Welding method for ferri-chromium-aluminum cold-rolled thin plate during continuous production of cold line

A technology of cold-rolled thin plates and welding methods, which is applied in welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of poor weldability of iron-chromium-aluminum materials, save time, manpower and material resources, avoid losses, Realize the effect of continuous mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0027] The welding method of iron-chromium-aluminum cold-rolled sheet during cold line continuous production comprises the following steps:

[0028] (1) Downward welding is adopted between the iron-chrome-aluminum plate and the 304 leader, the iron-chrome-aluminum plate is on top, and the 304 leader is on the bottom;

[0029] The width of FeCrAl strip is 1240mm, and the thickness of FeCrAl and 304 leader is 1.0mm.

[0030] (2) The overlap between the Fe-Cr-Al plate and the 304 leader should be 90-100mm, among which 90mm is the best;

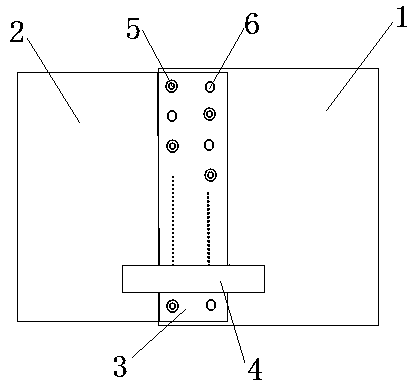

[0031] (3) The first step is automatic resistance spot welding by machine:

[0032] Two rows of machine solder joints are set in parallel in the overlapping area, and the solder joints on the two rows are staggered at 45°; The vertical distance in the direction is 50mm; the welding current is set to 30A;

[0033] (4) The second step is manual electric welding with ordinary welding machine:

[0034] A402 stainless steel electrode with a diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com