Laser pulse annealing equipment and annealing method

A technology of laser pulse annealing and annealing equipment, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of difficulty in meeting the thermal budget and low efficiency, and achieve the effect of improving annealing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

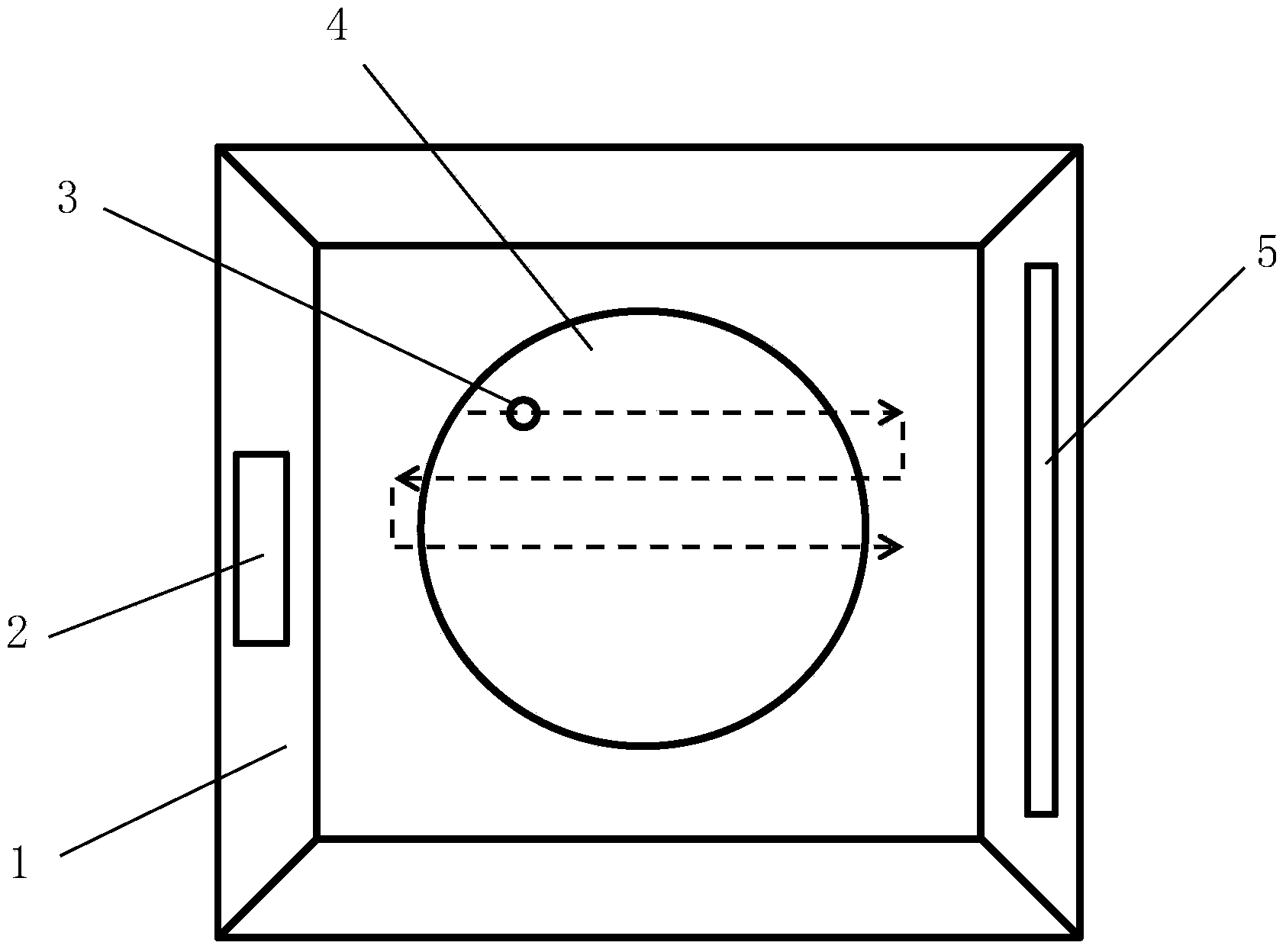

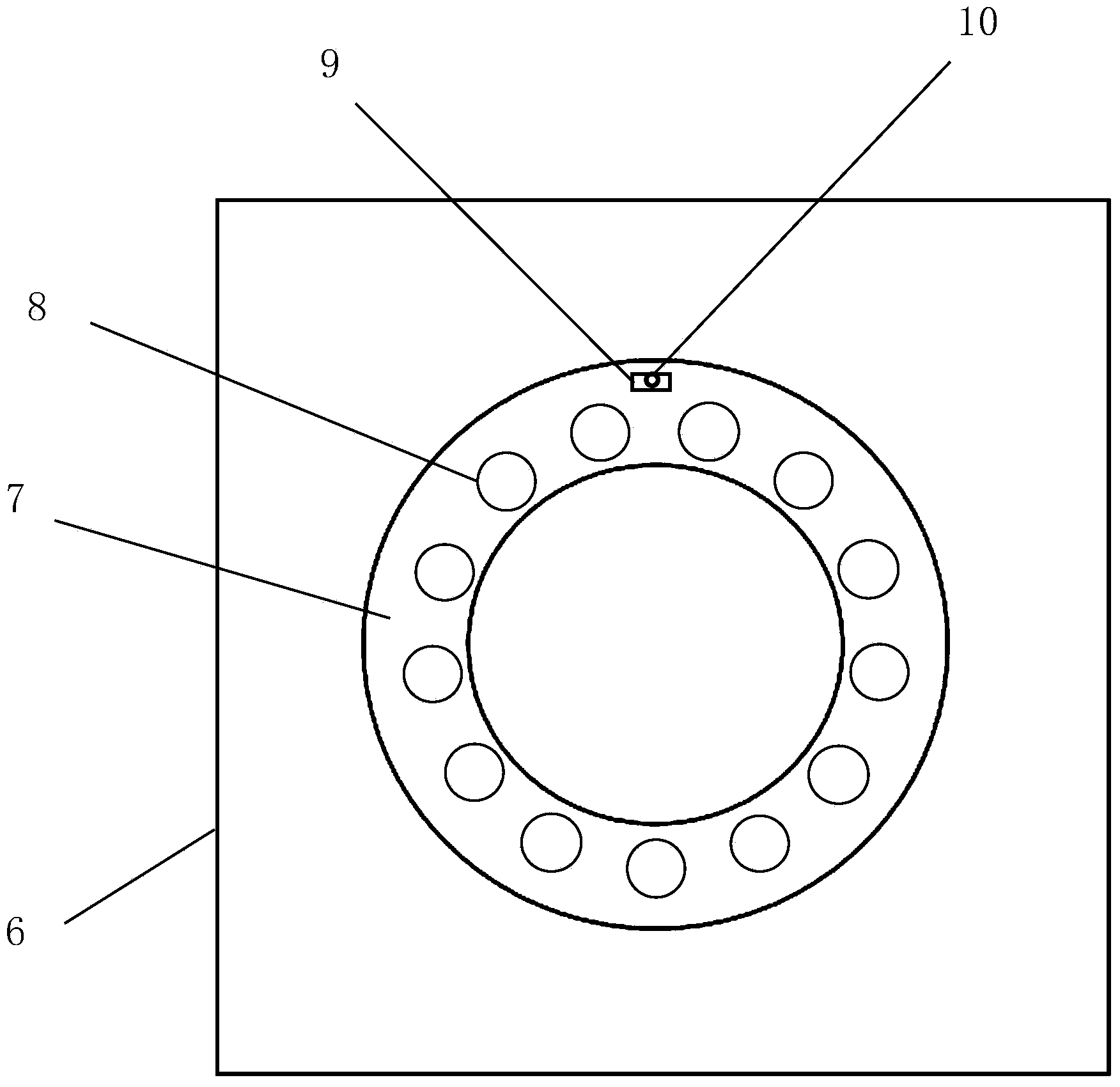

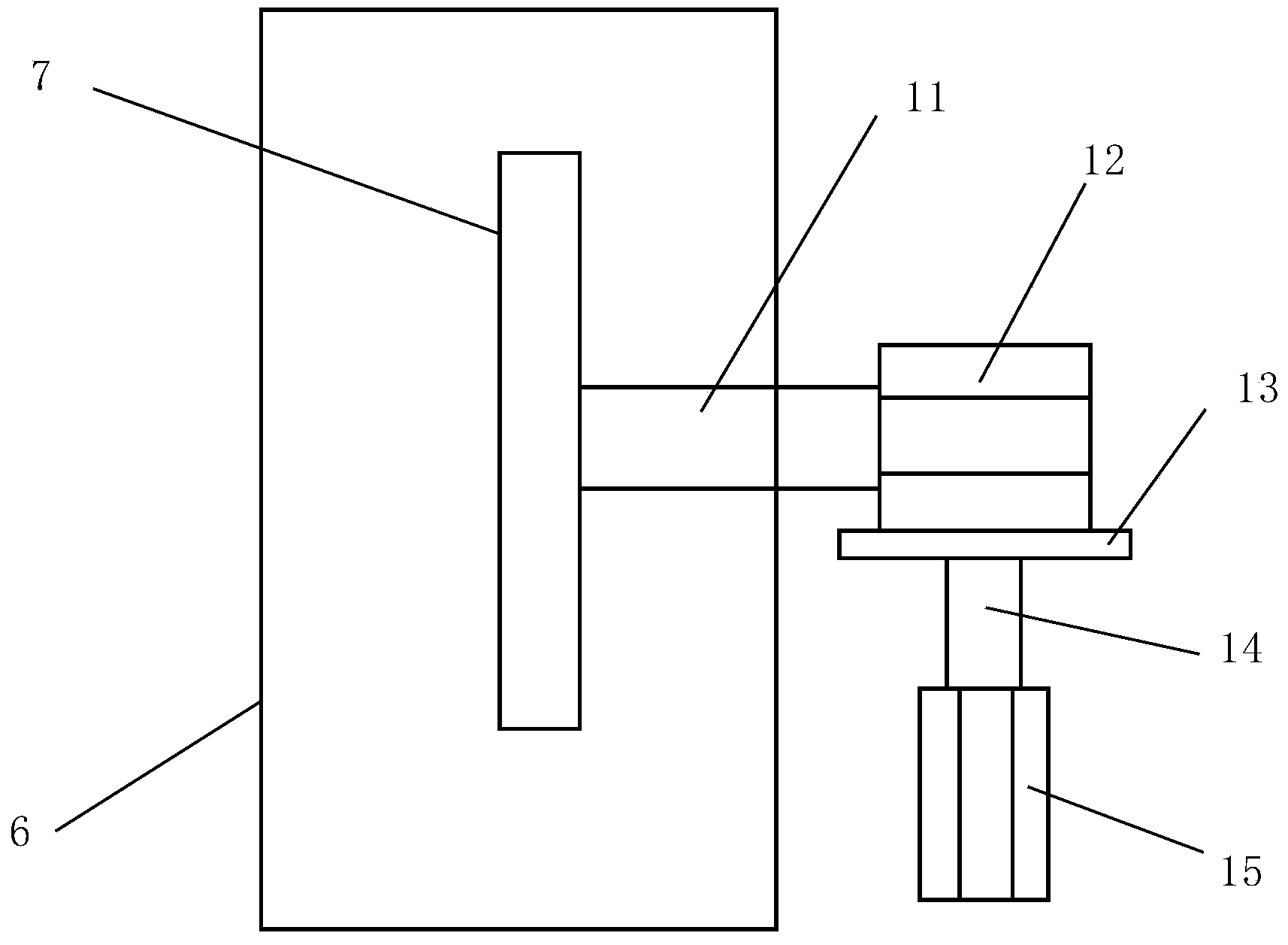

[0039] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] In this embodiment, firstly, the structure of a laser pulse annealing device of the present invention is introduced in detail. see figure 2 , figure 2 It is a front view structure diagram of a laser pulse annealing equipment reaction chamber of the present invention. As shown in the figure, in the present invention, a disk 7 for placing a wafer is arranged in a vertical state in the reaction chamber 6 of the laser pulse annealing device. The side of the disc 7 facing the laser emitter of the equipment (not shown) is evenly provided with 13 wafer placement grooves 8 around the circumference of the disc 7, and a 300mm wafer can be fixedly placed in each groove. The groove 8 can use a bayonet or a chuck to fix the wafer. The pulsed laser beam emitted by the laser emitter is irradiated to a predetermined position on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com