Patents

Literature

137results about How to "Improve annealing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

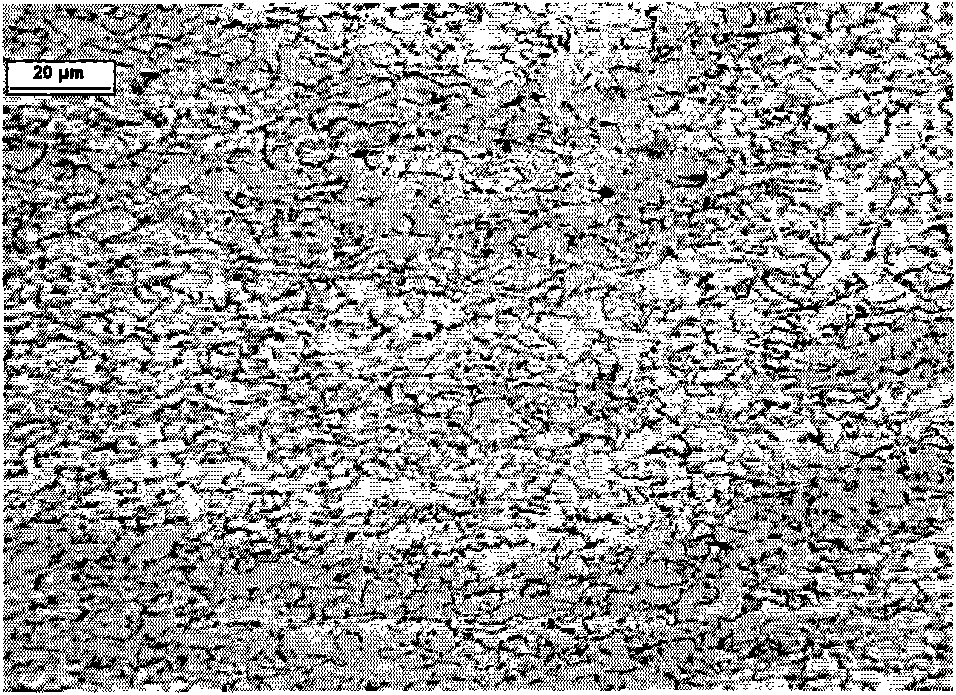

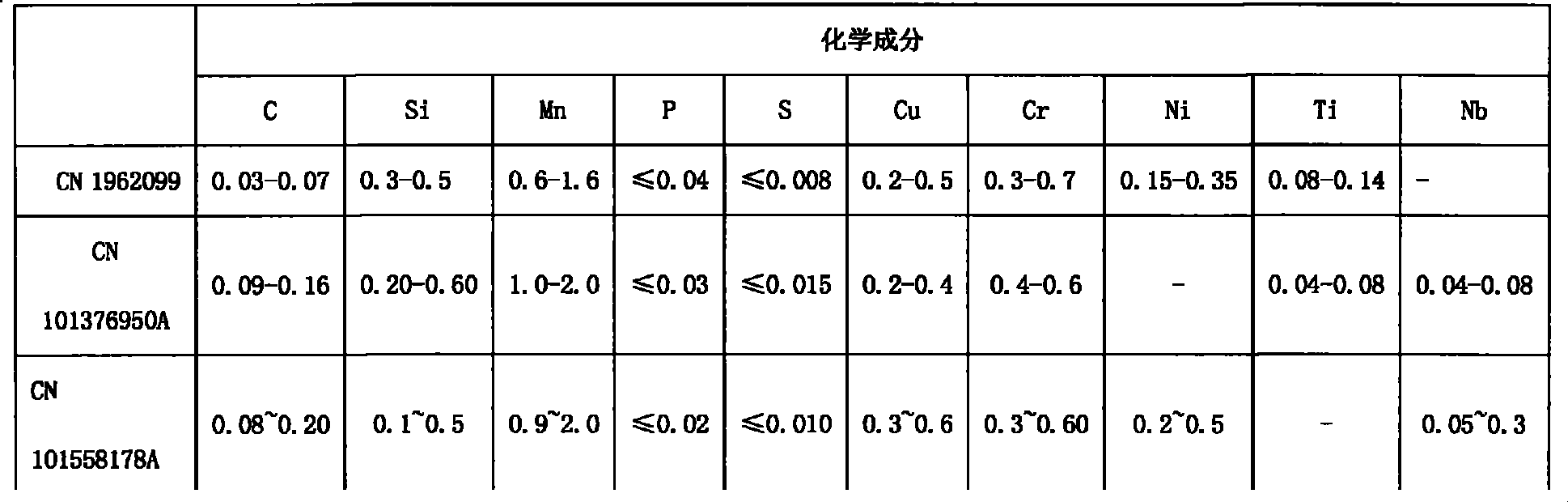

700MPa-grade cold rolled steel plate with high weather resistance and preparation method thereof

InactiveCN102011060AHigh standardAbundant resourcesTemperature control deviceBell type furnacesWeather resistanceChemical composition

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

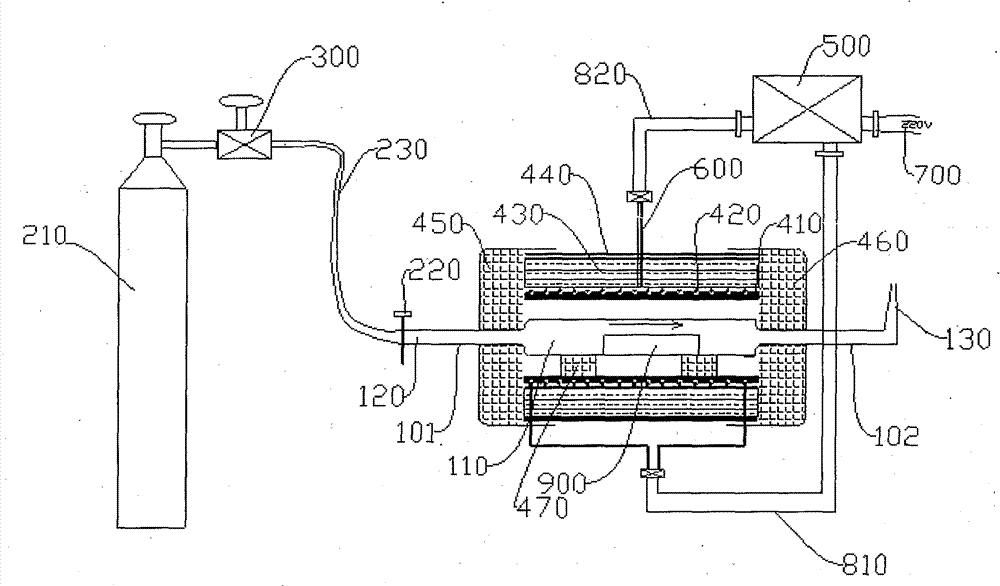

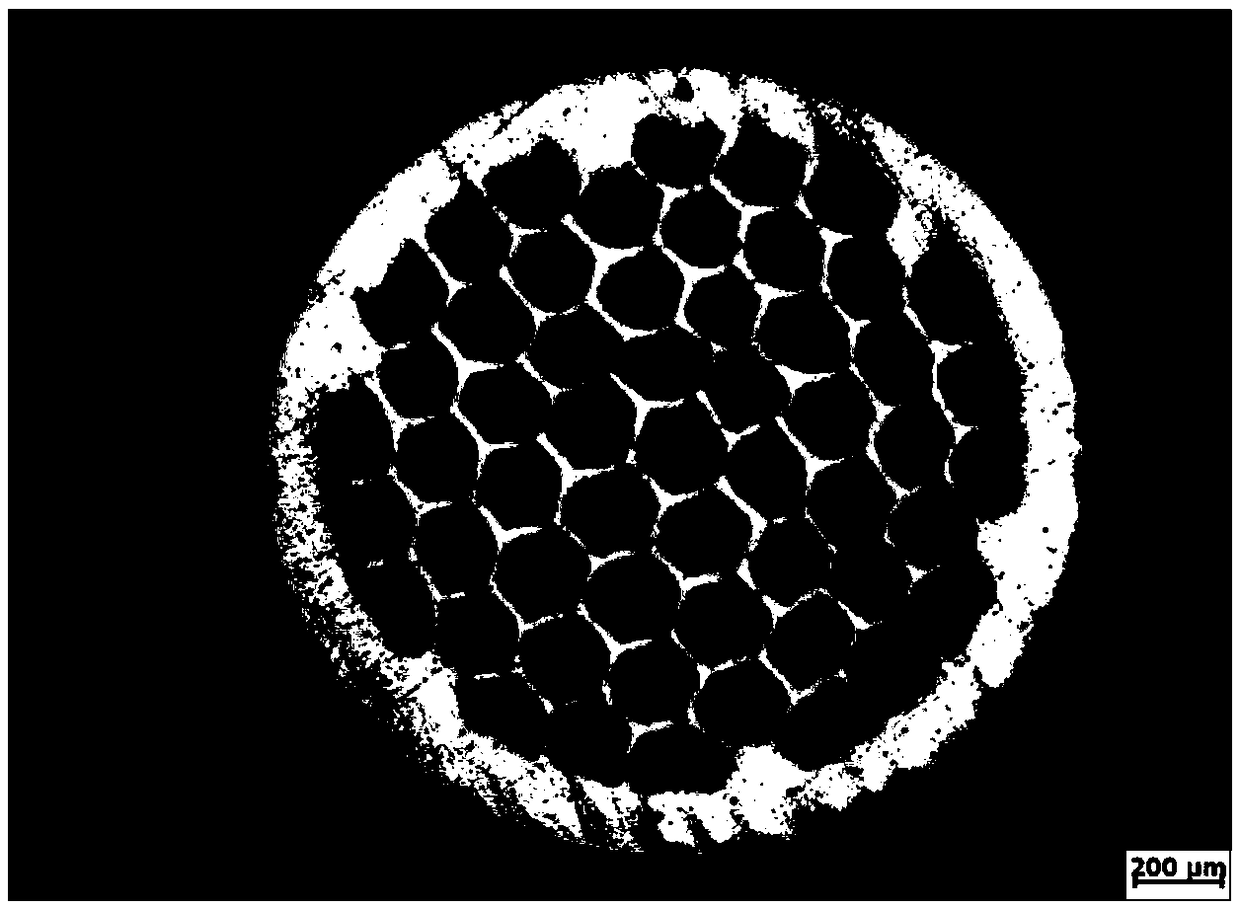

Pure-oxygen-atmosphere annealing device and method

ActiveCN103014873AStable temperature fieldImprove versatilityAfter-treatment detailsFurnace temperatureScintillation crystals

The invention discloses a pure-oxygen-atmosphere annealing device and method. According to the method, a material required for being annealed is loaded into quartz tubes, the quartz tubes are placed in an aluminum-oxide ceramic sleeve which is uniformly wound by nickel-chromium wires, oxygen of stable flow is introduced into the quartz tubes, the internal furnace temperature is uniformly and slowly increased, heat of a heater is transferred to crystals to be annealed in a radiation manner, and a temperature control instrument controls a heating-up rate, the degree of a constant temperature, the time for constant temperature and a cooling rate, so that the fully-automatic unattended annealing is realized, and the annealing temperature can reach 1,300 DEG C. The pure-oxygen-atmosphere annealing device and method disclosed by the invention are applicable to the pure-oxygen-atmosphere annealing of materials, such as laser crystals, scintillation crystals and the like, the annealing efficiency is high, and the light emitting efficiency of the laser and scintillation crystals can be increased by 20-40%; after annealing, the brightness, transparency, crystalline perfection and optical uniformity of the crystals can be greatly improved; and the pure-oxygen-atmosphere annealing device has the advantages of stable temperature field, simplicity and reliability, good universality and low energy consumption, so that the annealing cost is reduced.

Owner:SUZHOU SIHAI CHANGJING PHOTOELECTRIC MATERIAL

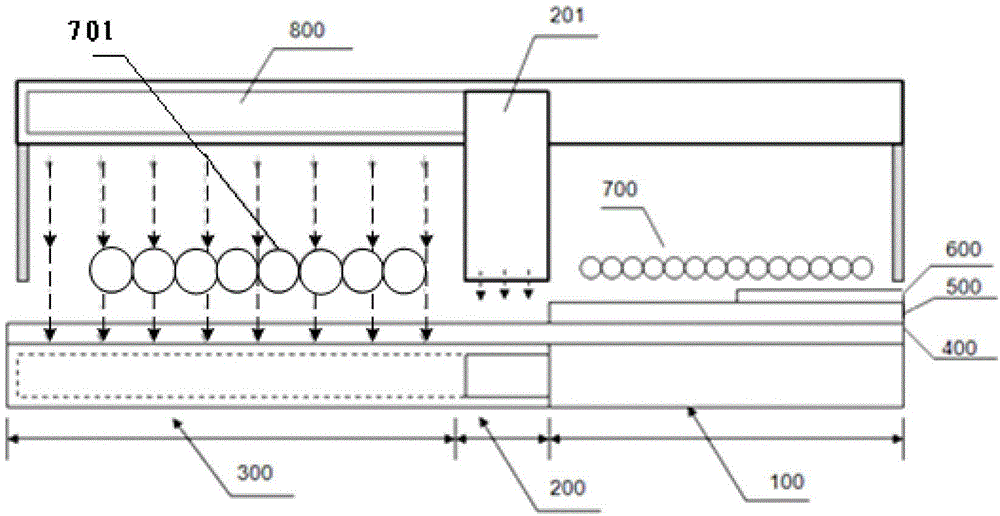

Copper belt production technology for new energy automobile connector

ActiveCN105420647AAvoid the phenomenon of rolling partsEasy to set upWork cooling devicesMetal rolling arrangementsNew energyEngineering

The invention discloses a copper belt production technology for a new energy automobile connector, and belongs to the technical field of the copper plate belt production technology. The technology comprises the first step of cast ingot smelting, the second step of face milling, the third step of hot rolling, the fourth step of rough rolling, the fifth step of one-time annealing, the sixth step of one-time cleaning, the seventh step of intermediate rolling, the eighth step of two-time annealing, the ninth step of two-time cleaning, the tenth step of intermediate rolling, the eleventh step of three-time annealing, the twelfth step of three-time cleaning, the thirteenth step of finish rolling, the fourteenth step of four-time cleaning and the fifteenth step of leveling, wherein in the fourth step of rough rolling, after rough rolling, the regulated thickness of a belt roll is 2.5 mm. By means of the technical scheme, the copper belt annealing technology quality and the copper belt surface quality can be improved, and therefore the workshop cost can be reduced, and the productive profit can be increased.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

Small-size LED copper strip production process

The invention discloses a small-size LED copper strip production process, and belongs to the technical field of the copper strip production process. The production process includes the following stepsof (1) smelting and ingot casting, (2) hot rolling, (3) milling, (4) rough rolling, (5) first annealing, (6) one-step cleaning, (7) intermediate rolling, (8) secondary annealing, (9) secondary cleaning, (10) intermediate finish rolling, (11) third annealing, (12) third cleaning, (13) finish rolling, (14) unwinding, (15) fourth annealing, (16) fourth cleaning, (17) refine rolling, (18) fifth cleaning, (19) flattening and (20) cutting and delivery. According to the technical scheme, the quality of small-size LED copper strips can be improved, the workshop cost is reduced, and the production profits are increased.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

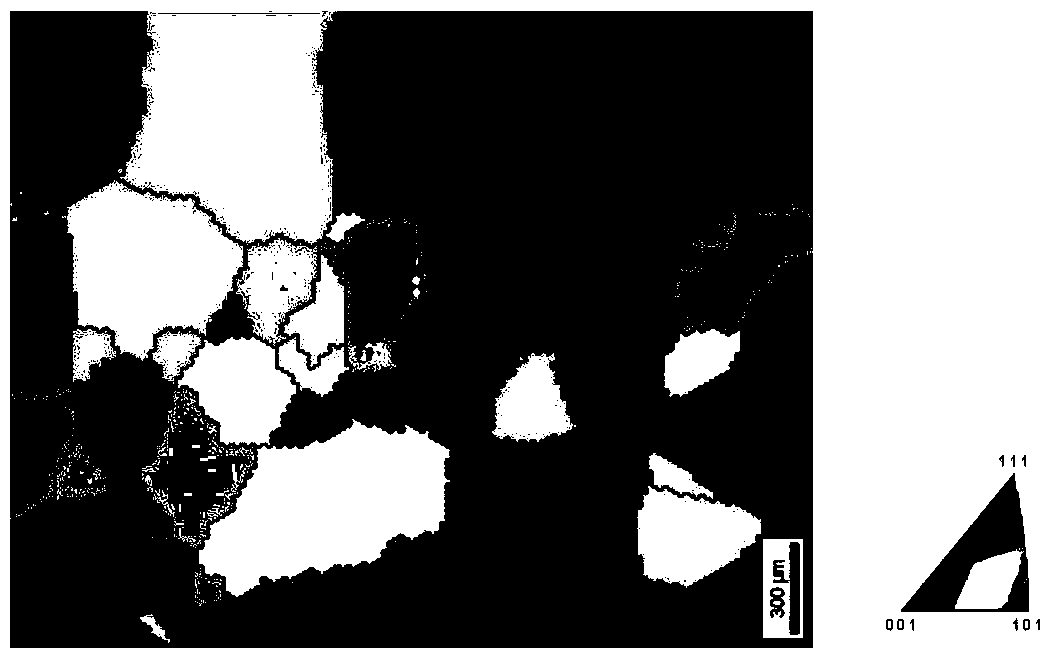

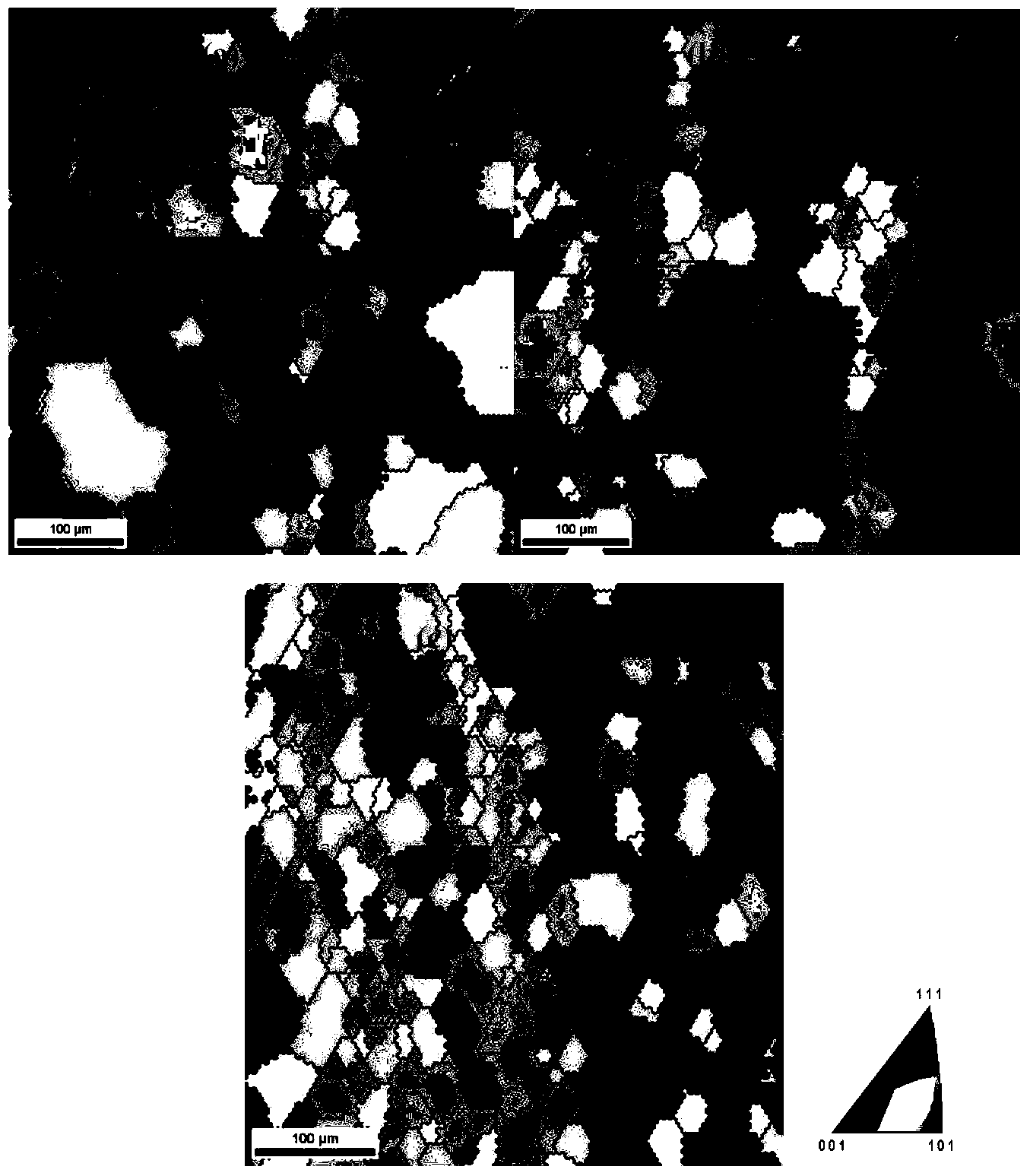

Fast heat treatment method for controlling magnetic property of double-roller thin-strip casting non-oriented silicon steel

The invention belongs to the technical field of metallurgy and provides a fast heat treatment method for controlling the magnetic property of double-roller thin-strip casting non-oriented silicon steel aiming at enhancing the magnetic property of non-oriented silicon steel. The fast heat treatment method comprises the following steps: pouring molten non-oriented silicon steel into a double-roller thin-strip casting machine through a tundish to cast a casting strip with the thickness of 2.5+ / -0.3 mm; cooling the casting strip, then coiling, pickling the coiled casting strip, and then directly carrying out first-stage cold rolling to obtain a thin strip of 0.5 mm; and fast annealing the thin strip after the first-stage cold rolling, and removing the residual stress of the annealed thin strip by adopting stress relief annealing after punching to obtain a non-oriented silicon steel finished product. The magnetic property of the non-oriented silicon steel finished product is as follows: an iron loss value is P15 / 504.76-7.34 W / kg, and the magnetic induction is B501.793-1.840 T. According to the fast heat treatment method, the non-oriented silicon steel produced by controlling fast heat treatment and combining with thin-strip casting is simple in technology, easy to realize, controlled in structure and structural component and high in annealing efficiency, and a product is obviously enhanced in magnetic property.

