Heating structure of annealing furnace

A technology of heating structure and annealing furnace, which is applied in the direction of furnace, furnace type, heat treatment furnace, etc., can solve the problems of poor temperature uniformity in the furnace body, short service life of heating tubes, large heating energy consumption of heating tubes, etc., to ensure the annealing effect, Reduce energy consumption and improve thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

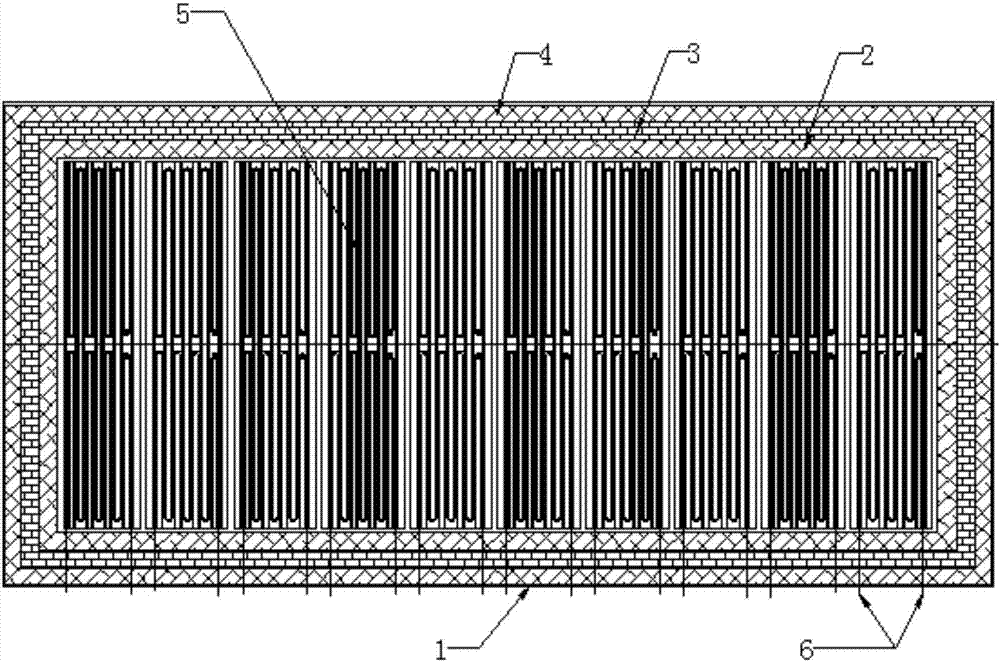

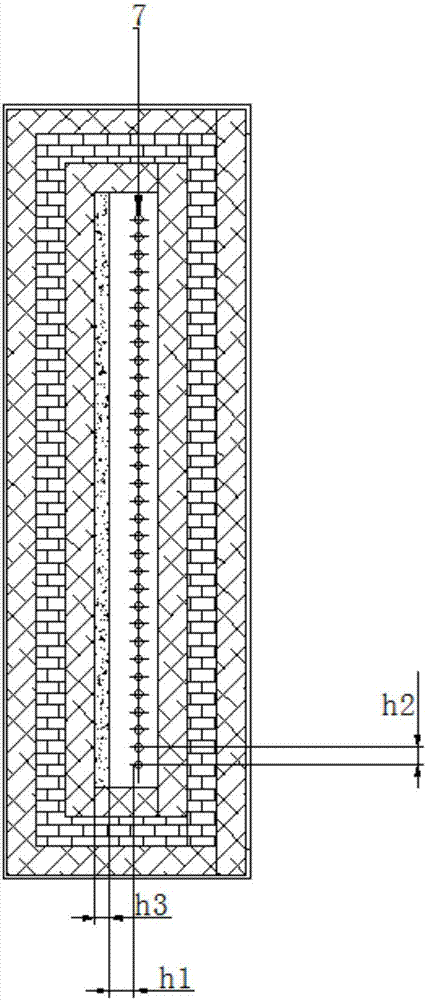

[0030] Embodiment: a kind of heating structure of annealing furnace, as Figure 1 to Figure 2 As shown, the annealing furnace includes a furnace body, the furnace body is provided with a heating structure, and the furnace body includes a shell 1 and an insulation layer located on the inner wall of the shell, with the center of the furnace body as the inside, The thermal insulation layer is provided with three layers, and from the inside to the outside is the first thermal insulation layer 2, the second thermal insulation layer 3 and the third thermal insulation layer 4, and the two adjacent thermal insulation layers are seamlessly bonded;

[0031] The heating structure includes a plurality of electric furnace reels 5 located inside the furnace body and heating wires 6 corresponding to and connected to the electric furnace reels one by one, and the number of groups of the heating wires is the same as that of the electric furnace reels. The numbers are equal, the electric furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com