Patents

Literature

158results about How to "Improve the annealing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

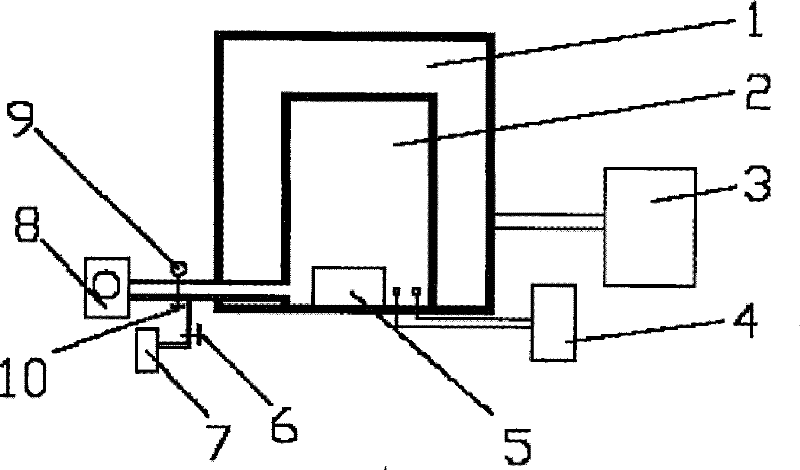

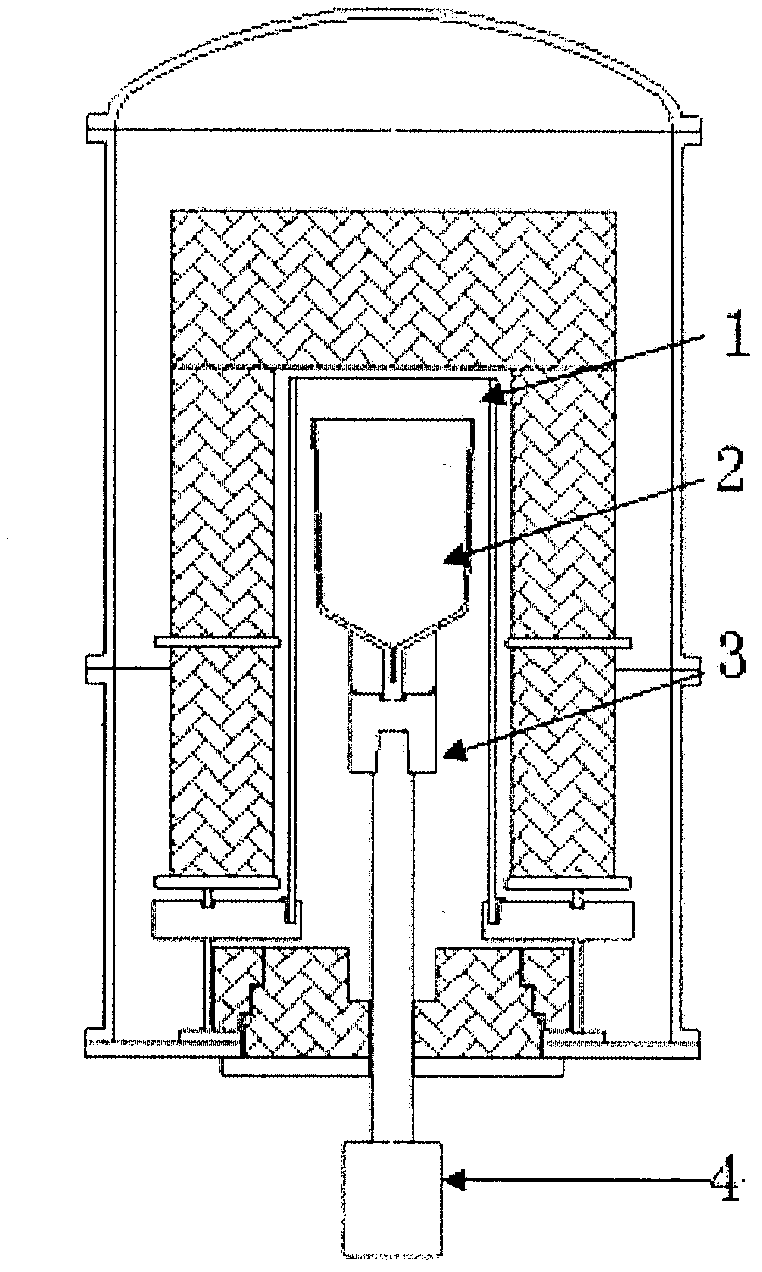

Destressing method and device for amorphous alloy transformer iron core

InactiveCN102337384AStress reliefReduce no-load lossInductances/transformers/magnets manufactureCore temperatureAlloy