Owner:NORTHEASTERN UNIV LIAONING

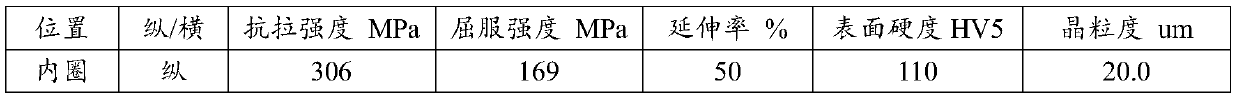

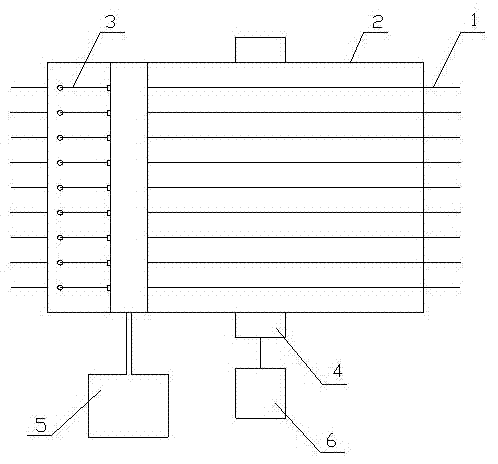

High-efficiency short-process heat treatment technology for marine titanium alloy

The invention discloses a high-efficiency short-process heat treatment technology for marine titanium alloy, wherein a plurality of TA5 (Titanium Alloy5) plates are overlapped, a Q235 pressing plate is arranged on the TA5 plates, the thickness of the Q235 pressing plate ranges from 30 to 50 mm, the roughness degree of the pressing plate is less than or equals to 5 mm / m, the charging is performed at the temperature ranging from 400 to 500 DEG C, heat preservation is performed for 50 to 70 minutes at the temperature of 550 DEG C, and temperature rises at the speed of 4 to 5 DEG C / min until reaching 700 DEG C and then heat preservation is performed for 150 to 200 minutes; in addition, the TA5 plates move about in a roller hearth furnace in a reciprocating manner during the whole heat treatment process, the rotational frequency of a roller ranges from 5 to 6 Hz, and the rotational frequency of the roller ranges from 10 to 15 Hz in a wind cooling stage. The TA5 plates that are processed through the high-efficiency short-process heat treatment technology achieve good performance uniformity, the shear strength of all parts of the TA5 plates ranges from 680 to 700 Mpa, the tensile strength ranges from 700 to 725Mpa, the elongation percentage ranges from 19 to 23 percent, and the high-efficiency short-process heat treatment technology is a plurality of times the annealing efficiency of a continuous annealing furnace.

Owner:LUOYANG SUNRUI TI PRECISION CASTING

Production technology of copper strip for automobile contact

The invention discloses a production technology of a copper strip for an automobile contact and belongs to the technical field of copper plate and strip production technologies. The production technology comprises 1, ingot melting casting, 2, surface milling, 3, hot rolling, 4, rough rolling, 5, primary annealing, 6, primary washing, 7, medium rolling, 8, secondary annealing, 9, secondary cleaning, 10, medium finish rolling, 11, tertiary annealing, 12, tertiary washing, 13, finish rolling, 14, quaternary washing and 15, leveling. The production technology improves annealing process quality and copper strip surface quality, reduces a workshop cost and improves productive profits.

Owner:ANHUI CHUJIANG TECHCAL NEW MATERIAL CO LTD

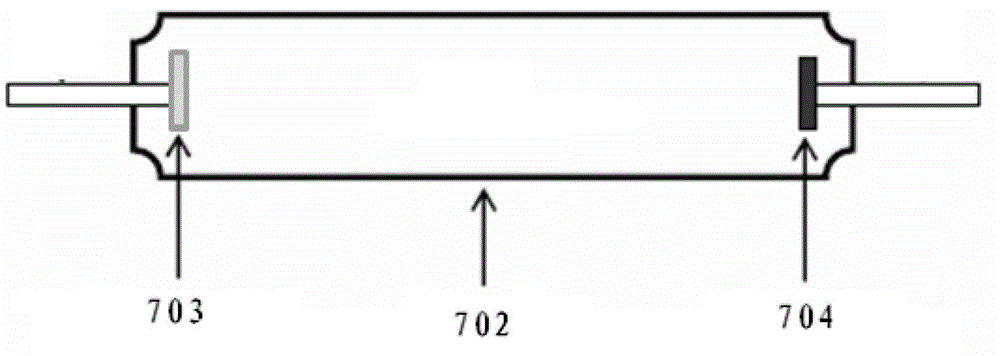

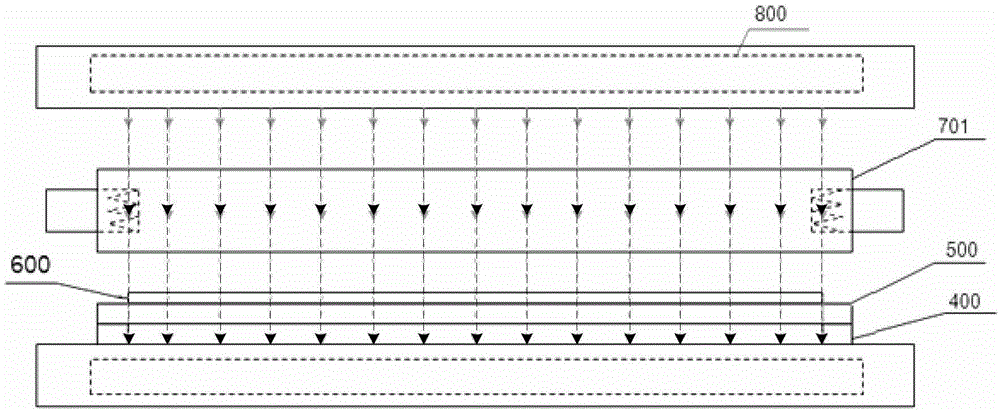

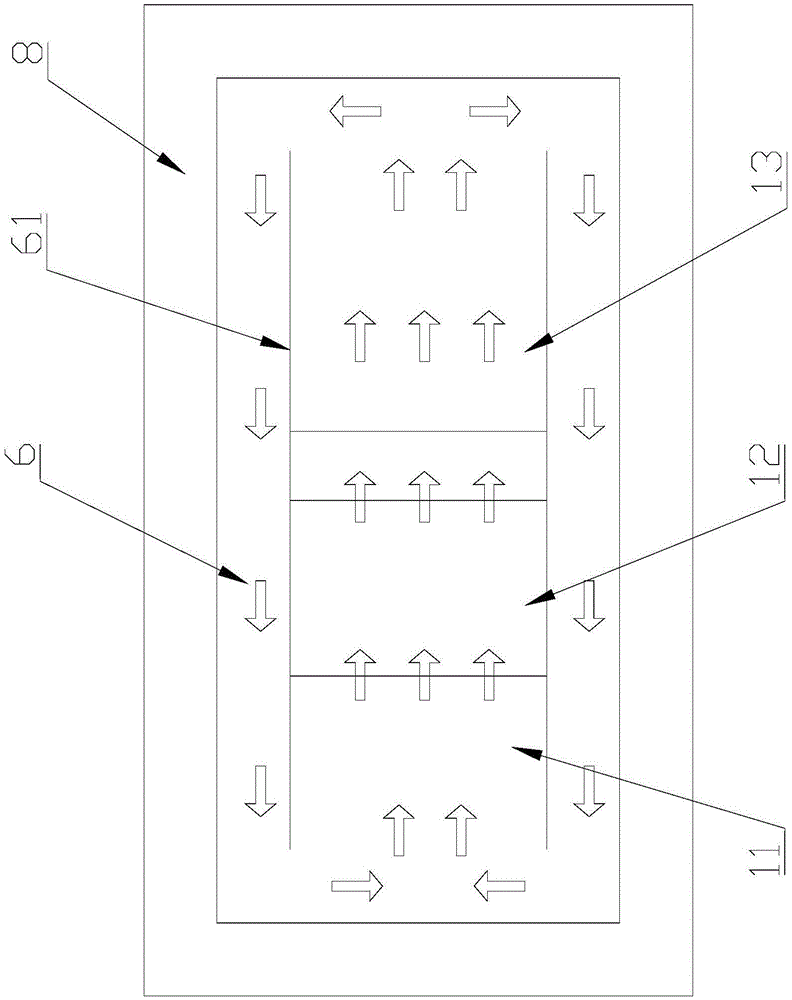

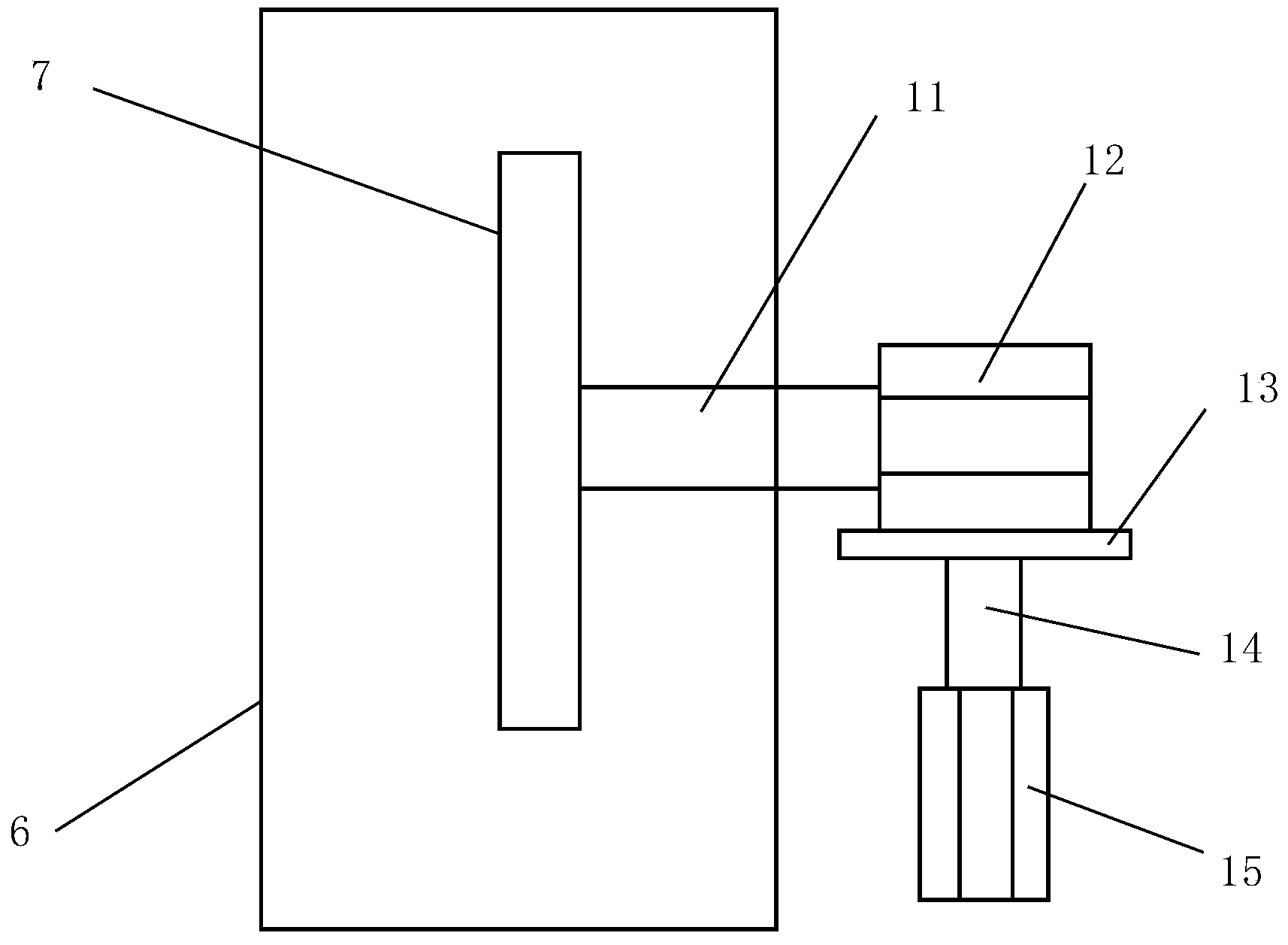

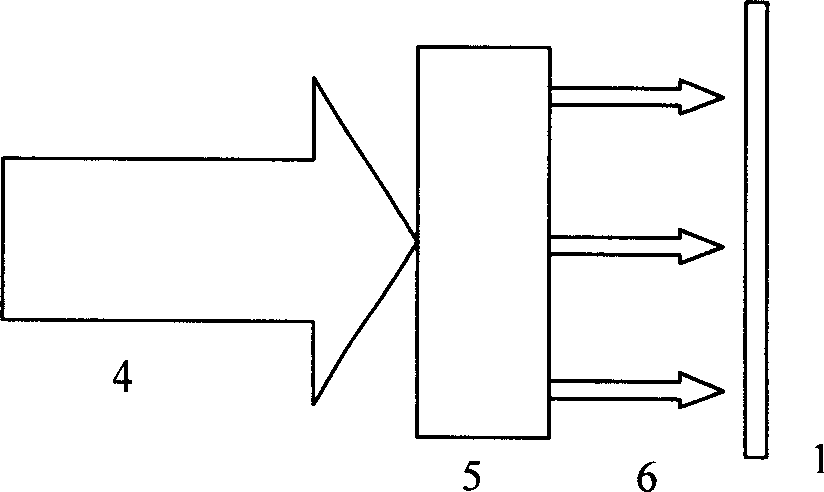

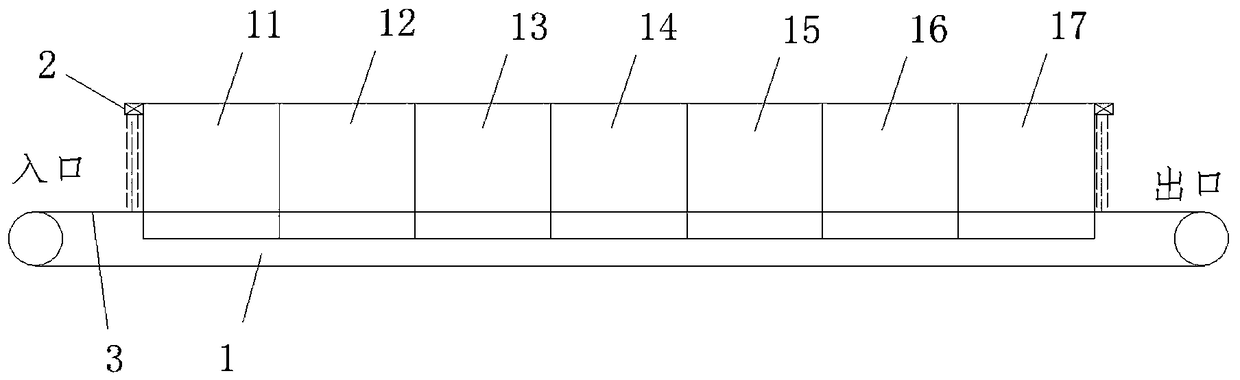

Annealing apparatus and annealing process

ActiveCN103337457AImprove annealing efficiencySemiconductor/solid-state device manufacturingOhmic-resistance heating devicesTemperature UnitElectromagnetic field

The invention relates to an annealing apparatus and an annealing process. The annealing apparatus comprises a temperature gradient preheating unit which is used for performing gradient heating on a to-be-annealed substrate by using gradient temperatures, a high temperature unit which is used for performing high-temperature heating on the preheated substrate, a moving apparatus which is used for transporting the substrate to the high temperature unit from the temperature gradient preheating unit during the gradient preheating of the substrate and / or after the preheating of the substrate. The beneficial effects of the annealing apparatus and the annealing process are that since the method of gradient heating is adopted and preheating processing is conducted on the substrate, the annealing efficiency is improved; since a plasma induction unit and the electromagnetic field auxiliary high temperature unit are added, multiple functions are integrated and the annealing efficiency is further improved.

