Method for preparing high-capacity long-life rare earth and magnesium-based hydrogen storage alloy

A hydrogen storage alloy, long-life technology, applied in the direction of electrical components, circuits, battery electrodes, etc., can solve the difficulty of stably realizing the pilot-scale industrial preparation of rare earth magnesium-based hydrogen storage alloys, poor safety of positive pressure smelting equipment, and poor composition uniformity And other problems, to achieve the effect of precise control, shorten residence time, and reduce volatilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

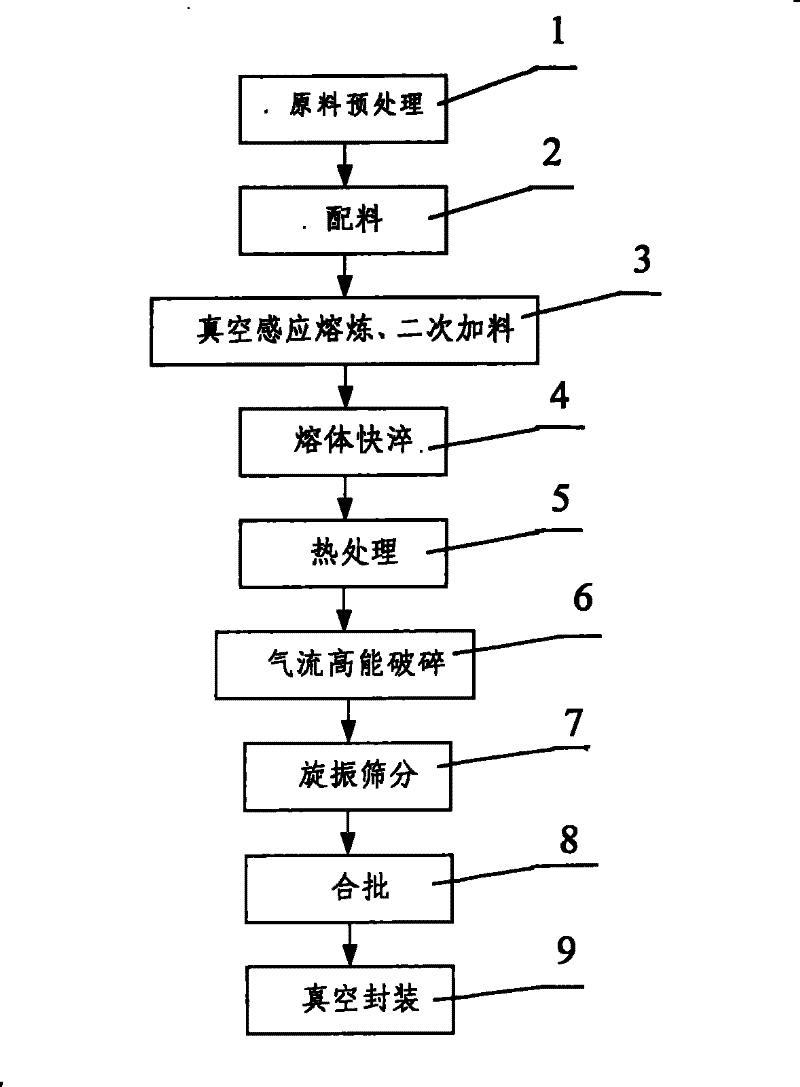

Method used

Image

Examples

Embodiment 1

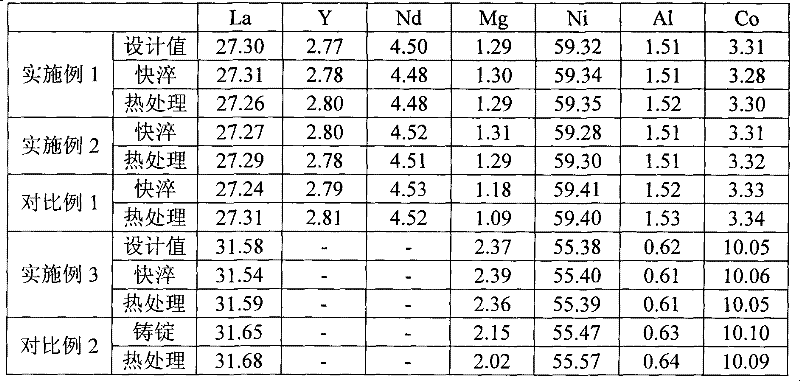

[0031] According to the designed composition La 0.63 Y 0.1 Nd 0.1 Mg 0.17 (Ni 0.90 Al 0.05 co 0.05 ) 3.6 , the preparation of La (purity > 99.5%, polished), Y (purity > 99.5%), Nd (purity > 99.5%, polished), nickel-magnesium master alloy (Mg content 30%, Ni+Mg total content > 99% ), Ni (purity > 99.5%, dried), Al (purity > 99.5%), Co (purity > 99.5%, dried) totaling 50kg, of which the Mg content is designed to exceed 5%. Put the raw metals into the crucible according to Al, Ni, Co, La, Nd, Y from bottom to top, and put the nickel-magnesium master alloy into the secondary feeding device. First evacuate to 5Pa, then bake and wash the furnace, fill it with argon to 0.05MPa, adjust the power to start melting, the temperature of the alloy melt is 1773K and keep it for 5 minutes, and then refine for 2 minutes. Reduce the melt temperature to 1573K through the "melt temperature online monitoring and control system", start the secondary feeding device to add nickel-magnesium ma...

Embodiment 2

[0035] Design composition is the same as embodiment 1

[0036] The ingredients are 500kg

[0037] The heat-treated alloy is pulverized by high-energy airflow crushing, rotary vibration screening, batching, and vacuum packaging to obtain rare earth magnesium-based hydrogen storage alloy powder products.

Embodiment 3

[0039] The design composition is La 0.7 Mg 0.3 (Ni 0.83 co 0.15 Al 0.02 ) 3.5

[0040] The ingredients are 50kg

[0041] Carry out heat treatment at 1123K for 10 hours

[0042] Then, it is pulverized by a mill and sieve machine and passed through a 150-mesh sieve to obtain rare earth magnesium-based hydrogen storage alloy powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com