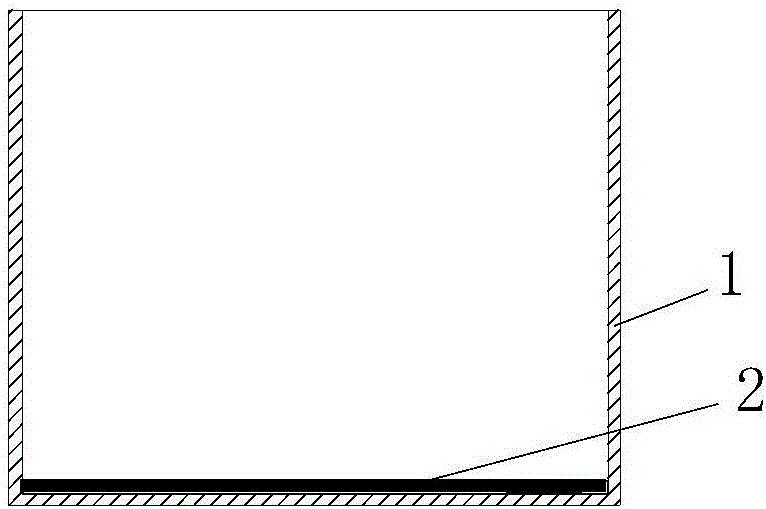

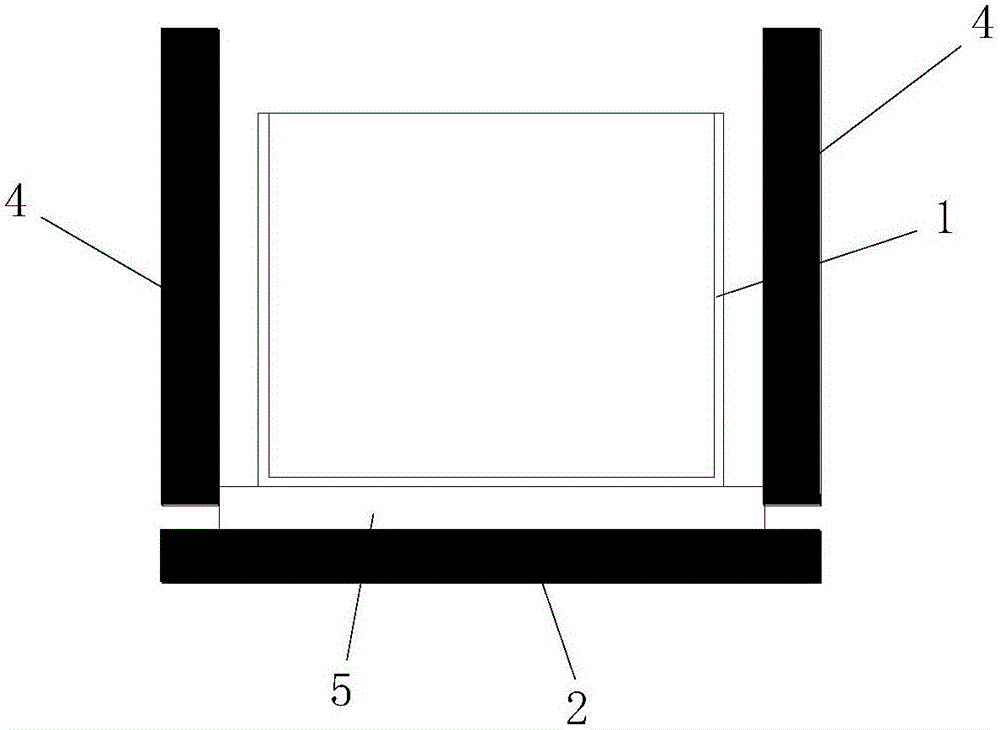

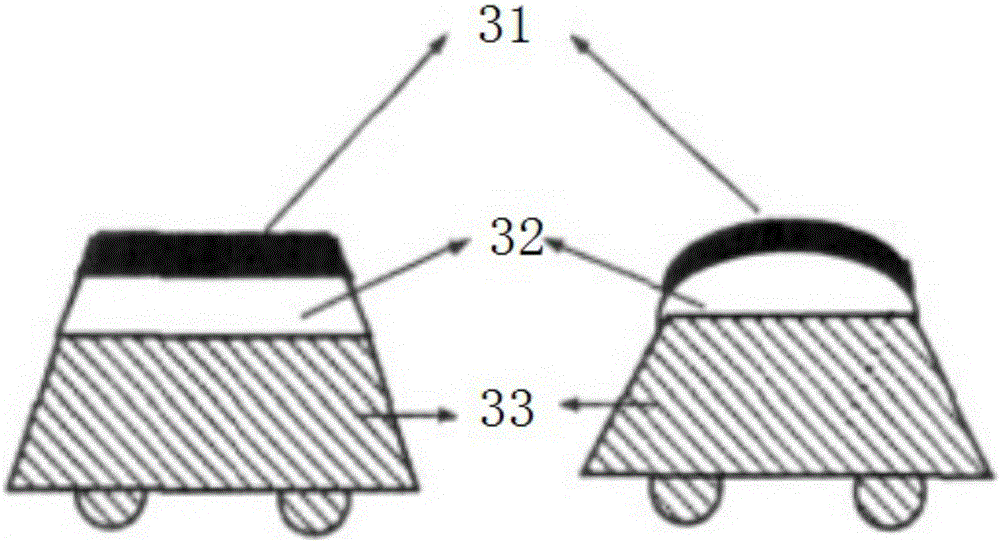

The invention discloses a destressing method and device for an amorphous alloy transformer iron core, wherein the method comprises the steps of: loading an iron core to a heating furnace chamber; exhausting the air inside the furnace chamber by injecting an inert gas into the heating furnace chamber; heating up the heating furnace chamber; keeping the temperature of the heating furnace chamber when the iron core temperature reaches a keeping temperature, wherein the iron core keeping temperature is 342-348 DEG C, and the temperature keeping time is 40-50 min; cooling the iron core, wherein the cooling step comprises a step of cooling the heating furnace chamber and a step of cooling the iron core along with the furnace; and keeping to feed the inert gas into the furnace in the processes of heating up, keeping temperature and cooling the heating furnace chamber. By adopting the method and the device disclosed by the invention, the stresses of the amorphous alloy generated in the processes of fast quenching, winding, cutting, forming and the like are effectively eliminated, and no-load loss of the amorphous alloy iron core is obviously reduced.