Owner:BOE TECH GRP CO LTD +1

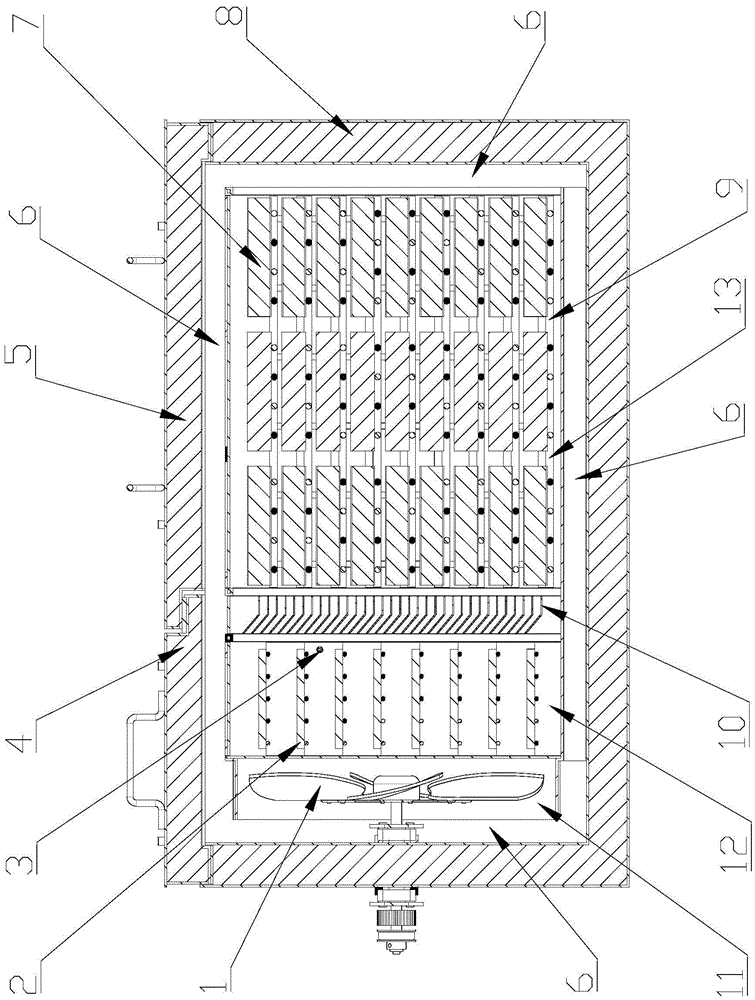

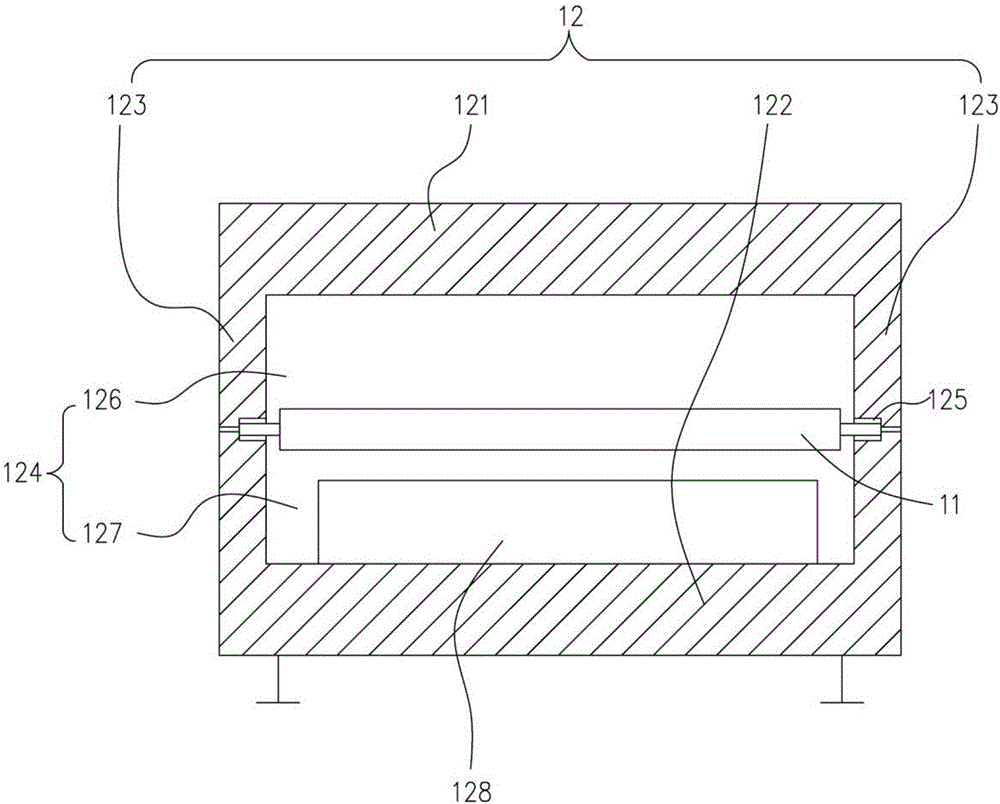

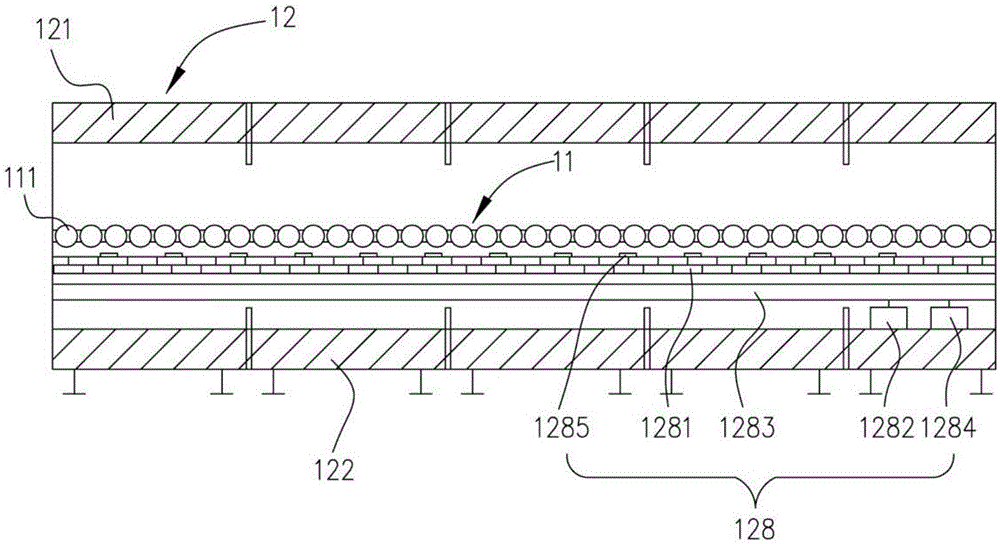

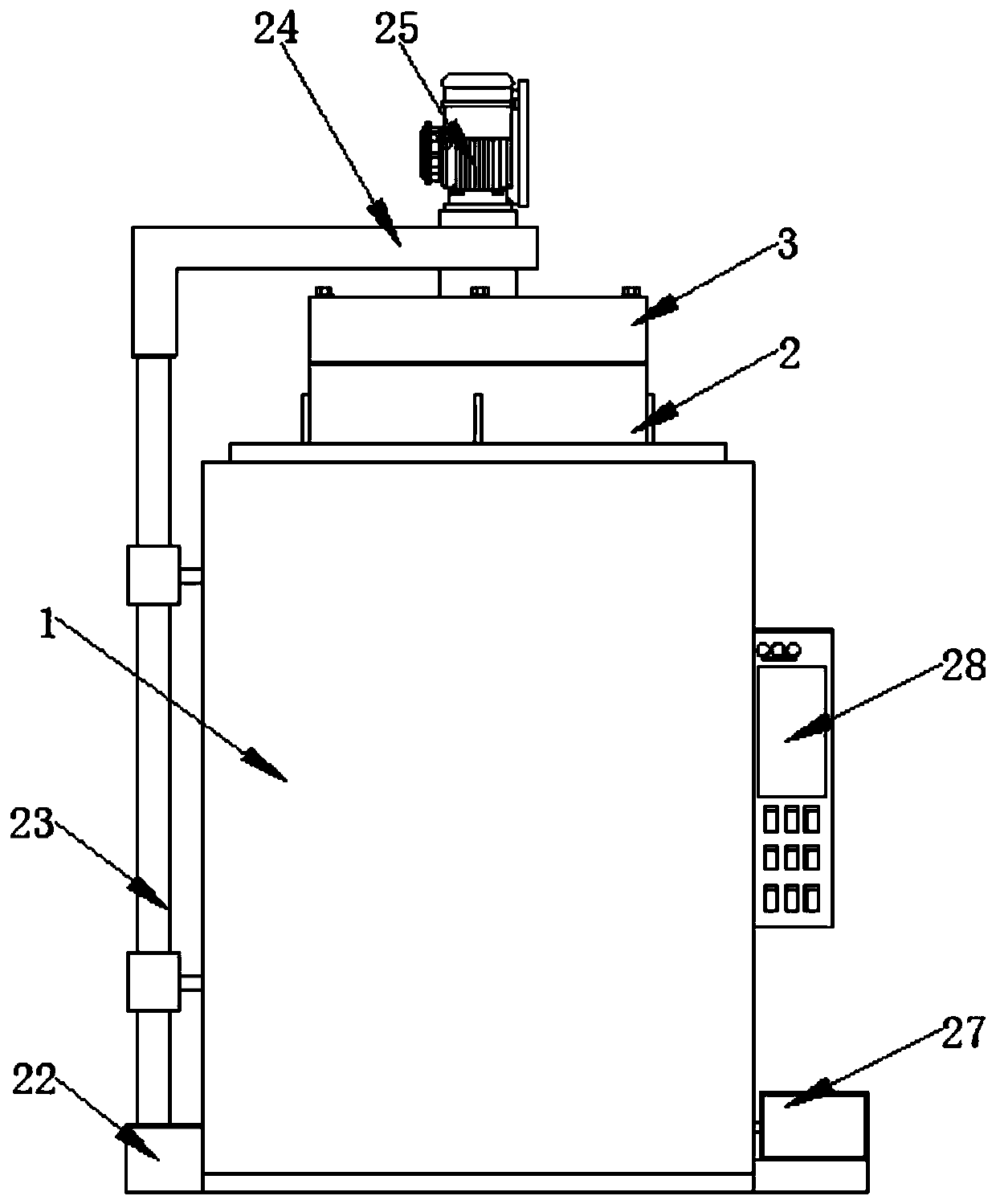

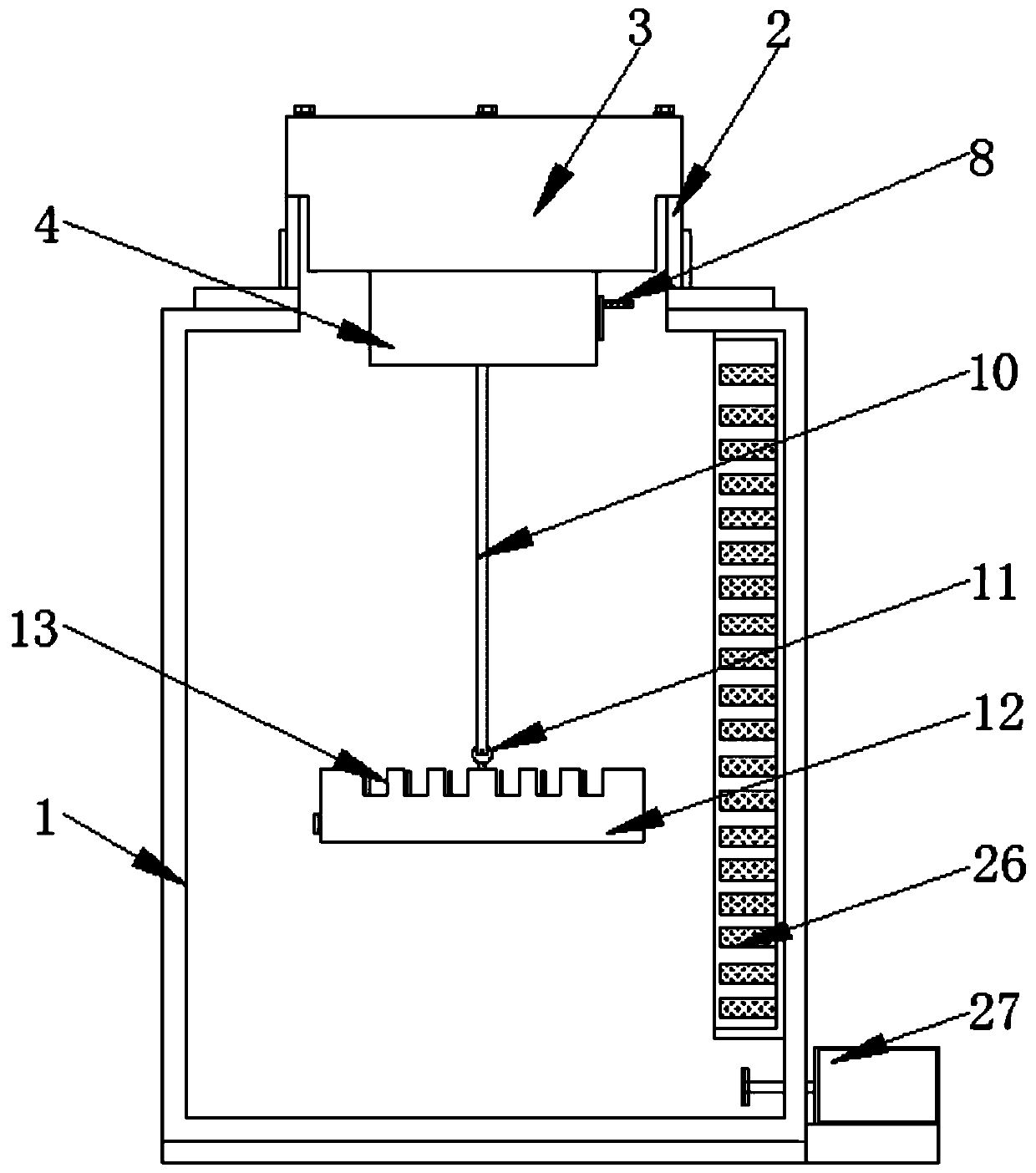

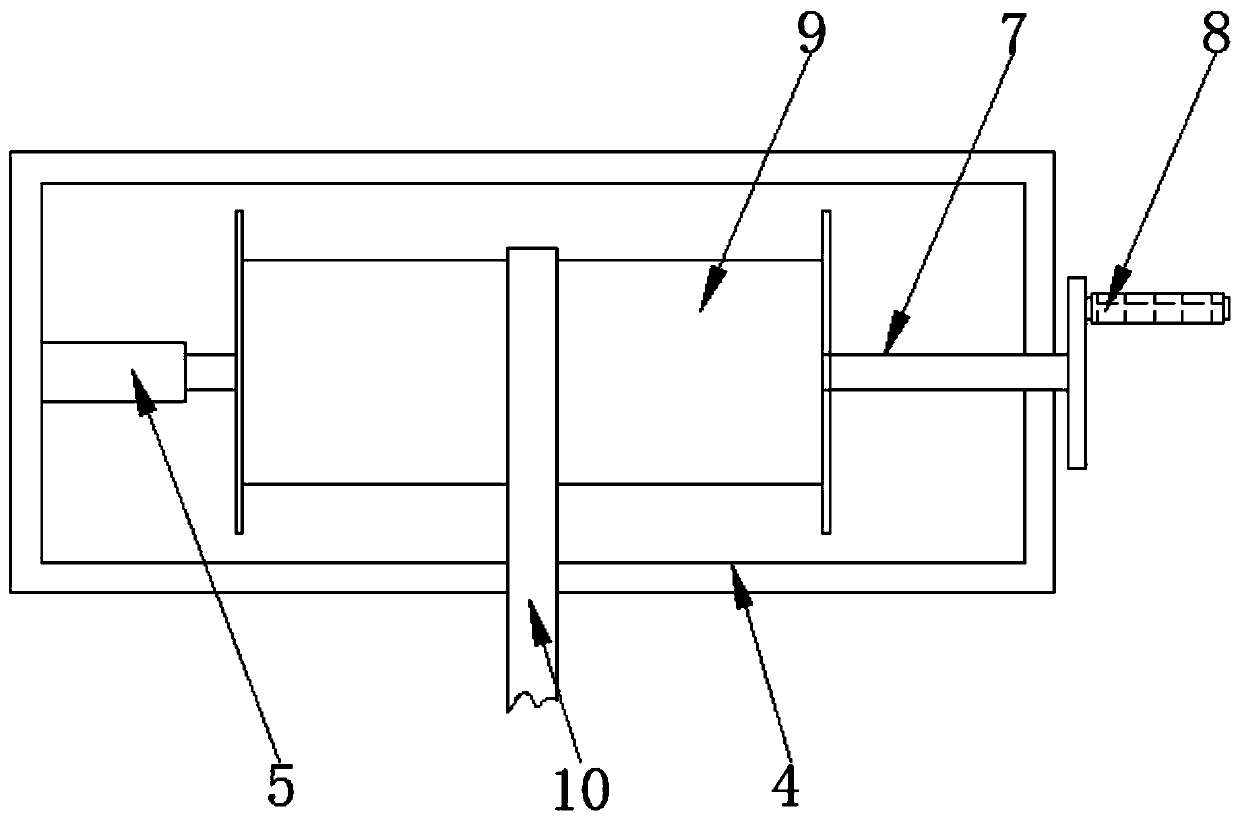

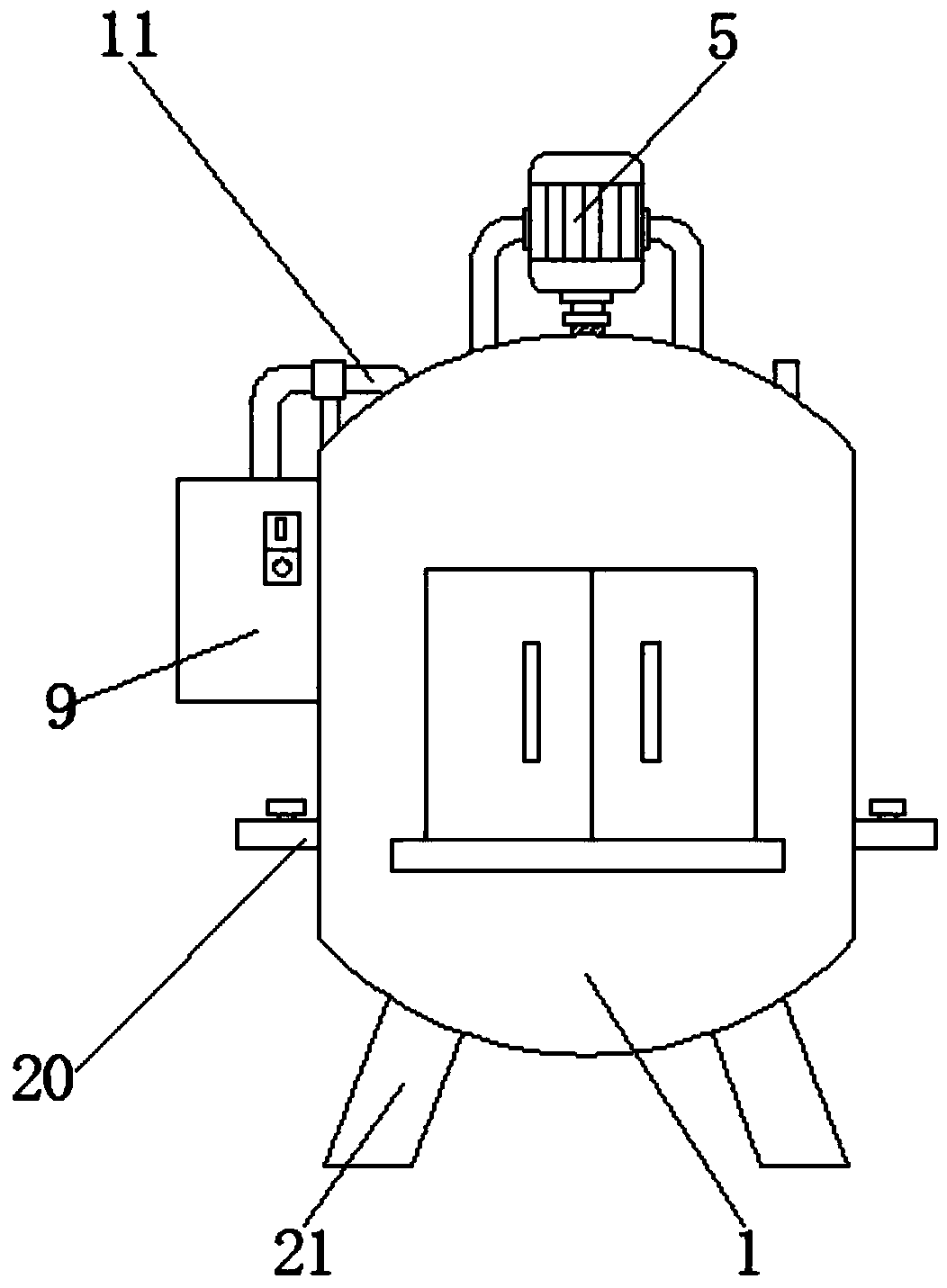

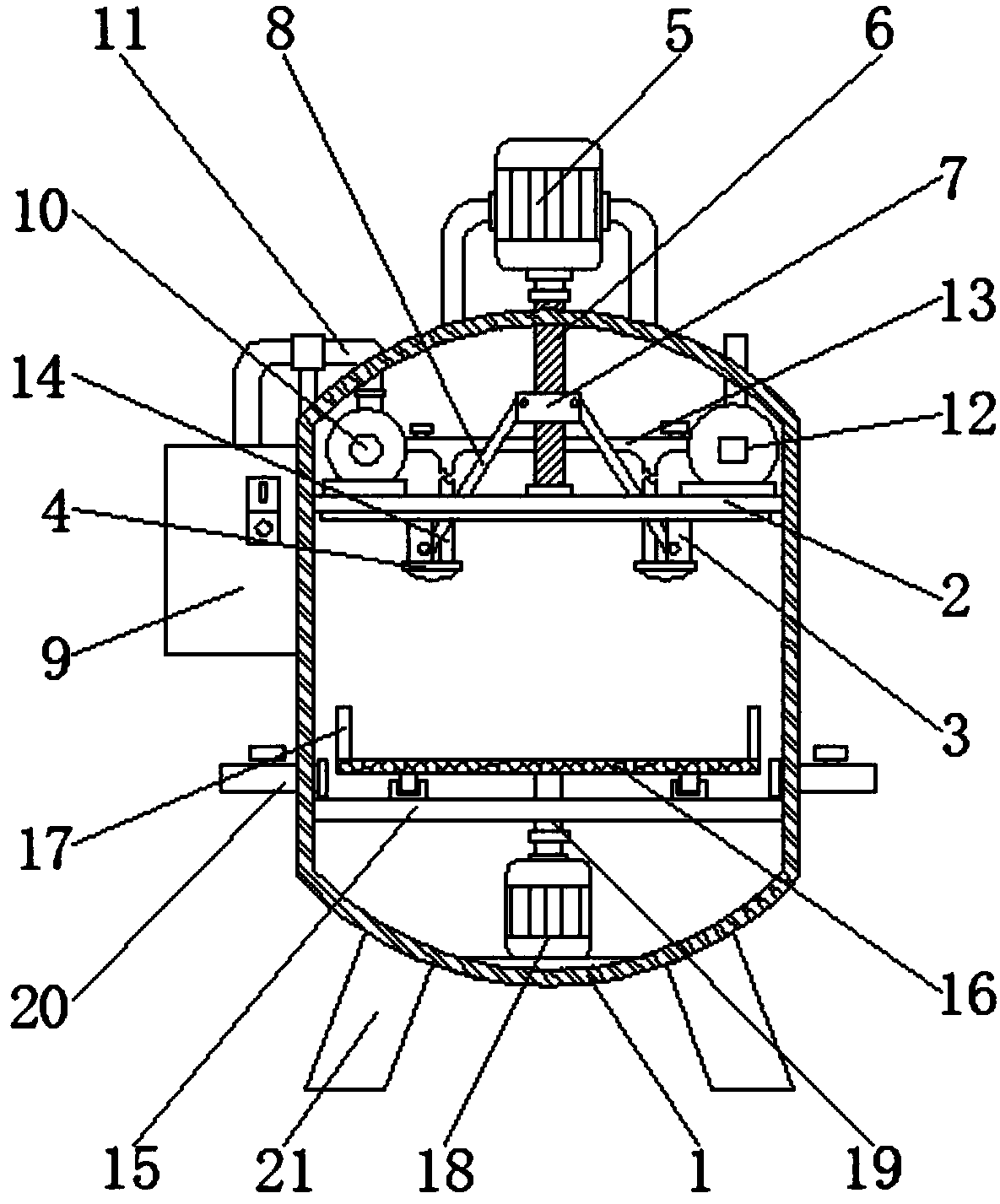

Box-type annealing furnace and annealing method using same

InactiveCN105603162AThe heating and cooling rate is fast and stable and controllableImprove annealing efficiencyProcess efficiency improvementTemperature controlMetallurgy

The invention discloses a box-type annealing furnace and an annealing method using the same. According to the box-type annealing furnace and the annealing method using the same, an arranged power chamber disturbs air flow, supplied air passes through a thermal power chamber, a heating device is arranged in the thermal power chamber, the air flow passes through a workpiece chamber after being heated to heat a workpiece in the workpiece chamber, the air flow flows back through an air flue, and a circulating flow channel is formed; the method that heating or cooling is achieved through air flow motion has the advantages that the temperature zone in the annealing furnace is more uniform, the temperature increasing and lowering speed of the annealing furnace is high, stable and controllable, the annealing efficiency is high, and a temperature control system of the annealing furnace is accurate and reliable. The box-type annealing furnace and the annealing method using the same are suitable for the field of annealing equipment.

