Annealing method for infrared nonlinear single crystal of multi-component compound containing easily volatile components

A nonlinear crystal and compound technology, applied in the field of annealing and modification of inorganic compound single crystal, can solve the problems of high annealing cost, inconvenient operation, complicated structure of annealing experimental device, etc., and achieve the effect of avoiding secondary volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

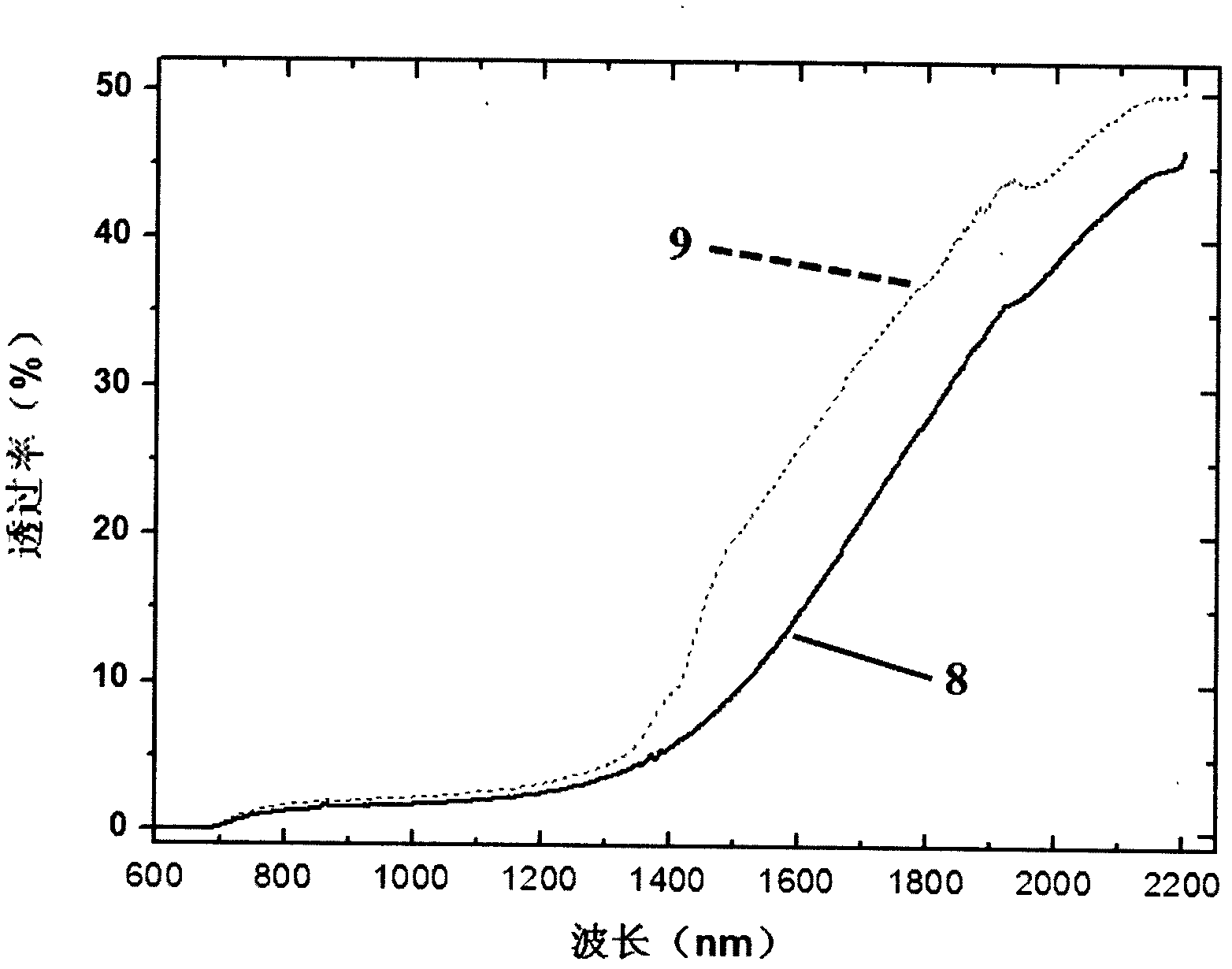

[0024] Embodiment 1: ZnGeP2 single crystal annealing method

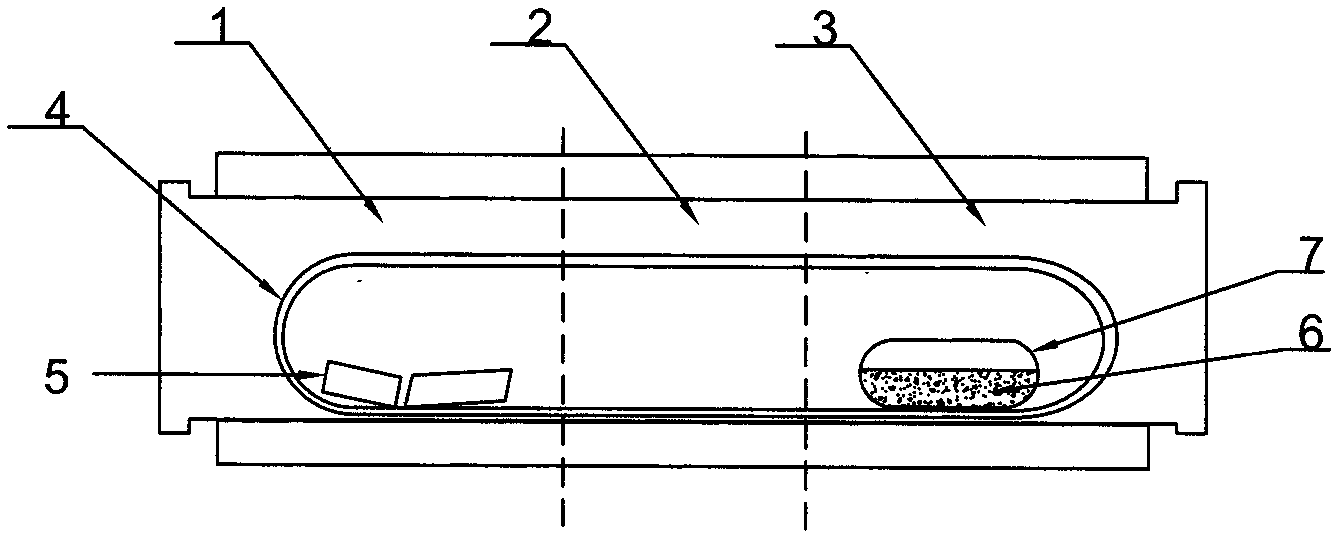

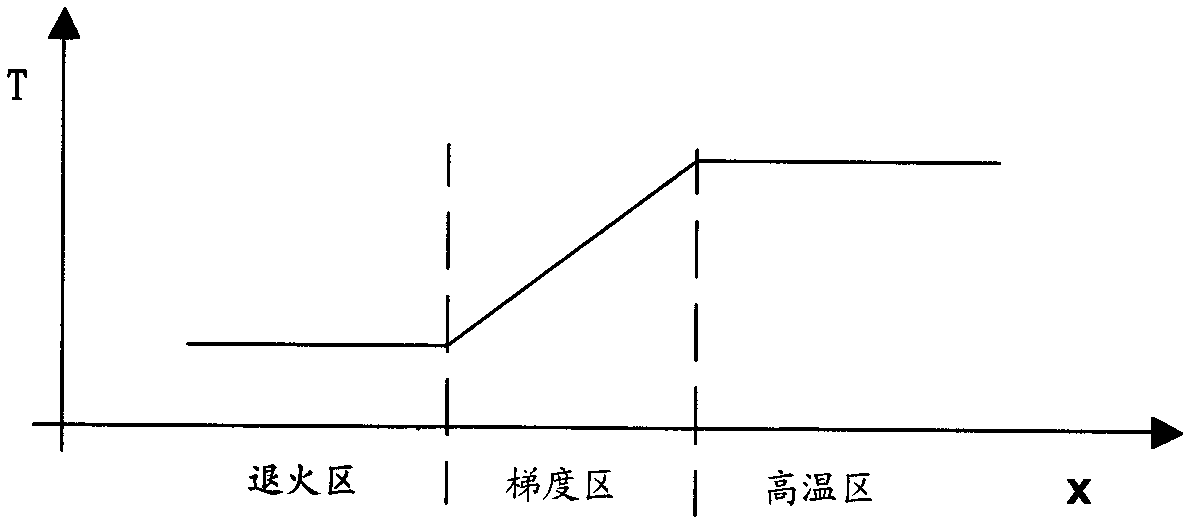

[0025] see figure 1 , 2 , first design and manufacture three-stage annealing furnace: annealing zone 1, gradient zone 2, high temperature zone 3, the lengths of which are 30cm, 20cm, 30cm respectively. Then the quartz crucible 4 was cleaned and dried with deionized water. Will be annealed ZnGeP 2 Wafer 5 placed on one end of crucible 4, ZnGeP 2 The polycrystalline powder is put into the carbon-coated boat 7 and placed on the other end of the crucible 4, and is vacuumed to 10°C at room temperature. -3 Seal the crucible after Pa. Then put the quartz crucible 4 after fusing into the appropriate position of the three-stage annealing furnace, place one end of the quartz crucible 4 with the polycrystalline material 6 in the high temperature zone 3, and place the one end of the quartz crucible 4 with the annealing wafer 5 in the annealing furnace. within Zone 1.

[0026] The high temperature zone 3 is raised to 930°...

Embodiment 2

[0029] Example 2: AgGaS 2 single crystal annealing method

