Patents

Literature

31results about How to "Guaranteed annealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

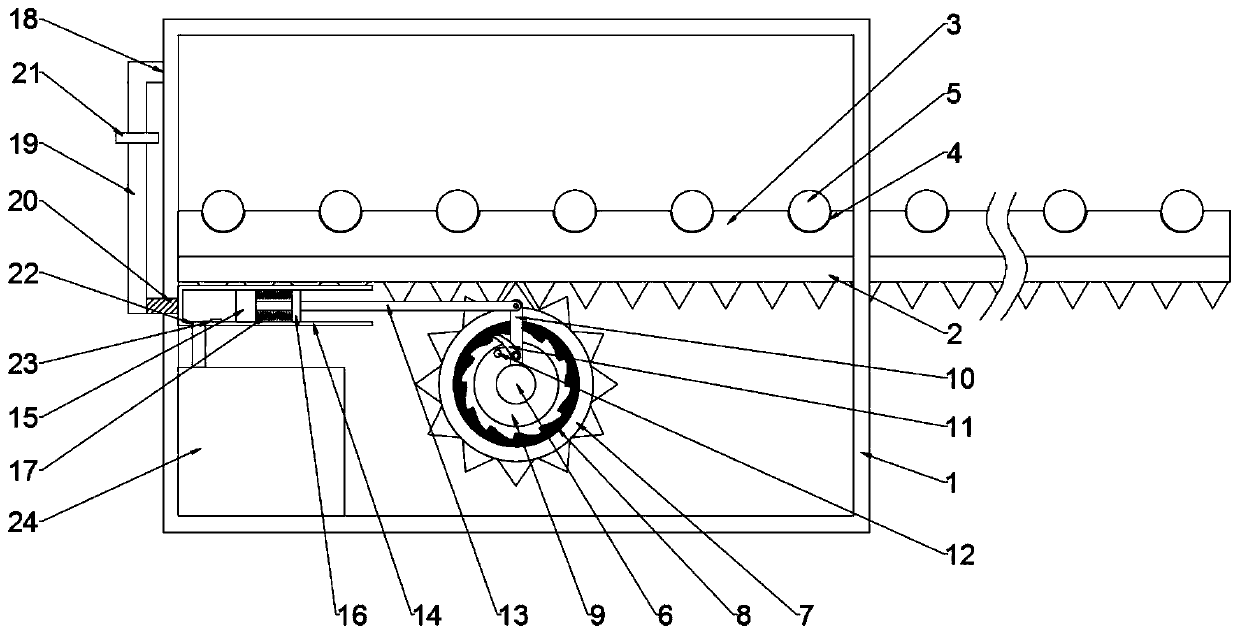

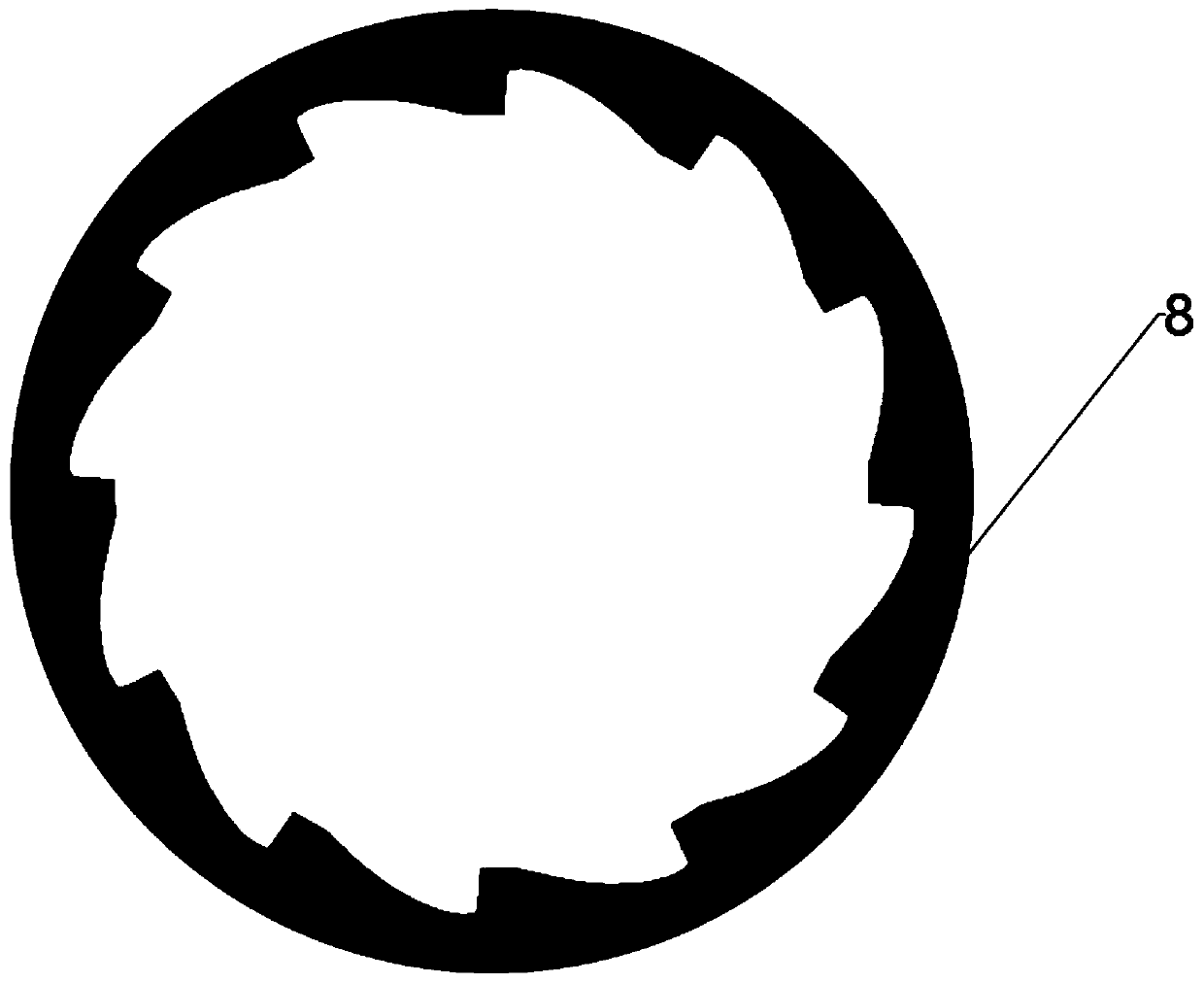

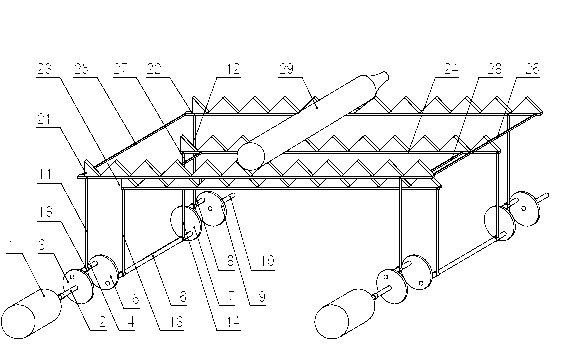

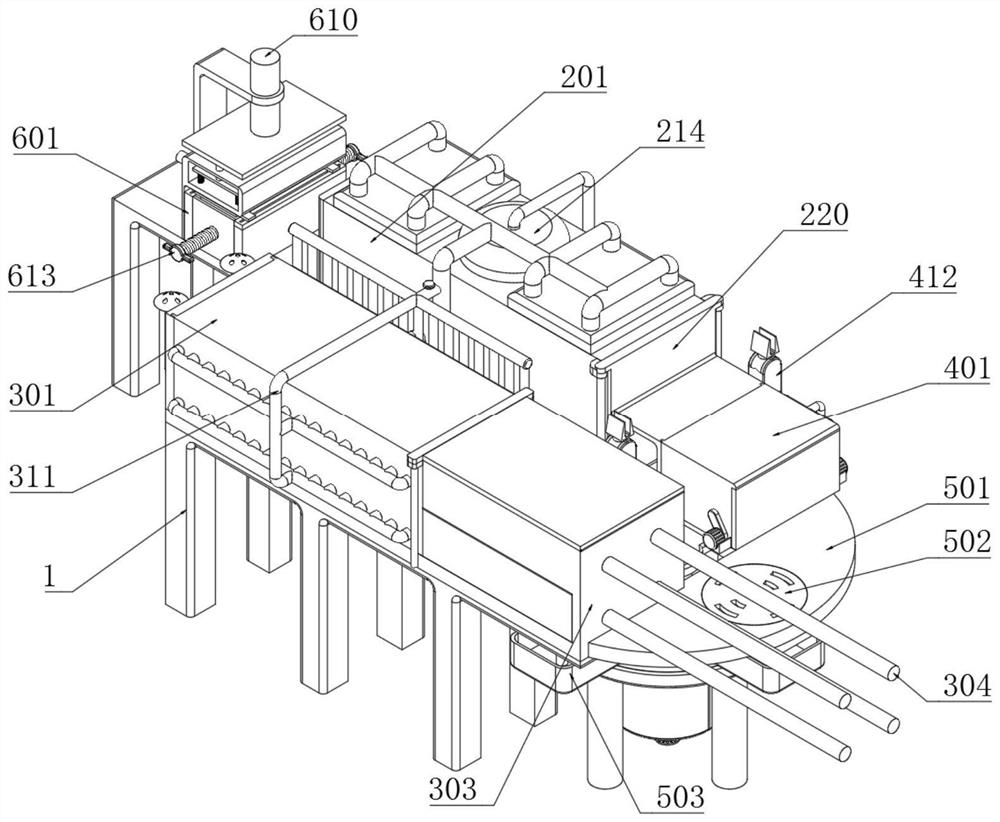

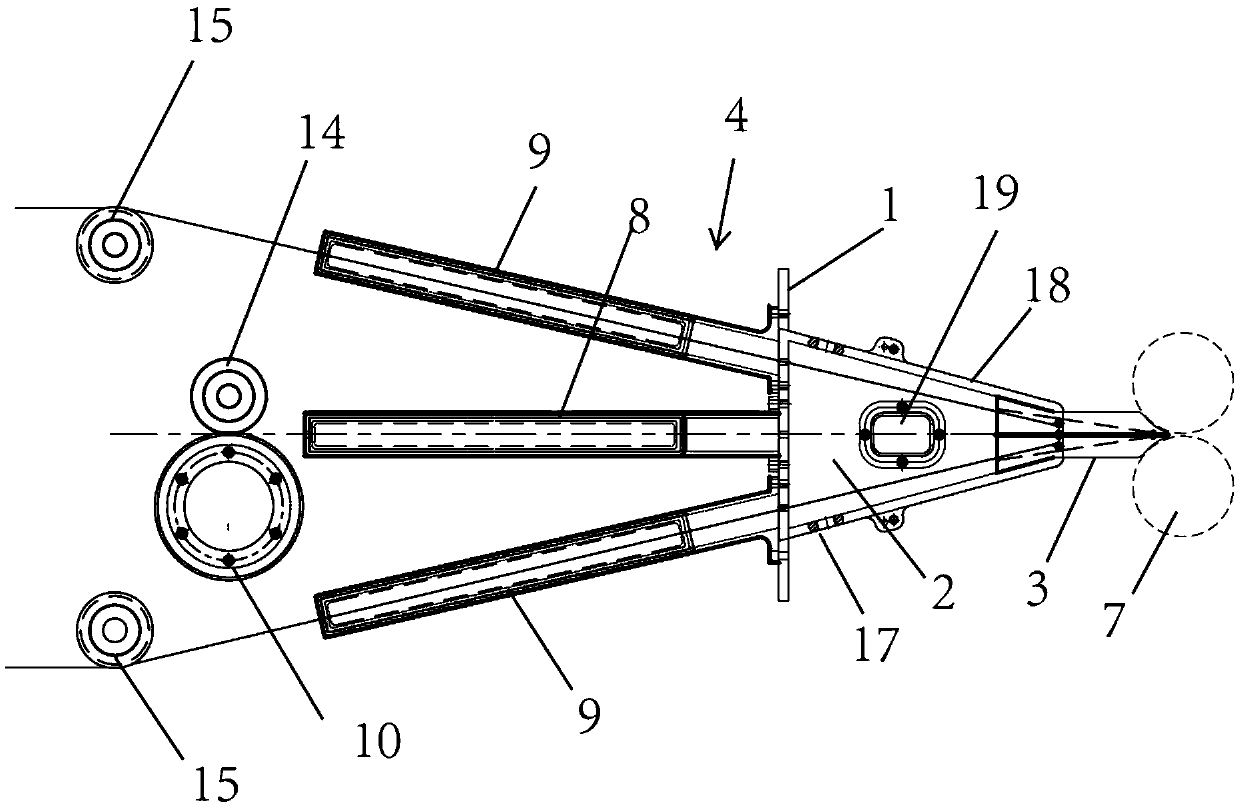

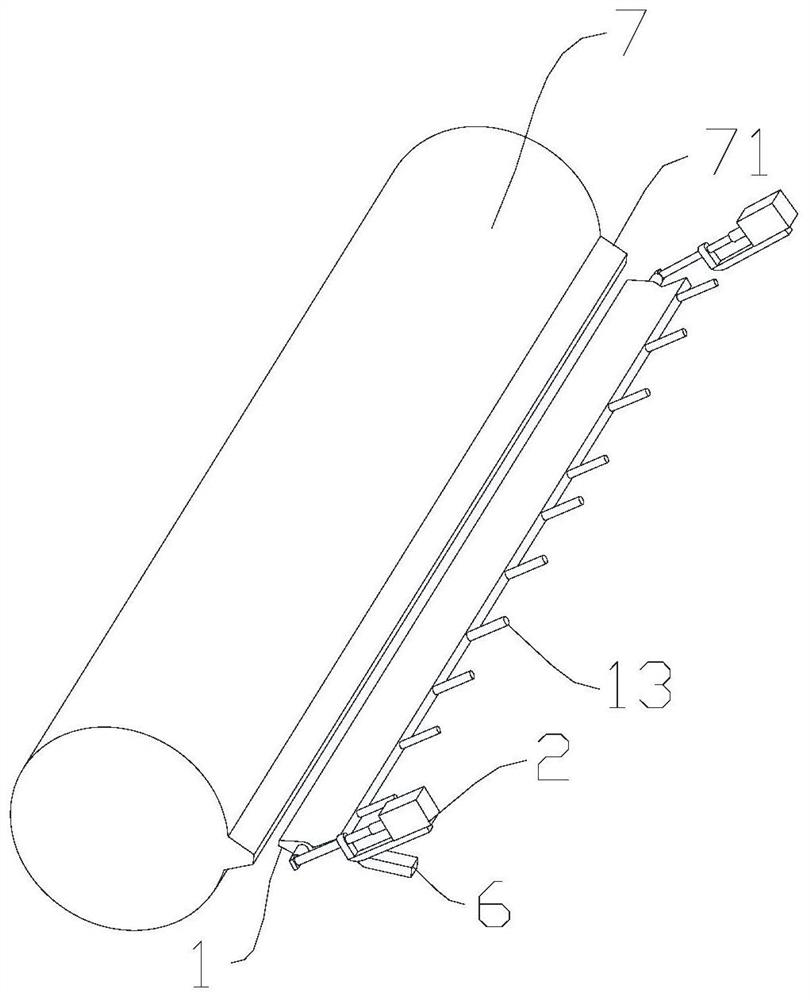

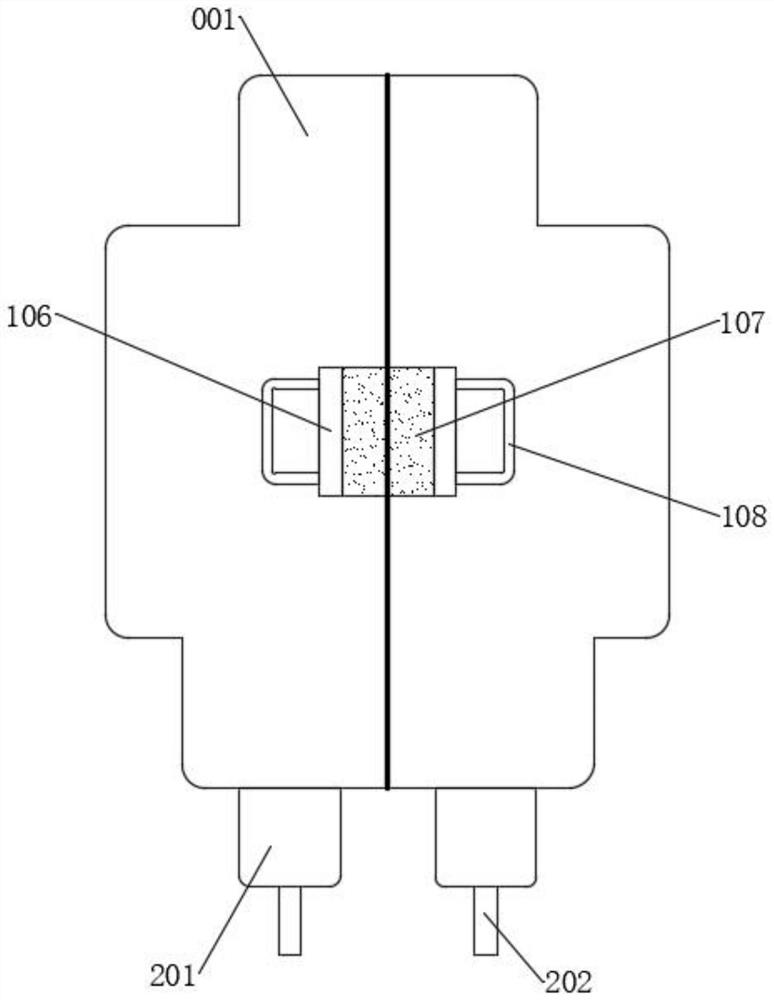

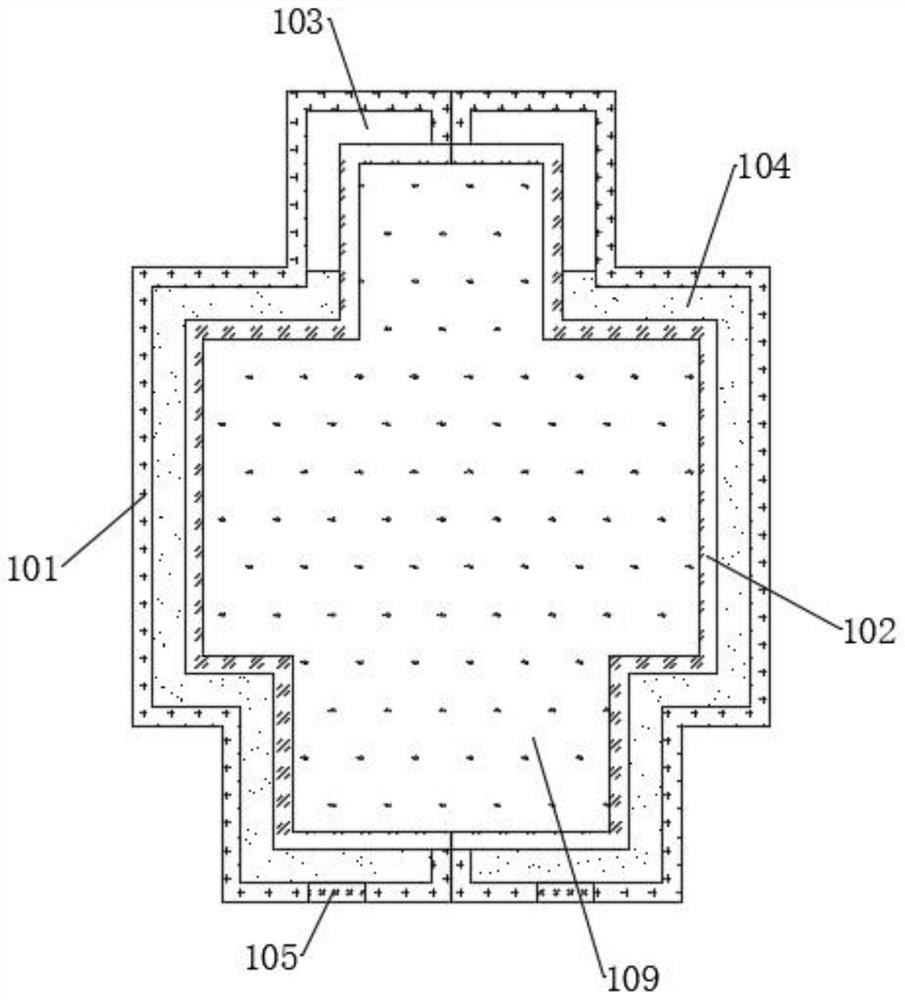

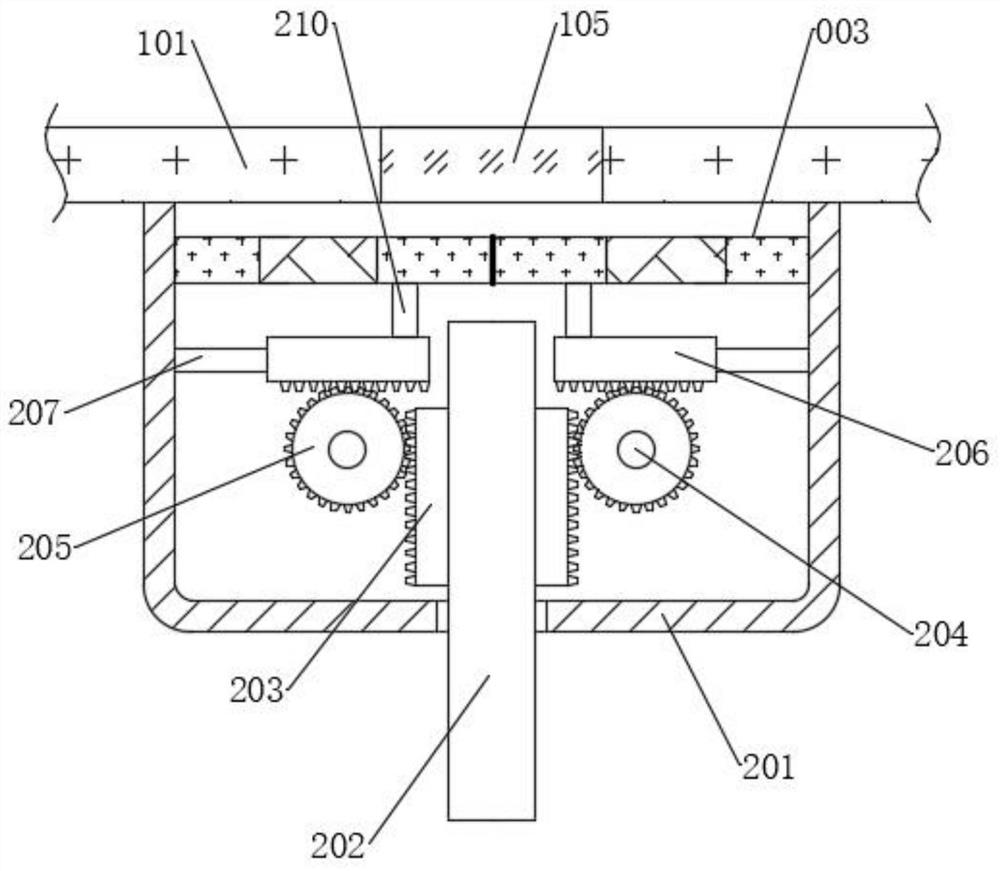

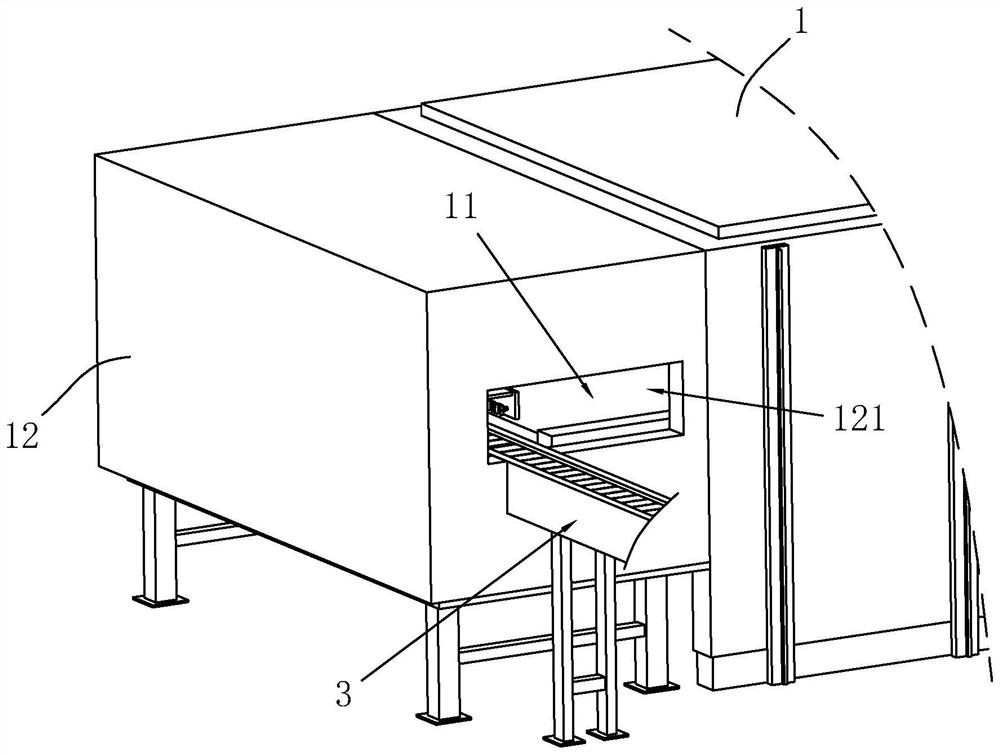

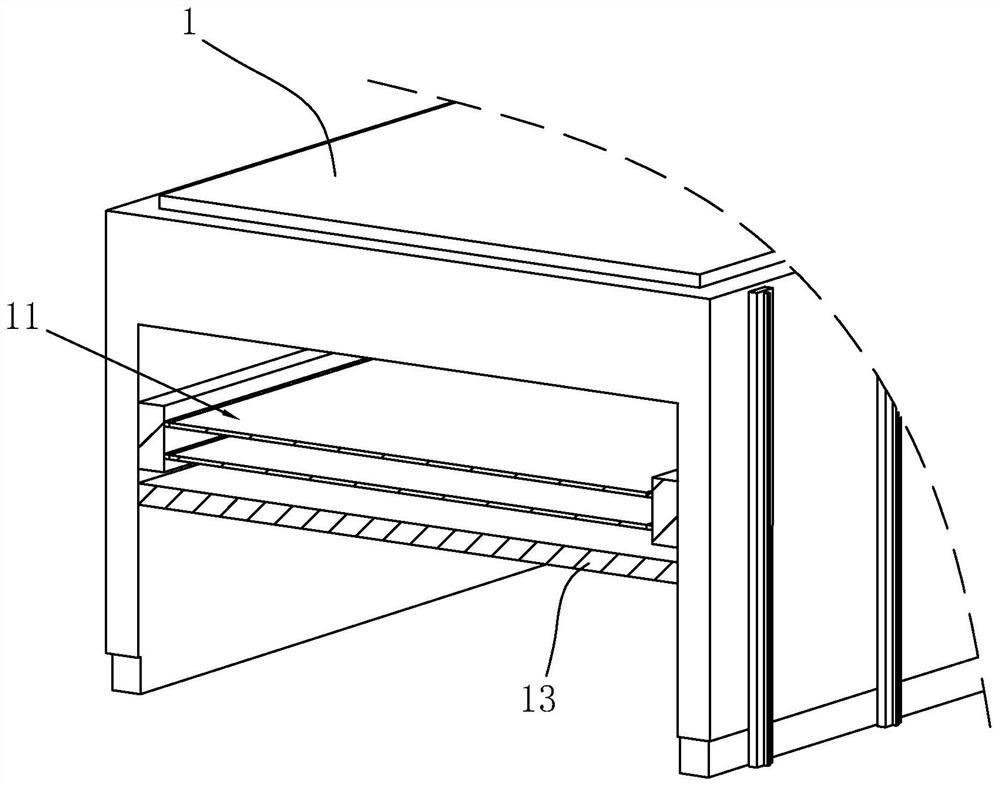

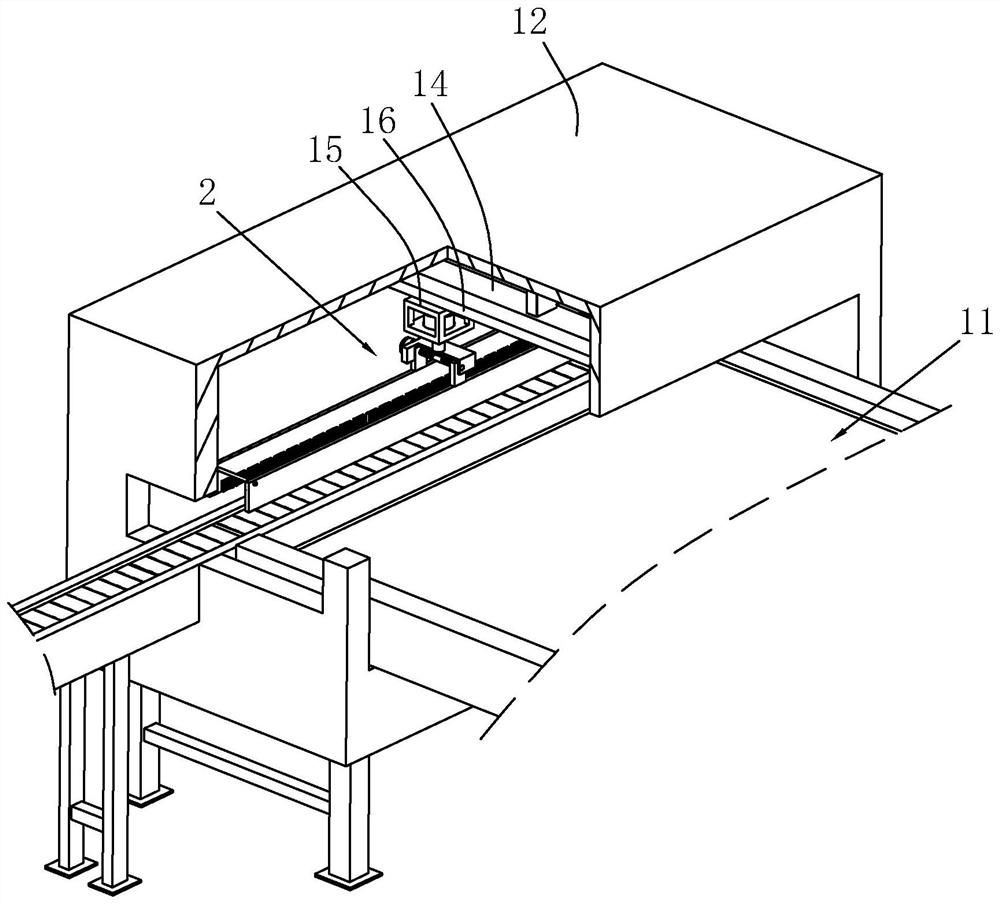

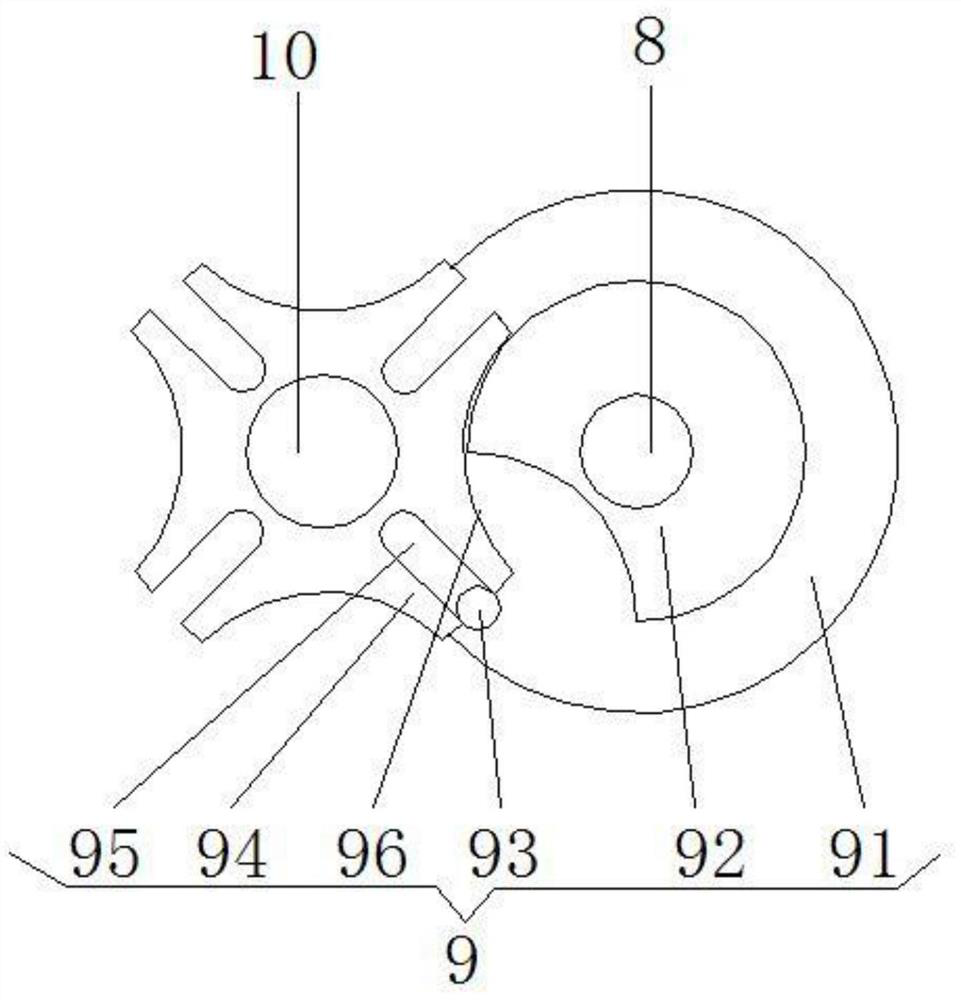

Conveying walking device for annealing processing of semiconductor electronic device

PendingCN111415897AGuaranteed annealing effectImprove stabilitySemiconductor/solid-state device manufacturingConveyor partsRatchetSemiconductor

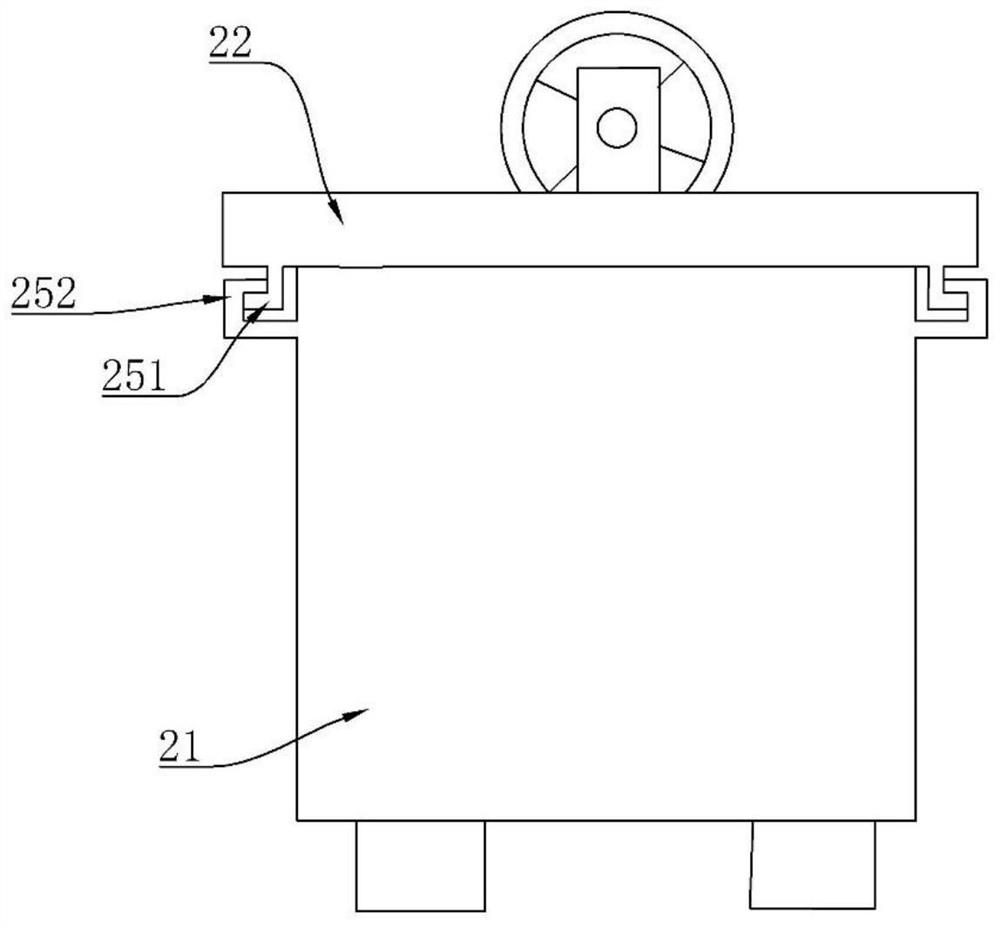

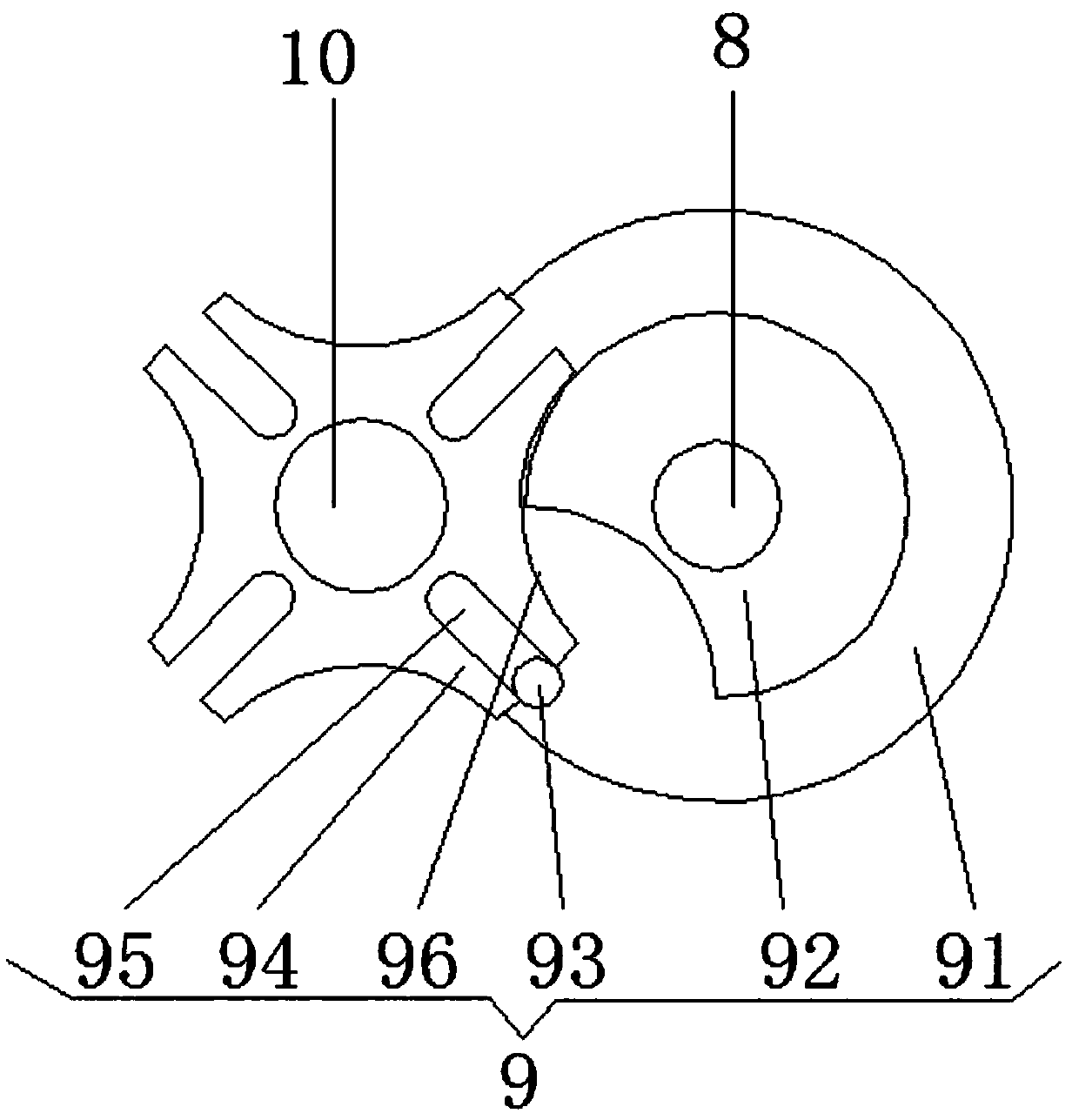

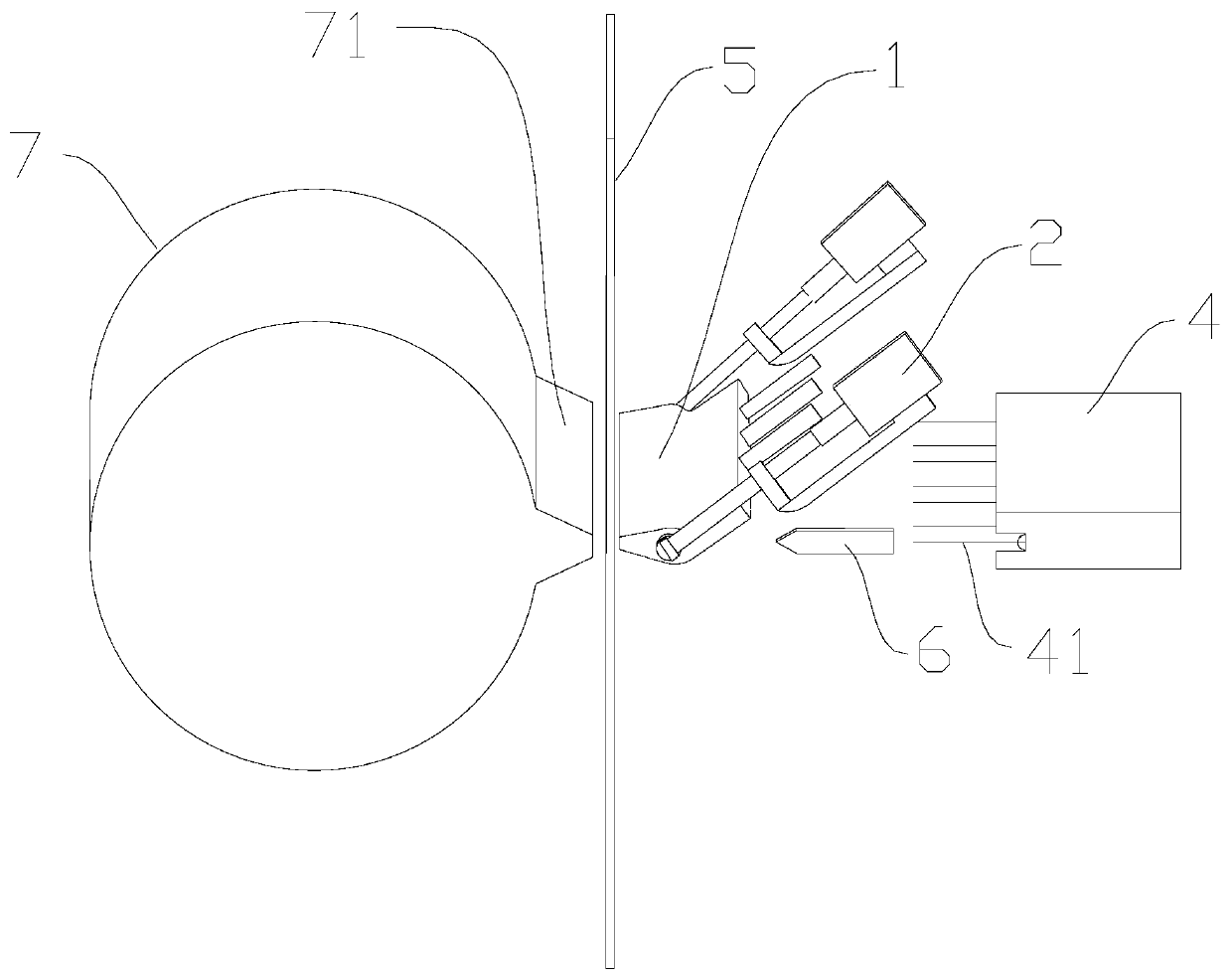

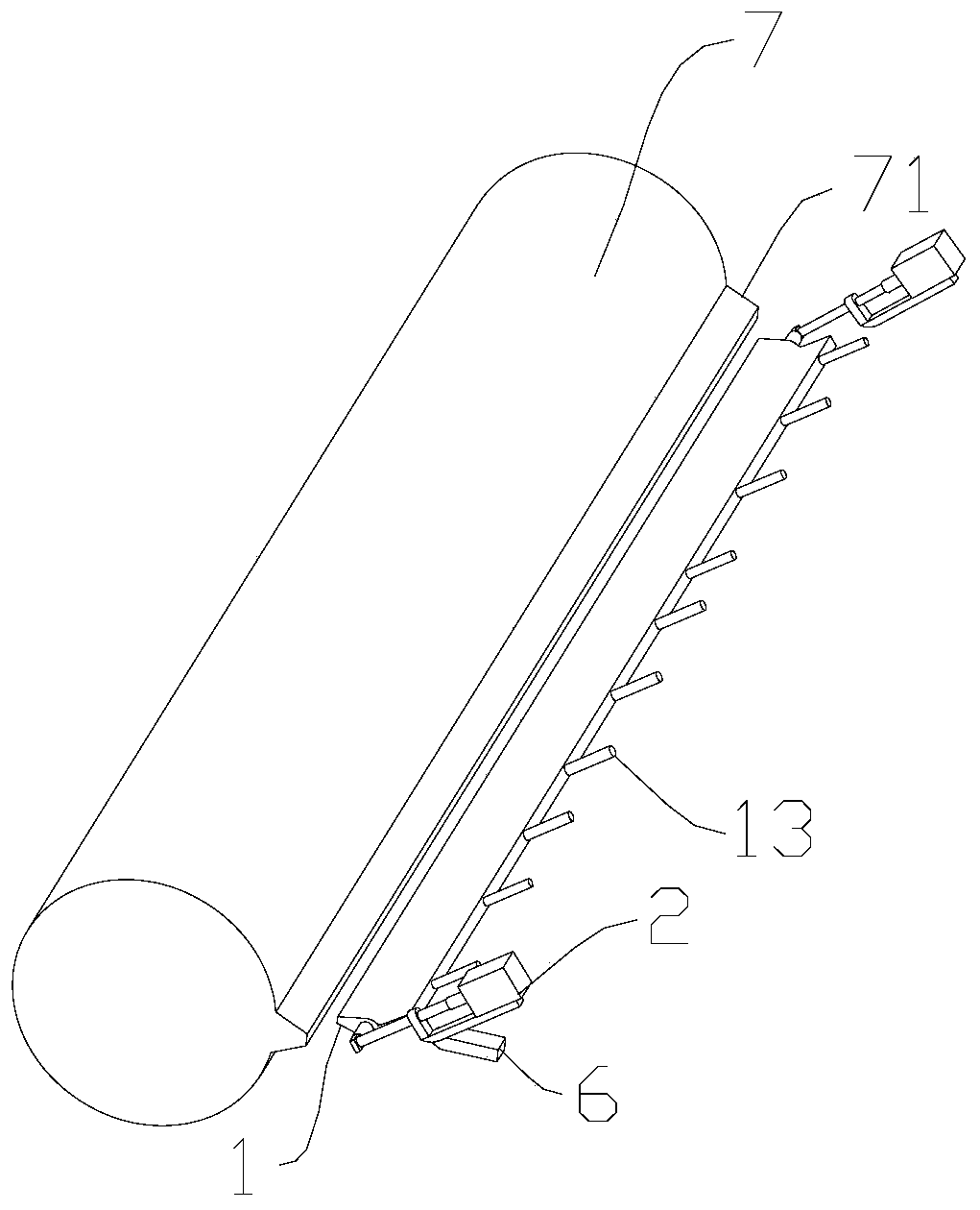

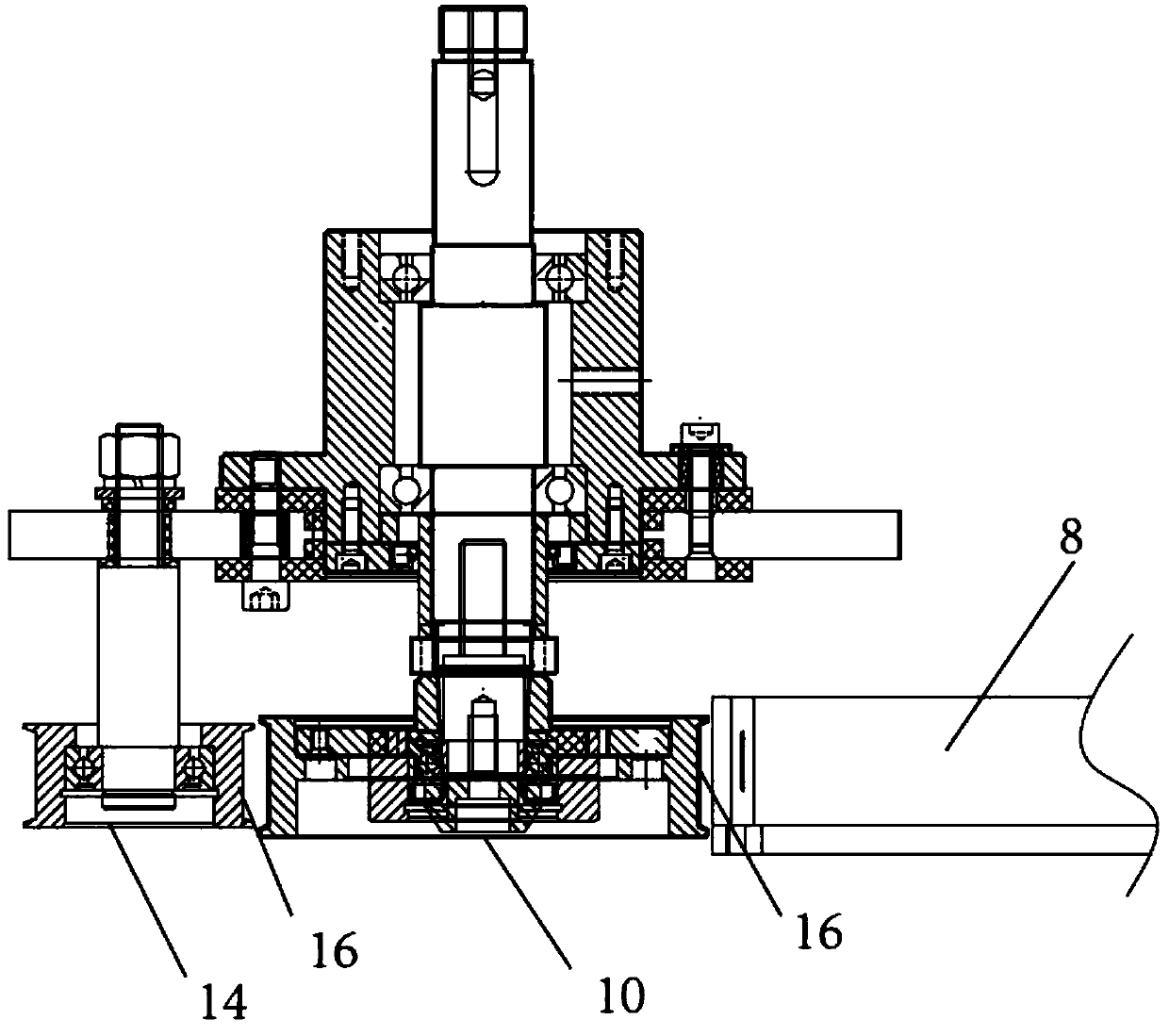

The invention discloses a conveying walking device for the annealing processing of semiconductor electronic devices and belongs to the technical field of electronic product processing. The conveying walking device for the annealing processing of the semiconductor electronic device comprises a furnace body shell; supporting plates are fixed to the inner walls of the front side and the rear side ofthe furnace body shell; toothed plates are slidably connected to the supporting plates; a plurality of teeth are integrally formed on the lower surfaces of the toothed plates; a plurality of semicircular grooves are formed in semiconductor tube placement grooves; a rotating shaft is inserted into the inner walls of the front side and the rear side of the furnace body shell; an outer gear is rotationally connected to the outer wall of the rotating shaft and is located below the teeth; the outer gear is meshed with the teeth; an inner edge ratchet wheel is coaxially fixed to the front side wallof the outer gear; the one-way intermittent conveying of to-be-machined semiconductor tubes can be achieved; manual operation is not needed for conveying the semiconductor tubes; due to the fact thatintermittent conveying can be achieved, the annealing treatment effect of the semiconductor tubes is guaranteed; and in addition, the stability of the whole device is high, and a deflection phenomenonis avoided.