Owner:GUANGZHOU HONSUN OPTOELECTRONICS

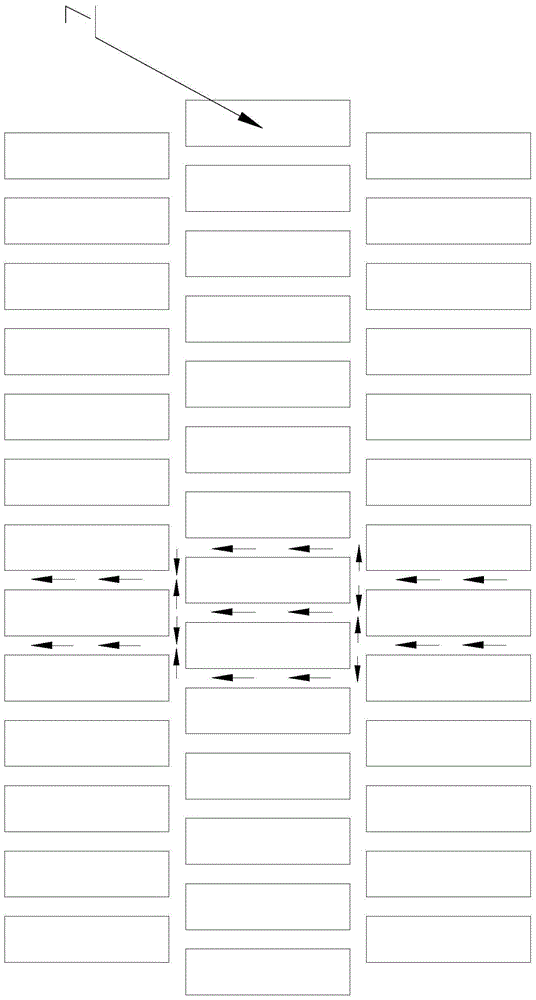

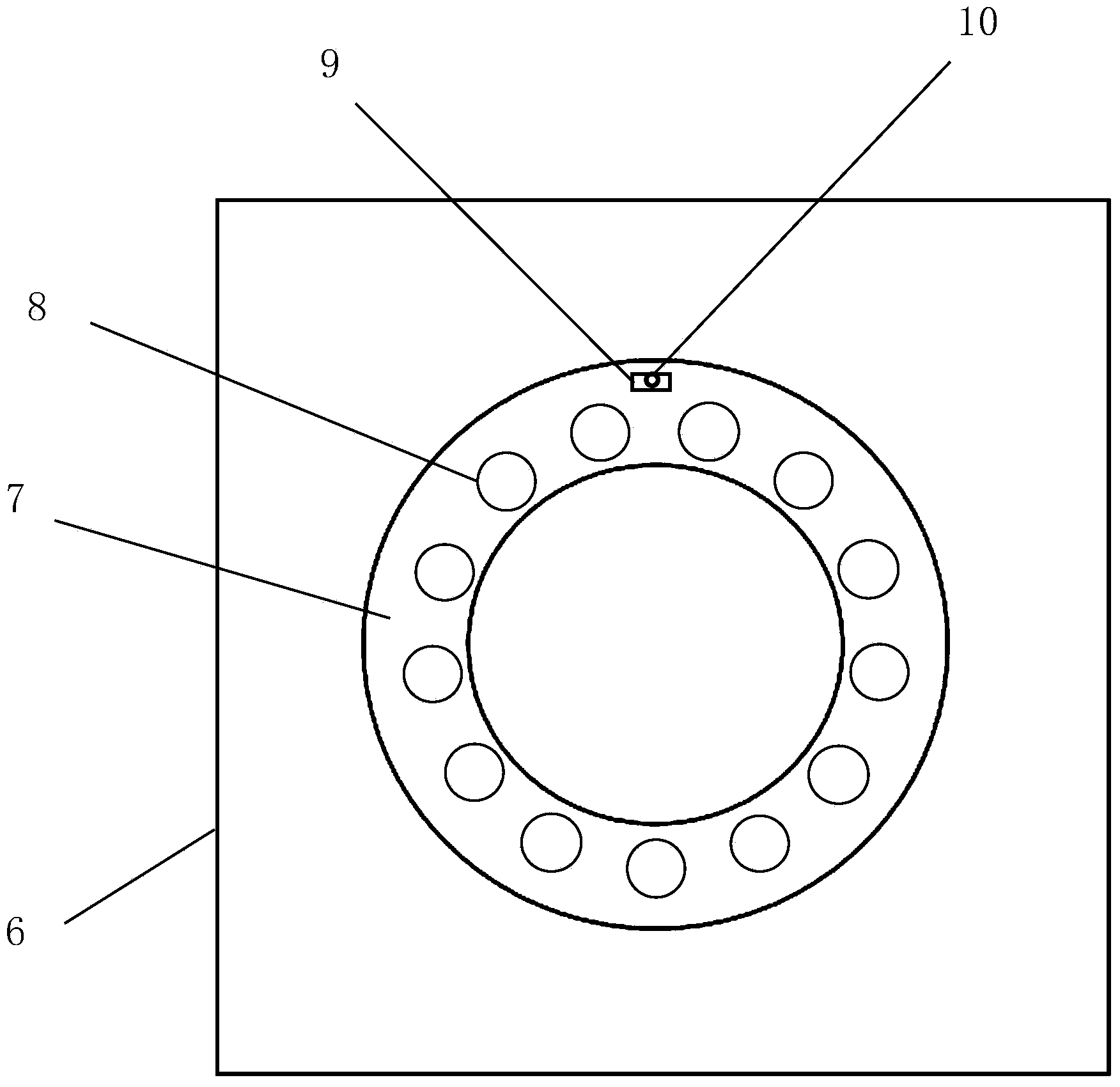

Roller kiln

PendingCN107525398AImprove annealing efficiencyIncrease productivityCharge composition/stateCharge manipulationKilnRaw material

The invention discloses a roller kiln. The roller kiln comprises a heating area and multiple annealing areas; the heating area is provided with a heating rail; each annealing area is provided with an annealing rail connected with the heating rail; the heating rail is used for placing ceramic raw materials; and the ceramic raw materials are respectively transmitted to the multiple annealing rails after heating in the heating area, and are respectively cooled in the multiple annealing areas. The multiple annealing rails transmit the ceramic raw materials of the heating roller at the same time, that is, the multiple annealing rails are used for annealing the ceramic raw materials at the same time, so that the annealing efficiency is improved, and the production efficiency is improved.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD

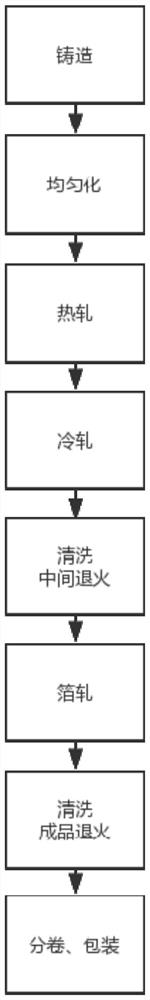

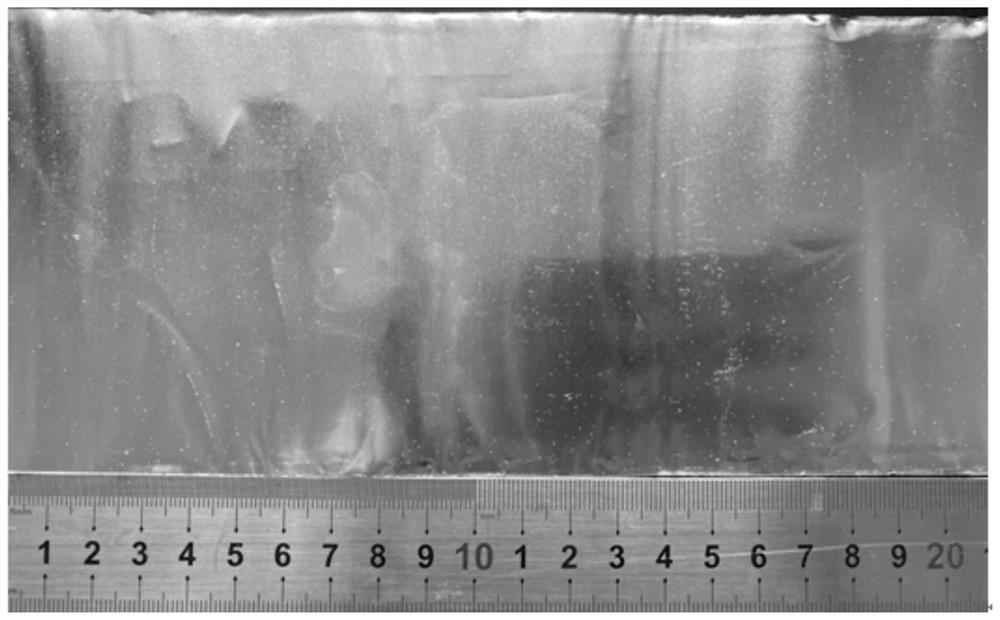

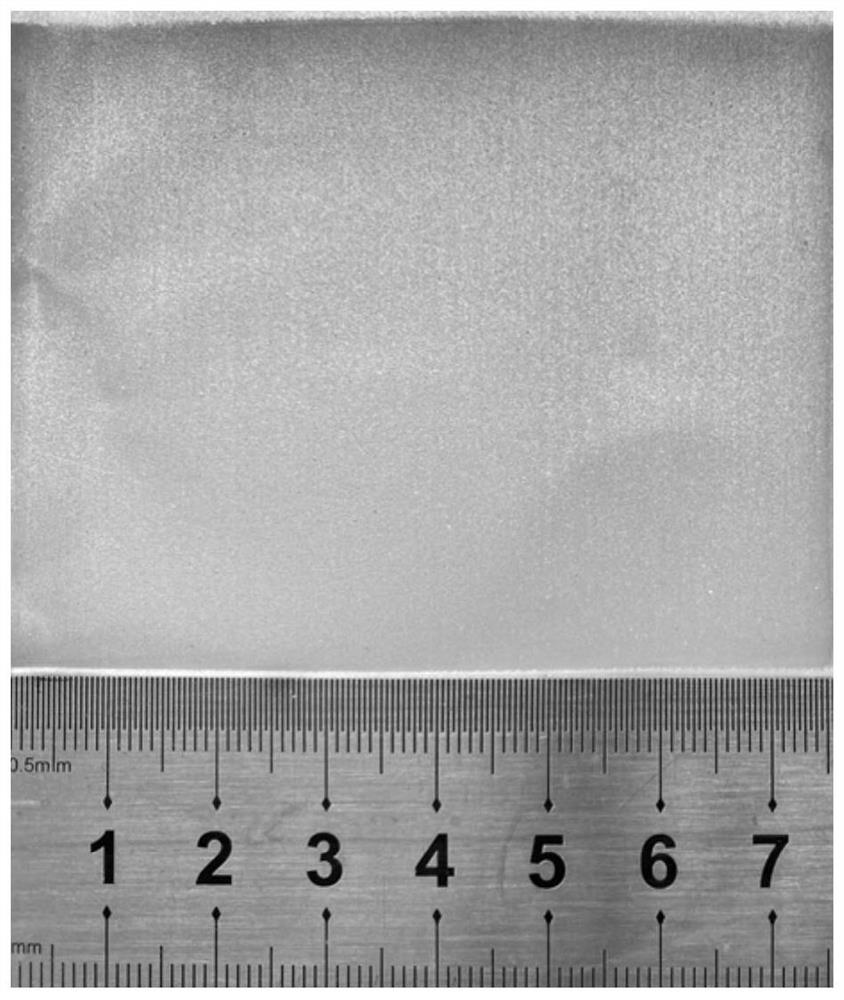

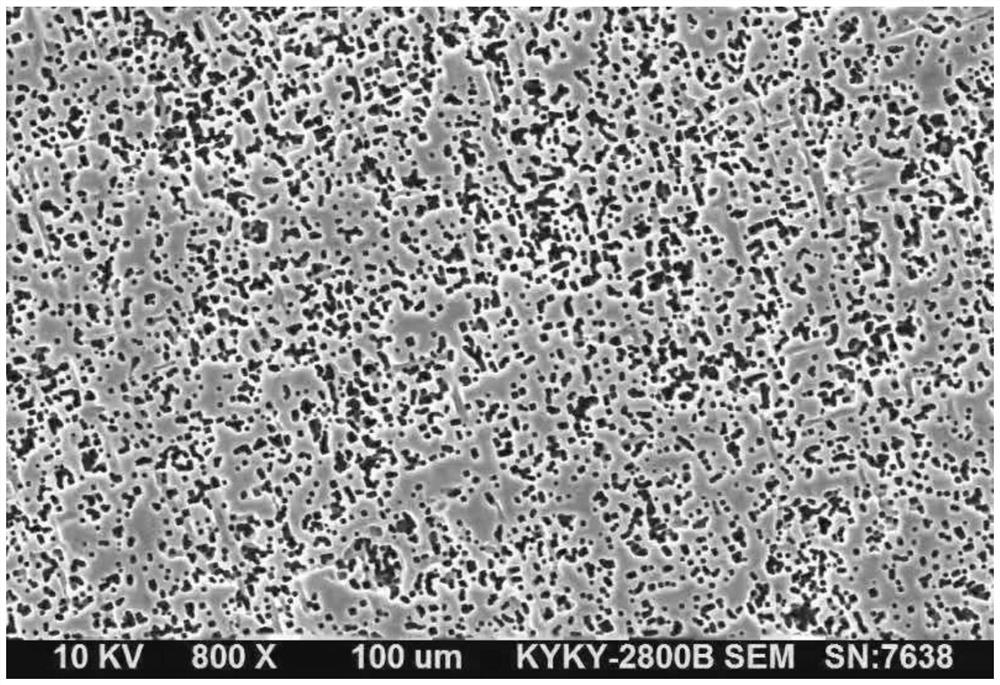

Medium-high-voltage electronic aluminum foil for high-capacity and high-strength capacitor and preparation method thereof

ActiveCN113234907AIncrease capacityIncrease the proportionElectrolytic capacitorsFurnace typesAluminum foilCapacitor

The invention discloses a medium-high-voltage electronic aluminum foil for a high-capacity and high-strength capacitor and a preparation method thereof. Through the production modes of casting and a continuous air cushion furnace, the specific volume is increased, and the production period is shortened; and the continuous air cushion furnace is used for multiple times for homogenization and annealing, and the problem that a casting structure is not uniform is solved, so that the performance and the cubic texture are improved, and the medium-high-voltage high-purity aluminum foil for the high-capacity and high-strength capacitor is obtained.