Owner:SHANGHAI RIGANG ZHIXIN AMORPHOUS METAL

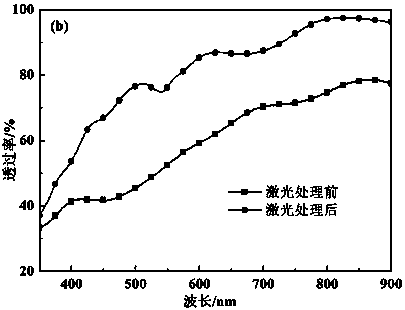

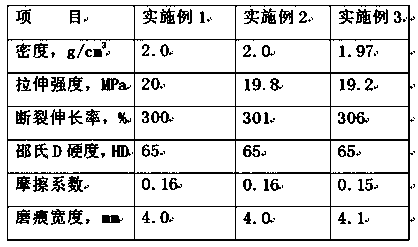

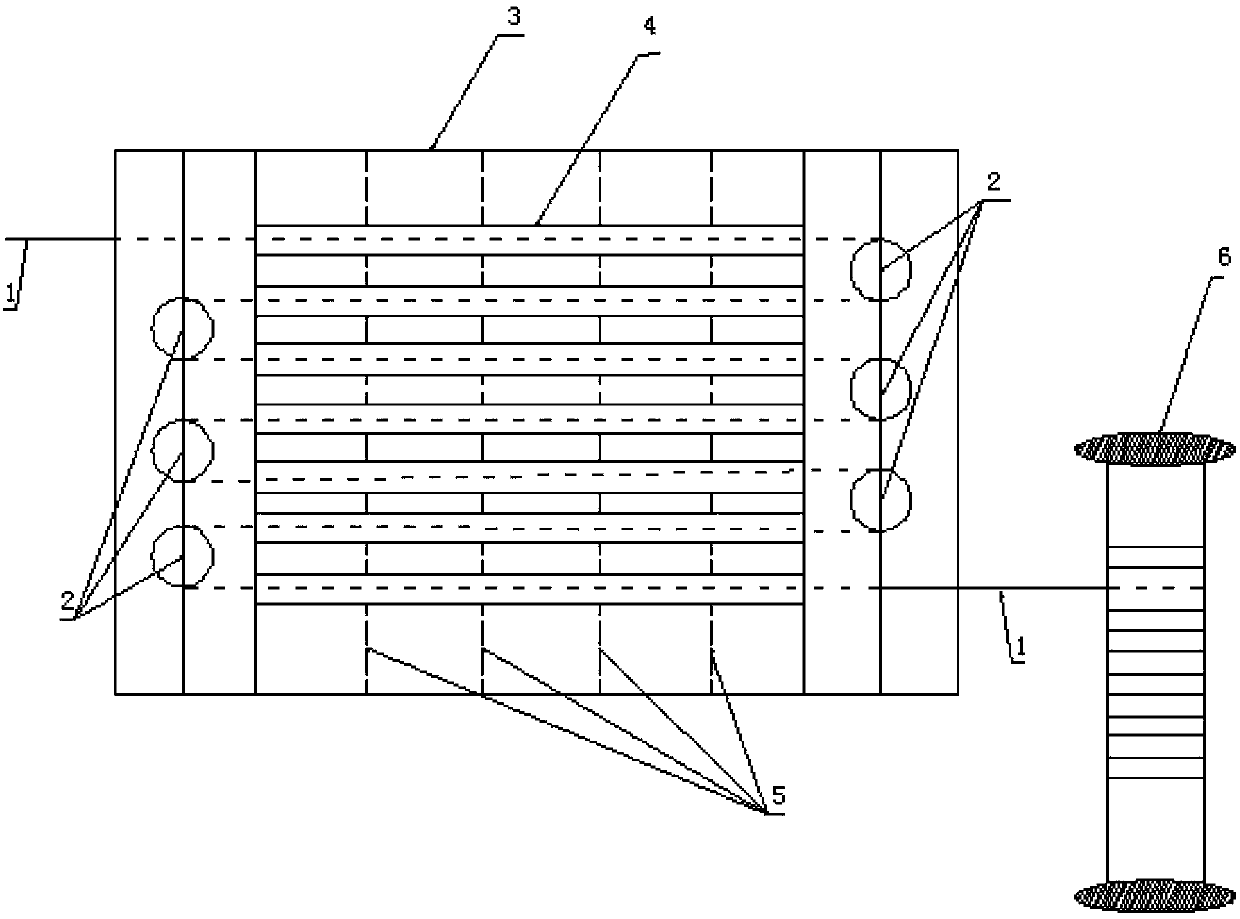

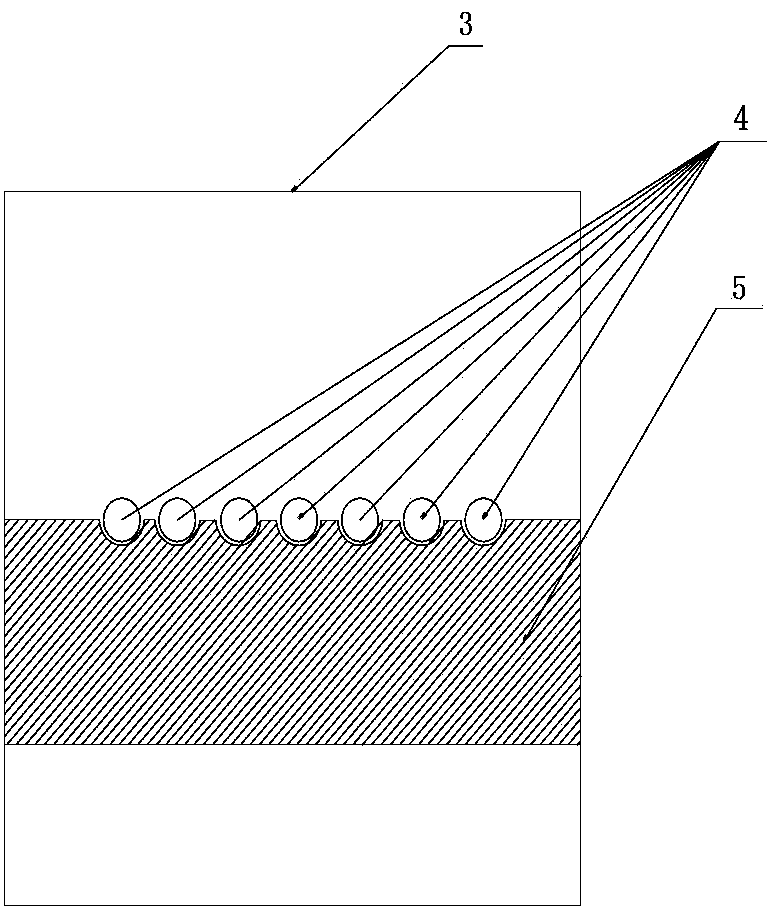

Preparation method of transparent conductive thin film with grating structure

ActiveCN103993261AShort preparation timeEasy to operateConductive layers on insulating-supportsVacuum evaporation coatingGratingLiquid medium

The invention discloses a preparation method of a transparent conductive thin film with a grating structure. The method comprises the steps of adopting a pulse laser of which the pulse width is less than 20ns, and the wavelength is 400-1000 nanometers, ensuring that a laser beam emitted from the pulse laser is positioned with a distance of 0-2.55 millimeter above an M layer of an M / TCO glass transparent conductive thin film after passing through a focus formed by lens focusing, controlling the laser energy to be 0.70-1.30J / cm<2>, and controlling the scanning speed to be 5-20mm / s; performing one-way line-by-line scanning on the laser beam, controlling the scanning line overlapping rate to be 50-70%, and performing laser irradiation treatment on the surface of the M / TCO thin film, so that crystals on the surface of the conductive thin film are subjected to re-crystallization, and a regular grating structure is induced on the surface. The preparation method is simple in process operation, short in preparation time and good in controllability, does not need to introduce harsh environmental conditions such as special gas or liquid medium and the like, and improves the light transmittance of the thin film.