Owner:江苏久茂精密电子科技有限公司

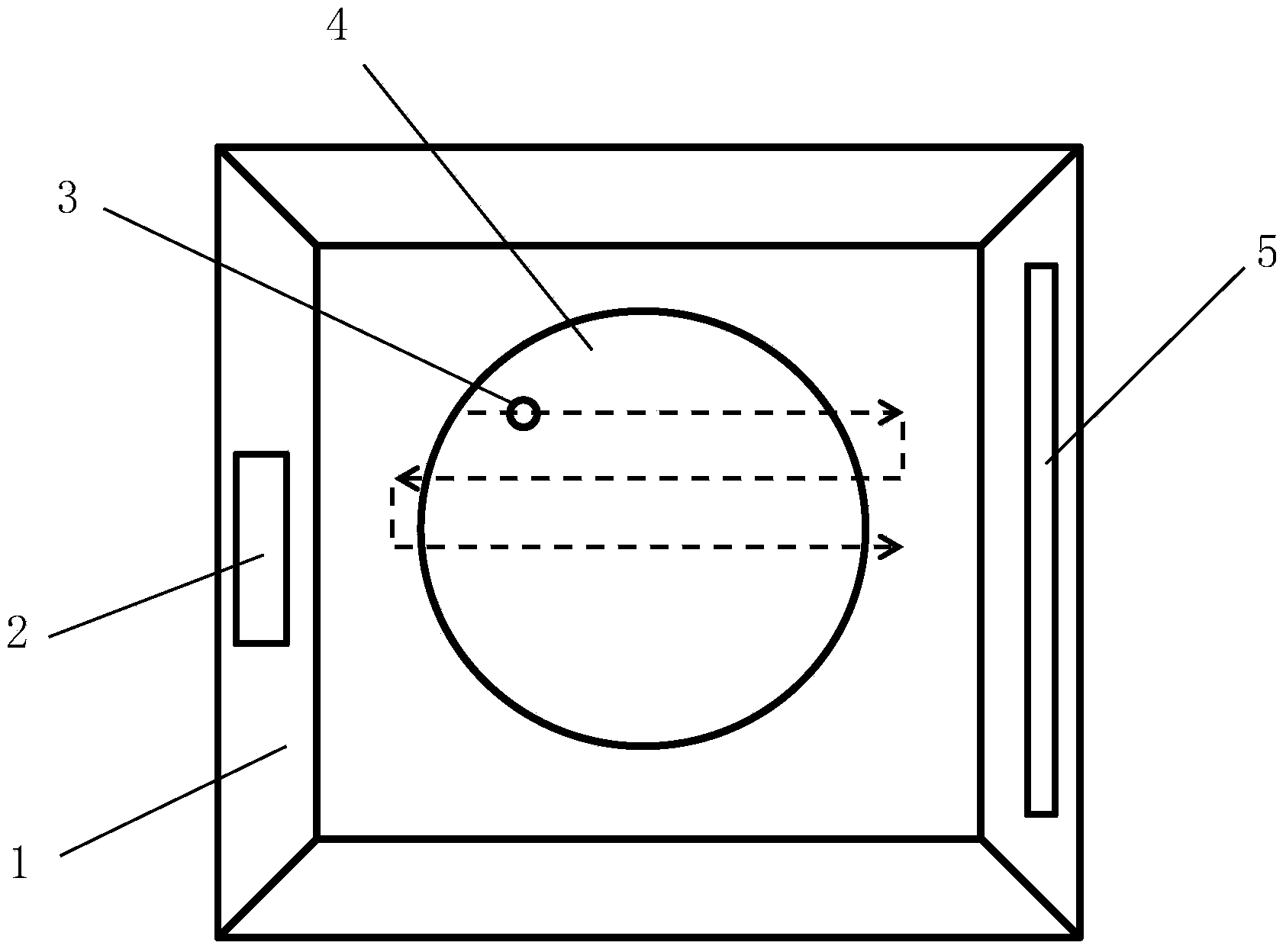

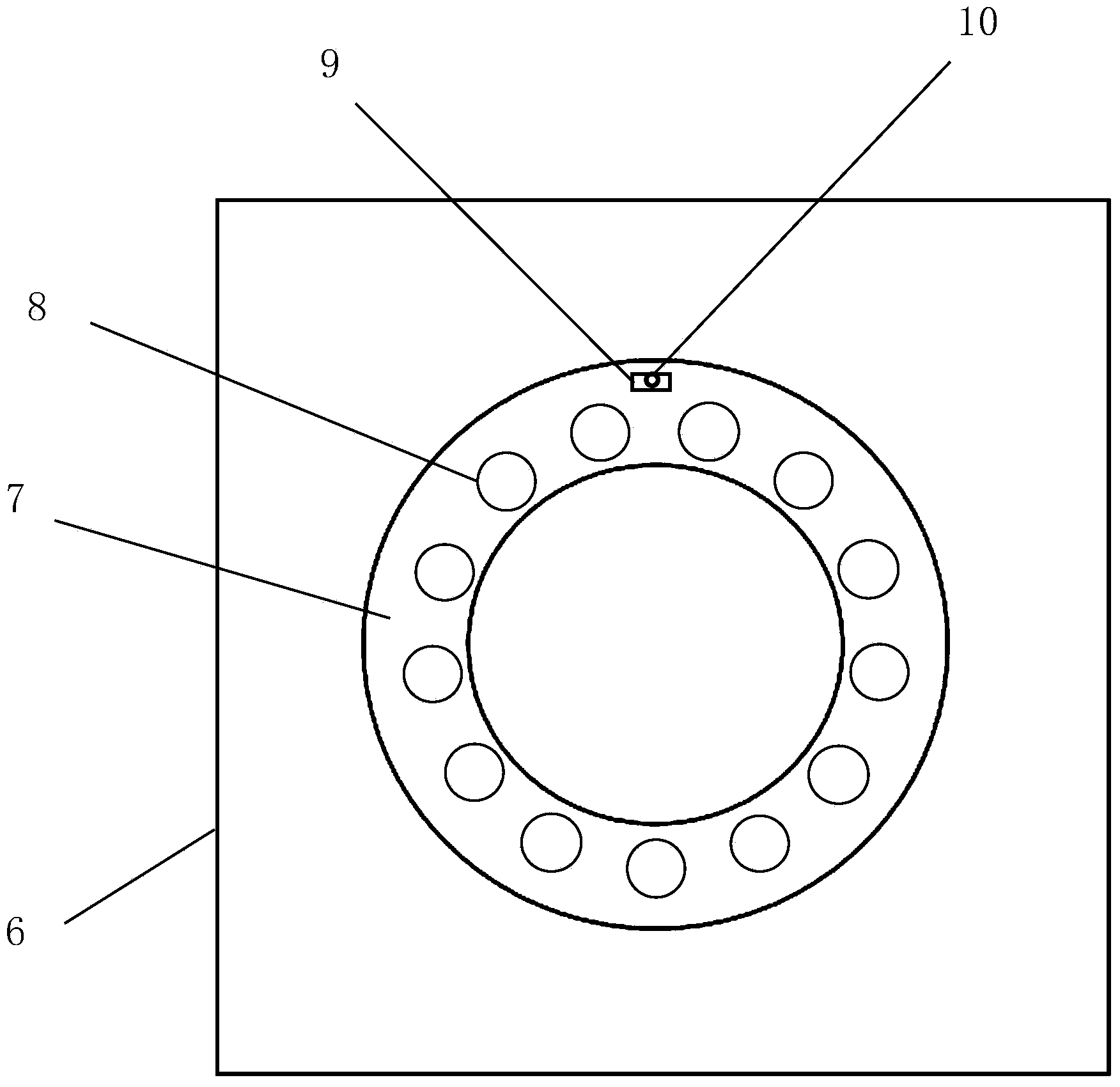

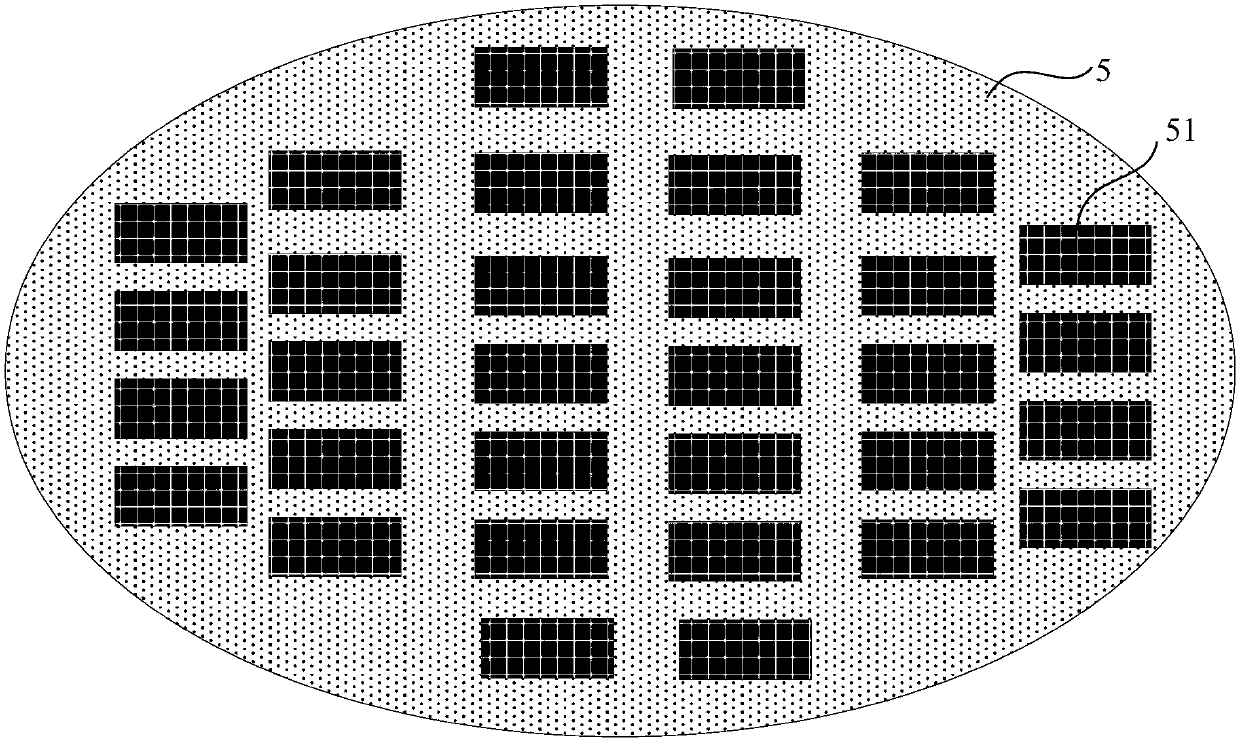

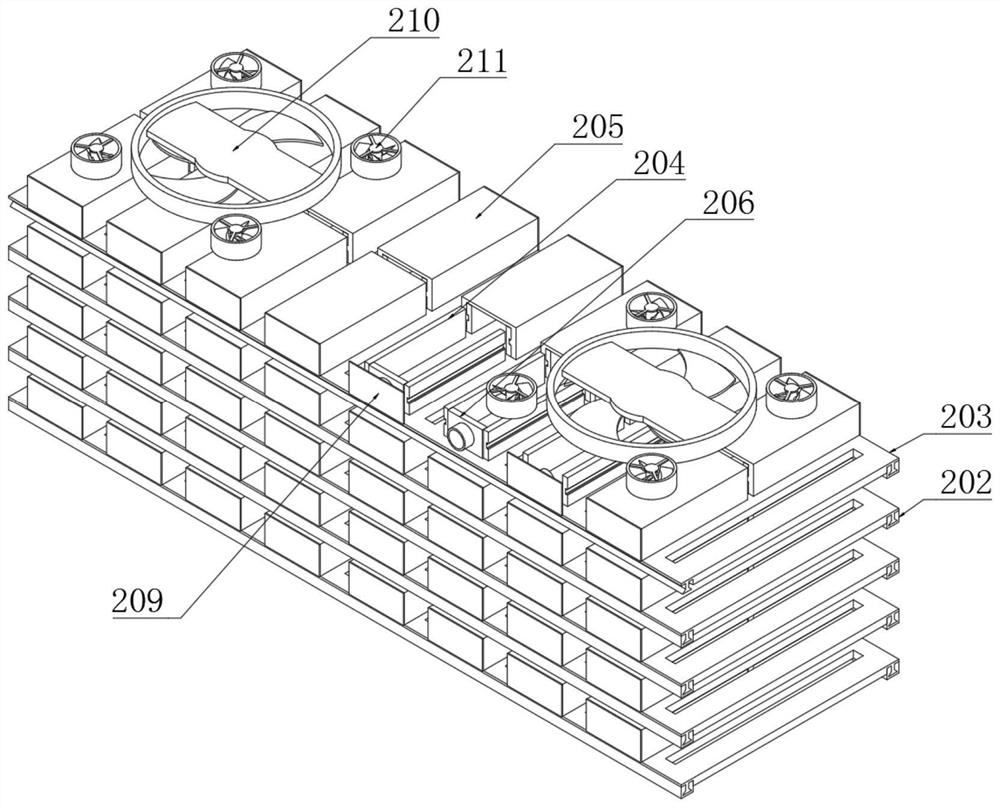

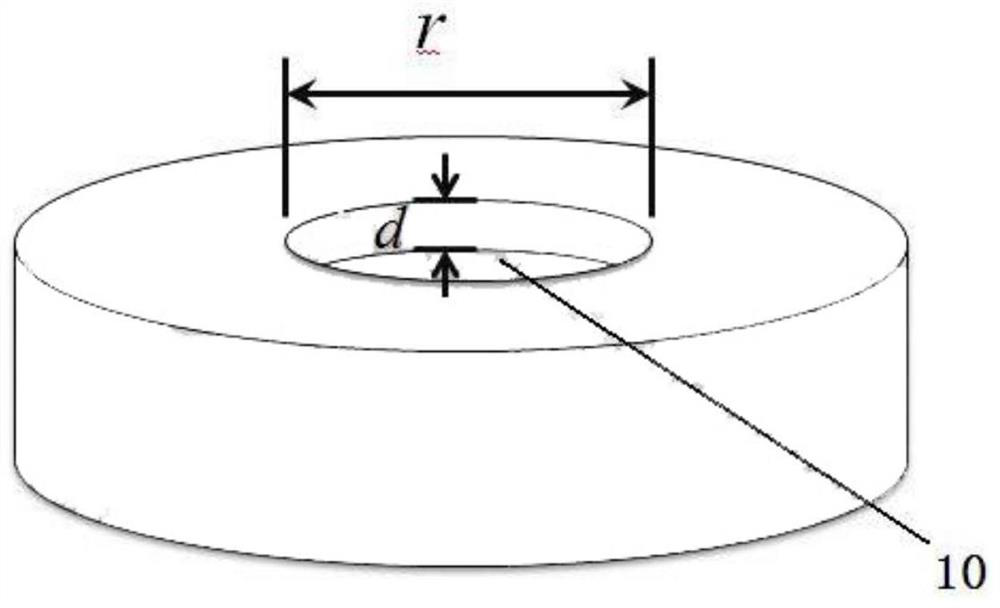

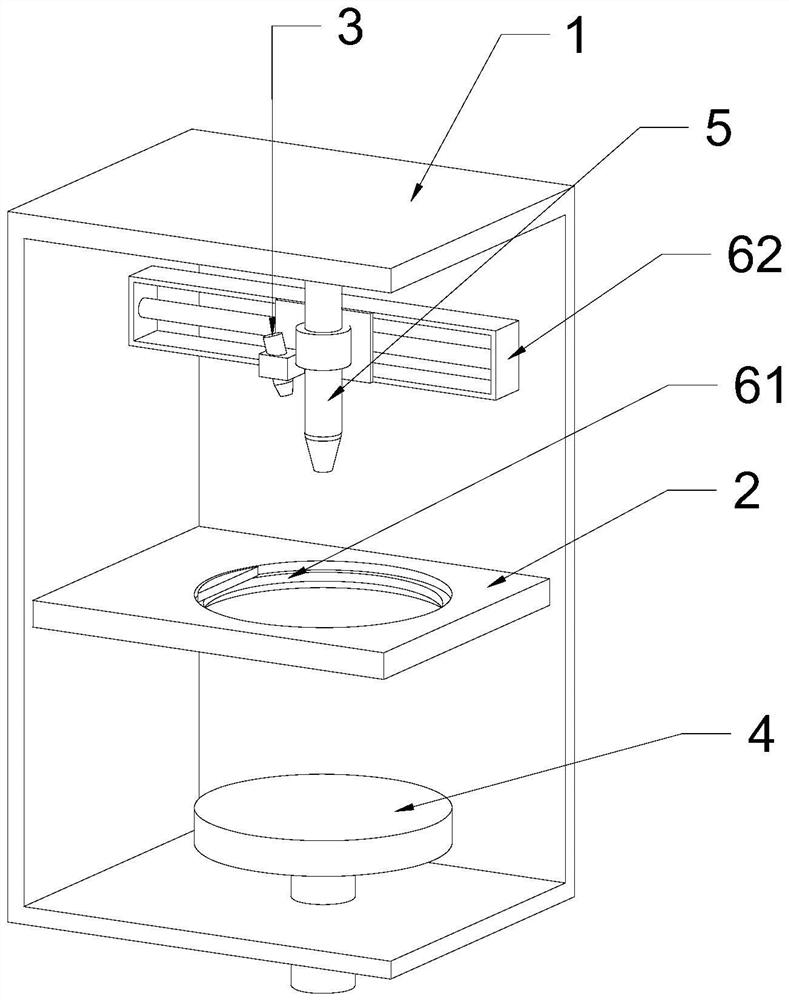

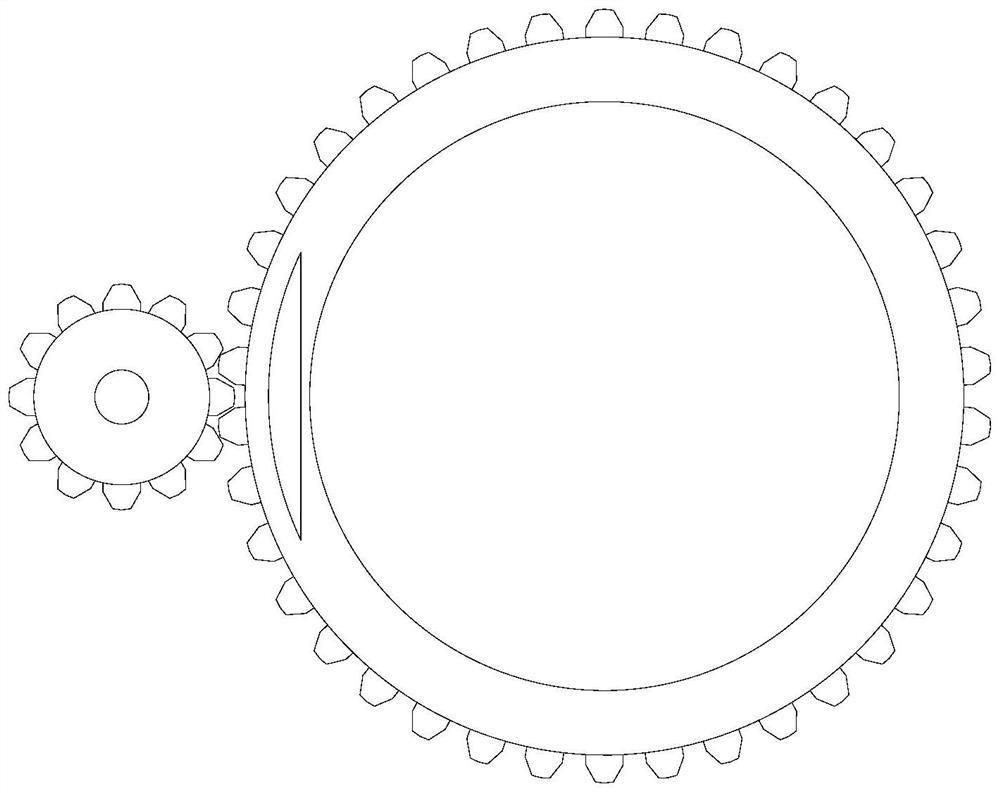

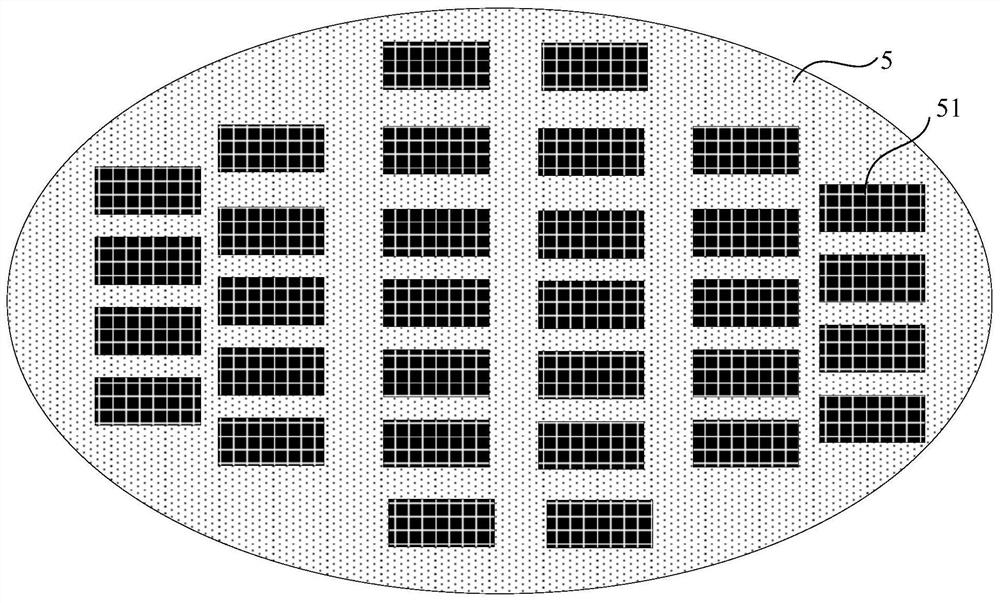

Laser pulse annealing equipment and annealing method

ActiveCN103920994ACool down as soon as possibleEnables batch annealingSemiconductor/solid-state device manufacturingLaser beam welding apparatusReciprocating motionOptoelectronics