Owner:广西广投正润新材料科技有限公司

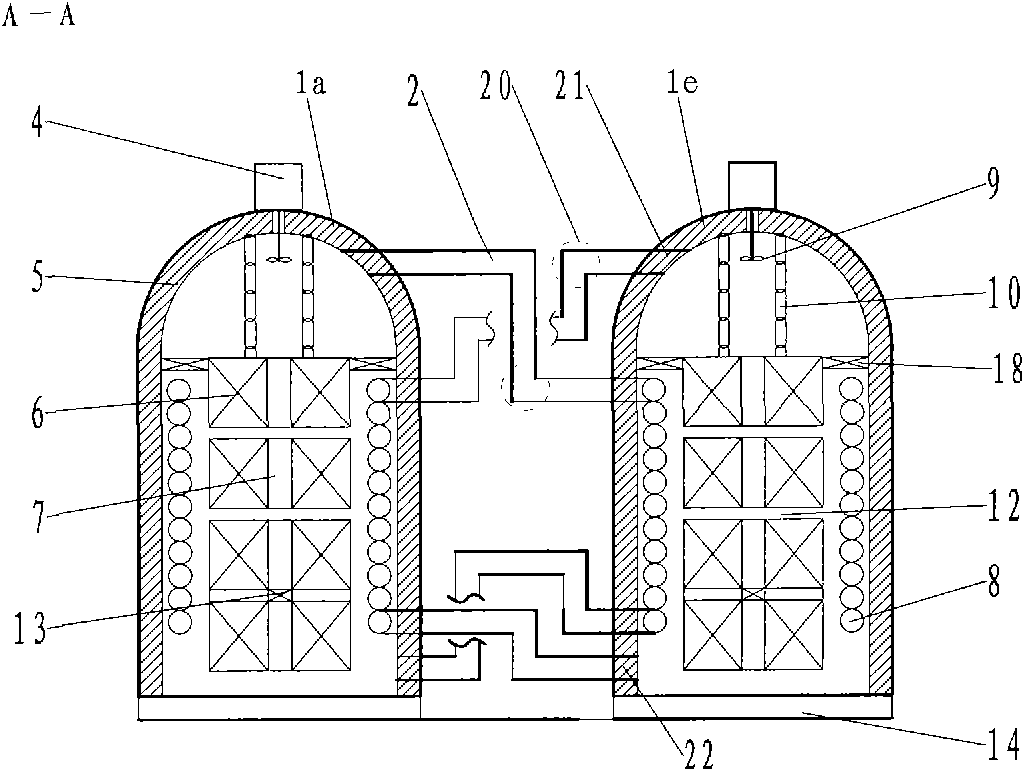

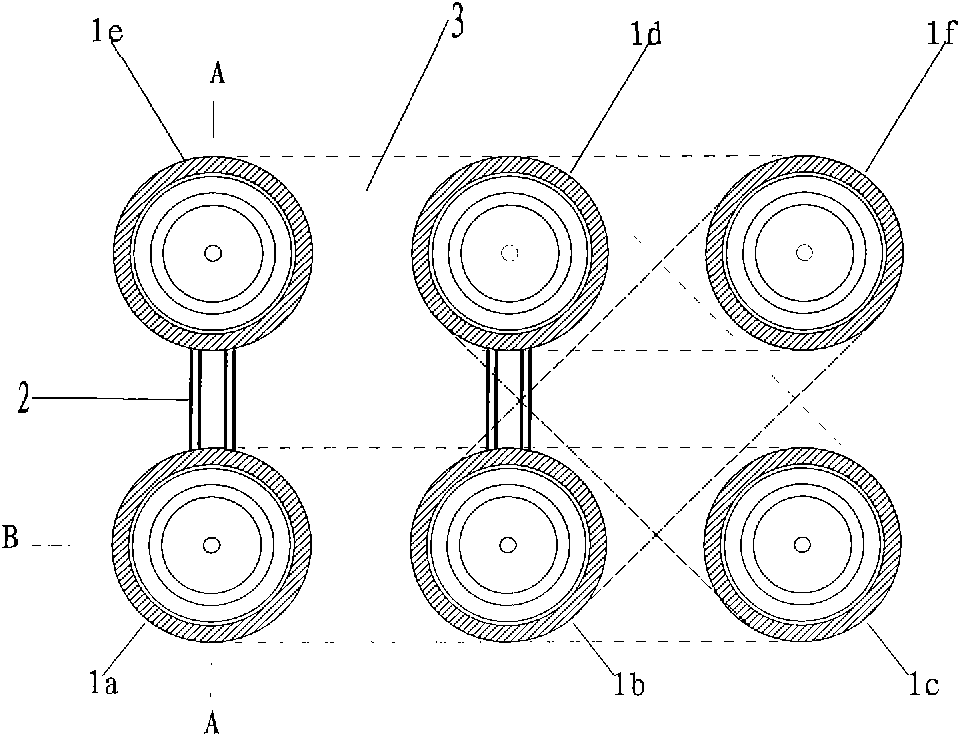

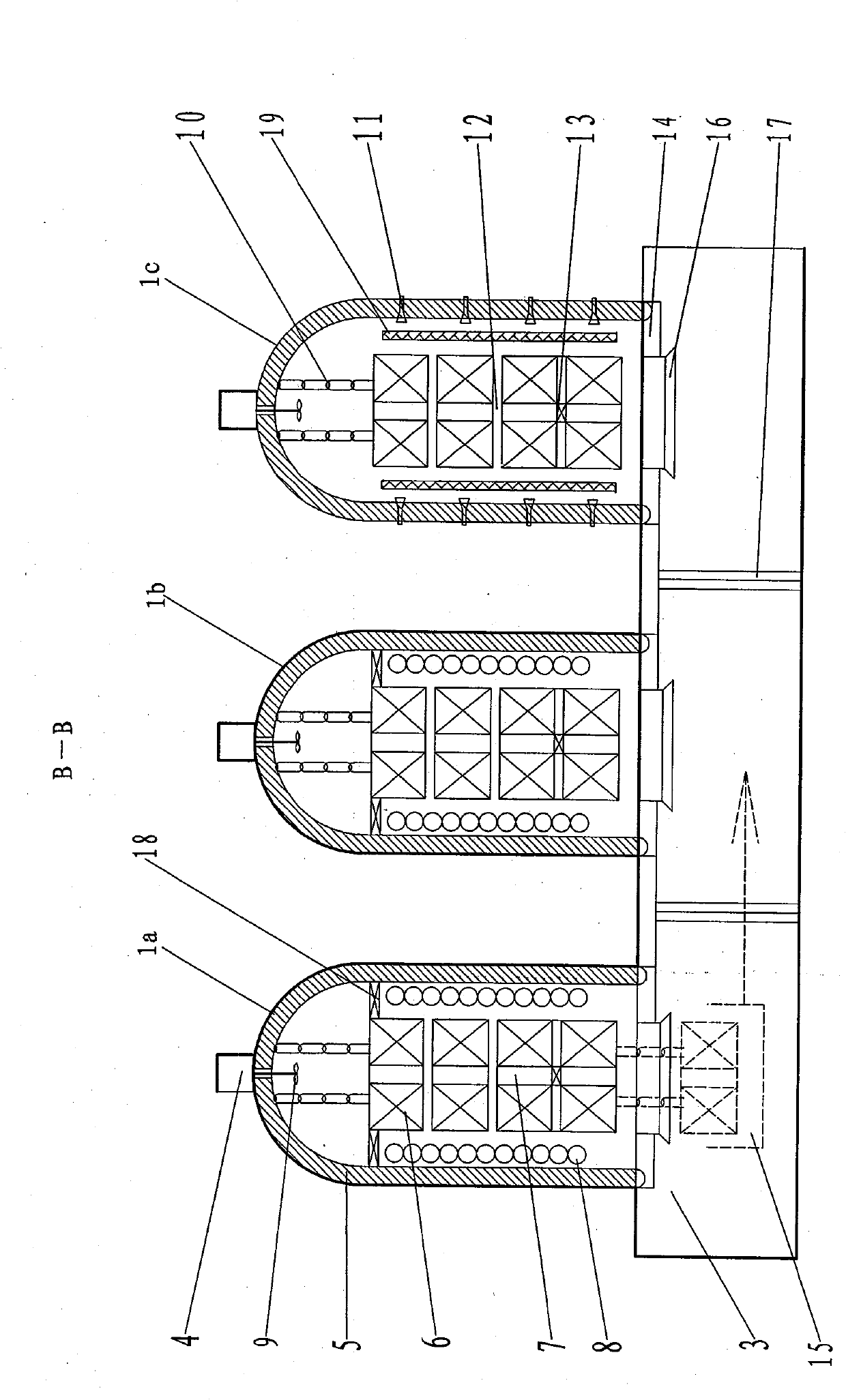

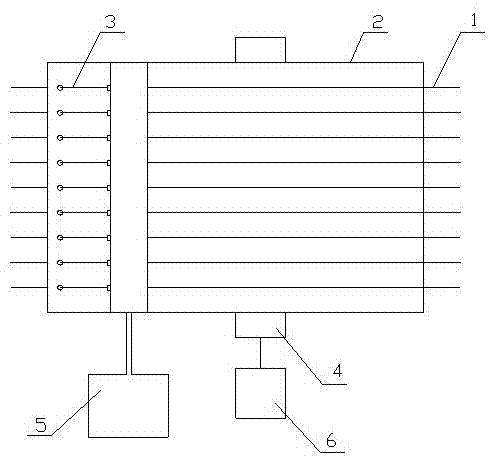

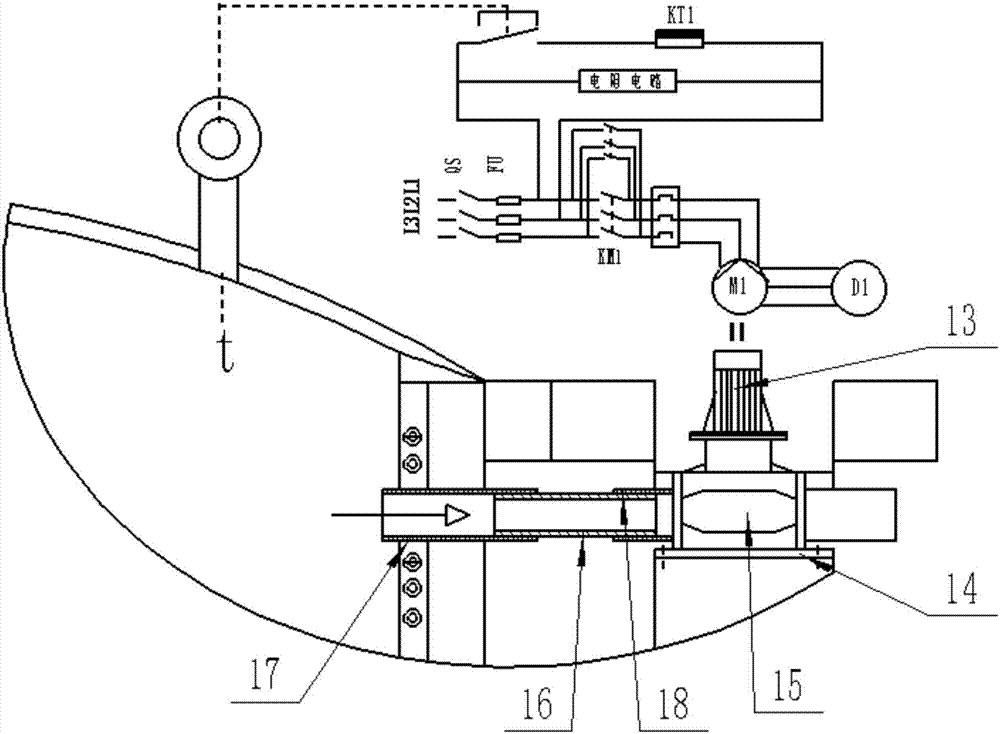

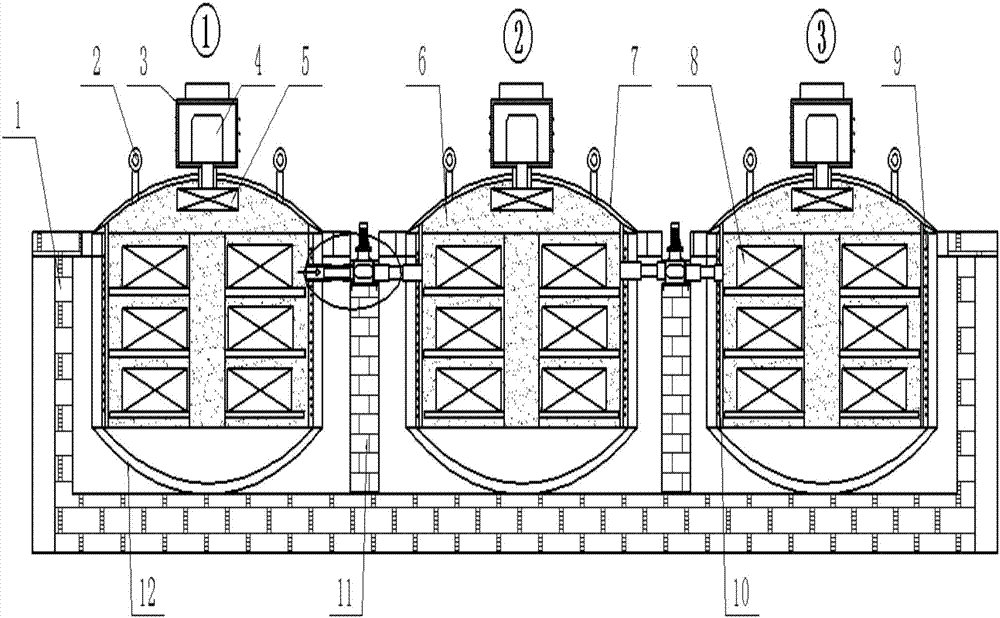

Annealing method and device of bell type furnaces

ActiveCN102002559AImprove surface qualityImprove annealing efficiencyMetallurgyCarbon Dioxide / Helium

The invention provides an annealing method and device of bell type furnaces, comprising 3-12 bell type furnaces and auxiliary systems, wherein each bell type furnace is internally provided with radiant pipes, the radiant pipes in a cooling bell type furnace are communicated are communicated with a preheating bell type furnace, and the radiant pipes in the preheating bell type furnace are communicated with the cooling bell type furnace. The bell type furnaces work in a serial connection mode and are respectively used for preheating, heating and cooling processes, materials to be annealed are sequentially conveyed among the preheating bell type furnace, a heating bell type furnace and the cooling bell type furnace, and the materials to be annealed in the preheating bell type furnace are heated by using heat generated by the cooling state bell type furnace through the circulating flow of shielding gas. In the invention, the shielding is adopted for direct heating, therefore a heating bell and a cooling bell are omitted, a flow is simplified, equipment investment and operation cost are saved; and dirt on the surfaces of the materials to be annealed are removed in the preheating bell type furnace, the heating process and the cooling process are carried out in a clean furnace, and the surface quality of an annealed product is good.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

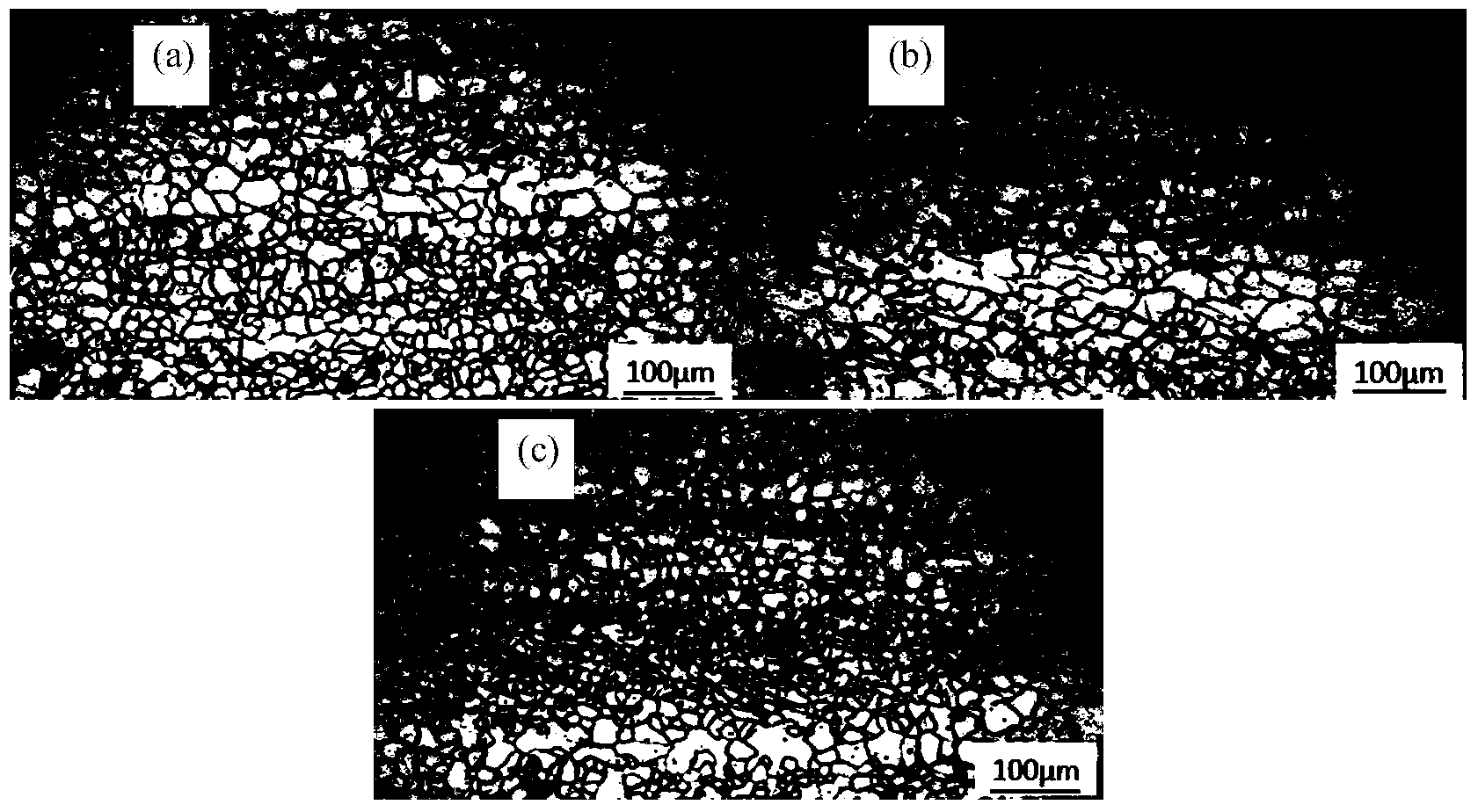

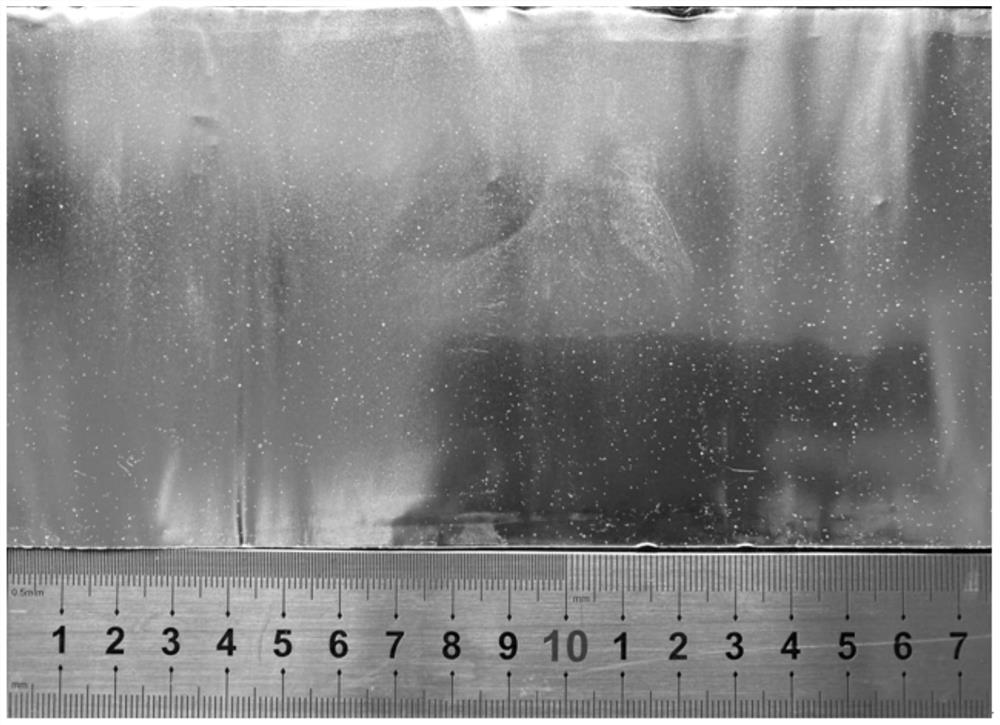

Preparing process of titanium strip coil used for high-end anode

InactiveCN110814079AUniform temperatureImprove performance uniformityMetal rolling arrangementsEtchingSurface oxidation

The embodiment of the invention provides a preparing process of a titanium strip coil used for a high-end anode. The preparing process comprises two rolling processes, the size and the uniformity of grains of a finished product are controlled conveniently, surface defects of the produced titanium coil are less, compared with first rolling process rolling, namely a hot rolling coil is directly rolled to the thickness of a second-thickness cold rolling coil, the pausing does not occur in the middle, and if continuous annealing and surface treatment are carried out firstly, and then second rolling process rolling is carried out, the surface defects of the finally obtained finished product are more. After the finished product is annealed, then flatten treatment is conducted, and then an oxidelayer on the surface of the titanium coil is uniformly crushed, so that a more consistent condition is provided for the etching of the subsequent titanium coil, the etching effect can be improved, thesurface color of an etched titanium plate is consistent, and finally, the titanium plate coating is better facilitated.

Owner:湖南湘投金天钛金属股份有限公司

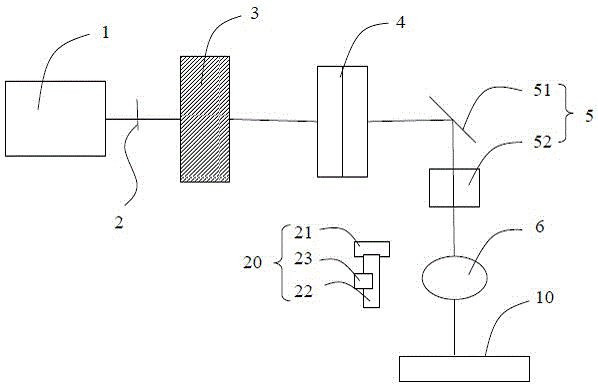

Laser annealing device

InactiveCN103824762AHigh activation rateImprove annealing efficiencySemiconductor/solid-state device manufacturingLaser beam welding apparatusLight spotLight beam

The invention discloses a laser annealing device. The laser annealing device comprises a laser source which provides a laser beam, a beam expanding module which is located on an optical path of an output beam of the laser beam, a beam shaping module which is used for enabling a beam output by the beam shaping module to have uniform energy density, and a flat field focus lens which is located on an optical path of the output beam of the beam shaping module, and is used for focusing the beam output by the beam shaping module into flat topped light spots. According to the laser annealing device and a laser annealing method, which are provided by the invention, the optical components are used to carry out adjusting, and the flat topped light spots of uniform energy distribution are transmitted; the annealing efficiency is high; good uniformity is realized; the activation rate of crystal arrangement is improved; and effective processing is realized.

Owner:SUZHOU DELPHI LASER

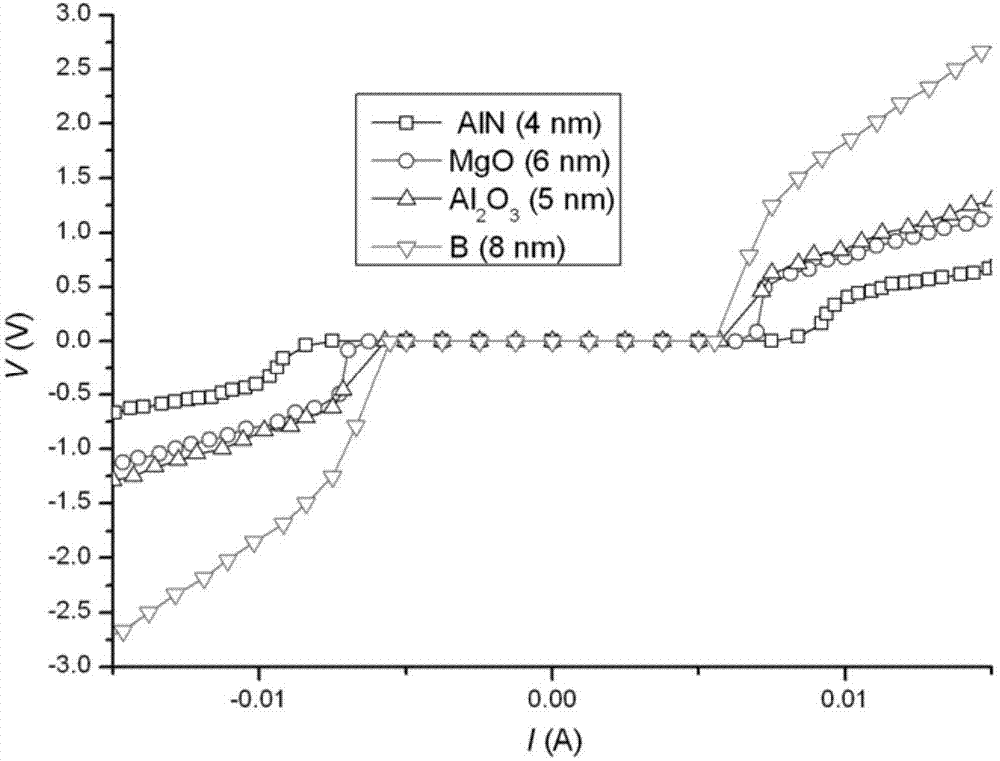

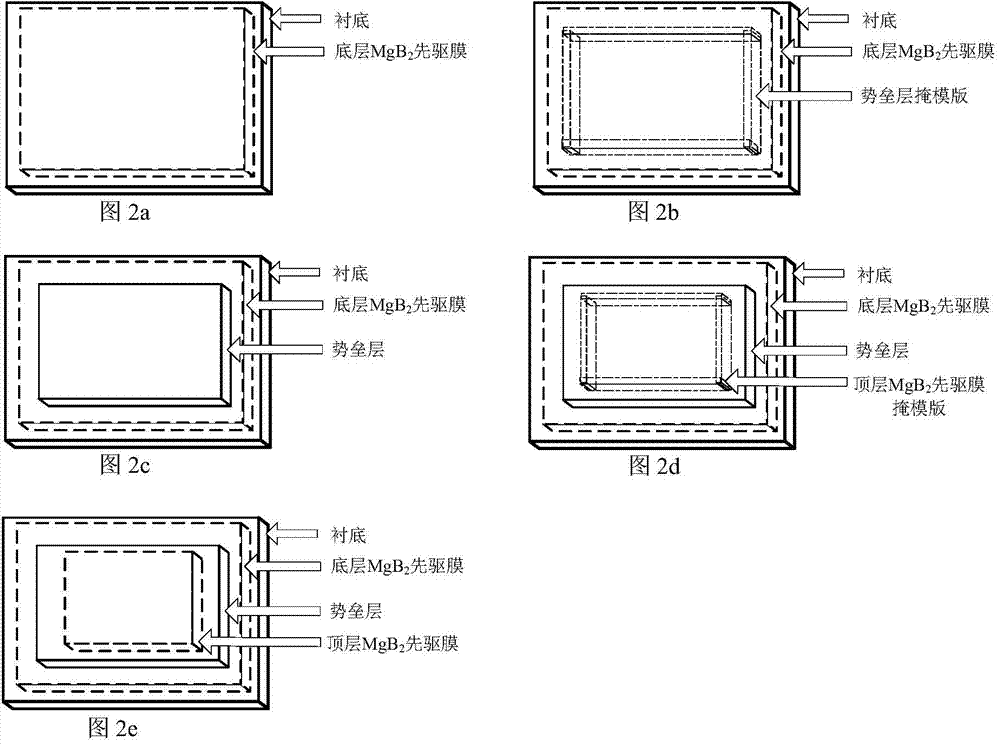

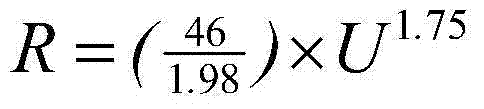

Method for preparing magnesium diboride superconductive Josephson junction through secondary mask method

ActiveCN103904210AReduce component diffusionShort annealing timeSuperconductor device manufacture/treatmentChemical reactionInsulation layer

Disclosed is a method for preparing a magnesium diboride superconductive Josephson junction through a secondary mask method. According to the method, an electron beam is adopted to carry out annealing on an interlayer type (sandwich type) magnesium diboride Josephson junction precursor film. The interlayer type magnesium diboride Josephson junction precursor film is a (Mg / B)-X-(Mg-B) structure precursor film prepared through the secondary mask method, X represents a standard conductor layer N or an insulation layer I, magnesium elementary substance and boron elementary substance in the precursor film are made to generate a chemical reaction within the annealing time of a second magnitude order, finally the SNS type or SIS type magnesium diboride superconductive Josephson junction of a MgB2-X-MgB2 structure is generated, and S represents a superconductive layer.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Hydrogen annealing furnace for bright heat treatment production line

InactiveCN102296170AWill not oxidizeMeet the requirements of the annealing processFurnace typesHeat treatment furnacesProduction lineTube furnace

The invention provides a hydrogen annealing furnace for a bright heat treatment production line, which includes a furnace body, a channel pipe, a gas pipe, a resistance wire, a gas source and a power supply. The gas source is connected, the resistance wire is installed in the furnace body and connected to the power supply, and the resistance wire is respectively insulated from the furnace body and the channel pipe; the equipment cost is low, the structure is simple, the annealing efficiency is high, and the process requirements for oxygen barrier annealing are met.

