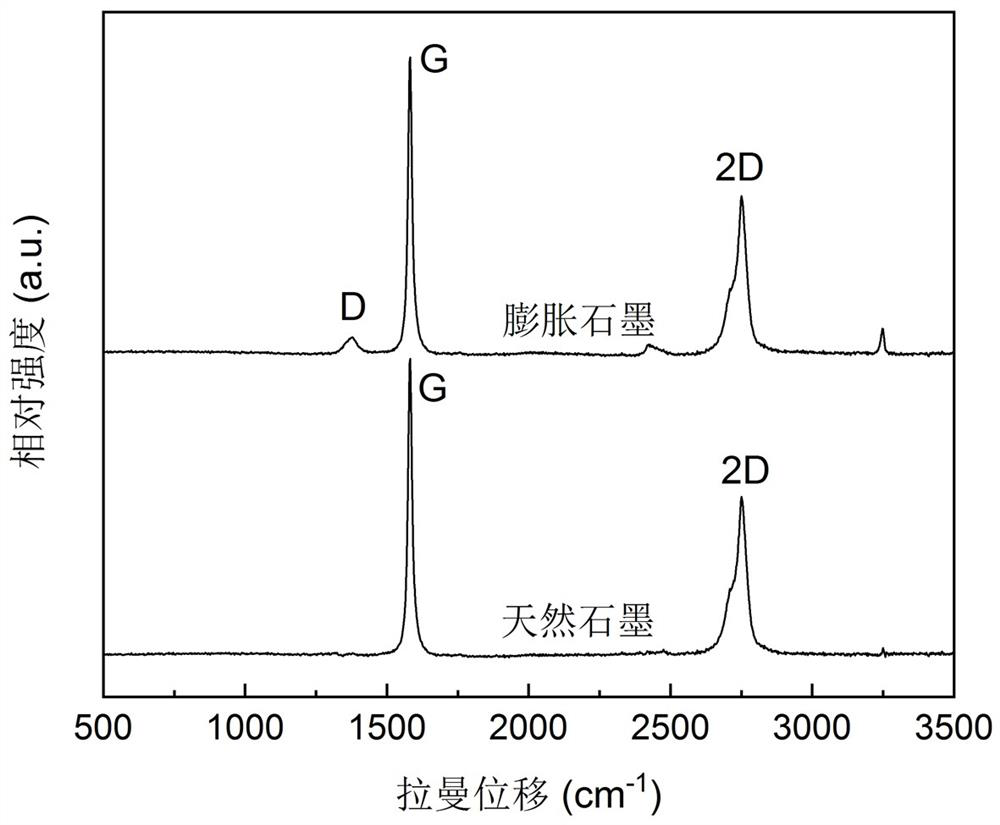

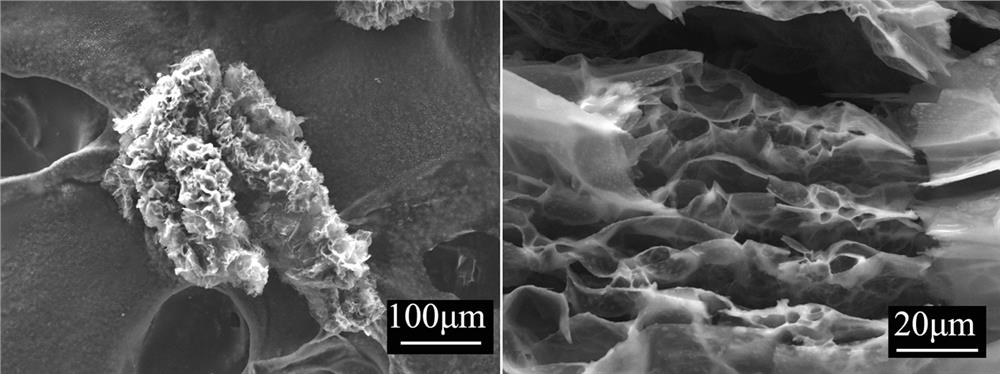

Natural flake graphite normal-pressure low-temperature expansion method

A technology of natural flake graphite and flake graphite, which is applied in the field of expanded graphite, can solve the problems of resource and energy waste, large environmental pollution, and small expansion volume, and achieve the effects of less energy consumption, simplified process flow, and less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) Weigh 0.3g of 50-mesh natural flake graphite and place it in a beaker, add 15mL of acetic acid and 1.5g of sodium nitrate, and stir evenly with a glass rod; 2) Add 1.5mL of 10mol / L nitric acid solution dropwise, let stand, and heat to 55°C , keep warm for 3h, wash after cooling until the filtrate is neutral, and obtain expanded graphite with an expansion volume of not less than 300mL / g.

Embodiment 2

[0020] 1) Weigh 0.3g of 200-mesh natural flake graphite and place it in a beaker, add 20mL of concentrated sulfuric acid and 1.5g of sodium persulfate, and stir evenly with a glass rod; 2) Add 1mL of 9.8mol / L hydrogen peroxide solution dropwise, let stand, and heat to 75°C, keep warm for 0.5h, cool and wash until the filtrate is neutral, and obtain expanded graphite with an expansion volume of not less than 300mL / g.

Embodiment 3

[0022] 1) Weigh 0.3g of 300-mesh natural flake graphite and place it in a beaker, add 10mL of concentrated sulfuric acid, 10mL of concentrated phosphoric acid and 2g of ammonium polyphosphate, and stir evenly with a glass rod; 2) dropwise add 5mol / L potassium permanganate and high Take 1 mL of each potassium bromate solution, let stand, heat to 65°C, keep warm for 1 h, wash after cooling until the filtrate is neutral, and obtain expanded graphite with an expansion volume of not less than 300 mL / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com