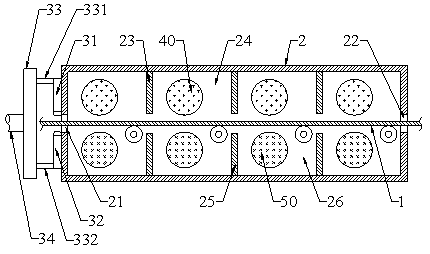

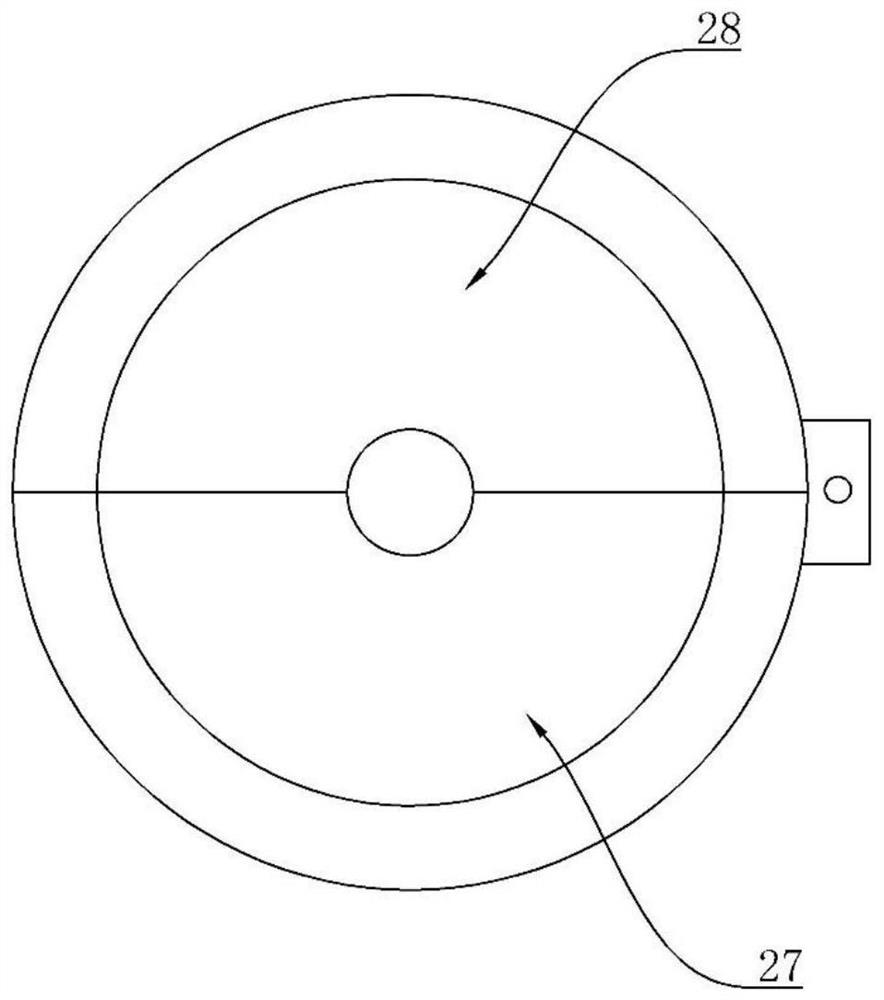

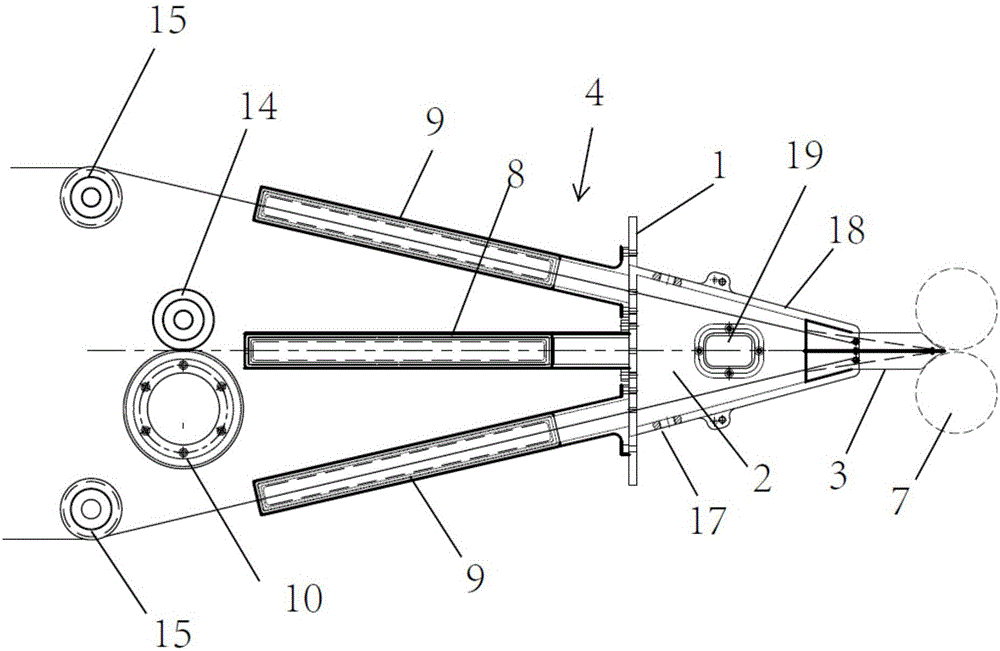

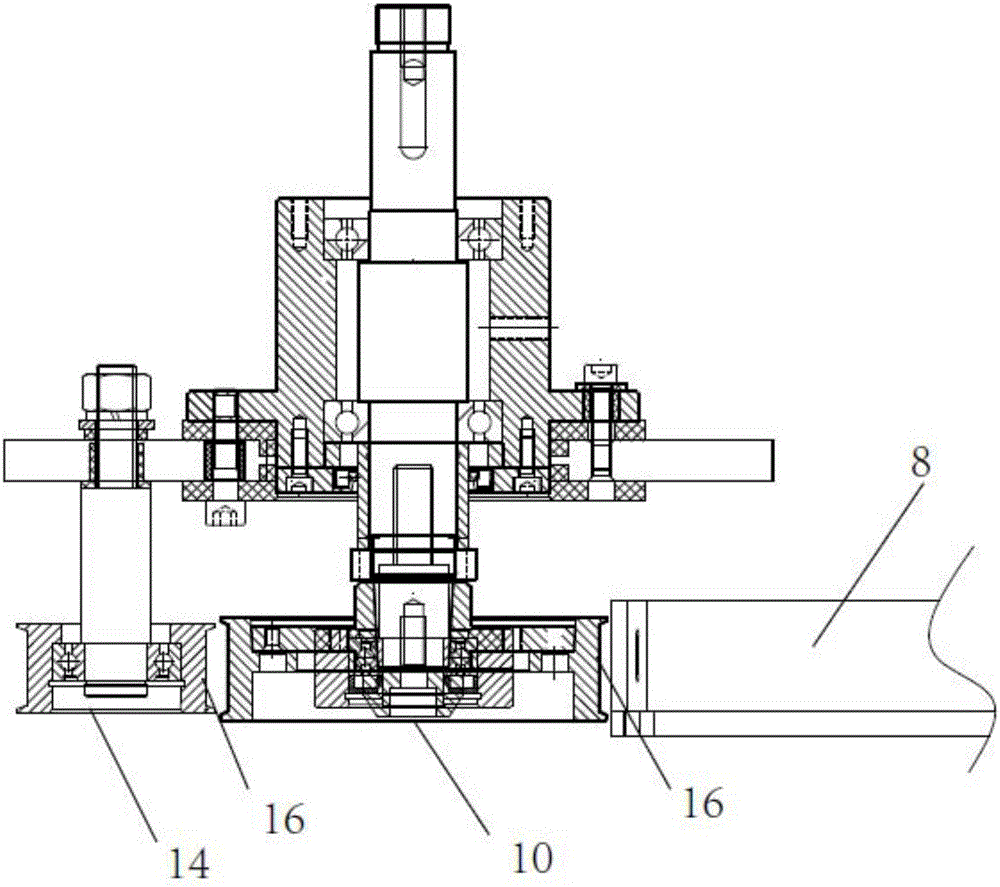

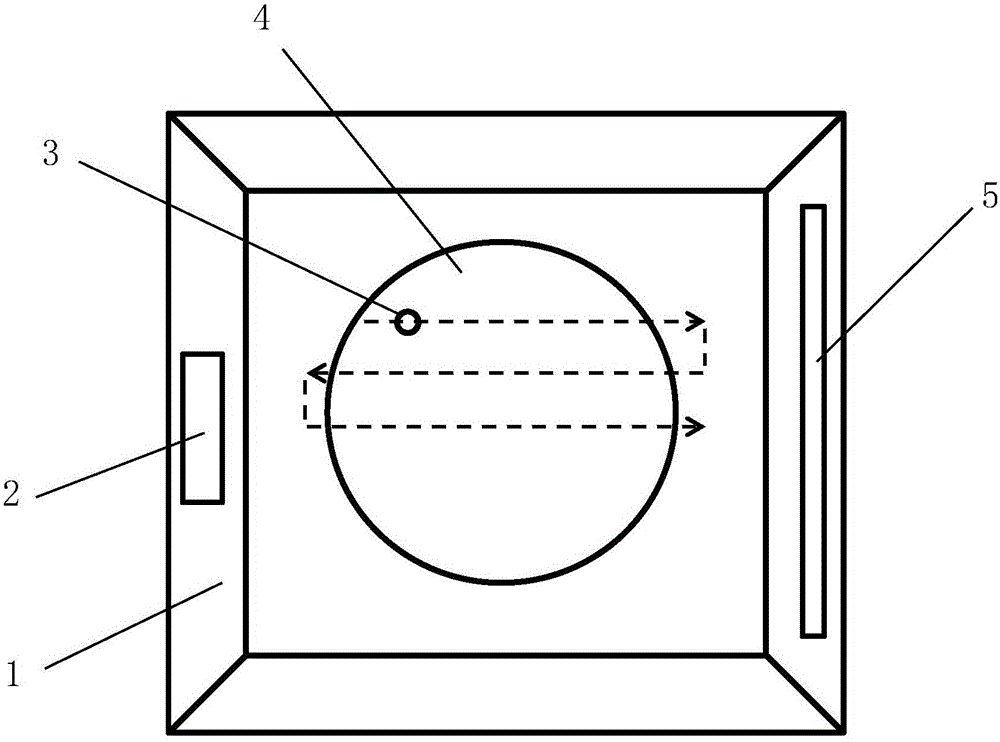

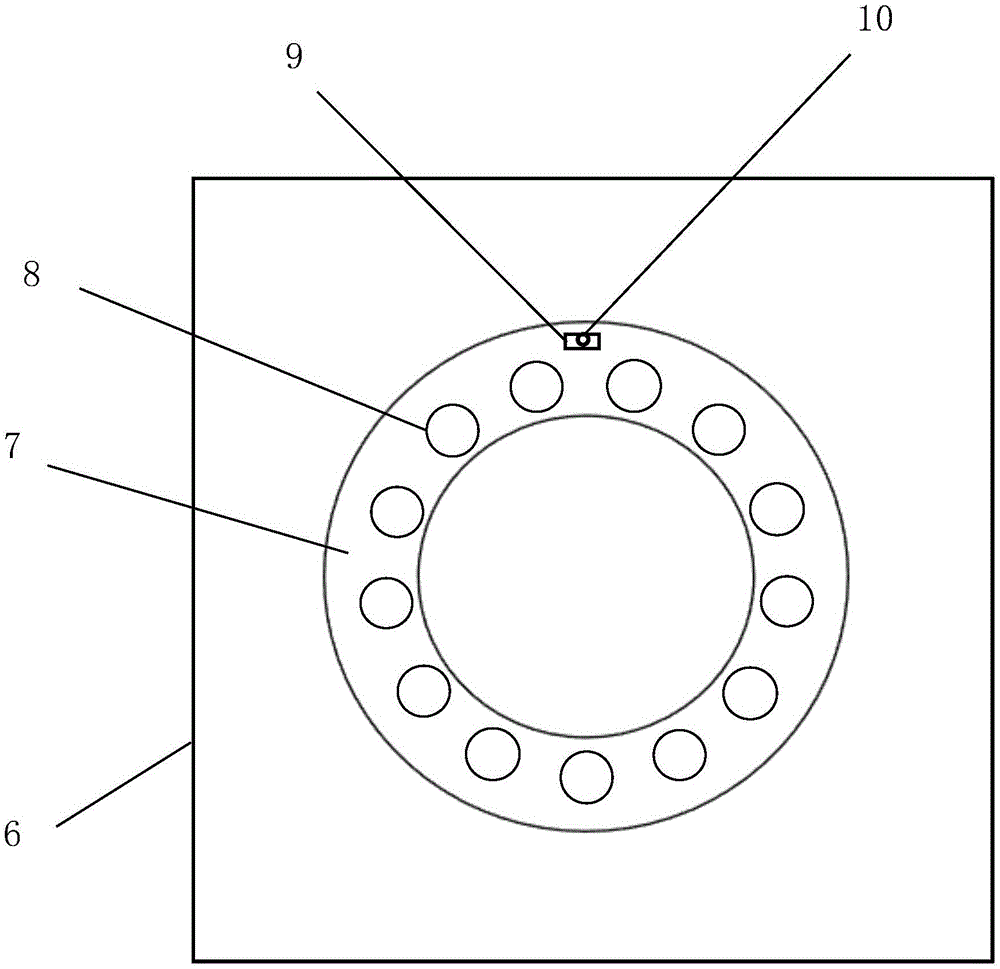

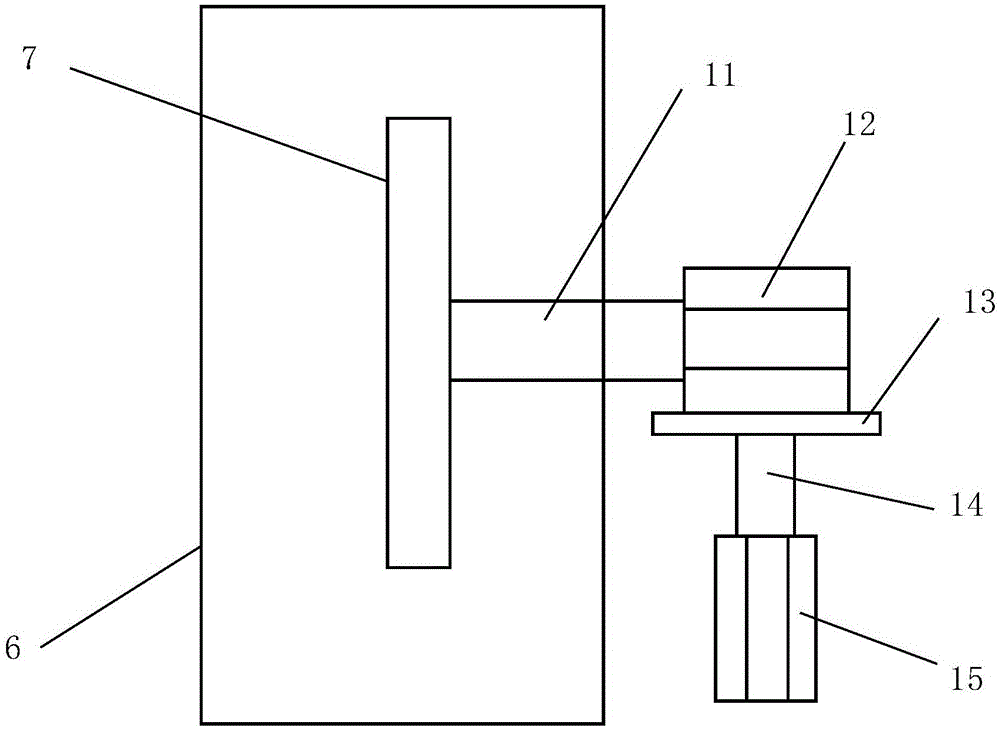

The invention discloses laser pulse annealing equipment and an annealing method applied to the laser pulse annealing equipment. A disk in which multiple wafers can be simultaneously placed is arranged in a reaction cavity of the laser pulse annealing equipment and is made to rotate and linearly move in the annealing treatment process, so that the wafers in wafer placement grooves in the disk sequentially and circularly pass through laser radiation points to be uniformly radiated by laser under driving of continuous rotation and linear reciprocating motion of the disk, and bulk annealing treatment on the wafers is achieved. According to the laser pulse annealing equipment and the annealing method, compared with traditional laser pulse annealing equipment which can only carry out annealing treatment on a single wafer, the laser pulse annealing equipment has the same annealing effect, annealing efficiency is remarkably improved, and the equipment and the method can well meet the process demands for annealing quality and efficiency in the high-end advanced process.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

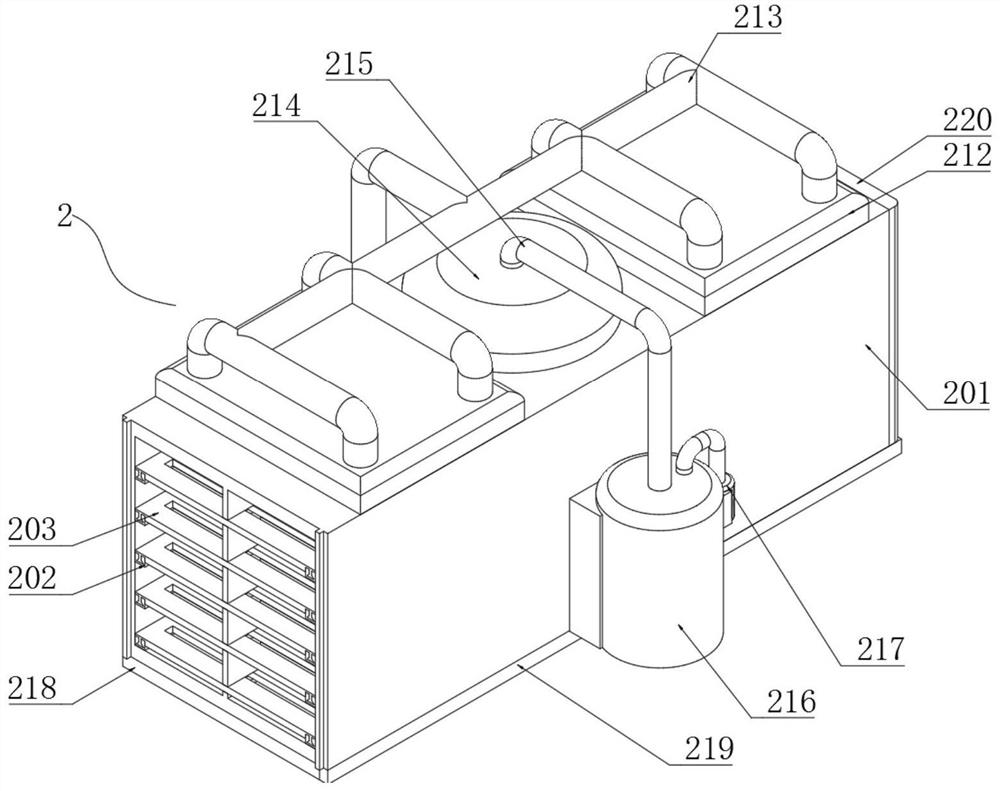

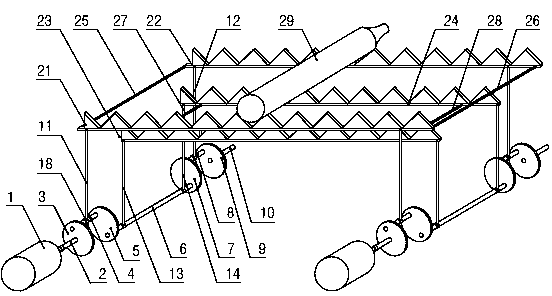

Special annealing kiln for producing float glass

ActiveCN108483882ADoes not affect continuous productionNot easy to bendGlass productionTemperature differenceKiln

The invention relates to a special annealing kiln for producing float glass. The special annealing kiln comprises a kiln body, wherein an inlet for the float glass to enter is formed in one side of the kiln body; a plurality of upper heat insulation boards are fixedly arranged inside the kiln body; the upper part of the kiln body is divided into a plurality of upper annealing regions by the upperheat insulation boards; lower heat insulation boards are arranged under the upper heat insulation boards; the lower part of the kiln body is divided into a plurality of lower annealing regions by thelower heat insulation boards; a wind screen mechanism is arranged outside the inlet; an upper cooling mechanism is arranged in each upper annealing region; a lower cooling mechanism is arranged in each lower annealing region. According to the special annealing kiln for producing the float glass, a wind curtain wall is formed by the wind screen mechanism arranged on the outer side of the inlet of the kiln body and is used for stopping external heat from entering the annealing kiln, so that the annealing effect is ensured, the operation is facilitated and the influence on continuous production of the float glass is avoided; by matching the upper cooling mechanisms with the lower cooling mechanisms, temperature difference between the side part and the middle part of the float glass is reduced, and the annealed float glass is not easy to bend.

Owner:TG ANHUI GLASS

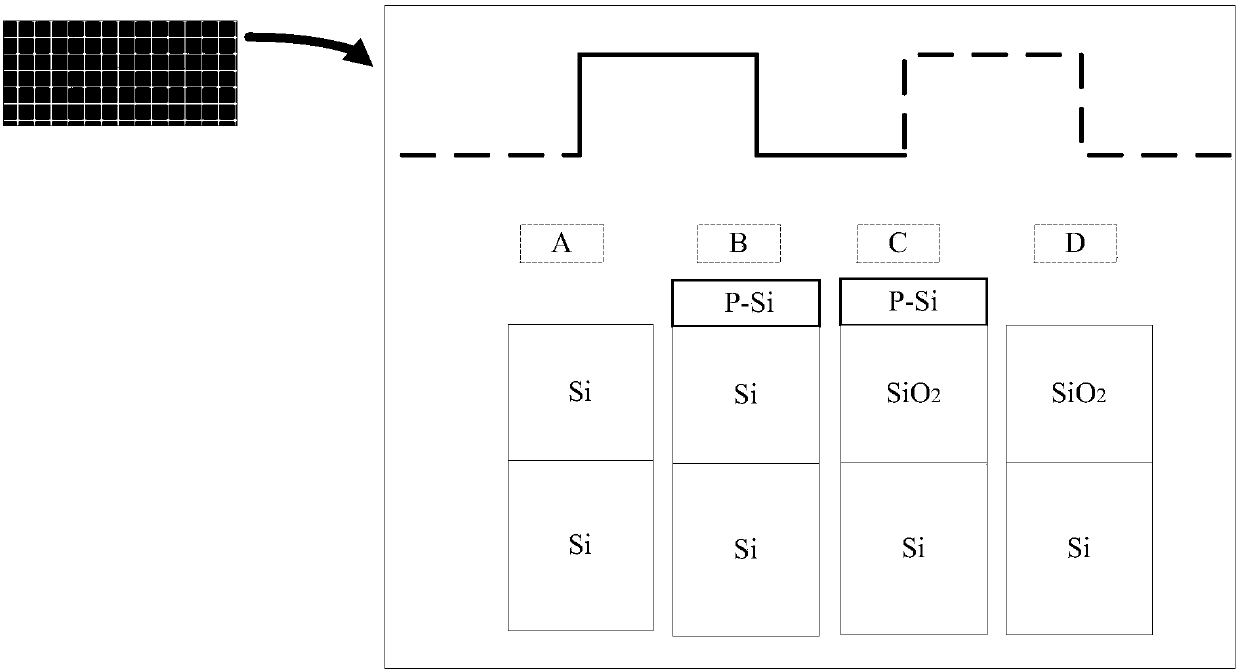

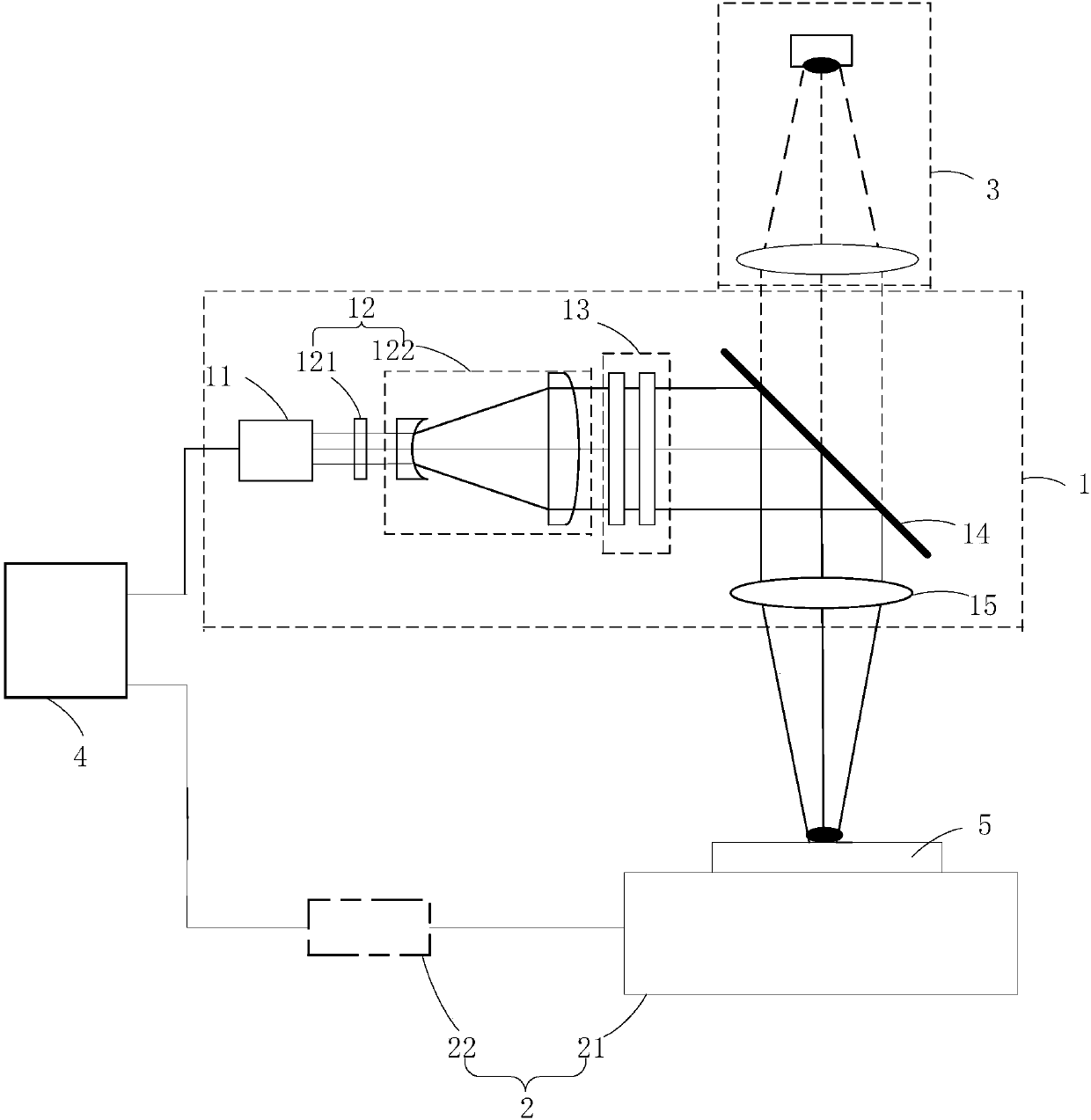

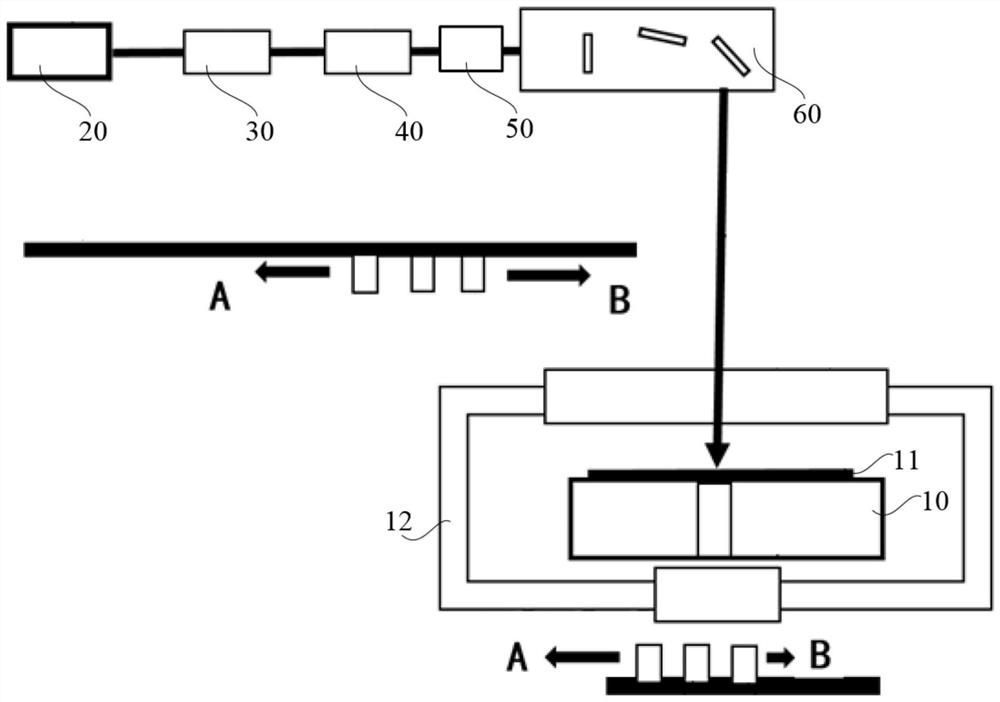

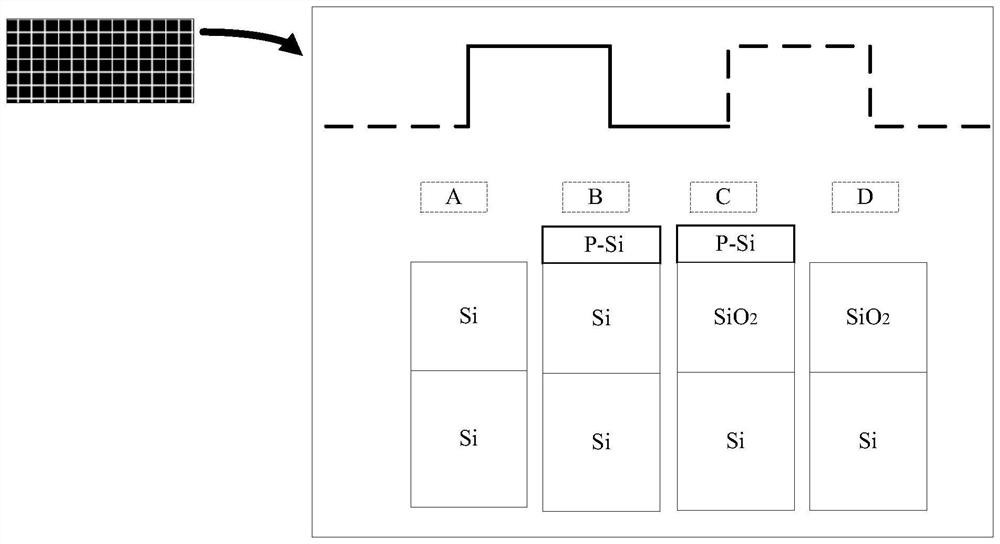

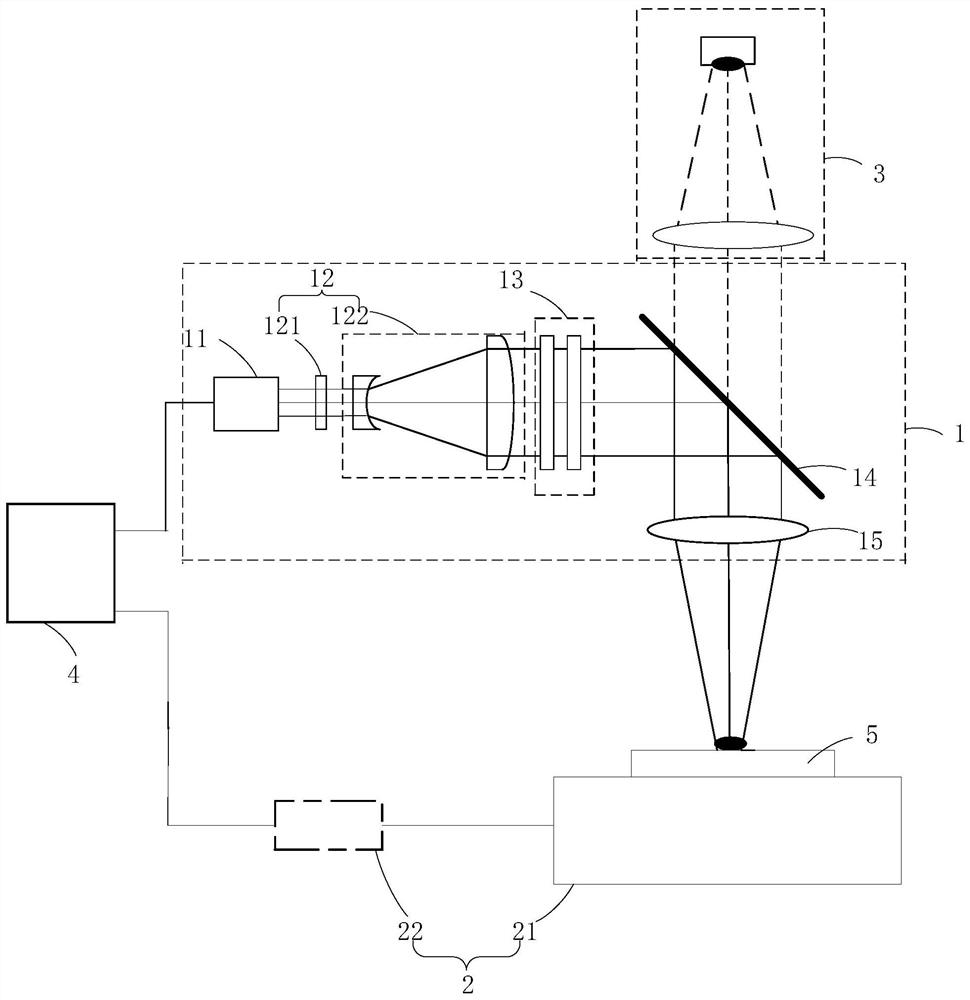

Laser annealing device and method

ActiveCN107665821AGuaranteed annealing temperature uniformityGuaranteed annealing effectSemiconductor/solid-state device manufacturingPhoto irradiationBeam splitting

