Glass reinforced plastic (GRP) blow mold

A blow molding mold and glass fiber reinforced plastic technology, applied in the field of blow molding molds made of glass fiber reinforced plastic, can solve the problems of heavy metal molds, easy to burst, inaccurate molding, etc., and achieve the effects of fast production, reduced production costs, and guaranteed integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

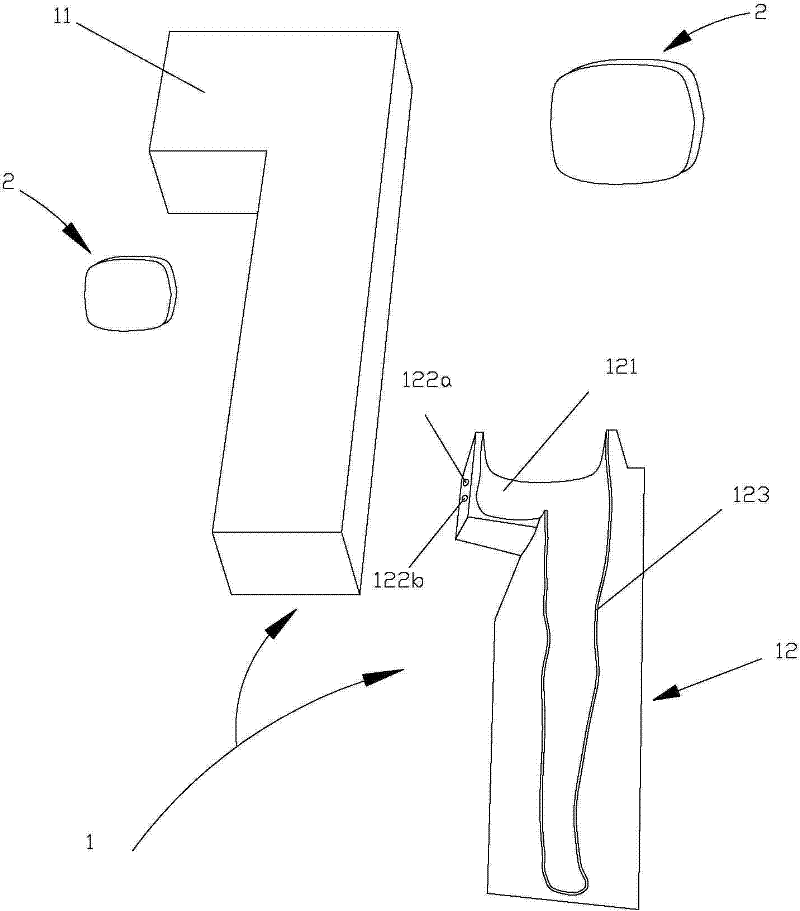

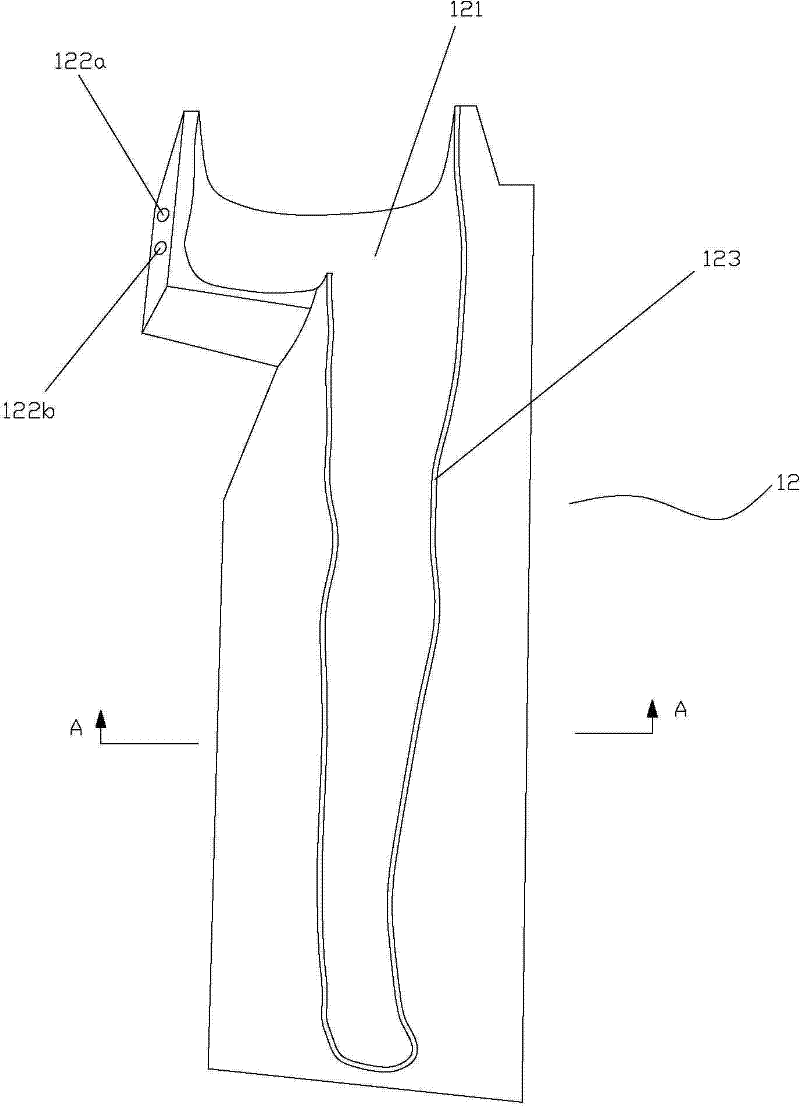

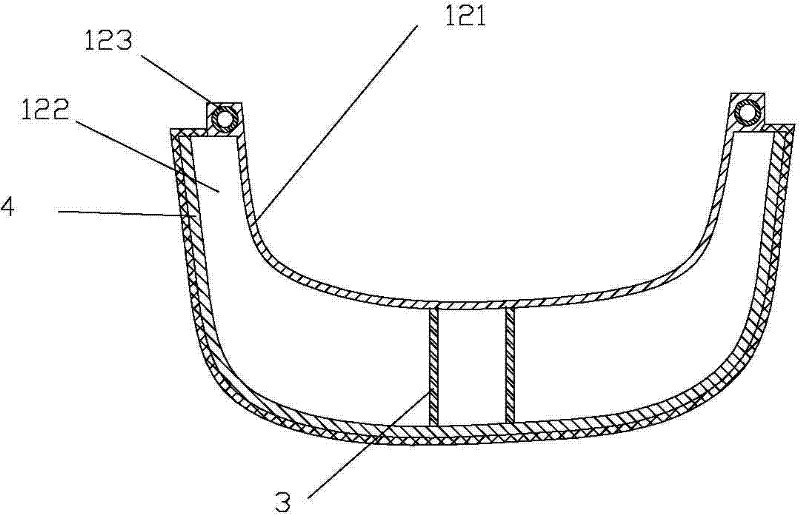

[0019] figure 1 , 2 As shown in and 3, the FRP blow mold of the present invention includes a mold body 1 and a connecting insert 2, the mold body 1 and the connecting insert 2 are fixedly connected by screws, and the mold body 1 is composed of an upper mold 11 and a lower mold with the same structure. Die 12 is formed, and described lower mold 12 is provided with lower mold cavity 121, is provided with cooling water chamber 122 on the back side of lower mold cavity 121, and this cooling water chamber 122 is provided with water inlet 122a and water outlet 122b, on lower mold 12 upper end Cooling hard water pipes 123 are buried at the mold clamping edge, and the two ends of the water pipes 123 extend to the outside of the mold body 1 respectively. A partition 3 is provided in the cooling water chamber 122 , and a circulating water channel is formed in the cooling water chamber 122 , so that the cooling water circulates throughout the cooling water chamber 122 and avoids the occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com