Owner:JIANGSU XINGHAI SPECIAL STEEL

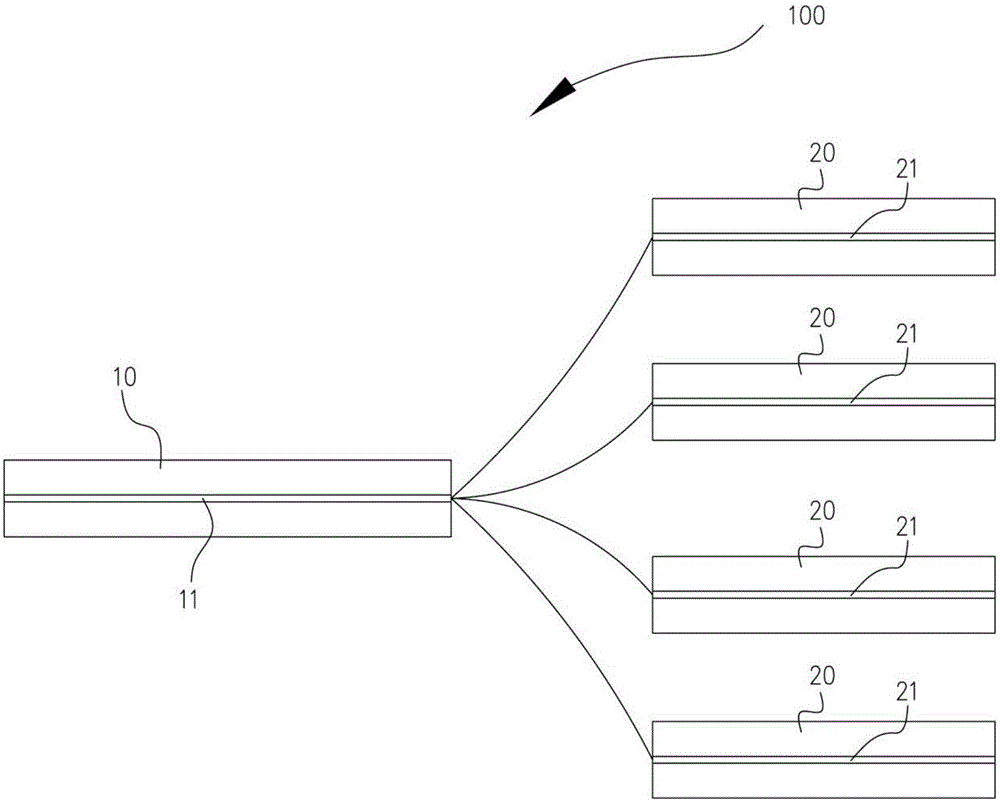

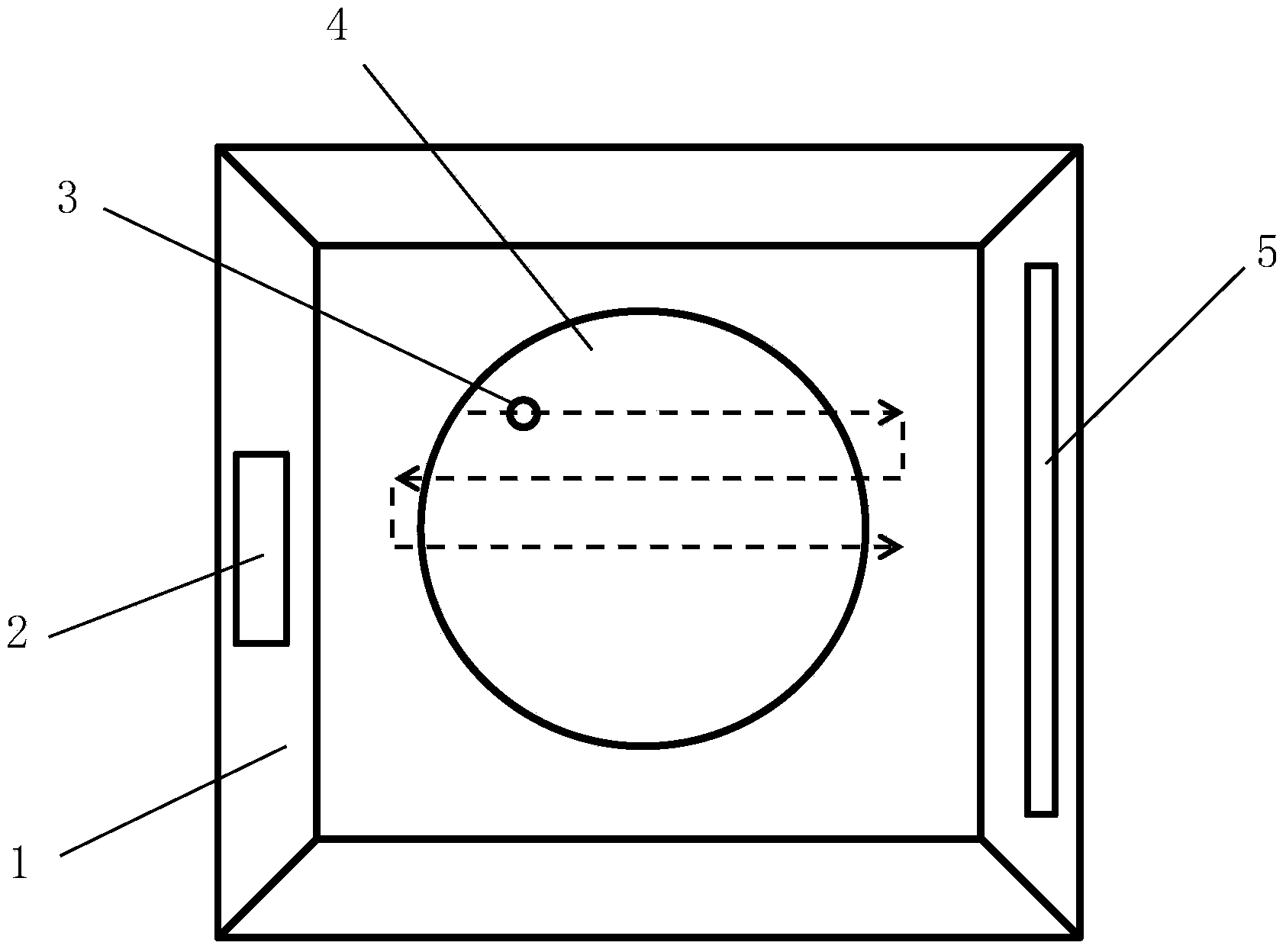

Laser pulse annealing equipment and annealing method

ActiveCN103920994ACool down as soon as possibleEnables batch annealingSemiconductor/solid-state device manufacturingLaser beam welding apparatusReciprocating motionOptoelectronics

The invention discloses laser pulse annealing equipment and an annealing method applied to the laser pulse annealing equipment. A disk in which multiple wafers can be simultaneously placed is arranged in a reaction cavity of the laser pulse annealing equipment and is made to rotate and linearly move in the annealing treatment process, so that the wafers in wafer placement grooves in the disk sequentially and circularly pass through laser radiation points to be uniformly radiated by laser under driving of continuous rotation and linear reciprocating motion of the disk, and bulk annealing treatment on the wafers is achieved. According to the laser pulse annealing equipment and the annealing method, compared with traditional laser pulse annealing equipment which can only carry out annealing treatment on a single wafer, the laser pulse annealing equipment has the same annealing effect, annealing efficiency is remarkably improved, and the equipment and the method can well meet the process demands for annealing quality and efficiency in the high-end advanced process.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

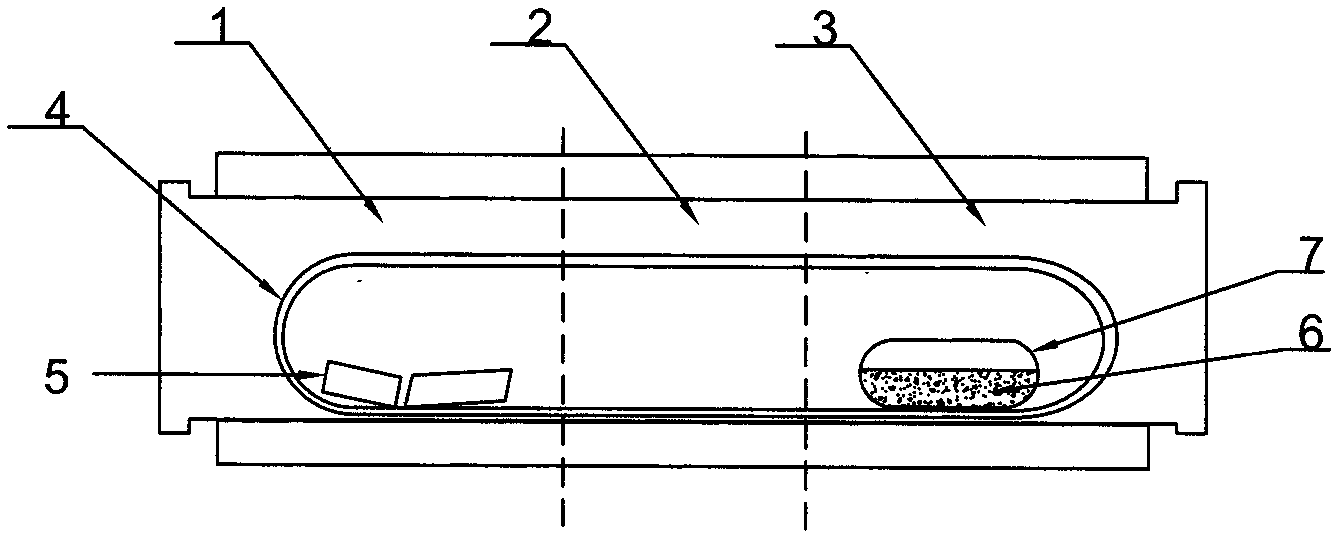

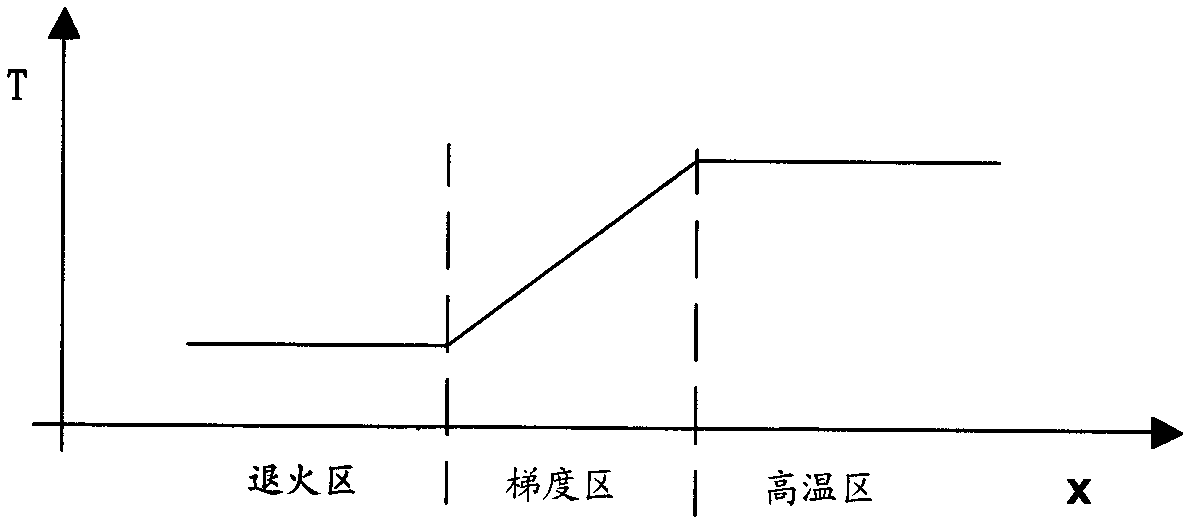

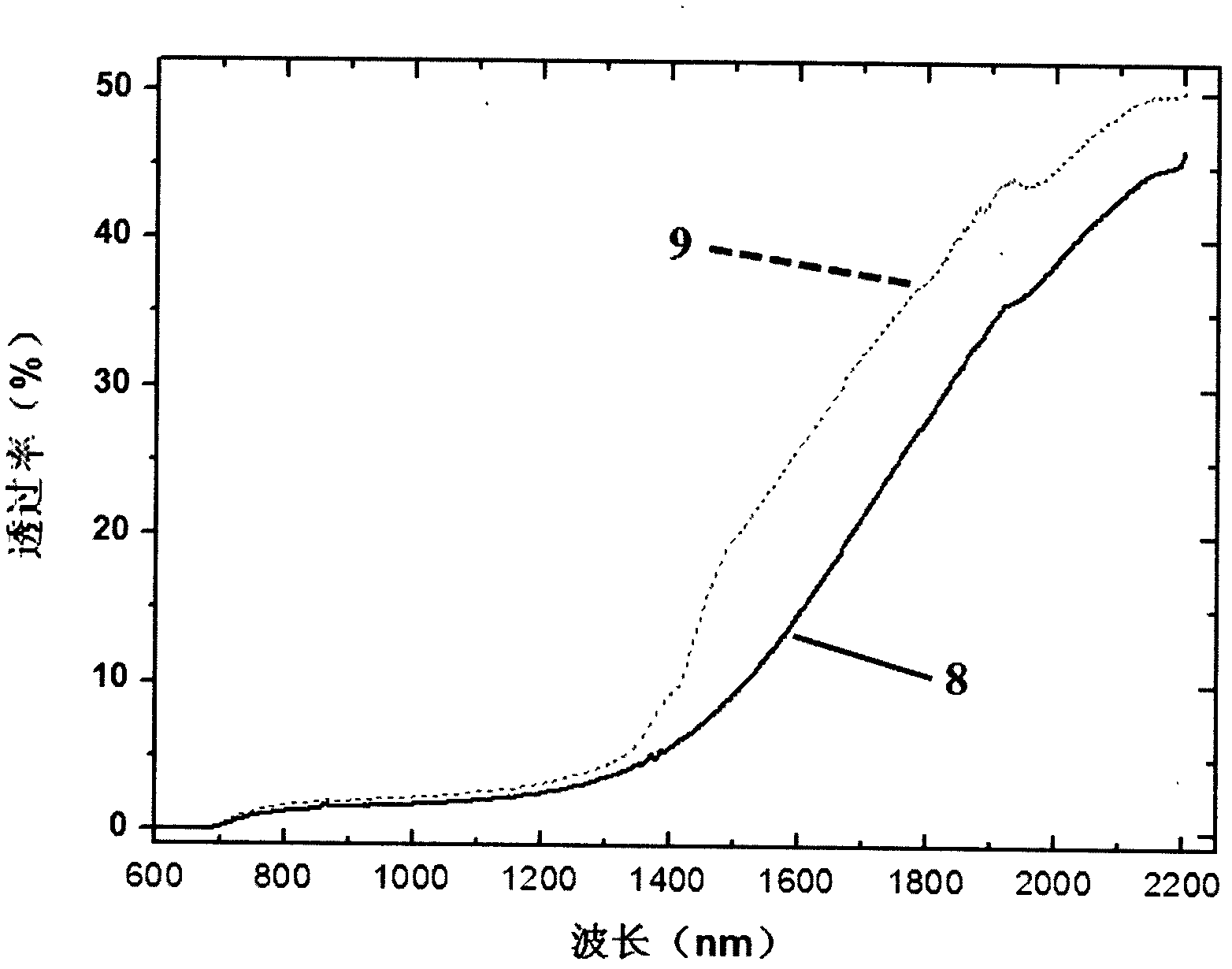

Annealing method for infrared nonlinear single crystal of multi-component compound containing easily volatile components

InactiveCN102618935AAvoid secondary volatilizationAvoid demandingAfter-treatment detailsChemical compoundNonlinear crystals

The present invention relates to the field of inorganic compound single crystal annealing modification, and especially to an annealing method for an infrared nonlinear single crystal of a multi-component compound containing easily volatile components. According to the method, a near-stoichiometric polycrystalline material is adopted as annealing atmosphere, and the polycrystalline material volatilization is separated from the single crystal annealing so as to overcome the blindness, wherein the blindness is attempting annealing experiments through change of various annealing parameters in the following cases, the cases comprise that defect type and proportion thereof of the crystal containing easily volatile components are not known; according to the complementation characteristic of the crystal growth and the temperature gradient annealing component volatilization, the temperature of the high temperature zone and the temperature gradient are changed so as to change the proportion of the volatile component and the annealing rate, and achieve the rapid and effective single crystal annealing.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

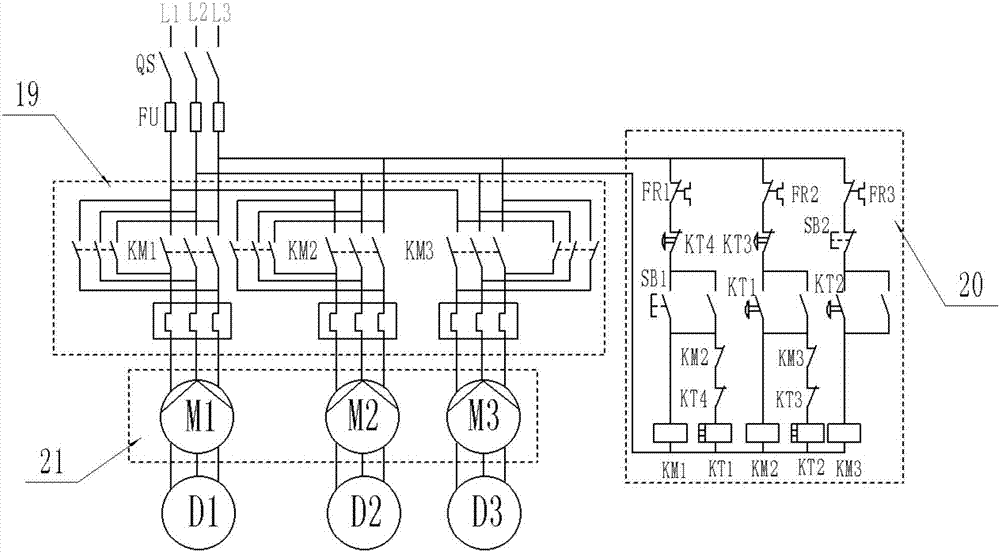

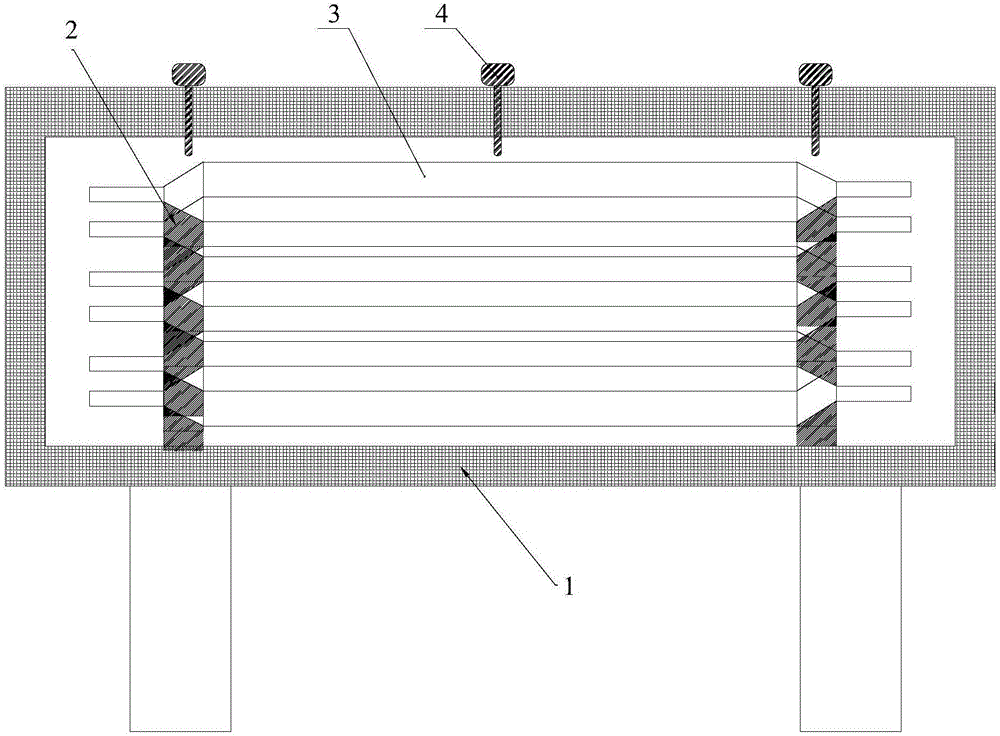

Aluminum alloy pipe cycle annealing treatment equipment furnace

ActiveCN107164627AAchieve recyclingReduce usageFurnace typesHeat treatment process controlThreaded pipeMetallurgy

The invention discloses an aluminum alloy pipe cycle annealing treatment equipment furnace comprising at least two annealing furnace bodies placed in a heat preservation foundation inner groove parallelly side by side. Penetrable temperature measuring probes are arranged on the two sides of the tops of annealing furnace body covers. The interiors of the annealing furnace bodies are uniformly layered, and aluminum alloy pipe plates are annularly placed in the layers correspondingly. A furnace partitioning wall is fixedly laid in the position, perpendicular to the bottom of the heat preservation foundation, between every two adjacent annealing furnace bodies. Two-way air pumps are mounted on the tops of the furnace partitioning walls through fixed bottom plates and matched with air pump motors. The two ends of the two-way air pumps are connected with the annealing furnace bodies through the air pump connectors, pipe connectors in threaded connection with the air pump connectors and thread pipes in threaded connection with the pipe connectors. The other ends of the thread pipes penetrate through heat preservation furnace liners to be connected to the interiors of the annealing furnace bodies. Ordered working and positive and negative working of the two-way air pump are achieved through a simple and effective electrical control circuit (a time relay), so that cycling and reutilization of high temperature nitrogen are achieved when the annealing nitrogen is cyclically heated and subjected to heat preservation in the annealing furnace bodies, and electric heating energy sources used in annealing are saved effectively.