The present invention discloses a laser annealing device and method. The device comprises a laser radiation system, a wafer carrying system and a reflection light detection system which are arranged in order along an optical path, and a host connected with the laser radiation system, the wafer carrying system and the reflection light detection system. The laser radiation system comprises a laser light source, a light beam regulation module, a light intensity distribution formation module, a beam splitting module and a focusing module which are arranged in order along the optical path; and optical elements on the light intensity distribution formation module are selected to form incident light intensity distribution required by a silicon wafer to allow a temperature field on the silicon wafer to achieve an effect of consistent temperature of a middle portion and an edge of the temperature field so as to ensure uniformity of an annealing temperature and improve uniformity of an annealingeffect. Since patterns at the same position are the same for the same batch of silicon wafers, optical elements used in an annealing process can be selected offline in advance, and the selected optical elements are written into an exposure flow according to a sequence; and monitoring is only performed in the exposure process, and the exposure process does not need regulation so as to improve efficiency and improve a productivity while ensuring an annealing performance.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

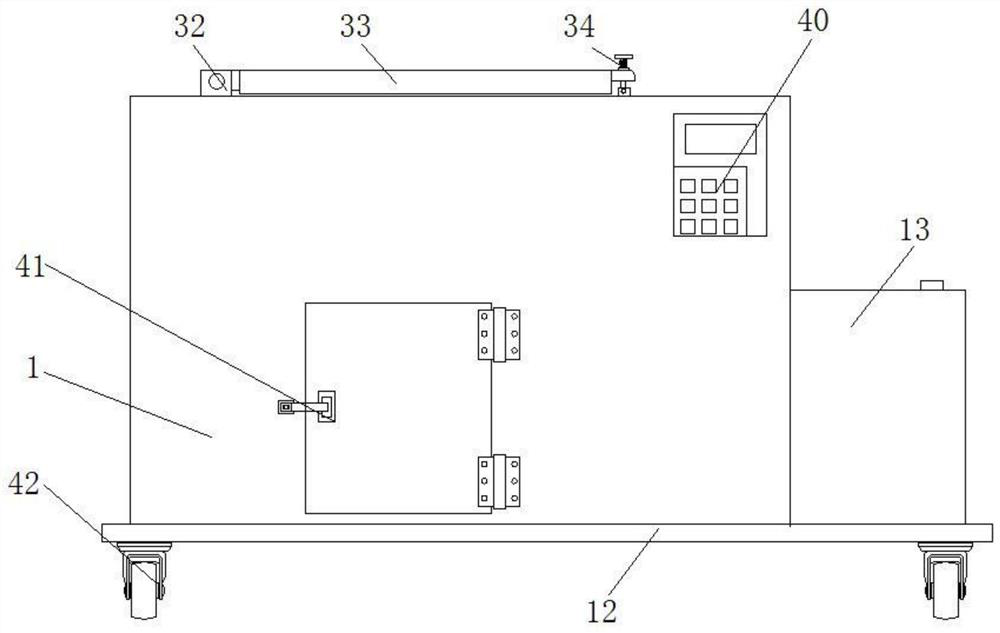

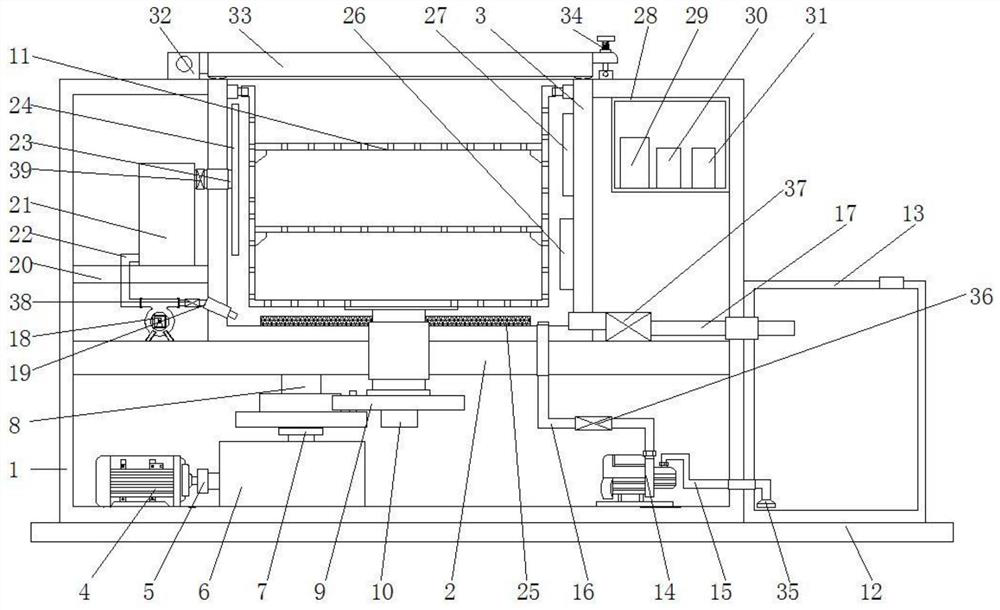

Annealing device for metal wire production

InactiveCN112267014AWide applicabilityImprove versatilityFurnace typesHeat treatment furnacesShielding gasHeating furnace

The invention relates to the technical field of annealing equipment, and discloses an annealing device for metal wire production. The annealing device for metal wire production comprises a metal wireforming device and further comprises: a supporting frame, a wire outlet of the metal wire forming device being erected on the supporting frame; an annealing furnace which is connected onto the supporting frame, a heating device being arranged in the annealing furnace; a conveying wheel which is arranged between the wire outlet of the metal wire forming device and the annealing furnace; and a shielding gas device which is connected to the annealing furnace, wherein the annealing furnace comprises: a heating furnace body, a discharging port being formed at the bottom of the heating furnace body;and a furnace cover which is buckled on the heating furnace body, a feeding inlet being formed on the furnace cover, and the feeding inlet and the discharging port being oppositely formed. Applicability of the annealing device for metal wire production is guaranteed to be wide, the universality of the annealing device for metal wire production is improved, and the shielding gas device is connected to the bottom of the annealing furnace, so that shielding gas can completely discharge air in the annealing furnace from the bottom of the annealing furnace, thereby ensuring the annealing effect ofthe device.

Owner:邯郸一三高研科技有限公司

Annealing device for plastic products

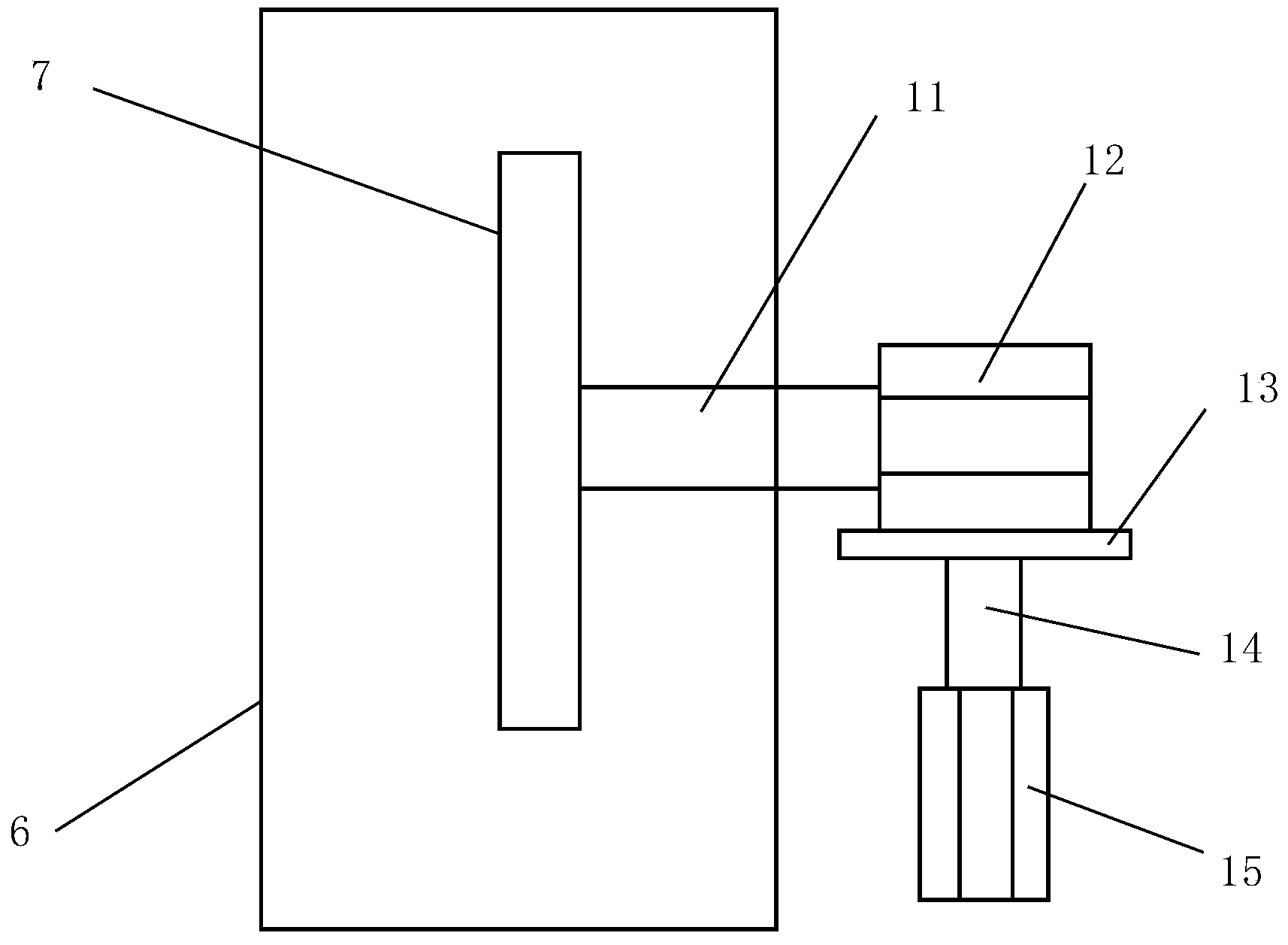

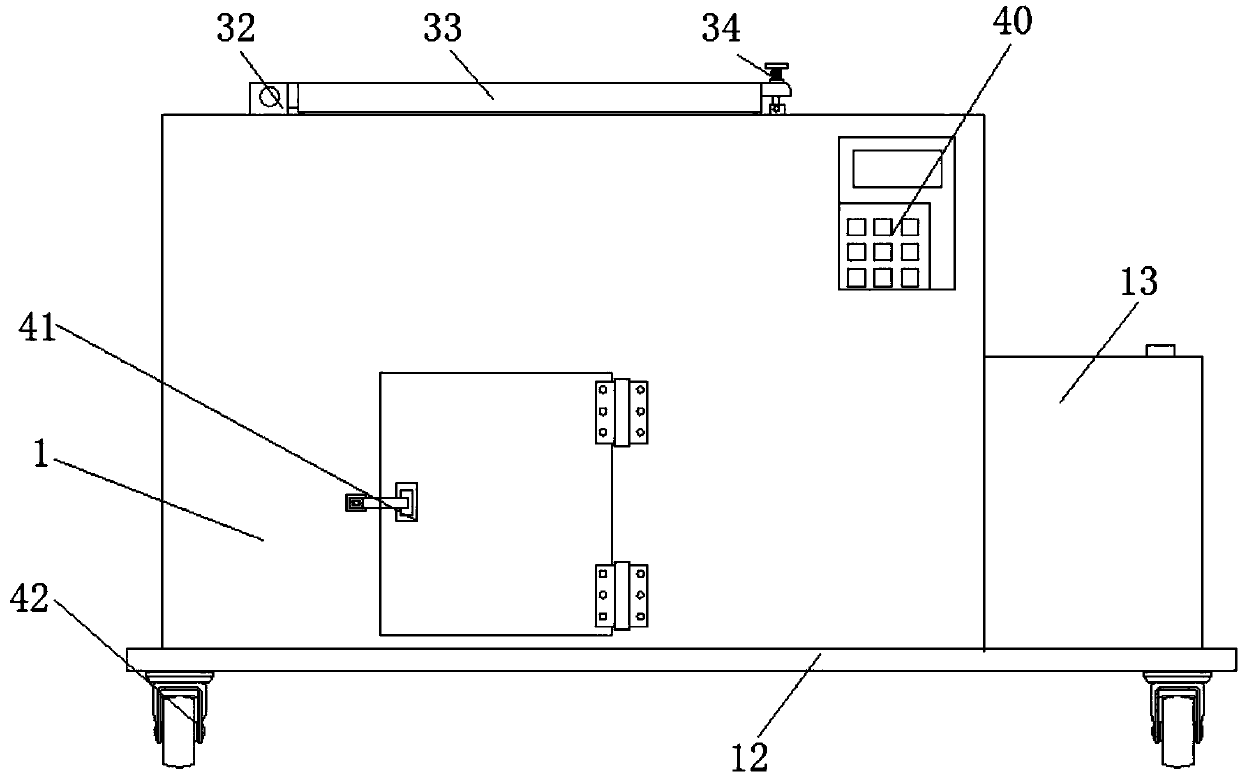

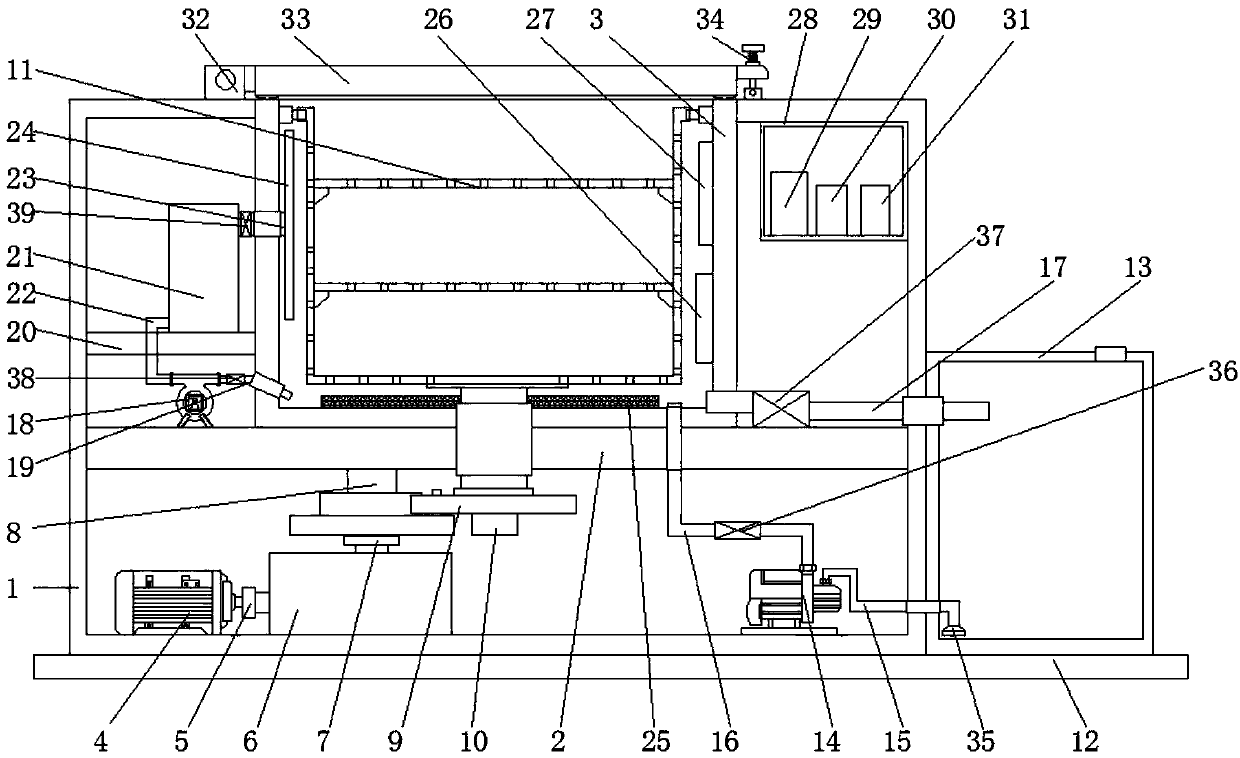

The invention discloses an annealing device for plastic products. The annealing device comprises a box body, wherein a work box is fixedly connected between the two opposite sides of an inner wall ofthe box body through a fixing plate, and a motor is fixedly connected with the bottom of the inner wall of the box body; the output shaft of the motor is fixedly connected with a shelf through a transmission and a rotating device, and the bottom of the outer wall of the box body is fixedly connected with a bearing plate; one side of the top of the bearing plate is fixedly connected with an oil tank, and one side, close to the oil tank, of the bottom of the inner wall of the box body is fixedly connected with an oil pump; one side of the top of a fixing plate is fixedly connected with a circulating air pump, and an air heater is fixedly connected between the two opposite sides of the outer wall of the work box and the inner wall of the box body through a supporting plate; the bottom of theinner wall of the work box is fixedly connected with a heating disc, and one side of the top of the inner wall of the box body is fixedly connected with a control box. The invention relates to the technical field of plastic product processing. The annealing device for the plastic products has the advantages of simple operation, optional annealing method, stable annealing temperature, ensuring of annealing quality and improvement on processing efficiency.

Owner:无锡普力斯特实验室设备科技有限公司

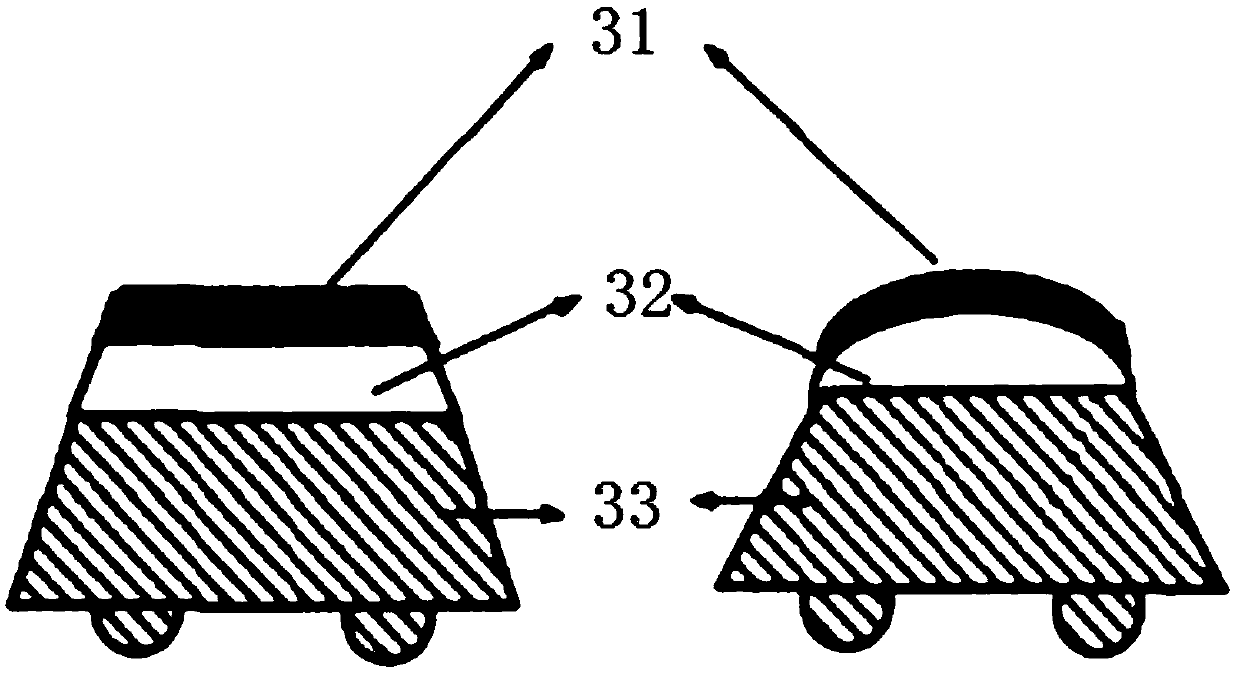

Lateral composite position guide device for three-layer composite material

ActiveCN106180179AReduce mutual interferenceReduce difficultyGuiding/positioning/aligning arrangementsFurnace typesComposite PositionEngineering

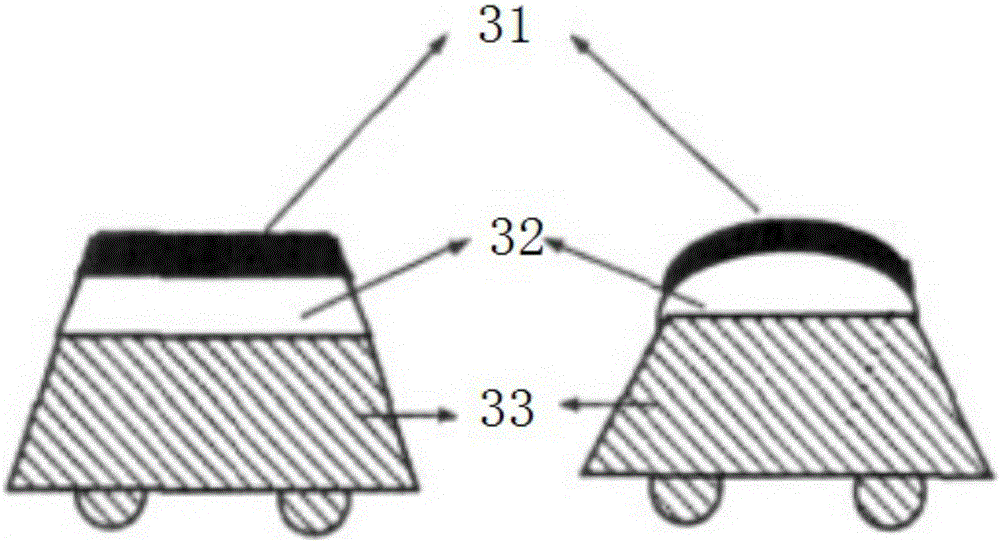

The invention discloses a lateral composite position guide device for a three-layer composite material. The lateral composite position guide device comprises a composite body, wherein a cavity is formed in the composite body; a wire guide nozzle is arranged on one side of the composite body, and a plurality of wire feeding rails are arranged on the other side of the composite body; a cavity penetrates through a wire guide channel of the wire guide nozzle and wire feeding channels of the wire feeding rails; a plurality of guide arrangement assemblies are arranged in the wire guide channel of the wire guide nozzle; and a composite rolling part is arranged on one side of the wire discharging end of the wire guide nozzle. The lateral composite position guide device is reasonable in design and compact in structure, can quickly enable three strips to be laterally and closely attached together, and can provide a basis for subsequent machining.

