Cylinder filling control device

A control device, gas cylinder technology, applied in the directions of transportation and packaging, container filling methods, equipment for loading pressure vessels, etc., and can solve problems such as unsuitable temperature control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

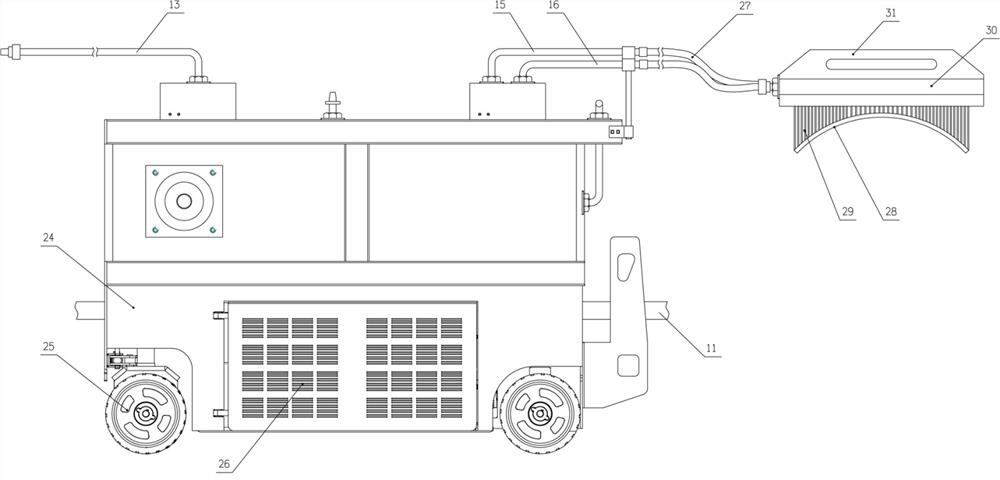

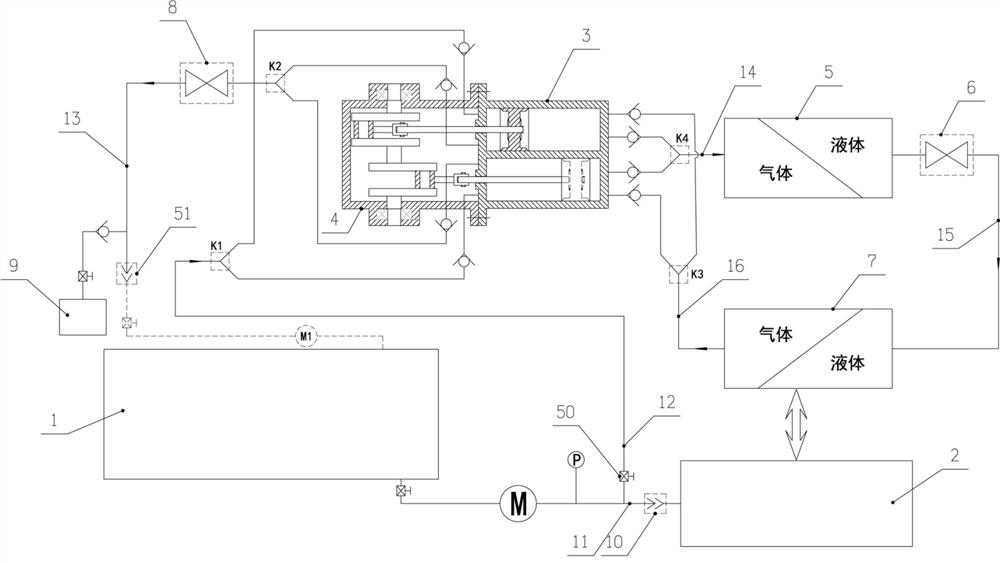

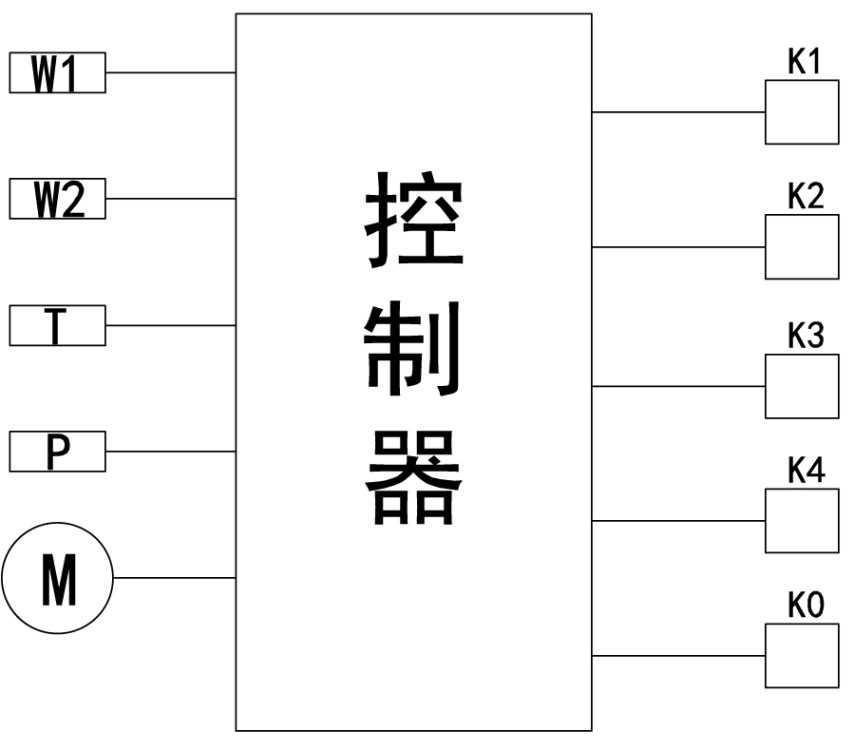

[0026] Embodiment 1: A gas cylinder inflation control device, which includes a gas tank 1 (compressed gas inflation equipment) and a gas cylinder 2 as a gas source for gas supply, and the device is suitable for the application of a variety of compressed liquefied gas inflation control, Such as compressed air, oxygen, liquefied petroleum gas, natural gas, inert gas or corrosive gas, etc., wherein, the output end of the gas tank 1 is pressurized by the gas pump (or compressor), and then connected to the gas tank through the gas connector 10 bottle 2. It also includes a cooling mechanism. The pressure supply main pipe 12 is drawn out from the inflation pipe 11 to perform work on the cooling mechanism. The evaporator 7 at the output end of the cooling mechanism is connected to the gas cylinder through a heat-conducting component, and is controlled by the controller according to the inflation progress in the gas cylinder 2. The power of the air pump increases until the cylinder is ...

Embodiment 2