Owner:太仓吉井机械有限公司

Dehydroxylation annealing method and device of large-size optical fiber perform

ActiveCN106673414AIncrease the number ofImprove annealing efficiencyGlass making apparatusThree stageThermal stability

The invention discloses a dehydroxylation annealing method and device of a large-size optical fiber perform. The method comprises the following steps of (1) putting the optical fiber perform into an annealing furnace; (2) heating the optical fiber perform to a stress release temperature through temperature rises for three times; (3) carrying out heat preservation; and (4) cooling the optical fiber perform to a cooling temperature through cooling for four times. The optical fiber perform is heated to the stress release temperature through temperature rises for three times, the temperature rise rates of three stages are different and are gradually reduced according to the characteristics of the optical fiber perform and the thermal stability of the optical fiber perform can be ensured by the heating mode. The target of heat preservation is fully heating the inside of the perform to ensure the stress release reliability. The cooling rate of a front stage is lower than that of a later stage in a manner of gradual cooling for four times, and the heat in the perform can be slowly and uniformly sent out by the cooling mode, so that the optical fiber perform is effectively prevented from generating new thermal stress in a thermal stress release process.

Owner:FUTONG GRP JIASHAN COMM TECH CO LTD +1

Dehydroxylation annealing method and device for large-size optical fiber preform

ActiveCN106830651AIncrease the number ofImprove annealing efficiencyGlass making apparatusHeat stabilityLarge size

The invention discloses a dehydroxylation annealing method and device for a large-size optical fiber preform. The method comprises the steps of (1) putting the optical fiber preform into an annealing furnace; (2) heating the optical fiber preform to a destressing temperature through heating for four times; (3) carrying out heat preservation; and (4) cooling the optical fiber preform to a cooling temperature through cooling for four times. The optical fiber preform is heated to the destressing temperature through gradual heating for four times, so that the heat stability of the preform can be ensured; the condition that the internal heat of the preform can be slowly and uniformly emitted can be effectively ensured through gradual heating for four times; heating and cooling are carried out in a vacuum environment; and relative to a non-vacuum environment, the vacuum state is more conductive to separation of residual He and hydroxyl in the optical fiber preform and the effect is better.

Owner:FUTONG GRP JIASHAN COMM TECH CO LTD +1

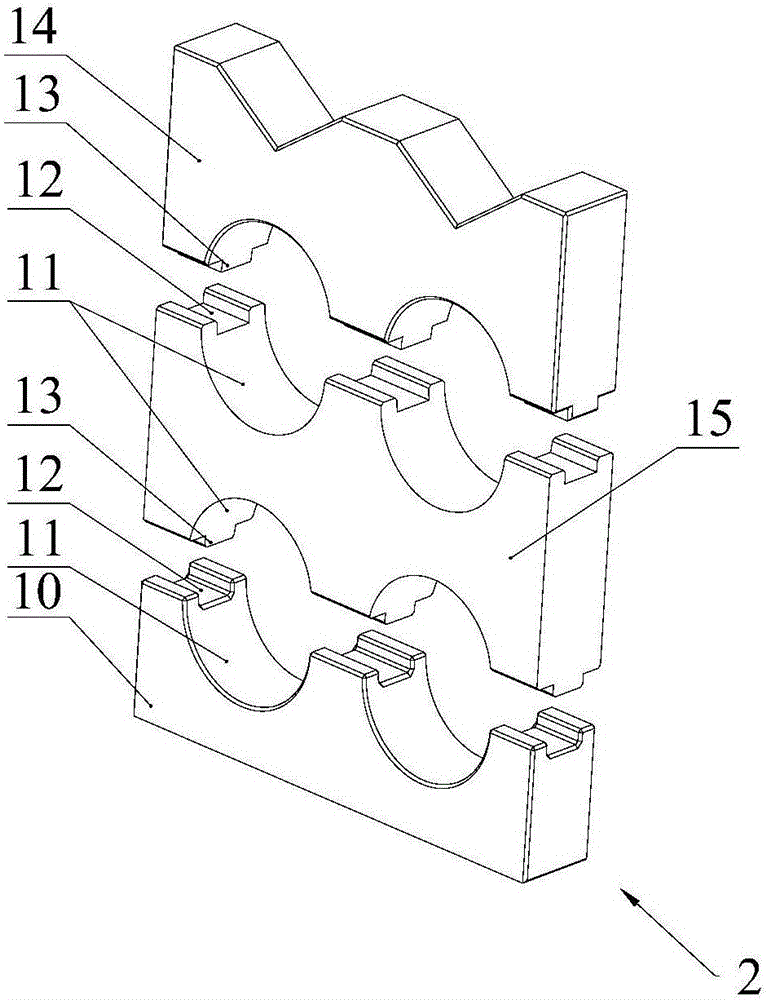

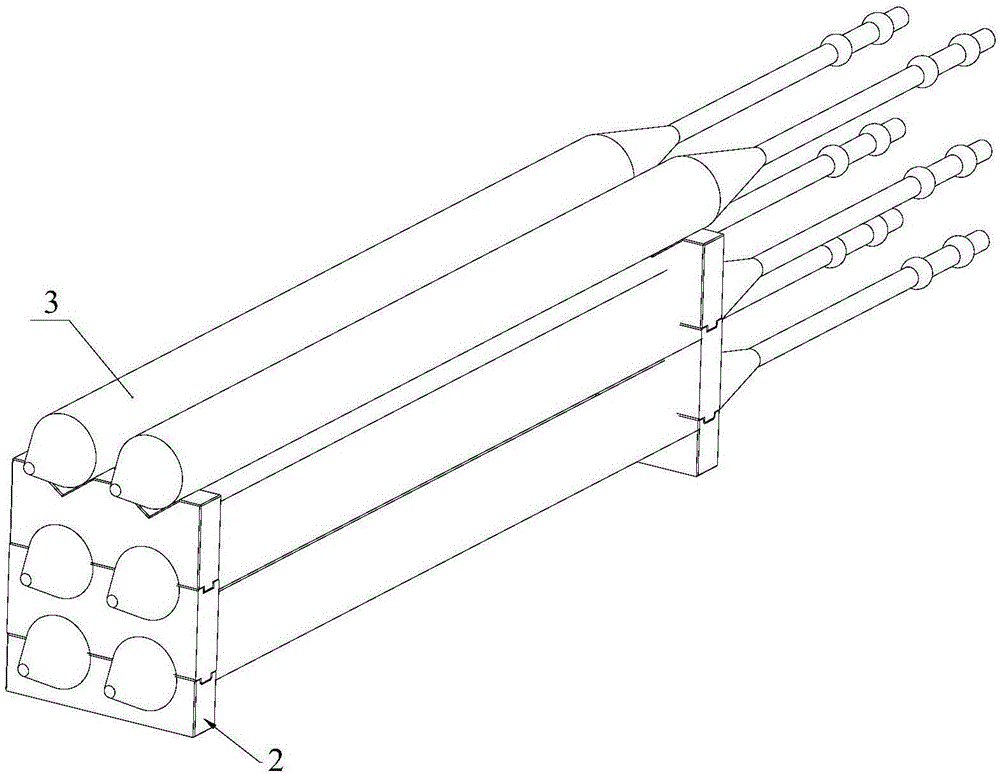

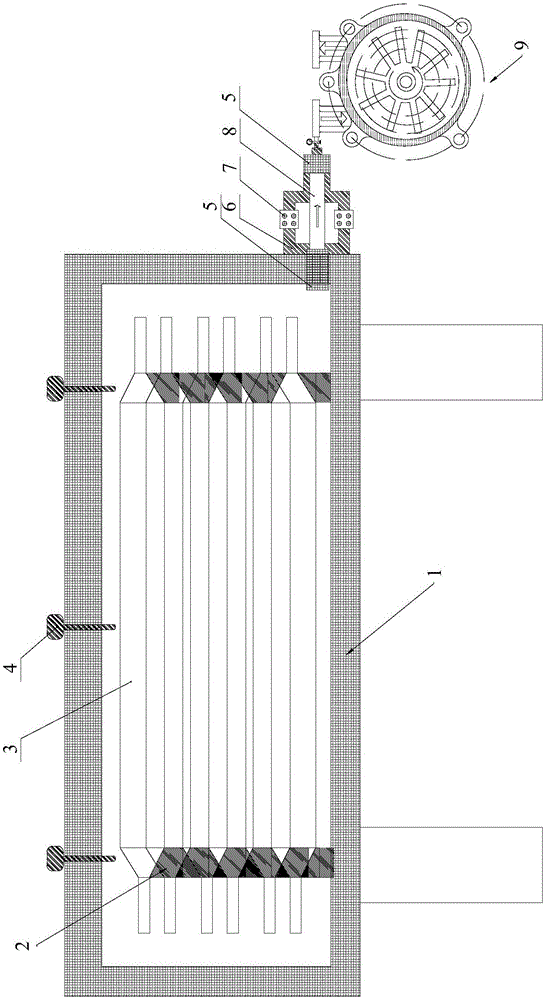

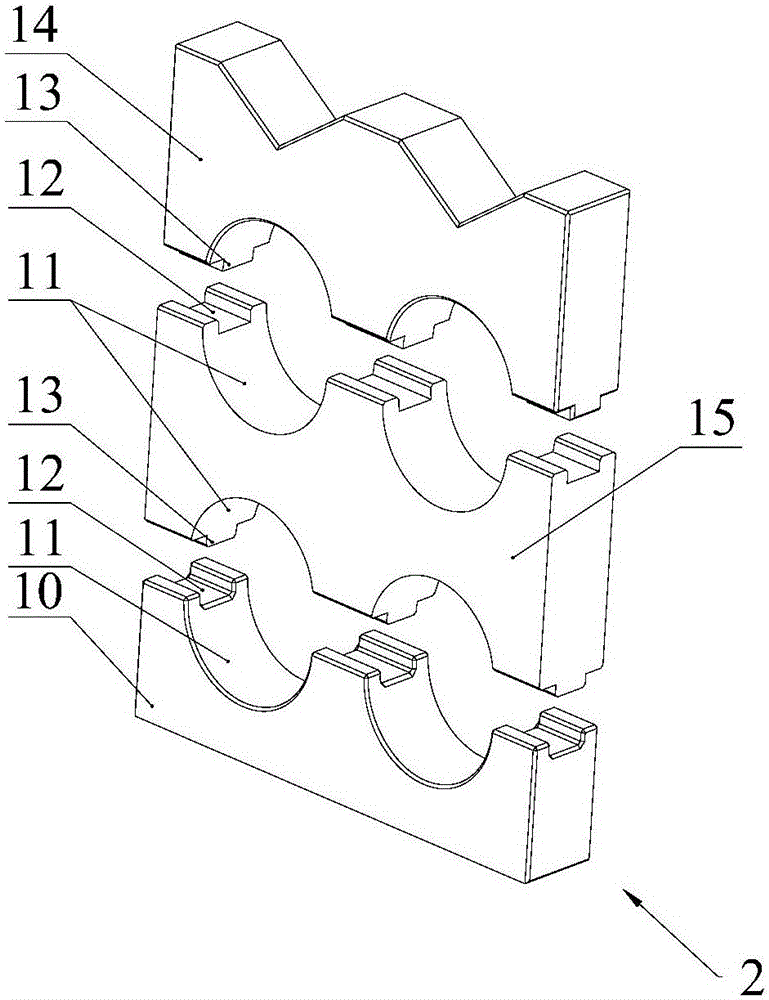

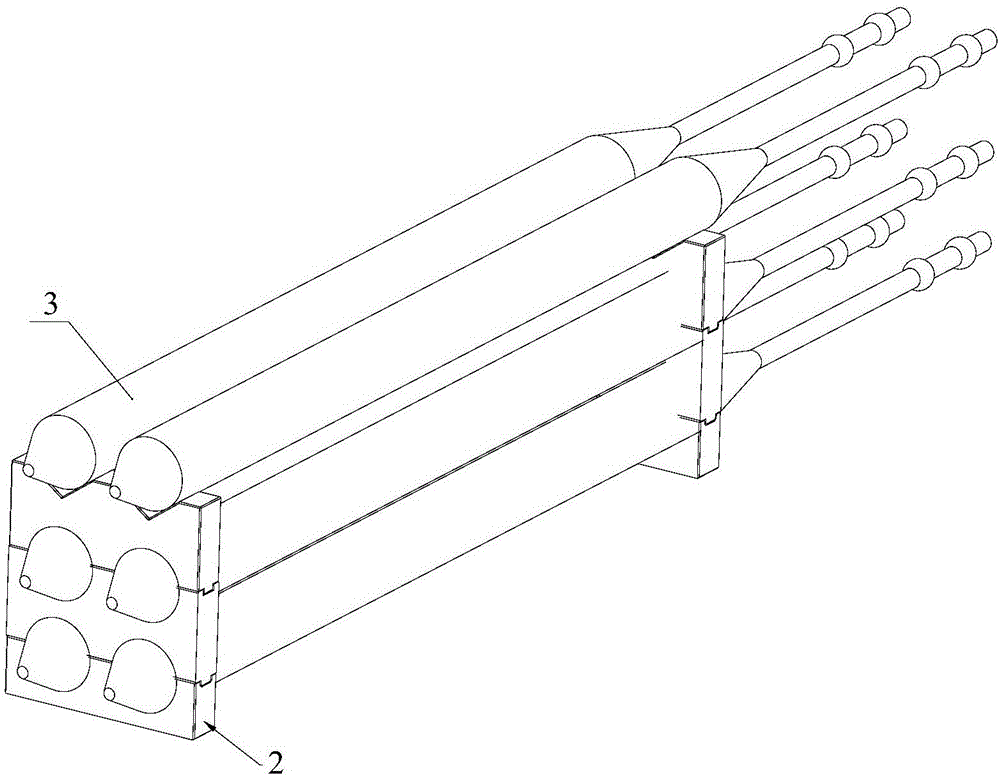

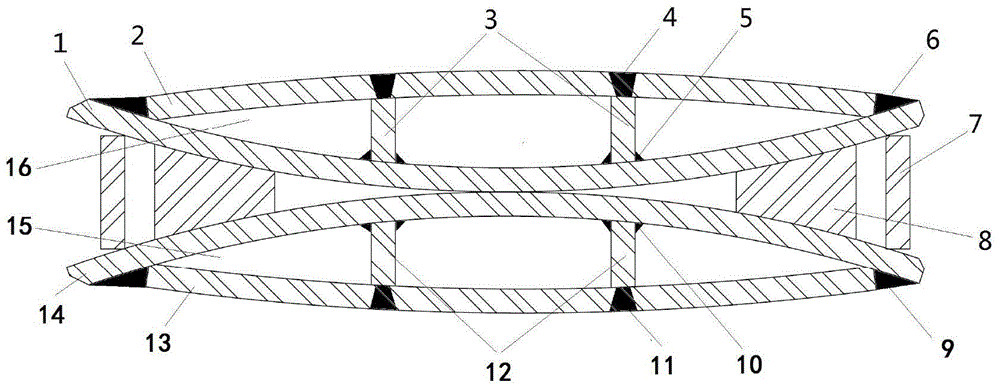

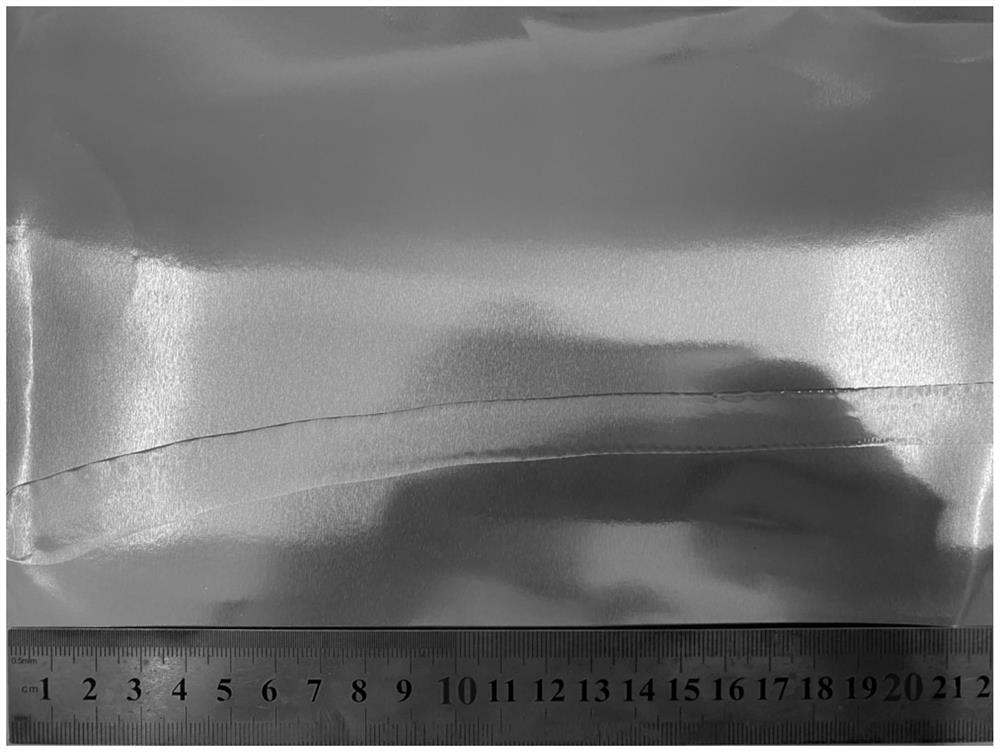

Welding technology method for assembling large length-width ratio hollow type fixed guide vane of large-scale hydroturbine

InactiveCN104625353AReduce manufacturing costReduce weightArc welding apparatusLeg lengthWidth ratio

The invention relates to a welding technology method, in particular to a welding technology method for assembling a large length-width ratio hollow type fixed guide vane of a large-scale hydroturbine. The fixed guide vane is made by welding an upper clack body, a lower clack body and a reinforcing plate, the technology method solves the critical technology problem of the large length-width ratio hollow type fixed guide vane by a technology process of split charging, stack charging, stack welding, annealing and splitting, the technology method for assembling and welding the large length-width ratio hollow type fixed guide vane of the large-scale hydroturbine has the advantages that the production cost is low, the welding technology process is reasonable and simple, the strength of a structure can be improved, the operating space is saved, and the quality of a product is improved.