Owner:SUZHOU CHUANGHAO NEW MATERIAL TECH CO LTD

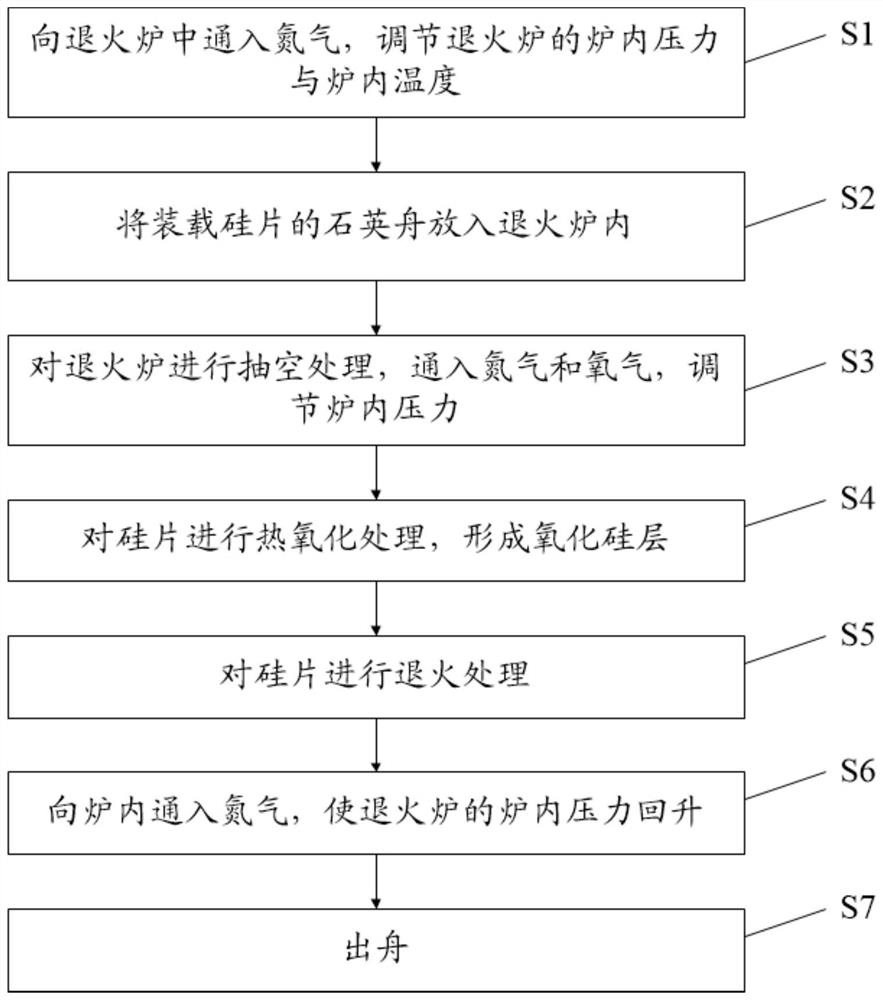

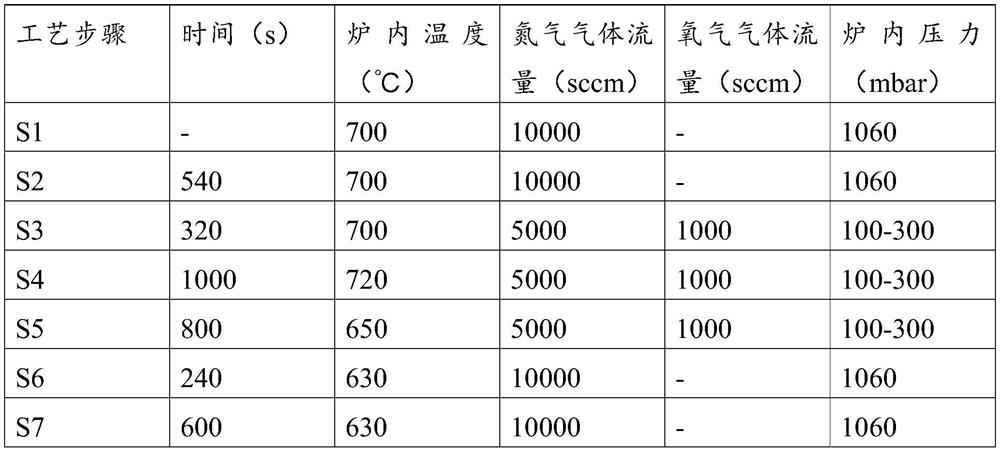

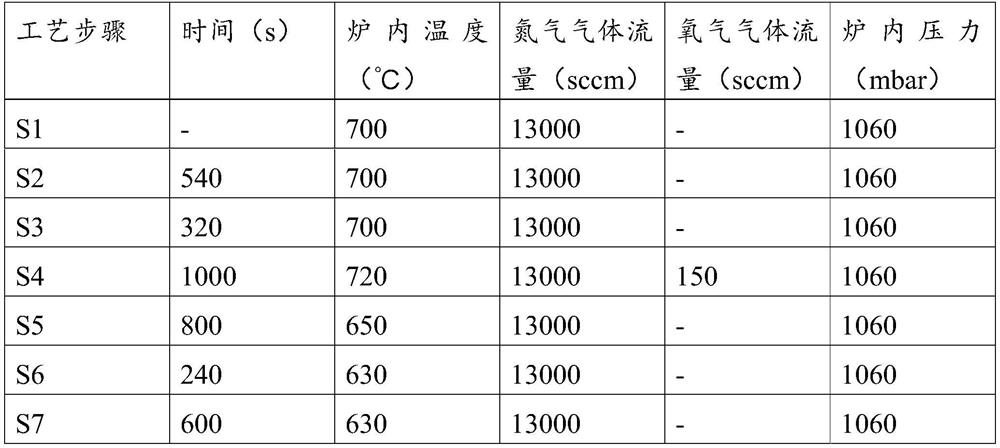

Low-pressure annealing method for crystalline silicon solar cell

PendingCN112670374AEnhancing the free path of molecular diffusionIncrease open circuit voltage and short circuit currentFinal product manufacturePhotovoltaic energy generationPhysicsSilicon chip

The invention discloses a low-pressure annealing method of a crystalline silicon solar cell, wherein the method comprises the steps: (1) introducing nitrogen into an annealing furnace, and regulating the in-furnace pressure and the in-furnace temperature of the annealing furnace; (2) putting a quartz boat loaded with a silicon wafer into the annealing furnace; (3) vacuumizing the annealing furnace, introducing nitrogen and oxygen, and adjusting the in-furnace pressure; (4) carrying out thermal oxidation treatment on the silicon wafer to form a silicon oxide layer; (5) annealing the silicon wafer; (6) introducing nitrogen into the annealing furnace to enable the pressure in the annealing furnace to rise again; and (7) discharging the boat, wherein the in-furnace pressure in the step (3), the step (4) and the step (5) is kept at 100-300 mbar. According to the invention, thermal oxidation treatment and annealing treatment are carried out under a low-pressure condition, the operation is simple and controllable, and a uniform and compact silicon oxide layer can be grown by adopting the method, so that the conversion efficiency and reliability of the cell are improved.

Owner:GUANGDONG AIKO SOLAR ENERGY TECH +2

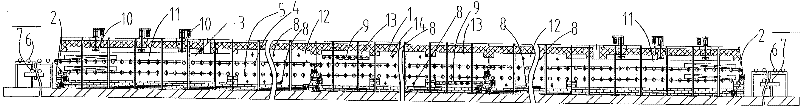

Conveying device in hollow glass product annealing furnace

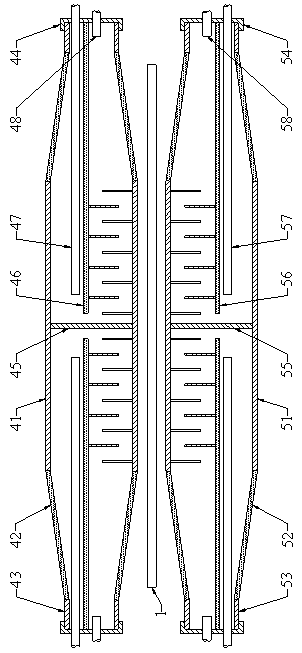

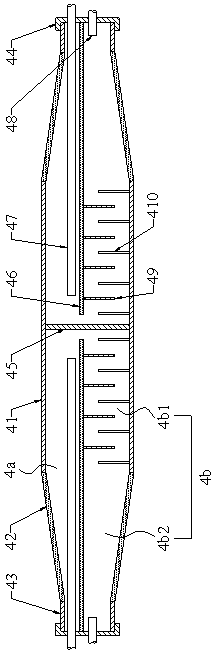

The invention discloses a conveying device in a hollow glass product annealing furnace which is capable of evenly heating the hollow glass products in the annealing process. The conveying device comprises a conveying rack and a conveying transmission device, wherein the conveying rack comprises two pairs of conveying bars; placement grooves are evenly formed on the conveying bars; the conveying transmission device comprises two conveying transmission mechanisms with the same structure; each conveying transmission mechanism comprises four driving discs which are orderly arranged in parallel to each other along a straight line; the center line of the four driving discs is perpendicular to the conveying direction of the conveying rack; the two middle driving discs are connected through an eccentric transmission shaft; the two middle driving discs and the corresponding driving discs are connected through transmission shafts arranged symmetrical to the driving discs, respectively; each driving disc is provided with a driving shaft and a support shaft along the center line of the driving disc, respectively; and support rods are movably articulated between the end parts of the inner and outer conveying bars and the corresponding transmission shafts, respectively. The conveying device in the hollow glass product annealing furnace can be applied to the annealing furnaces for various hollow glass products.

Owner:ZHANGJIAGANG JUNFENG GLASS PRODS

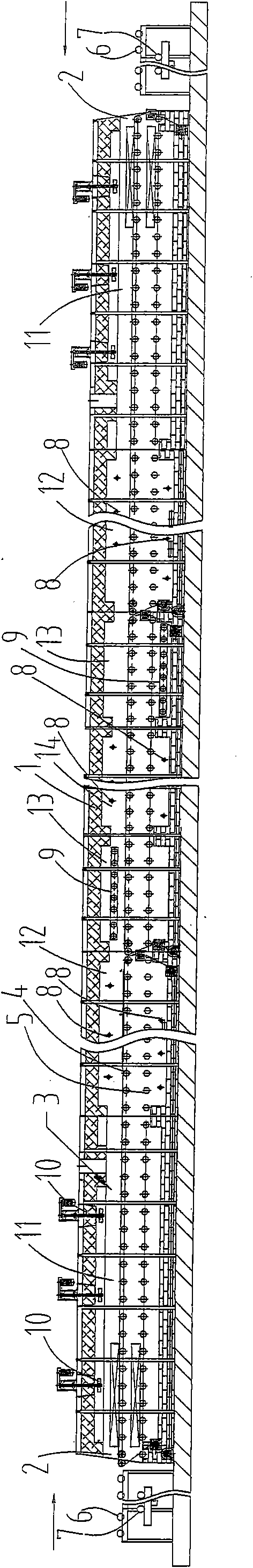

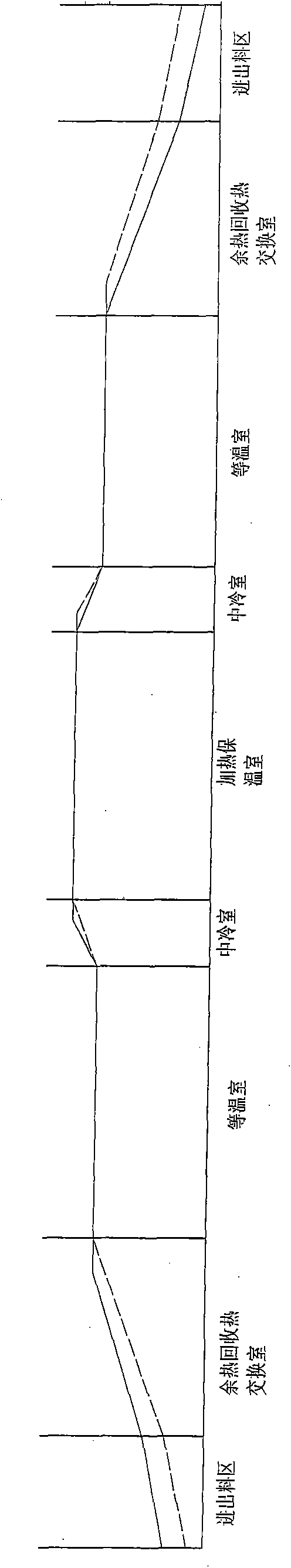

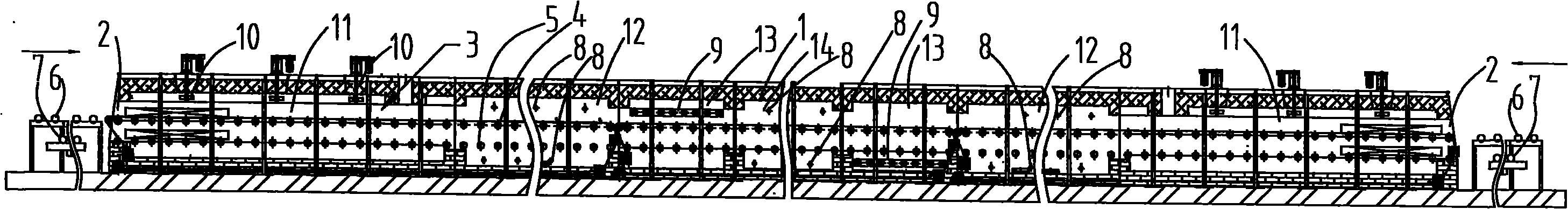

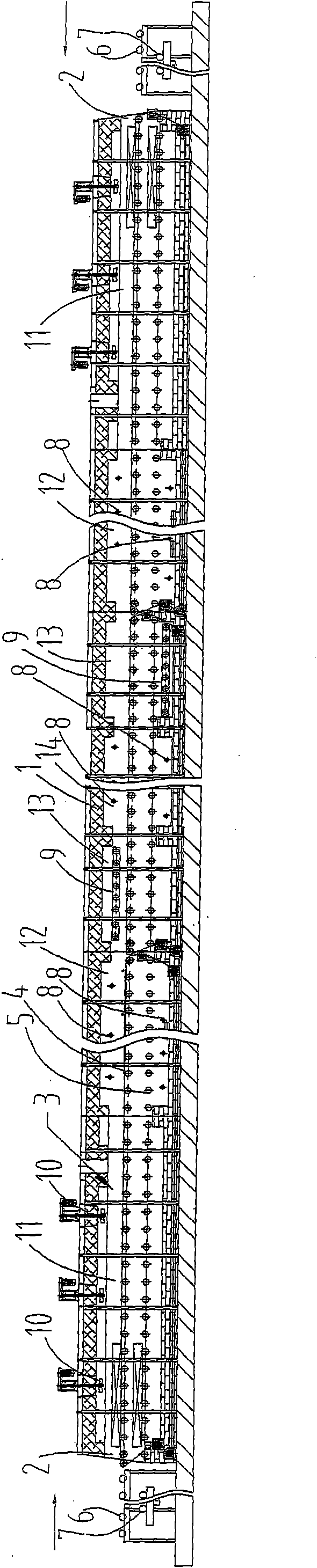

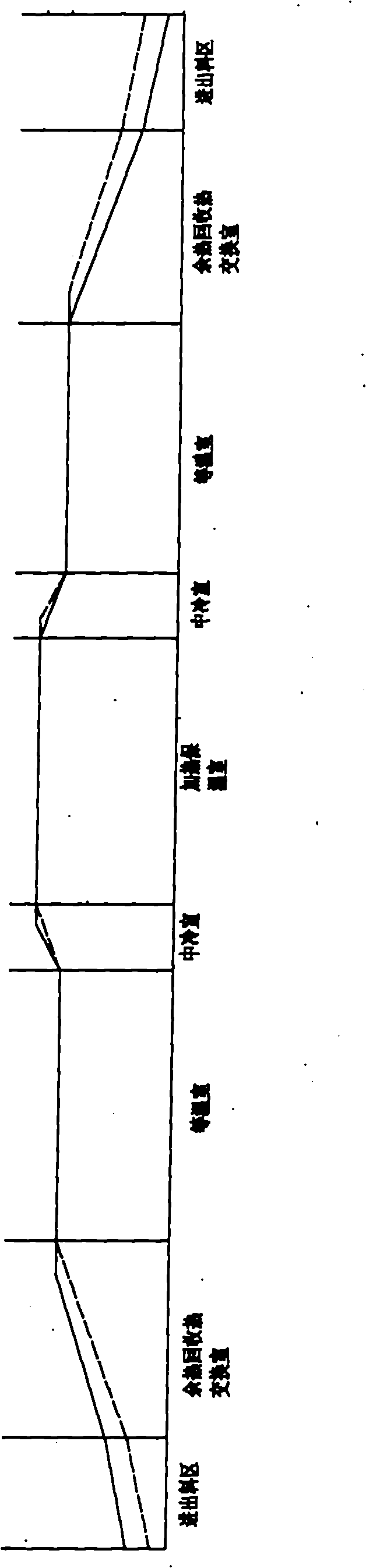

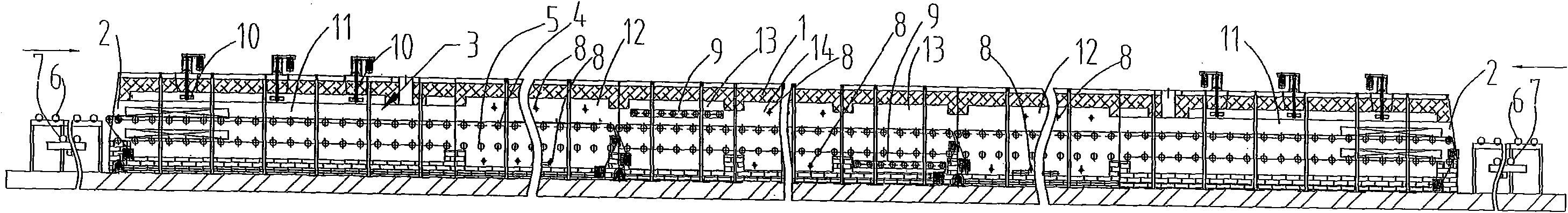

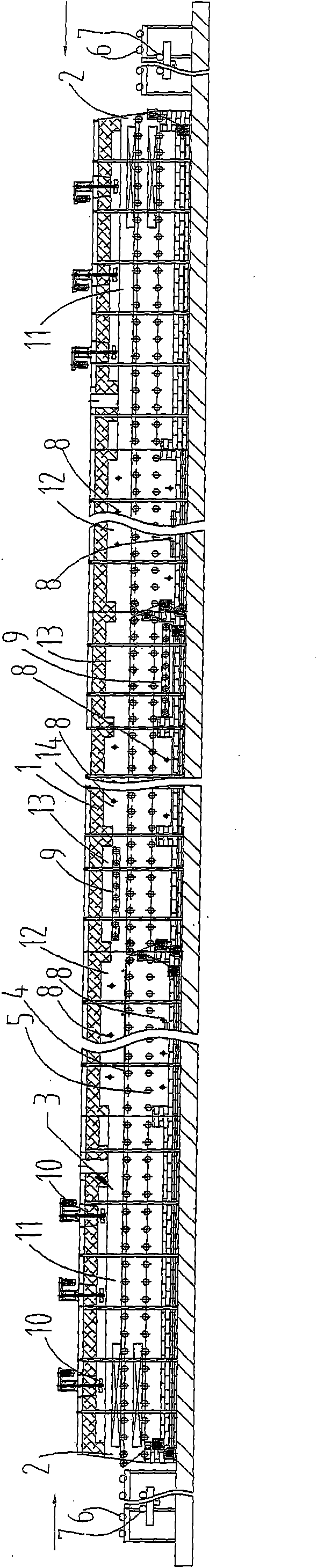

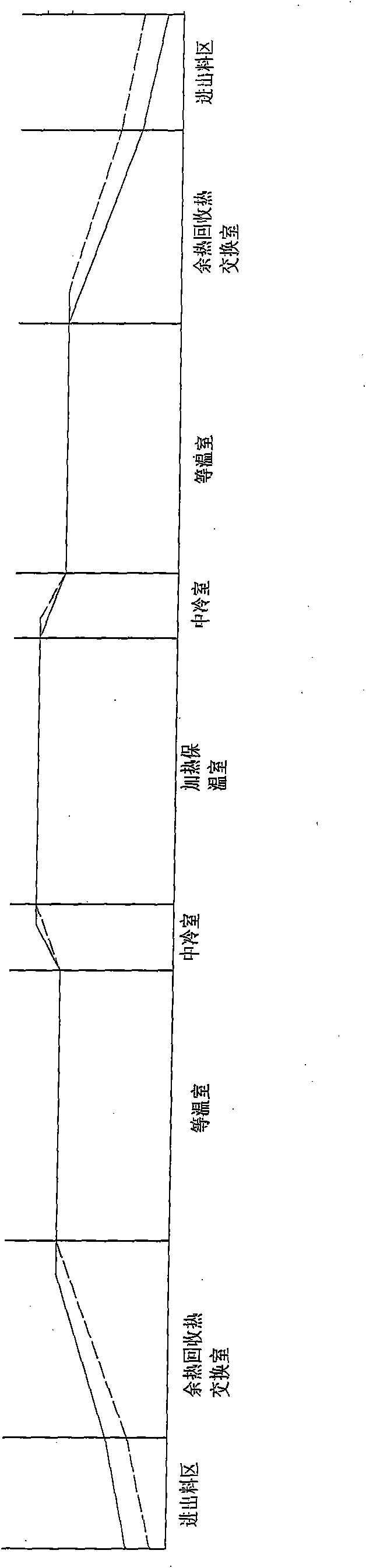

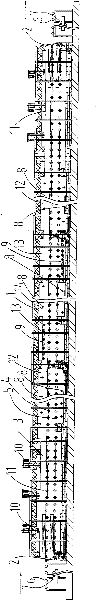

Arranging structure of heaters on bearing-steel isothermal spheroidized annealing furnace

The invention discloses an arranging structure of heaters on a bearing-steel isothermal spheroidized annealing furnace. Bearing steel on an upper layer of driving roller set and a lower layer of driving roller set respectively is made to enter a hearth from a front furnace mouth and a rear furnace mouth and is conveyed in opposite directions, and the diagonal symmetrical arrangement of the heaters ensures the heating, insulating and isothermal treatment of the bearing steel on the upper layer of driving roller set and the lower layer of driving roller set and ensures the annealing treatment effect of the two layers of the bearing steel in the two directions. Accordingly, if high-temperature bearing steel to be conveyed out of the furnace mouth is conveyed on one of the upper layer of driving roller set and the lower layer of driving roller set, i.e. the high-temperature bearing steel is conveyed out of an isothermal chamber and made to enter an afterheat recovery exchanger chamber, normal-temperature bearing steel (also called as cold burden) which is just made to enter the furnace mouth is conveyed on the other layer of driving roller set, and the high-temperature bearing steel and the normal-temperature bearing steel can exchange heat so that the temperature of the normal-temperature bearing steel rises, the heat of the high-temperature bearing steel is recovered, and the heat needed for subsequently entering the isothermal chamber is reduced and energy is saved. In an intercooling chamber, a cooler can cool the high-temperature bearing steel discharged from a heating and insulating chamber while the high-temperature bearing steel and the lower-temperature bearing steel on the upper layer of driving roller set and the lower layer of driving roller set can exchange heat so that heat needed by lower-temperature bearing steel to subsequently enter the heating and insulating chamber is lowered, the energy is saved and heat waste is reduced.

Owner:SUZHOU ZHONGMENZI TECH

Preparing method for ultra-thin galvanized plate

InactiveCN109023200AGuaranteed annealing effect and flatnessUniform heatingHot-dipping/immersion processesControl modePull force

The invention discloses a preparing method for an ultra-thin galvanized plate. The technological control mode of an annealing reduction furnace is changed, it is ensured that the temperature of the annealing furnace is about 550 DEG C-600 DEG C, the annealing effect and levelness of a plate face are ensured, and heated force of all sections is more uniform. A W-shaped radiant tube of a heating assembly resistance belt is changed into a U-shaped radiant tube, the power of a heating assembly of a soaking zone of a rear area is improved, the temperature of the soaking zone of the rear area is improved, it is ensured that the technology pot entering temperature is about 550 DEG C, and the product quality is improved. The lining pulling tension machine roller diameters of all sections are reduced, the wrap angle of the steel belt plate face is reduced, and the lining pulling force of the steel belt plate face can be more uniform. A boron element is added in a steeping zinc pot, the surfacehardening capability of a soaked steel belt is ensured, the surface hardness of the steel belt is improved, and stability of the plate pattern of the finished product is ensured.

Owner:山东省博兴县云光钢铁有限公司

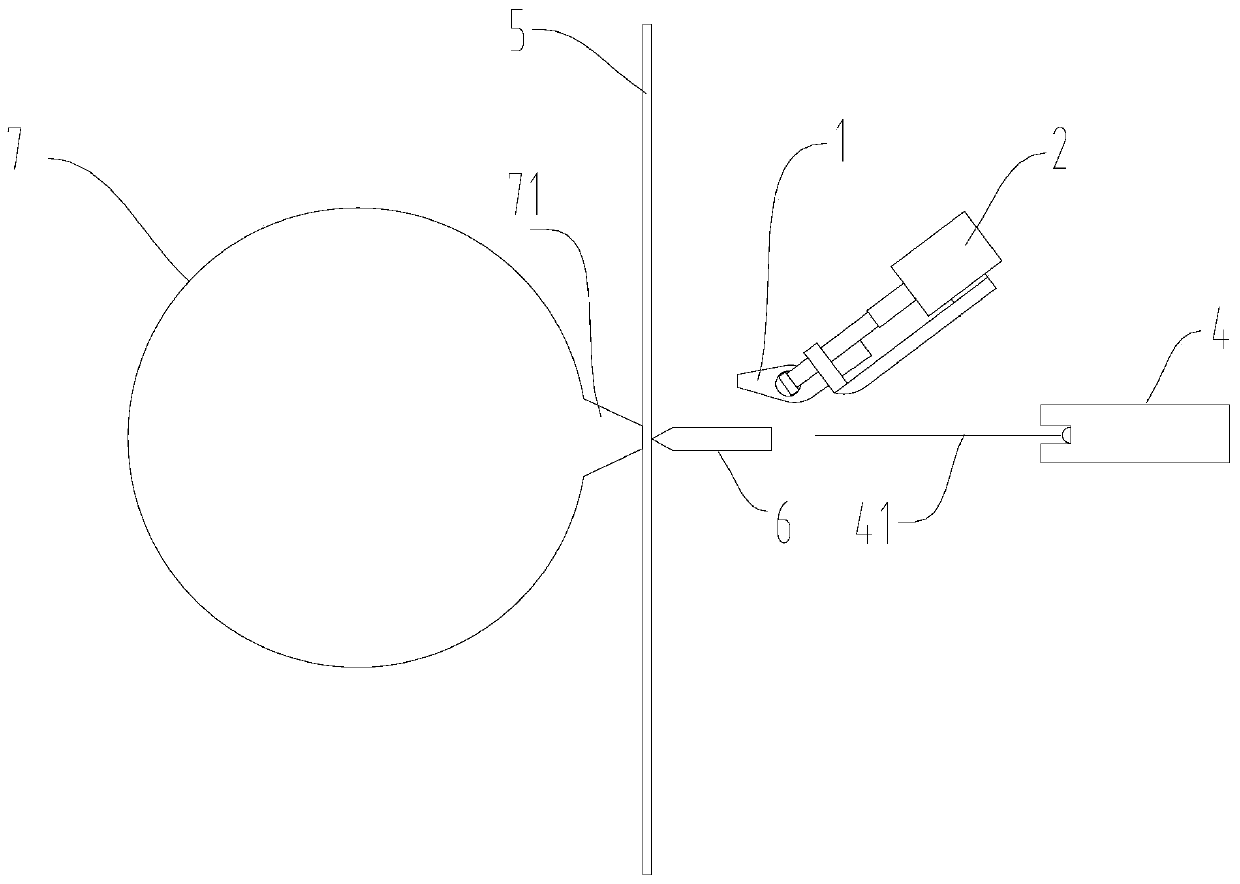

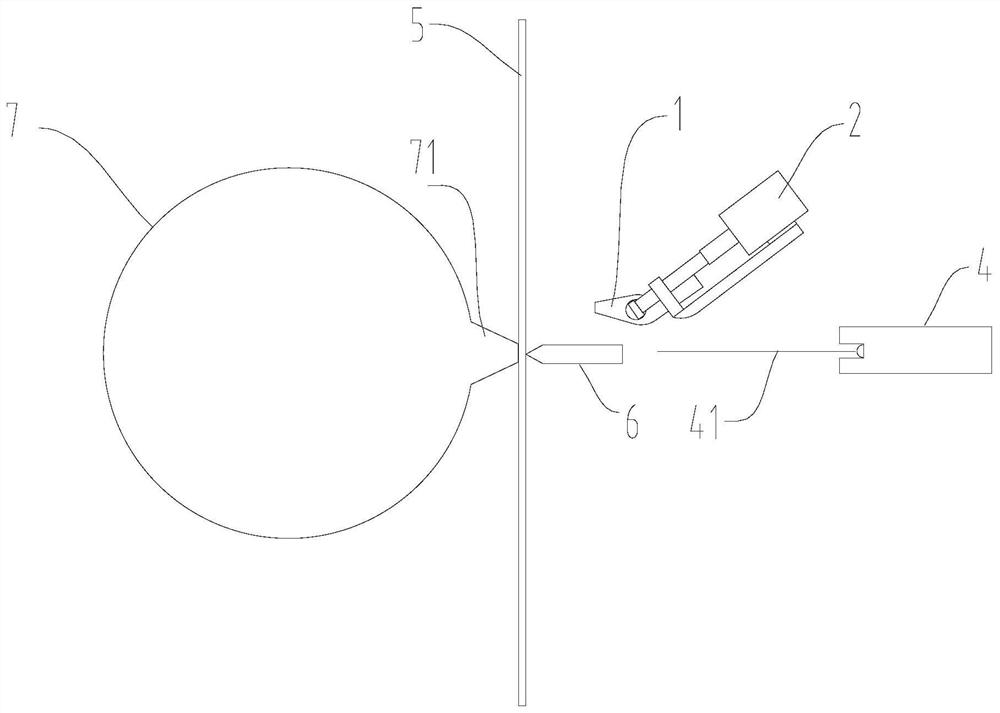

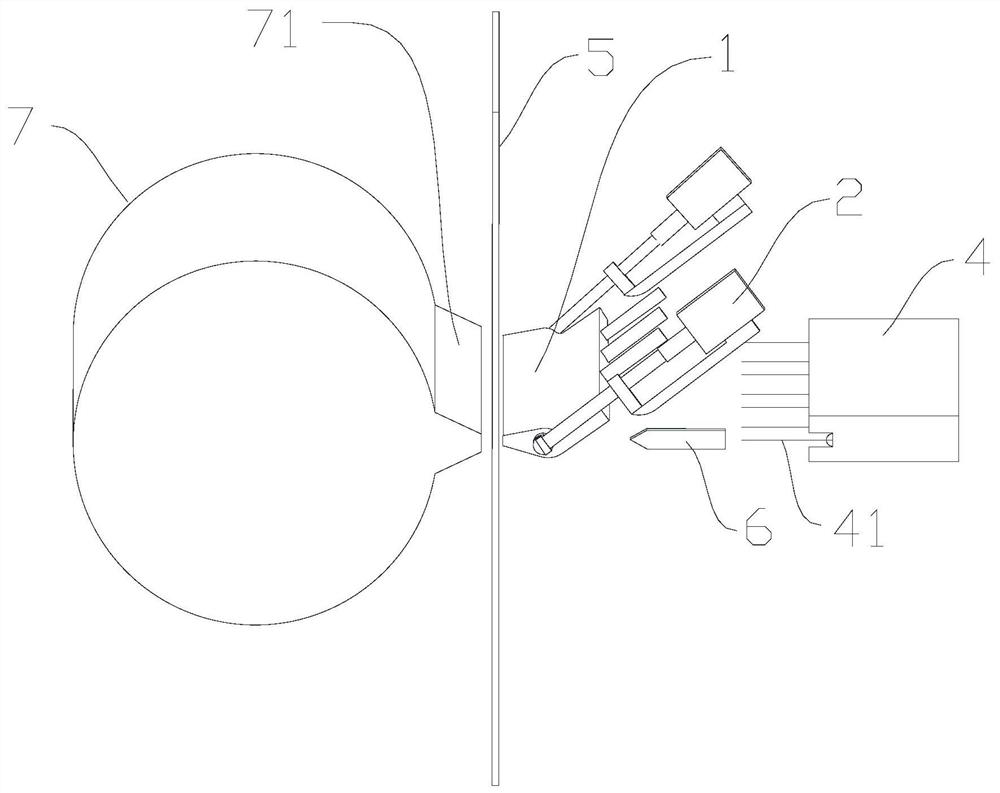

Glass substrate cutting machine

ActiveCN110255874AUniform temperatureImprove qualityGlass severing apparatusEngineeringElectrical and Electronics engineering

The present disclosure relates to a glass substrate cutting machine. The glass substrate cutting machine comprises a heating device (1) and driving devices (2), the heating device (1) is used for heating the cutting zone of a glass substrate (5), and the driving devices (2) are used for driving the heating device (1) to move in a direction close to or away from the cutting zone. The driving devices (2) drive the heating device (1) to get close to or away from the glass substrate (5) to heat the cutting zone, so the overall temperature of the cutting zone keeps uniform, dust aggregation caused by uneven temperature of the cutting zone during cutting is prevented, and the dusts are avoided from adhering to the surface of the glass substrate (5), thereby the quality of the glass substrate (5) is improved, the wearing of a cutting blade (6) is reduced, and the service life of the cutting blade (6) is prolonged.