[0037] Embodiment 2: as Figure 5 As shown, on the basis of the improvement of the condenser in Embodiment 1, in this embodiment, a shaft tube 33 is connected to the rear side of the sealing box 30 through a fixing seat 32, and one end of the handle 34 is set on the shaft through a shaft sleeve 35. On the outside of the tube 33, a connector 36 is arranged at the end of the shaft tube, and a guide rod 39 is set on the other end of the handle through the sleeve 2 37. The front end of the guide rod is designed as an arc-shaped hook body 38 for clamping the gas cylinder. A rear seat and a handle 40 are arranged at the rear end of the guide rod, and a thrust spring is connected between the second axle sleeve and the rear seat.

Embodiment 3

[0038] Embodiment 3: A kind of gas tank inflation control device, such as Figure 6 As shown, the compressed gas from the compressed gas pipeline or the total storage tank 42 is introduced into the compressed gas transport vehicle-mounted gas tank through the inflation pipe, the air pump and the inflation joint 10, and the gas tank as described in Embodiment 1 is arranged near the vehicle-mounted gas tank. Cool down the power system. Such as Figure 6 As shown in , the dotted line part is the system arranged on the compressed gas transport vehicle. The detailed structure of the system is described in Implementation 1, and will not be described in detail. The system has three external joints: the inflation joint 10 and the pressurization joint 43 And return air joint 44. The inflation joint 10 is connected with the inflation pipe 11 , the booster joint 43 is connected with the booster main pipe 12 , and the air return joint 44 is connected with the return main pipe 13 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com