[0030] Same as Example 1, the AgGaS to be annealed 2 The wafer is placed in a section of the crucible 4, AgGaS 2Polycrystalline powder is put into carbon-coated boat 7 and is placed on the other end of crucible 4. Vacuum at room temperature to 10 -3 Seal the crucible after Pa. Then put the sealed quartz crucible 4 into an appropriate position in the three-stage annealing furnace. The high temperature zone 3 is raised to 950°C at a rate of 10-30°C / h, and the annealing zone 1 and gradient zone 2 are raised to 830°C and 890°C at corresponding heating rates. Maintain gradient zone 2 temperature linearly with position. After the temperature rise is completed, enter the constant temperature stage, keep the temperature of the furnace body constant and continue for 100h for crystal annealing. After the annealing is completed, the temperature in the high temperature zone 3 is lowered to room temperature at a constant ra...

Embodiment 3

[0031] Example 3: CdGeAs 2 single crystal annealing method

[0032] Same as Example 1, the CdGeAs to be annealed 2 Wafer placed on one end of crucible 4, CdGeAs 2 The polycrystalline powder is put into the carbon-coated boat 7 and placed on the other end of the crucible 4, and is vacuumed to 10°C at room temperature. -3 After Pa, the crucible 4 is welded and sealed, and then the sealed quartz crucible 4 is placed in an appropriate position in the three-stage annealing furnace. The high temperature zone 3 is raised to 620°C at a rate of 10-30°C / h, and the annealing zone 1 and gradient zone 2 are raised to 480°C and 550°C at corresponding heating rates, respectively, and the temperature of the gradient zone 2 is kept changing linearly with the position. After the temperature rise is completed, enter the constant temperature stage, keep the temperature of the furnace body constant and continue for 200h to carry out crystal annealing. After the annealing is completed, the temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com