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +1

Heating structure of annealing furnace

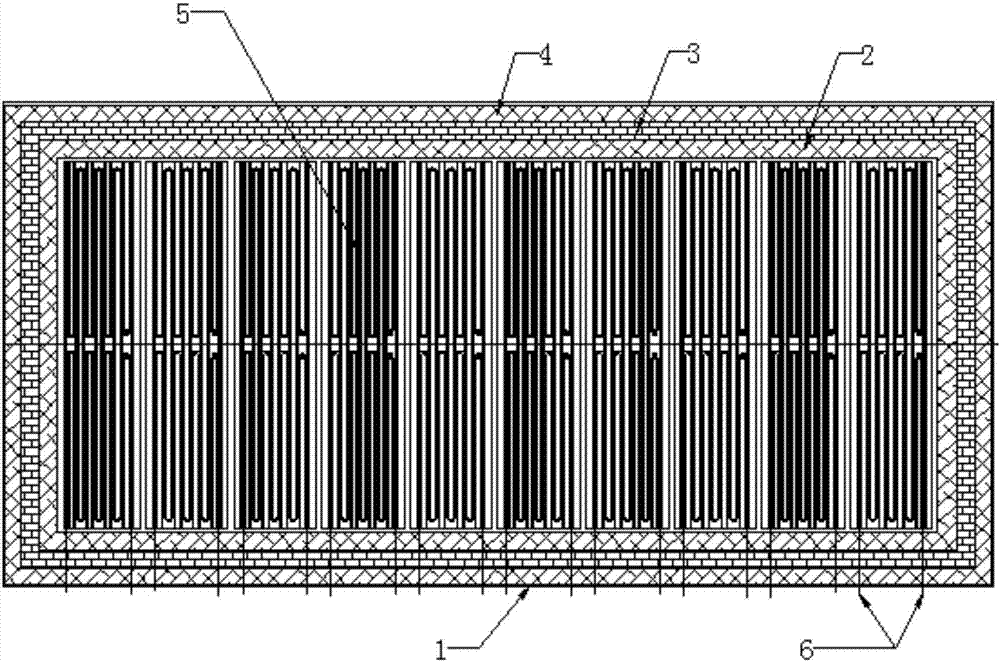

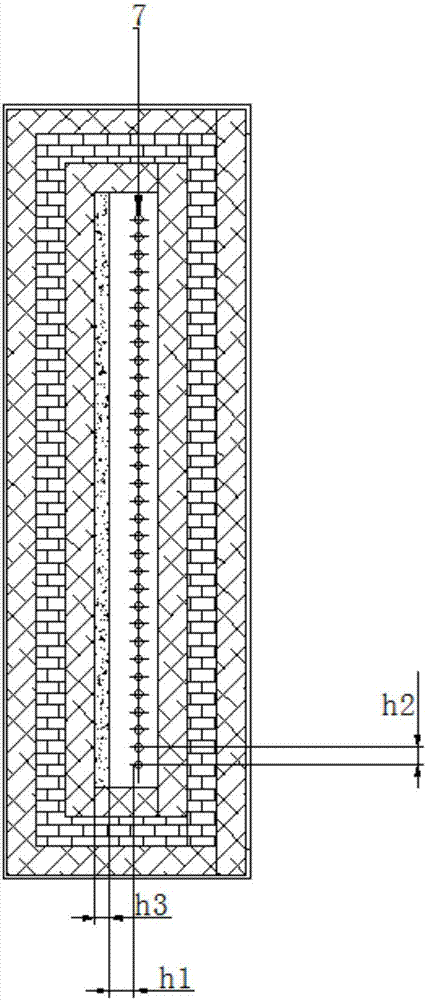

InactiveCN107130091AImprove thermal insulation performanceUniform and stable heatingFurnace typesHeat treatment furnacesInsulation layerStress relief

The invention discloses a heating structure of an annealing furnace. The heating structure is arranged in a furnace, the furnace comprises a shell and three heat-insulation layers, the heat-insulation layers are positioned on the inner wall of the shell, and every two adjacent heat-insulation layers seamlessly tightly cling to each other. The heating structure comprises a plurality of electric furnace heating wire discs and heating wires, the heating wires are in one-to-one correspondence with the electric furnace heating wire discs and are connected with the electric furnace heating wire discs, the group number of heating wires is equal to the number of the electric furnace heating wire discs, and the multiple electric furnace heating wire discs are parallelly arranged along the length direction of the furnace at intervals; each group of heating wires comprises two single wires, the two single wires of each group of heating wires are connected with two ends of the corresponding electric furnace heating wire disc, and the heating wires are mounted in furnace disc holes of the shell and are nickel-chromium wires; a plurality of annealing furnace tubes are further arranged in the furnace, and to-be-annealed wires can pass the annealing furnace tubes. The heating structure has the advantages the inside of the furnace can be uniformly and stably heated, accordingly, the wires can be uniformly and stably annealed, and good stress relief effects can be realized; the inside of the furnace is heated by the nickel-chromium wires, and accordingly the heating structure is low in energy consumption, long in service life and low in cost; the furnace is excellent in heat-insulation performance, and accordingly energy consumption further can be reduced.

Owner:昆山金源光电科技有限公司

Isothermal spheroidizing annealing furnace for bearing steels

ActiveCN102041362AGuaranteed annealing effectReduce wasteCombustion processIndirect carbon-dioxide mitigationTreatment effectRoom temperature

The invention discloses an isothermal spheroidizing annealing furnace for bearing steels, which can be used for treating the bearing steels in a mode of double layers and double directions. Length ratio of a waste heat recovery heat-exchanging chamber to an isothermal chamber to an intercooling chamber to a heating preservation chamber in a hearth is 1:(2-5):(0.2-0.5):(2-5) along with the front and rear directions, thus annealing treatment effect of the bearing steels in double layers and double directions can be ensured. In the waste heat recovery heat-exchanging chamber, if one layer of driving roller group in the upper and lower layers of driving roller groups is used for conveying high-temperature bearing steels to be sent out of a furnace mouth, and the other layer of driving roller group is used for conveying room-temperature bearing steels (called cold metals) which are input into a furnace mouth, the high-temperature bearing steels and the room-temperature bearing steels can exchange the heat mutually, thus the room-temperature bearing steels are heated so as to recover heat (to be wasted) of the high-temperature bearing steels, reduce subsequent heat which enters into the isothermal chamber, and reach energy-saving effect. In the intercooling chamber, a cooler can be used for cooling the high-temperature bearing steels which are sent out of the heating preservation chamber, while the high-temperature bearing steels and the room-temperature bearing steels on the upper and lower layers of driving roller groups exchange heat mutually, thus recovering the heat of the high-temperature bearing steels, heating the low-temperature bearing steels, reducing the subsequent heat which enters into the heating preservation chamber and is required by the low-temperature bearing steels, further saving energy, and lowering the waste of the heat.

Owner:SUZHOU ZHONGMENZI TECH

Preparation device for high-strength corrosion-resistant alloy plate, and corrosion-resistant alloy plate thereof

The invention discloses a preparation device for a high-strength corrosion-resistant alloy plate, and a corrosion-resistant alloy plate thereof. A limiting plate is welded at the top end of a sintering placement plate, and a shaping box is clamped at the side end of the limiting plate; an inner extrusion plate is placed at one end of the shaping box, and an extrusion spring is welded at one end of the inner extrusion plate; the outer side of the extrusion spring is sleeved with a double-layer protection sleeve; one end of the extrusion spring is spot-welded on an outer extrusion plate, and a cooling fan is installed at the top end of a sintering furnace; an exhaust pipe penetrates through the top end of an air collecting box, and an inlet-outlet pipe penetrates through the top end of an inlet-outlet box; the air inlet end of the inlet-outlet pipe is installed at the top end of the gas tank in a penetrating mode. Liquid-phase metal is extruded through the inner extrusion plate an the extrusion spring, and therefore the occupied space of molten metal is reduced; meanwhile, gas contained in liquid phases can be extruded during extrusion, and therefore the amount of the gas in the metal is reduced; the gas in the metal is exhausted through repeated pumping and inflating of the gas tank, and the influence of the gas on the metal in a solid-liquid state during sintering is reduced; and the quality and yield of the metal are guaranteed.

Owner:李红

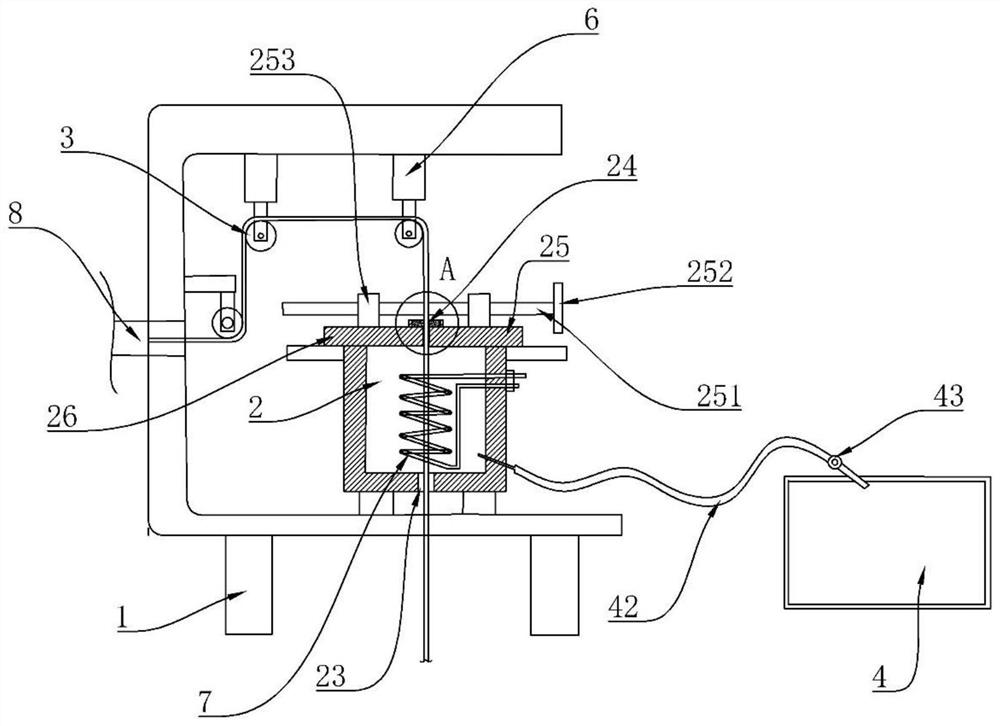

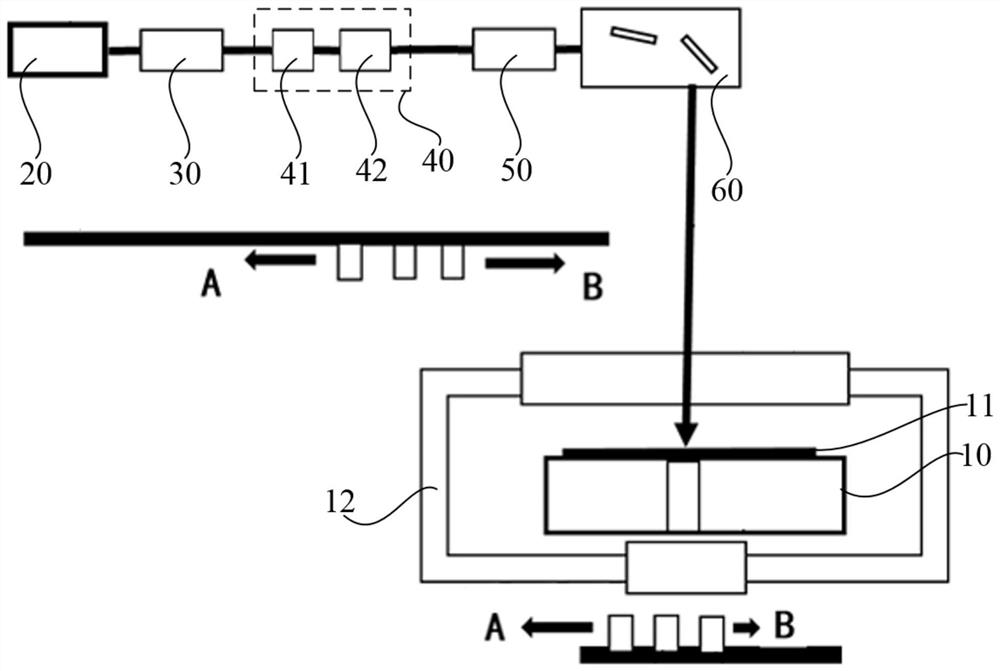

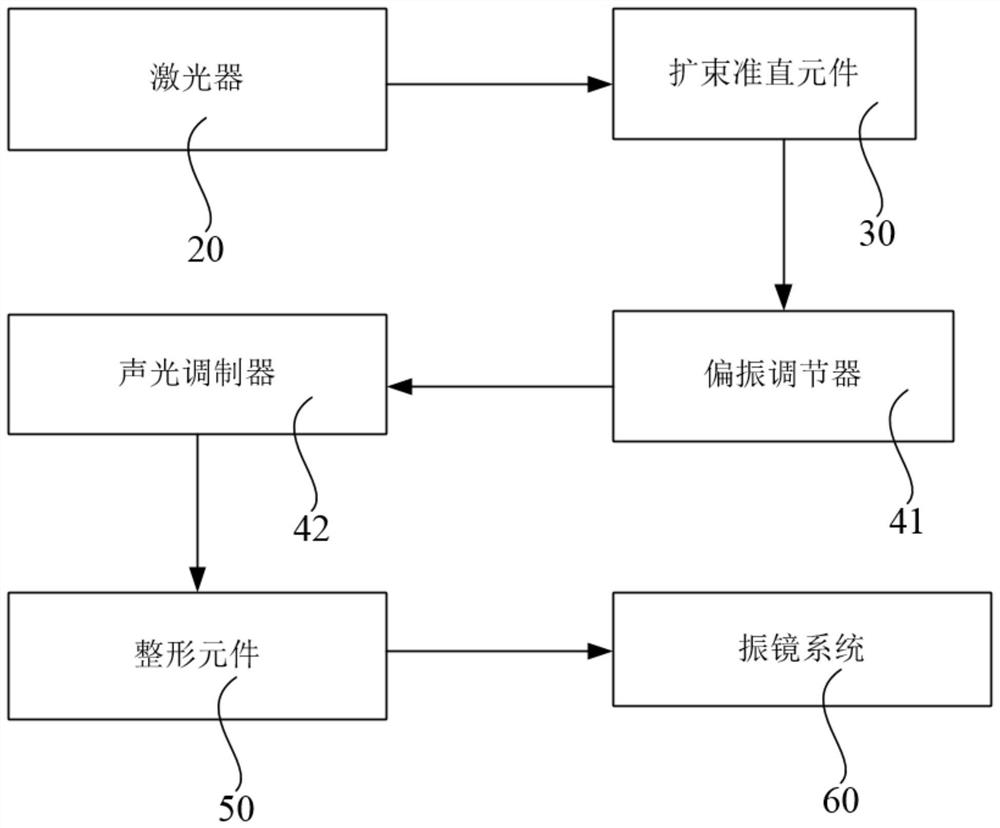

Laser annealing device and annealing method

ActiveCN111952158AShorten the time intervalGuaranteed annealing effectLaser detailsSemiconductor/solid-state device manufacturingLight spotWafer

The invention provides a laser annealing device and annealing method, and the device comprises an objective table which is used for emitting a laser beam with a first set frequency and first set energy. The device further comprises a beam expanding and collimating element for expanding the laser beams and an adjusting module. The adjusting module is used for adjusting the frequency and the energyof the laser beams emitted from the beam expanding and collimating element; during preheating, the adjusting module adjusts the frequency and the energy of the laser beam to be a first set frequency and a second set energy respectively; during annealing, the adjusting module adjusts the frequency and the energy of the laser beam to be a second set frequency and a first set energy respectively. Thelaser annealing device further comprises a shaping element used for shaping the light beams emitted from the adjusting module, and a galvanometer system used for focusing the light beams emitted fromthe shaping element on a set depth layer of the wafer and enabling light spots focused on the set depth layer to move on the set depth layer. By controlling a single laser, the situation of unstablecontrol caused by multiple lasers is effectively avoided.