Owner:HARBIN ELECTRIC MASCH CO LTD

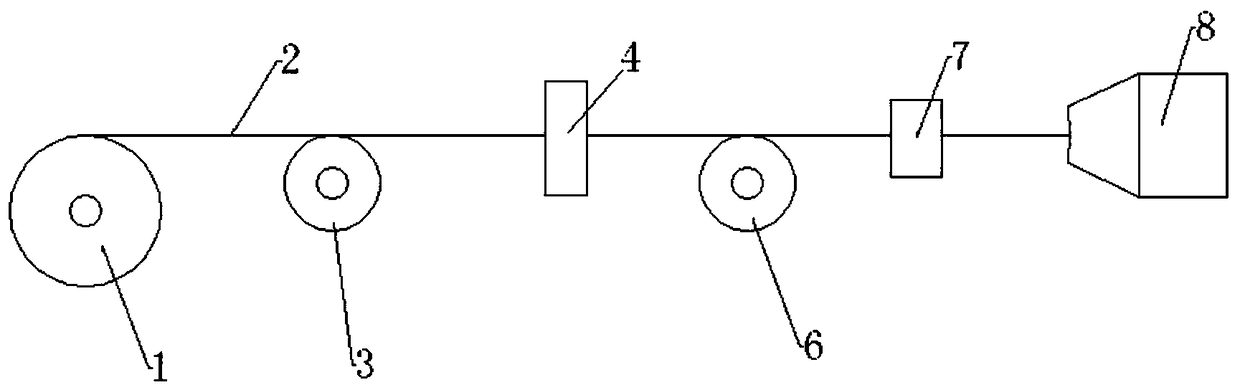

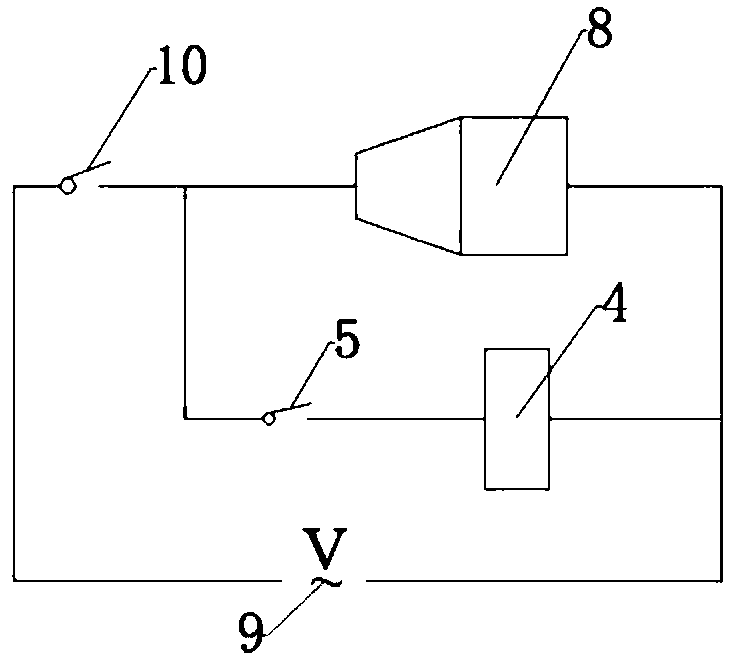

Method for preparing superconducting wire/strip

ActiveCN108878052ASmall temperature changeGuaranteed mechanical propertiesSuperconductors/hyperconductorsFurnace typesMechanical propertyMetal

The invention discloses a method for preparing a superconducting wire / strip. The method for preparing the superconducting wire / strip comprises the following steps that 1, a metal package sheathing / ceramic core wire composite wire is wound on a pay-off reel after the metal package sheathing / ceramic core wire composite wire is cleaned, the metal package sheathing / ceramic core wire composite wire penetrates through a first guide pulley, an induction coil device, a second guide pulley and a drawing die in sequence, and the metal package sheathing / ceramic core wire composite wire is clamped on a wire drawing machine drawing device to complete assembling; 2, the wire drawing machine drawing device is started to drive the metal package sheathing / ceramic core wire composite wire to draw; 3, the drawn metal package sheathing / ceramic core wire composite wire is collected, then the assembling and drawing process are repeated, and then the superconducting wire / strip is obtained through heat treatment; and induction annealing and synchronous drawing are carried out on the metal package sheathing / ceramic core wire composite wire during repeated drawing. According to the method for preparing thesuperconducting wire / strip, induction annealing is introduced into the drawing, so that the metal package sheathing of the metal package sheathing / ceramic core wire composite wire rapidly heats up, induction annealing and synchronous drawing are realized, the mechanical properties of the superconducting wire / strip are guaranteed, the core breaking phenomenon is avoided, and the processing uniformity of the superconducting wire / strip is improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Method for eliminating stress and damage in producing monolithic photoelectric integrated receiver

InactiveCN1716540ASimple and fast operationImprove annealing efficiencySemiconductor/solid-state device manufacturingLaser beam welding apparatusHigh power densityShort duration

The present invention provides method of eliminating stress and damage of light receiver during monolithic photoelectronic integration. The area of semiconductor surface to be annealed is irradiated with laser beam of very high power density to produce abrupt temperature change process with great temperature change rate, short duration and proper range, so as to improve the performance of the semiconductor and eliminate defects, damage, etc. The method of the present invention is especially suitable for eliminating stress and damage of PDIC after ion implantation during monolithic PDIC manufacture.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Tunnel type oriented silicon steel continuous high-temperature annealing process

ActiveCN106435102AImprove annealing efficiencyReduce energy consumptionFurnace typesHeat treatment furnacesEnergy consumptionProduction cycle

The invention discloses a tunnel type oriented silicon steel continuous high-temperature annealing process. Continuous annealing production of oriented silicon steel is achieved, and the problem of a long production cycle is solved, and the energy consumption is reduced. According to the adopted technical scheme, the tunnel type oriented silicon steel continuous high-temperature annealing process comprises the following steps of loading; furnace filling: a trolley loaded with a steel coil is moved to the inlet position of an annealing furnace through a laid rail, and is pushed into the annealing furnace through a hydraulic push rod; annealing treatment; cooling; discharging; unloading; trolley overhauling; and executing the above steps repeatedly to achieve continuous annealing treatment, wherein protection gas is introduced into sealing covers of the oriented silicon steel in the whole annealing furnace. The tunnel type oriented silicon steel continuous high-temperature annealing process can be widely applied to the field of oriented silicon steel continuous annealing furnaces.

Owner:BAOTOU WEIFENG NEW MATERIAL CO LTD

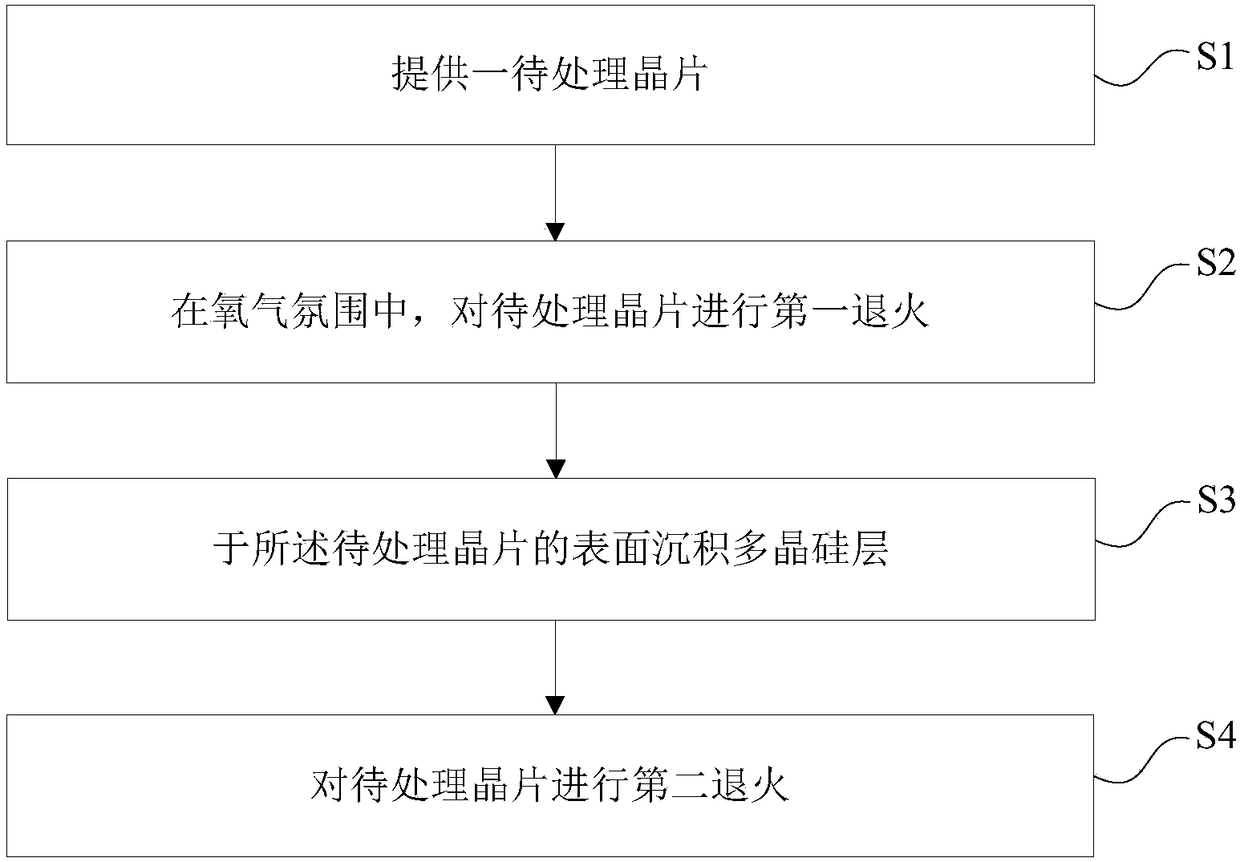

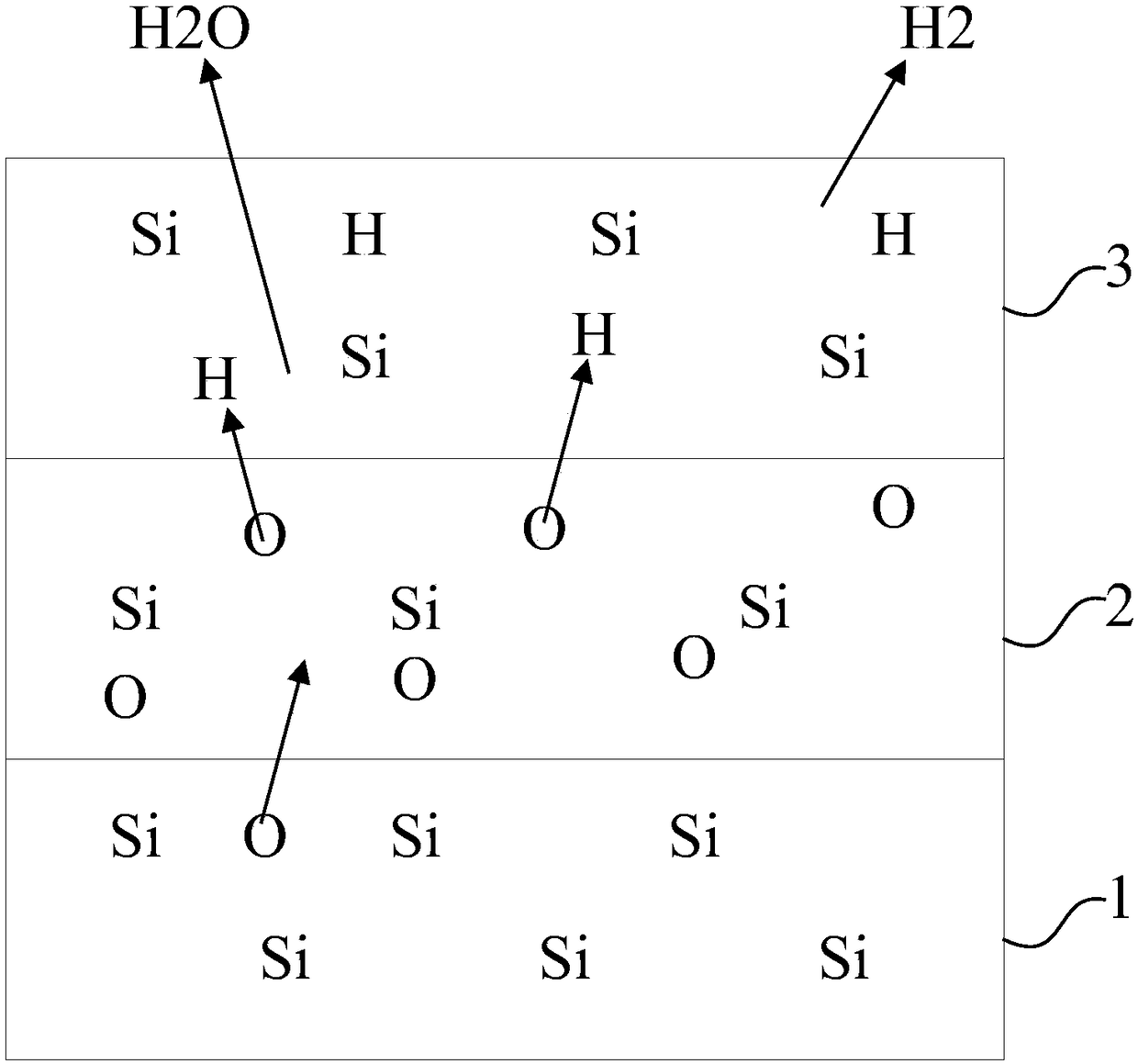

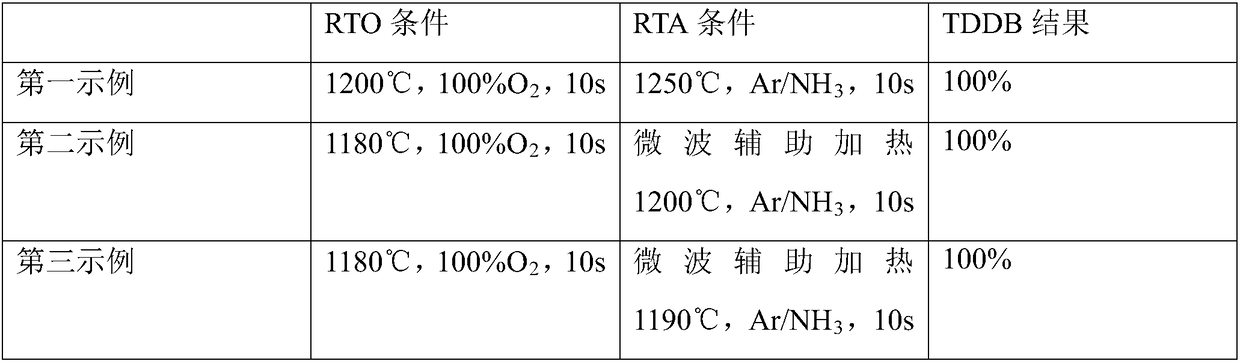

Wafer gettering method

ActiveCN108666215AReduce defectsAvoid warpingSemiconductor/solid-state device manufacturingWaferingMetallurgy

The present invention provides a wafer gettering method. The method comprises: performing a first annealing on a to-be-treated wafer, wherein the first annealing is performed under an oxygen atmosphere and a first temperature condition for a first time; depositing a polysilicon layer on a surface of the to-be-treated wafer; performing a second annealing on the to-be-treated wafer, wherein the second annealing is performed under an inert gas atmosphere and a second temperature condition for a second time which is greater than or equal to the first temperature. According to the wafer gettering method, the polysilicon layer can effectively adsorb oxygen atoms in the vacancies, thereby removing wafer defects; the two annealing processes can promote atom rearrangement and further eliminate defects in the to-be-treated wafer; the second annealing can uniformly heat the to-be-treated wafer in a short time by microwave annealing, thereby improving the activity of atomic motion and further improving the annealing efficiency; and the two annealings are performed at lower temperatures, which can avoid wafer warpage caused by high annealing temperature and improve wafer quality.

Owner:ZING SEMICON CORP

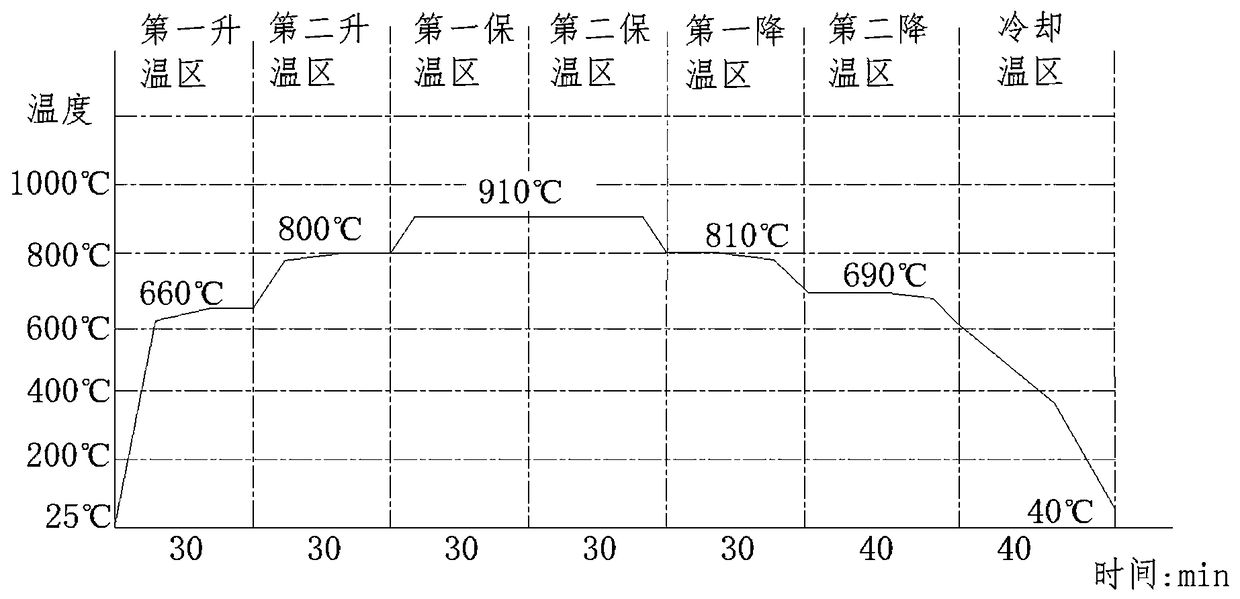

Soft magnetic material annealing thermal treatment method

InactiveCN109022701AImprove annealing efficiencyImprove microstructureFurnace typesHeat treatment furnacesMicrostructureChain type

The invention discloses a soft magnetic material annealing thermal treatment method. The soft magnetic material annealing thermal treatment method comprises the following steps of: S1, performing rust-removal treatment on a soft magnetic material; S2, performing de-oiling rust-removal treatment on the soft magnetic material; S3, drying the soft magnetic material; andS4, adopting a chain type furnace to perform annealing treatment on the soft magnetic material, wherein a furnace hearth of the chain type furnace comprises a first heating area, a second heating area, a first heat-preserving area,a second heat-preserving area, a first cooling region, a second cooling area and a cooling warm area from an inlet to an outlet. Continuous annealing thermal treatment is performed on the soft magnetic material under an unsealed environment, so that annealing efficiency can be greatly improved; an annealing curve is formed in each warm area, so that a microstructure of the soft magnetic materialcan be improved, magnetic conductivity of the soft magnetic material is improved, and coercive force of the soft magnetic material is reduced; after being subjected to annealing thermal treatment, thesoft magnetic material has high magnetic conductivity and low coercive force, and can quickly respond to outer magnetic field changes; and under the low coercive force condition, the soft magnetic material improves sensitivity of an electromagnetic product.

Owner:蚌埠市双环电子集团股份有限公司

Pit type annealing furnace for nonferrous metal copper processing

ActiveCN110317940AImprove efficiencyShorten the timeFurnace typesHeat treatment furnacesNonferrous metalCopper

The invention discloses a pit type annealing furnace for nonferrous metal copper processing. The pit type annealing furnace for nonferrous metal copper processing comprises a furnace body, a feed hopper and a furnace lid, wherein the top part of the furnace body communicates with the bottom part of the feed hopper; the inner wall of the feed hopper is fixedly connected with the surface of the furnace lid through a screw; a winding box is fixedly connected to the bottom part, located in an inner cavity of the feed hopper, of the furnace lid; a limiting barrel is fixedly connected to one side ofan inner cavity of the winding box; and a rotary shaft is rotatably connected between the top part and the bottom part of the inner wall of the limiting barrel through a rolling wheel. The pit type annealing furnace for nonferrous metal copper processing provided by the invention relates to the technical field of pit type annealing furnaces. According to the pit type annealing furnace for nonferrous metal copper processing, metal copper to be processed can be conveniently placed by a user, and the annealed metal copper can be well taken out, so that the whole annealing efficiency is greatly improved, the time of the user is saved, the labor intensity of working personnel is reduced to a certain extent, the potential safety hazard of direct operation of working personnel is avoided, the practicability is high, and the user can conveniently operate the furnace and can be assisted to close the furnace lid.

Owner:TIANJIN SANMUSEN ELECTRIC FURNACE

Annealing method in high-voltage electronic aluminum-foil production for high-capacity high-strength capacitor

ActiveCN113235024ANot prone to oxidationEasy to cleanAnti-corrosive paintsMetal rolling arrangementsAluminum foilCapacitor

The invention discloses an annealing method in high-voltage electronic aluminum-foil production for a high-capacity high-strength capacitor. The annealing method comprises the following steps: performing intermediate annealing in a belt mode through a continuous type gas cushion furnace, uniformly heating an aluminum belt, controlling speed by the continuous type gas cushion furnace during heating, guaranteeing growth consistency of grown crystalline grains as annealing time is stable and controllable, thereby obtaining a uniform structure; eliminating internal stress, and reducing aluminum foil processing hardening degree; performing aluminum foil finished product annealing by the continuous type gas cushion furnace, and controlling a regrowth rate of the crystalline grains in a mode of annealing at different temperatures in multiple regions, changing a non-cubic texture into a cubic texture, increasing the proportion of the cubic texture, enriching trace elements on the surface, and increasing a corrosion porosity; and quickly cooling and coiling after discharging to prevent surface damages due to blocking under warming.

Owner:广西广投正润新材料科技有限公司

Isothermal spheroidizing annealing furnace for automobile bearing ring machining

ActiveCN108300847AImprove the annealing effectQuality improvementFurnace typesHeat treatment furnacesMachiningCoupling

The invention discloses an isothermal spheroidizing annealing furnace for automobile bearing ring machining. The isothermal spheroidizing annealing furnace for automobile bearing ring machining comprises an annealing furnace body, wherein a fixing plate is fixedly connected between the two sides of the inner wall of the annealing furnace body, and slide blocks are slidably connected to the two sides of the bottom of the fixing plate; a spray head is fixedly connected to the bottom of each slide block; a first motor is fixedly connected to the top of the annealing furnace body through a supportframe; a thread rod is fixedly connected to the output shaft of the first motor through a shaft coupling; the bottom end of the thread rod penetrates through the annealing furnace body and extends into the annealing furnace body; and one end extending into the annealing furnace body, of the thread rod, is rotationally connected with the top of the fixing plate through a bearing. The invention relates to the technical field of automobile bearing ring machining equipment. The isothermal spheroidizing annealing furnace for automobile bearing ring machining is capable of greatly annealing a bearing ring, and short in annealing time, thereby greatly increasing the annealing efficiency and improving the quality of the bearing ring.

Owner:襄阳润欣圆锻造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com