Owner:北京中科镭特电子有限公司

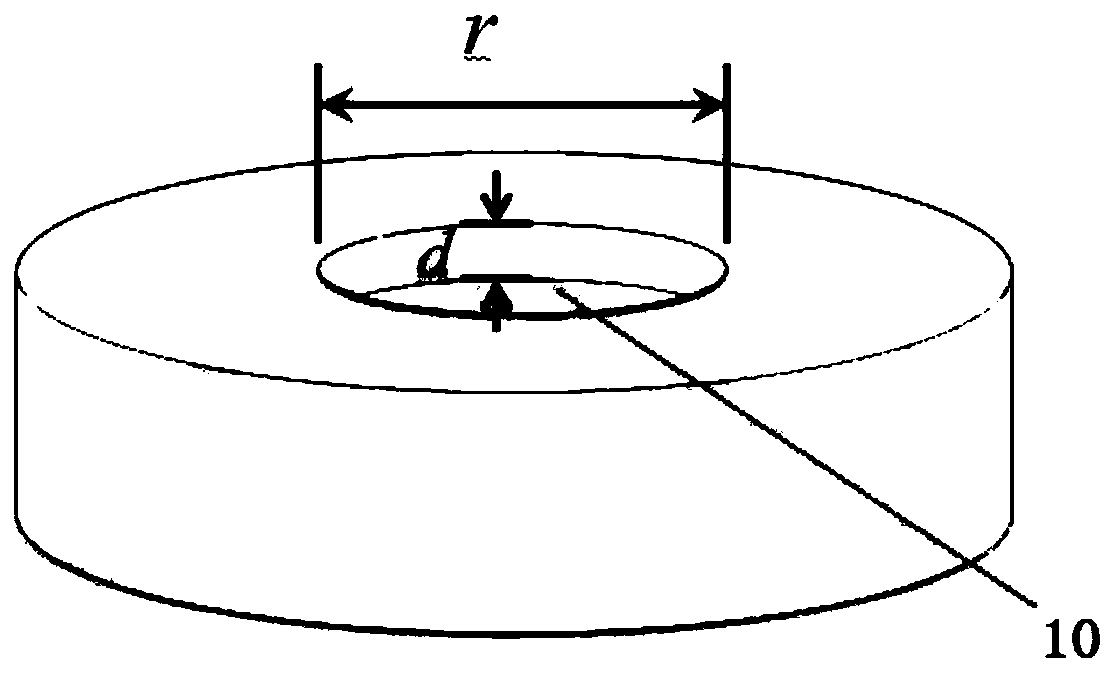

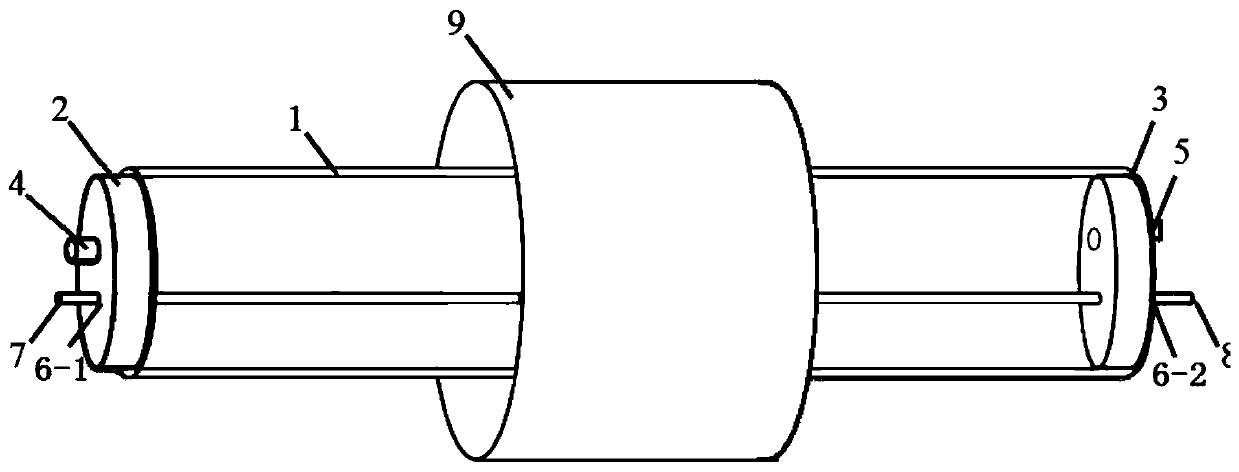

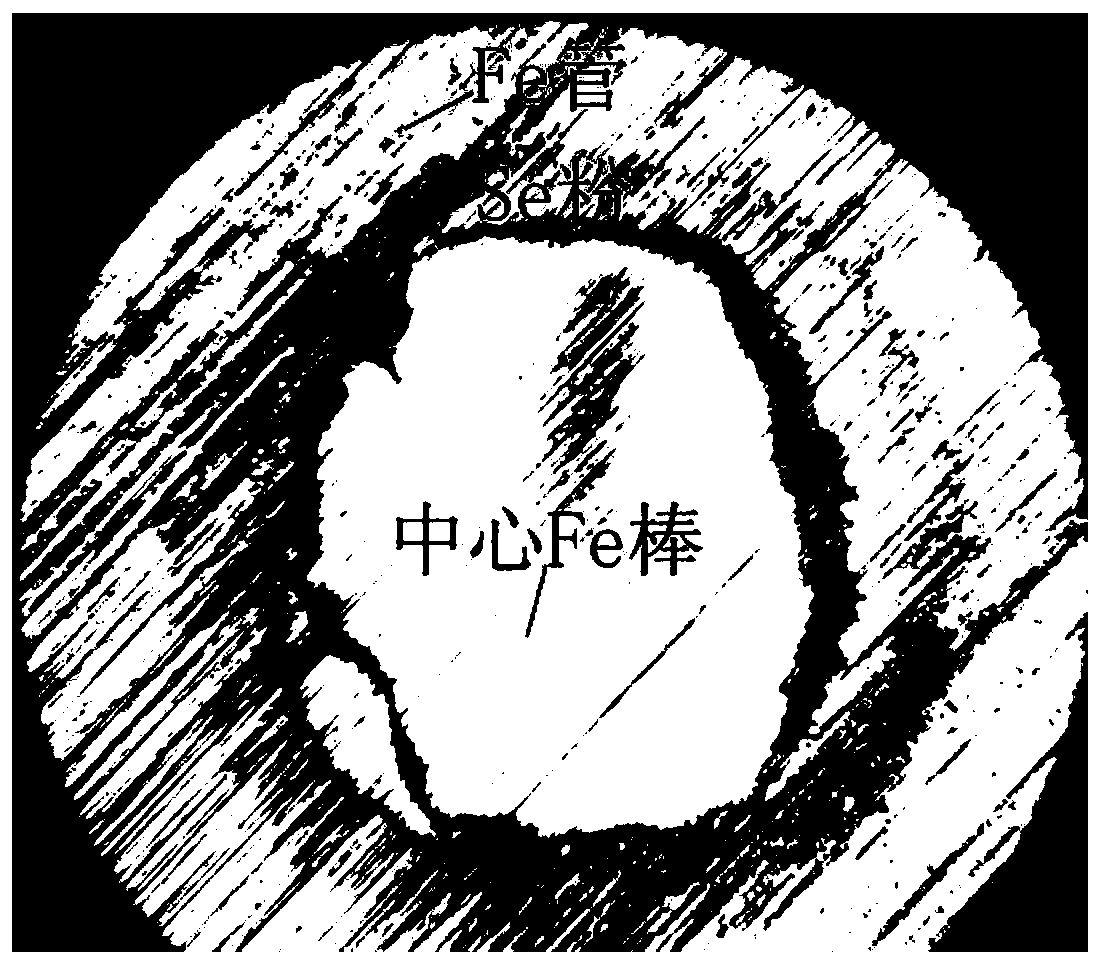

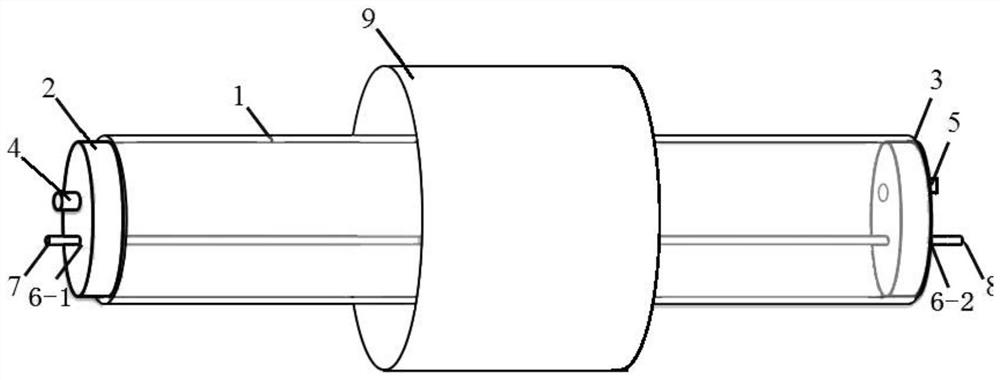

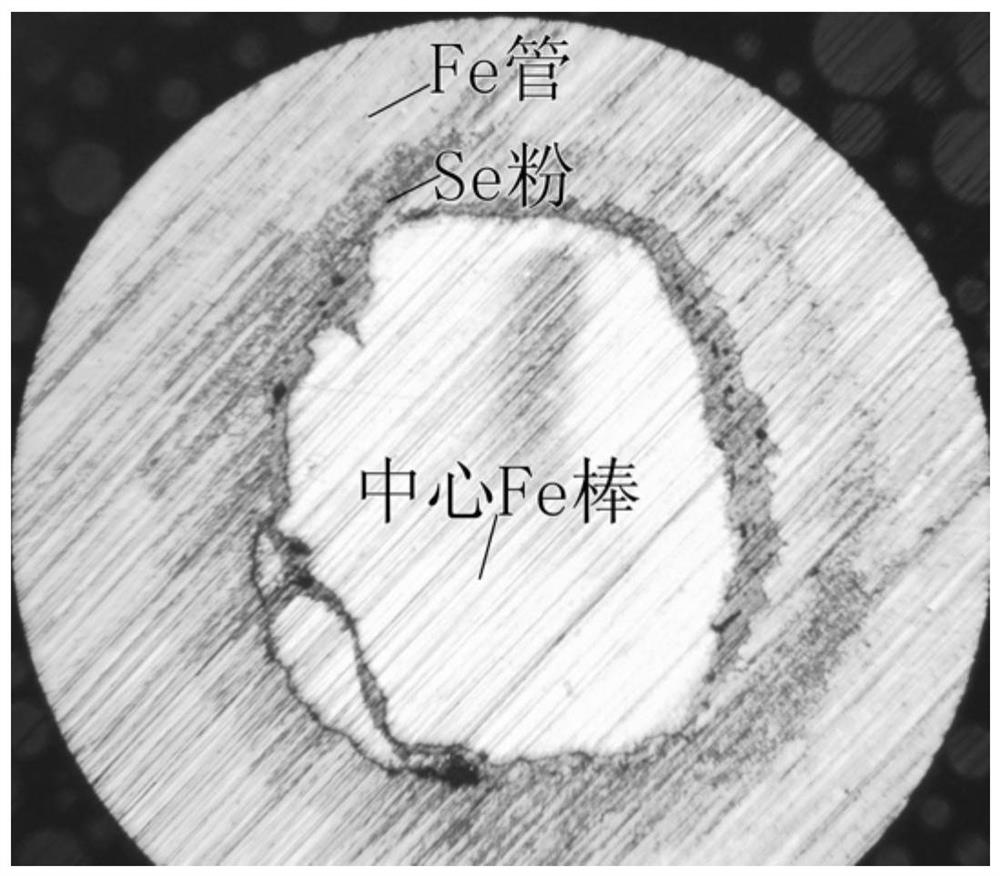

Preparation method of FeSe-based superconducting wire

ActiveCN110867283APromote oxidation precipitationGuaranteed annealing effectSuperconductors/hyperconductorsFurnace typesMetallurgyWire rod

The invention discloses a preparation method of a FeSe-based superconducting wire. The method comprises the following steps: 1, assembling an iron tube, an iron rod and an iron plug to obtain a tubingcomplex; 2, sealing the two ends of the tubing complex, and then obtaining a single-core FeSe-based wire through rotary swaging and drawing in sequence; 3, sintering the single-core FeSe-based wire to obtain a FeSe-based wire; and 4, annealing the FeSe-based wire to obtain a FeSe-based superconducting wire. According to the invention, the single-core FeSe-based wire is formed through powder charging by adopting a vibration tubing method and cold processing, and the iron rod diffuses into the molten Se powder in the subsequent sintering process to generate a compact FeSe layer and form a central hole, so that the intergranular connectivity is improved; and the oxidizing atmosphere is introduced through the central hole to be in full contact with the FeSe-based superconducting phase for annealing, so that the precipitation of interstitial iron is promoted, the superconductivity of the FeSe-based superconducting wire is improved, and the current-carrying performance of the FeSe-based superconducting wire is further improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

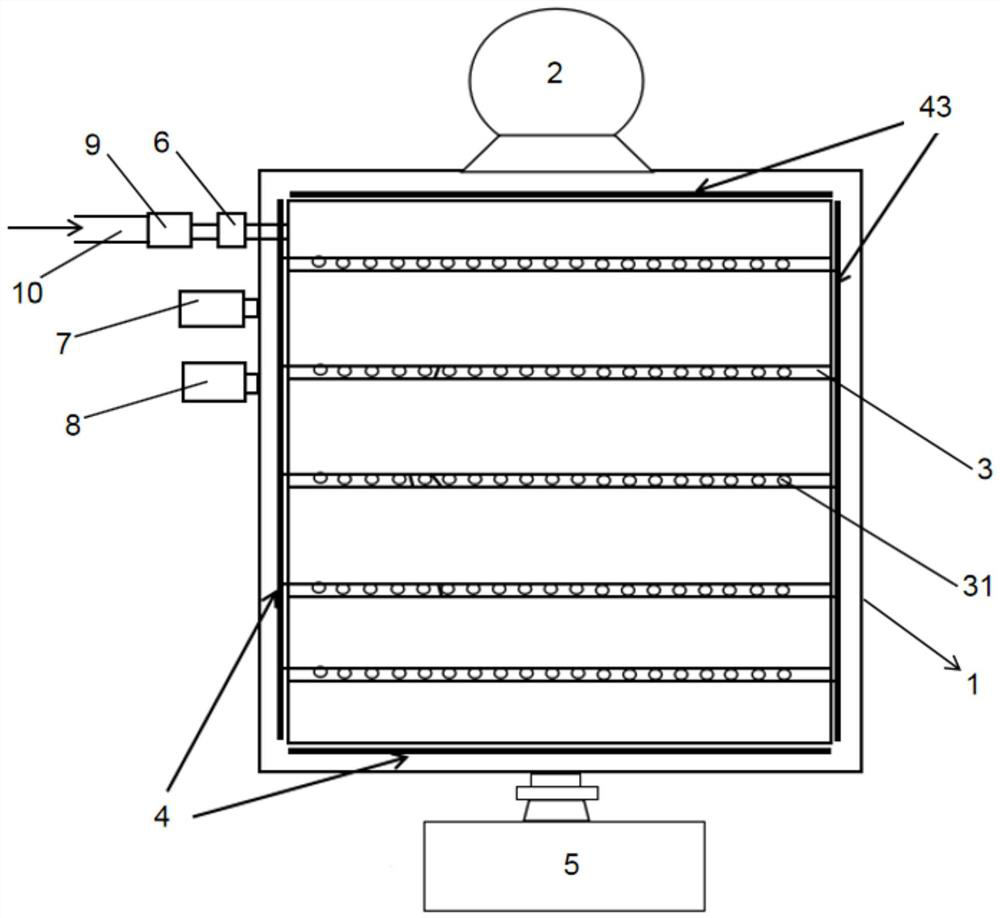

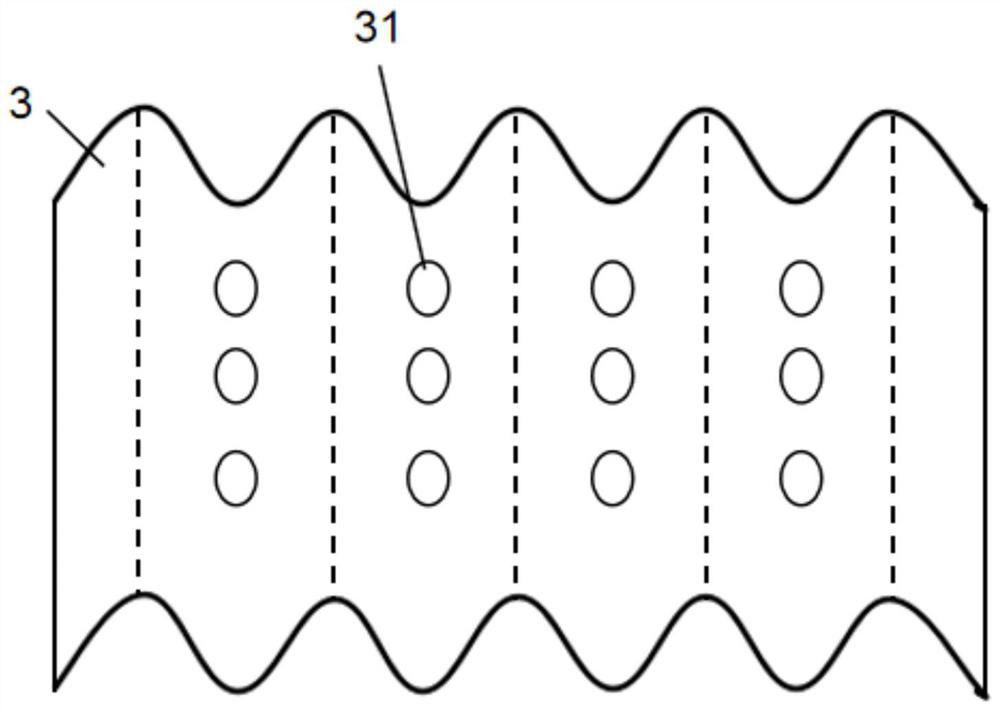

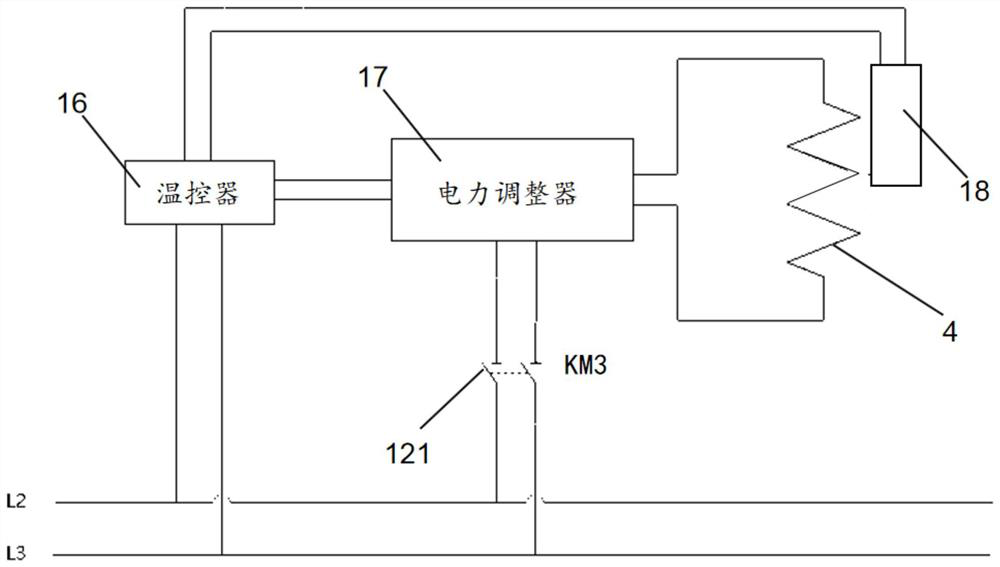

Annealing device and working method thereof

InactiveCN112981541AImprove uniformityAvoid insufficient annealingAfter-treatment detailsDiffusion/dopingInterior spaceMaterials science

The invention provides an annealing device and a working method thereof. The annealing device comprises an annealing cavity body and an airflow circulating fan, the airflow circulating fan is arranged outside the annealing cavity body, the airflow circulating fan comprises a rotating part and a shell arranged on the outer side of the rotating part, and the shell is in sealing communication with the annealing cavity body. In the annealing process, the rotating part rotates to drive airflow in the annealing cavity body to flow, so that heat at different positions in the annealing cavity body is exchanged, and the temperature uniformity of the different positions in the annealing cavity body is improved. Meanwhile, the airflow circulating fan is arranged outside the annealing cavity body and does not occupy the internal space of the annealing cavity body, so that the number of to-be-annealed parts which can be annealed simultaneously is increased, and the annealing efficiency is improved.

Owner:SUZHOU EVERBRIGHT PHOTONICS CO LTD +1

A kind of preparation method of FeSe-based superconducting wire rod

ActiveCN110867283BExcellent superconductivityFully contactedSuperconductors/hyperconductorsFurnace typesWire rodMetallurgy

The invention discloses a preparation method of a FeSe-based superconducting wire. The method comprises the following steps: 1, assembling an iron tube, an iron rod and an iron plug to obtain a tubingcomplex; 2, sealing the two ends of the tubing complex, and then obtaining a single-core FeSe-based wire through rotary swaging and drawing in sequence; 3, sintering the single-core FeSe-based wire to obtain a FeSe-based wire; and 4, annealing the FeSe-based wire to obtain a FeSe-based superconducting wire. According to the invention, the single-core FeSe-based wire is formed through powder charging by adopting a vibration tubing method and cold processing, and the iron rod diffuses into the molten Se powder in the subsequent sintering process to generate a compact FeSe layer and form a central hole, so that the intergranular connectivity is improved; and the oxidizing atmosphere is introduced through the central hole to be in full contact with the FeSe-based superconducting phase for annealing, so that the precipitation of interstitial iron is promoted, the superconductivity of the FeSe-based superconducting wire is improved, and the current-carrying performance of the FeSe-based superconducting wire is further improved.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A lateral composite guide device for three-layer composite materials

ActiveCN106180179BReduce mutual interferenceReduce difficultyGuiding/positioning/aligning arrangementsFurnace typesComposite PositionMachining

The invention discloses a lateral composite position guide device for a three-layer composite material. The lateral composite position guide device comprises a composite body, wherein a cavity is formed in the composite body; a wire guide nozzle is arranged on one side of the composite body, and a plurality of wire feeding rails are arranged on the other side of the composite body; a cavity penetrates through a wire guide channel of the wire guide nozzle and wire feeding channels of the wire feeding rails; a plurality of guide arrangement assemblies are arranged in the wire guide channel of the wire guide nozzle; and a composite rolling part is arranged on one side of the wire discharging end of the wire guide nozzle. The lateral composite position guide device is reasonable in design and compact in structure, can quickly enable three strips to be laterally and closely attached together, and can provide a basis for subsequent machining.

Owner:SUZHOU CHUANGHAO NEW MATERIAL TECH CO LTD

A kind of laser pulse annealing method

ActiveCN103920994BEnables batch annealingGuaranteed annealing effectSemiconductor/solid-state device manufacturingLaser beam welding apparatusReciprocating motionOptoelectronics

The invention discloses laser pulse annealing equipment and an annealing method applied to the laser pulse annealing equipment. A disk in which multiple wafers can be simultaneously placed is arranged in a reaction cavity of the laser pulse annealing equipment and is made to rotate and linearly move in the annealing treatment process, so that the wafers in wafer placement grooves in the disk sequentially and circularly pass through laser radiation points to be uniformly radiated by laser under driving of continuous rotation and linear reciprocating motion of the disk, and bulk annealing treatment on the wafers is achieved. According to the laser pulse annealing equipment and the annealing method, compared with traditional laser pulse annealing equipment which can only carry out annealing treatment on a single wafer, the laser pulse annealing equipment has the same annealing effect, annealing efficiency is remarkably improved, and the equipment and the method can well meet the process demands for annealing quality and efficiency in the high-end advanced process.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Isothermal spheroidizing annealing furnace for bearing steels

ActiveCN102041362BGuaranteed annealing effectReduce wasteCombustion processIndirect carbon-dioxide mitigationRoom temperatureHearth

Owner:SUZHOU ZHONGMENZI TECH

Glass substrate cutting machine

ActiveCN110255874BUniform temperatureImprove qualityGlass severing apparatusEngineeringMechanical engineering

The disclosure relates to a glass substrate cutting machine, comprising a heating device (1) and a driving device (2), the heating device (1) is used for heating the cutting area of the glass substrate (5), and the driving device (2) is used for The heating device (1) is driven to move towards the cutting area or away from the cutting area. Through the above technical solution, the driving device (2) drives the heating device (1) to approach or stay away from the glass substrate (5) to heat the cutting area, so that the overall temperature of the cutting area can be kept uniform, and dust can be prevented from being caused by the cutting area during cutting. The temperature is uneven and aggregated to prevent dust from adhering to the surface of the glass substrate (5), thereby improving the quality of the glass substrate (5), reducing the wear of the cutting knife (6), and prolonging the service life of the cutting knife (6) .

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +1

Conveying device in hollow glass product annealing furnace

The invention discloses a conveying device in a hollow glass product annealing furnace which is capable of evenly heating the hollow glass products in the annealing process. The conveying device comprises a conveying rack and a conveying transmission device, wherein the conveying rack comprises two pairs of conveying bars; placement grooves are evenly formed on the conveying bars; the conveying transmission device comprises two conveying transmission mechanisms with the same structure; each conveying transmission mechanism comprises four driving discs which are orderly arranged in parallel to each other along a straight line; the center line of the four driving discs is perpendicular to the conveying direction of the conveying rack; the two middle driving discs are connected through an eccentric transmission shaft; the two middle driving discs and the corresponding driving discs are connected through transmission shafts arranged symmetrical to the driving discs, respectively; each driving disc is provided with a driving shaft and a support shaft along the center line of the driving disc, respectively; and support rods are movably articulated between the end parts of the inner and outer conveying bars and the corresponding transmission shafts, respectively. The conveying device in the hollow glass product annealing furnace can be applied to the annealing furnaces for various hollow glass products.

Owner:ZHANGJIAGANG JUNFENG GLASS PRODS

Arranging structure of heaters on bearing-steel isothermal spheroidized annealing furnace

The invention discloses an arranging structure of heaters on a bearing-steel isothermal spheroidized annealing furnace. Bearing steel on an upper layer of driving roller set and a lower layer of driving roller set respectively is made to enter a hearth from a front furnace mouth and a rear furnace mouth and is conveyed in opposite directions, and the diagonal symmetrical arrangement of the heaters ensures the heating, insulating and isothermal treatment of the bearing steel on the upper layer of driving roller set and the lower layer of driving roller set and ensures the annealing treatment effect of the two layers of the bearing steel in the two directions. Accordingly, if high-temperature bearing steel to be conveyed out of the furnace mouth is conveyed on one of the upper layer of driving roller set and the lower layer of driving roller set, i.e. the high-temperature bearing steel is conveyed out of an isothermal chamber and made to enter an afterheat recovery exchanger chamber, normal-temperature bearing steel (also called as cold burden) which is just made to enter the furnace mouth is conveyed on the other layer of driving roller set, and the high-temperature bearing steel and the normal-temperature bearing steel can exchange heat so that the temperature of the normal-temperature bearing steel rises, the heat of the high-temperature bearing steel is recovered, and the heat needed for subsequently entering the isothermal chamber is reduced and energy is saved. In an intercooling chamber, a cooler can cool the high-temperature bearing steel discharged from a heating and insulating chamber while the high-temperature bearing steel and the lower-temperature bearing steel on the upper layer of driving roller set and the lower layer of driving roller set can exchange heat so that heat needed by lower-temperature bearing steel to subsequently enter the heating and insulating chamber is lowered, the energy is saved and heat waste is reduced.

Owner:SUZHOU ZHONGMENZI TECH

Automobile part machining device and using method thereof

InactiveCN113564315AEvenly heatedAchieve heatingFurnace typesHeat treatment furnacesHeat conservationMechanical engineering

The invention discloses an automobile part machining device and a using method thereof, and belongs to the technical field of automobile part machining. A semi-heater body matched with an automobile part in shape is arranged, and after the automobile part is placed in the semi-heater body, a liner of the device can be tightly attached to the automobile part, heat absorbed by a rheological heating body can be uniformly conducted to the automobile part, the automobile part can be uniformly heated, and the annealing effect is remarkably improved; in the annealing process, the heat preservation effect is good, heat loss is small, by arranging a heat conduction and insulation self-adjusting assembly and a movable heat preservation plate, and the rheological heating body can be heated only through simple operation; and after heating is carried out, heat preservation and heat insulation can be carried out only by inverting the device and enabling a heating rod to face upwards, loss of heat from a heat conduction block is greatly reduced, so that the rheological heating body can be conveniently heated on the premise that the heat preservation effect is guaranteed, and practicability is greatly improved.

Owner:杭州中橙科技有限公司

Furnace end device of annealing furnace suitable for glass bottle

PendingCN114804599AAnnealing effect guaranteeImprove the annealing effectGlass transportation apparatusStructural engineeringManufacturing engineering

The invention relates to an annealing furnace end device suitable for glass bottles, which comprises an annealing furnace body and a chain scraper conveyor used for conveying the glass bottles to a furnace end of the annealing furnace body, and a mesh belt conveyor used for conveying the glass bottles is arranged on the annealing furnace body; a supporting frame is fixedly arranged at the furnace end of the annealing furnace body, a mounting frame is arranged on the supporting frame in the conveying direction of the mesh belt conveyor in a sliding mode, a first driving piece used for driving the mounting frame to slide is arranged on the supporting frame, and a mounting block is arranged on the mounting frame in the vertical direction in a sliding mode; a second driving piece used for driving the mounting block to slide is arranged on the mounting frame, and a clamping mechanism used for clamping the glass bottle is arranged on the mounting block. The annealing furnace has the effect that the glass bottle is easily knocked down when entering the annealing furnace body.

Owner:绵竹市红森玻璃制品有限责任公司

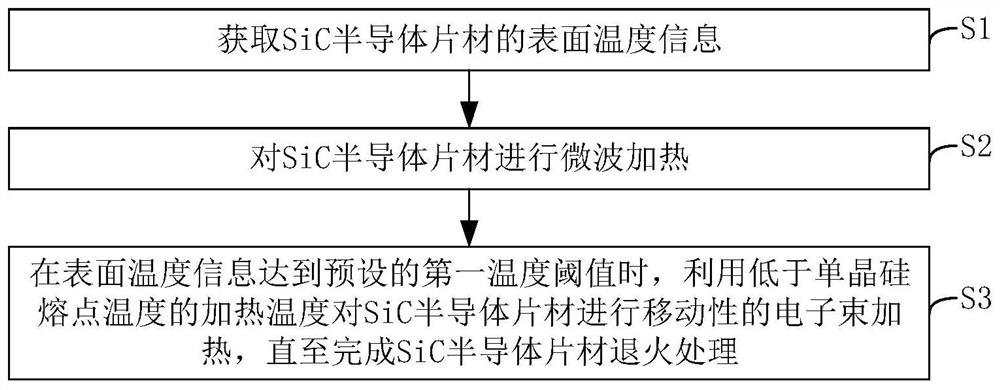

Semiconductor annealing method, annealing device and annealing system

PendingCN114823307AAvoid damageGuaranteed annealing effectAfter-treatment detailsSemiconductor/solid-state device manufacturingDevice materialSemiconductor

The invention relates to the technical field of semiconductor device preparation, and particularly discloses a semiconductor annealing method, an annealing device and an annealing system.The method comprises the following steps that surface temperature information of a SiC semiconductor sheet is obtained; performing microwave heating on the SiC semiconductor sheet at a heating temperature lower than the melting point temperature of the monocrystalline silicon; when the surface temperature information reaches a preset first temperature threshold value, movable electron beam heating is conducted on the SiC semiconductor sheet till annealing treatment of the SiC semiconductor sheet is completed; according to the method, the SiC semiconductor sheet is heated to the first temperature threshold value through microwave heating treatment, the temperature needed by annealing treatment of the SiC semiconductor sheet can be reduced to be within the expected range, then accurate temperature control annealing treatment is conducted on the SiC semiconductor sheet through electron beam heating, and the temperature of the SiC semiconductor sheet can be reduced under the condition that the annealing treatment effect is guaranteed. The annealing treatment temperature is reduced, and the annealing treatment efficiency is improved.

Owner:JIHUA LAB

A kind of laser annealing apparatus and method

ActiveCN107665821BGuaranteed annealing temperature uniformityGuaranteed annealing effectSemiconductor/solid-state device manufacturingPhoto irradiationBeam splitting

The invention discloses a laser annealing device and method. The device comprises a laser irradiation system, a slide system and a reflected light detection system sequentially arranged along the optical path, and a host computer connected with the laser irradiation system, the slide system and the reflected light detection system The laser irradiation system includes a laser light source, a beam adjustment component, a light intensity distribution forming component, a beam splitting component and a focusing component arranged in sequence along the optical path; the incident light intensity required for the silicon wafer is formed by selecting the optical elements on the light intensity distribution forming component distribution, so that the temperature field on the silicon wafer reaches the effect of consistent temperature between the middle and the edge, ensuring the uniformity of the annealing temperature, thereby improving the uniformity of the annealing effect; based on the same batch of silicon wafers, the patterns at the same position are the same, and the annealing The optical components used in the process are well selected, and the exposure process is written in order. During the exposure process, only monitoring is performed without adjustment, which can improve efficiency and increase productivity while ensuring annealing performance.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Annealing device for plastic products

The invention discloses an annealing device for plastic products. The annealing device comprises a box body, wherein a work box is fixedly connected between the two opposite sides of an inner wall ofthe box body through a fixing plate, and a motor is fixedly connected with the bottom of the inner wall of the box body; the output shaft of the motor is fixedly connected with a shelf through a transmission and a rotating device, and the bottom of the outer wall of the box body is fixedly connected with a bearing plate; one side of the top of the bearing plate is fixedly connected with an oil tank, and one side, close to the oil tank, of the bottom of the inner wall of the box body is fixedly connected with an oil pump; one side of the top of a fixing plate is fixedly connected with a circulating air pump, and an air heater is fixedly connected between the two opposite sides of the outer wall of the work box and the inner wall of the box body through a supporting plate; the bottom of theinner wall of the work box is fixedly connected with a heating disc, and one side of the top of the inner wall of the box body is fixedly connected with a control box. The invention relates to the technical field of plastic product processing. The annealing device for the plastic products has the advantages of simple operation, optional annealing method, stable annealing temperature, ensuring of annealing quality and improvement on processing efficiency.

Owner:无锡普力斯特实验室设备科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com