Owner:JIANGSU UNIV

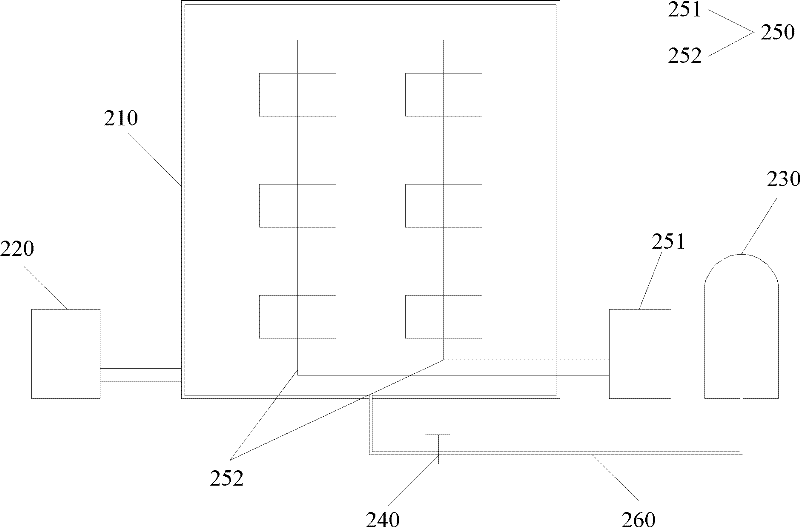

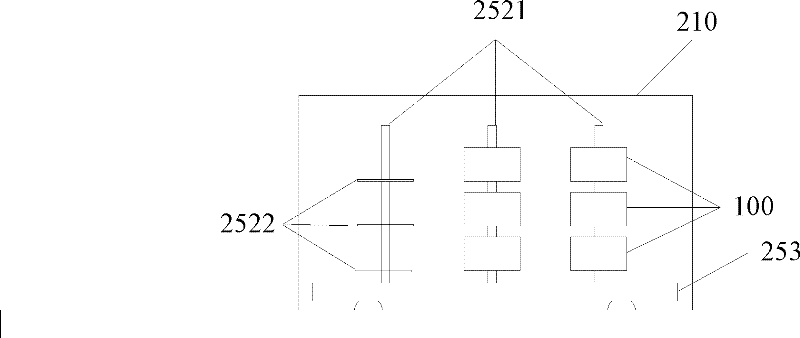

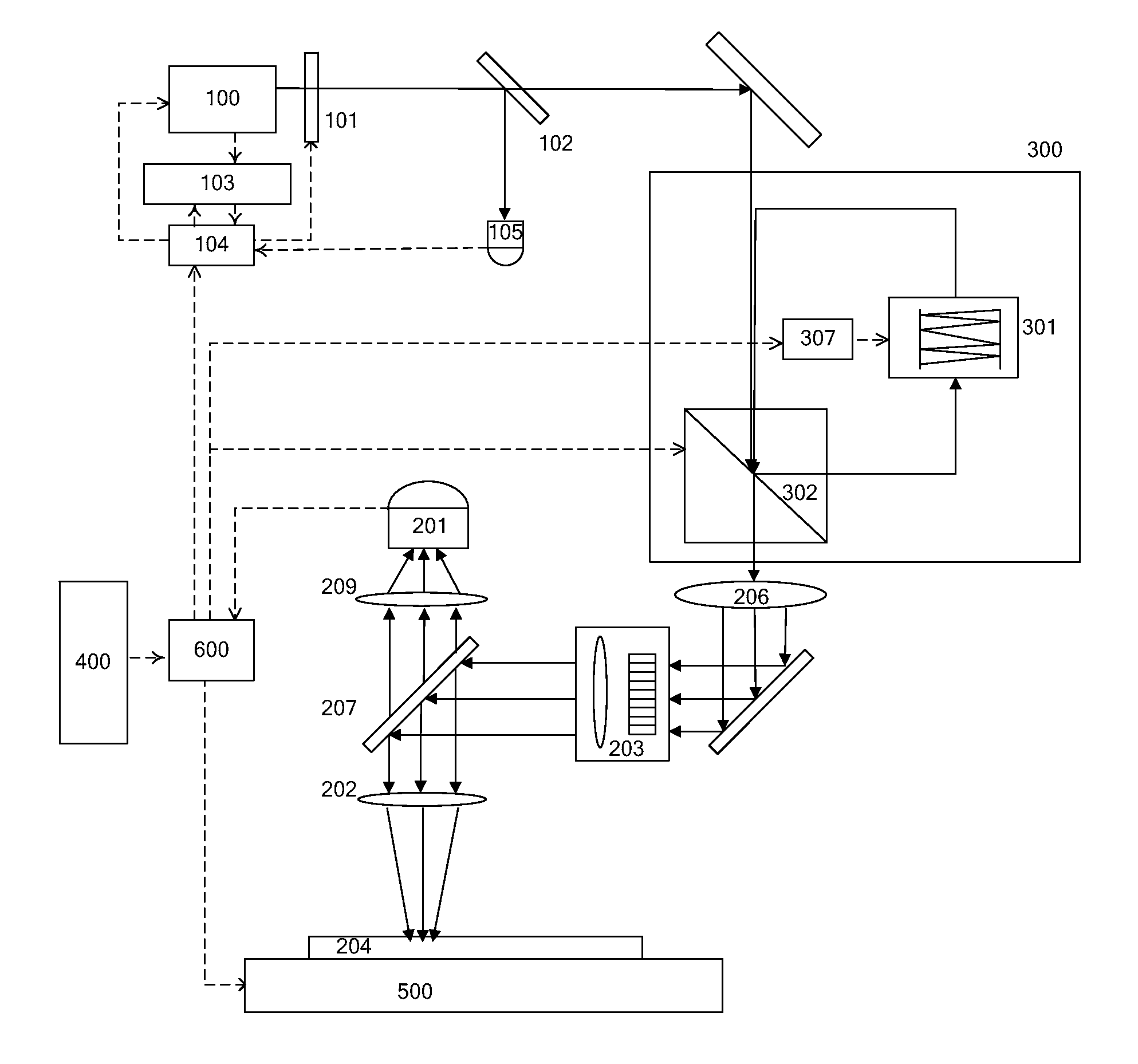

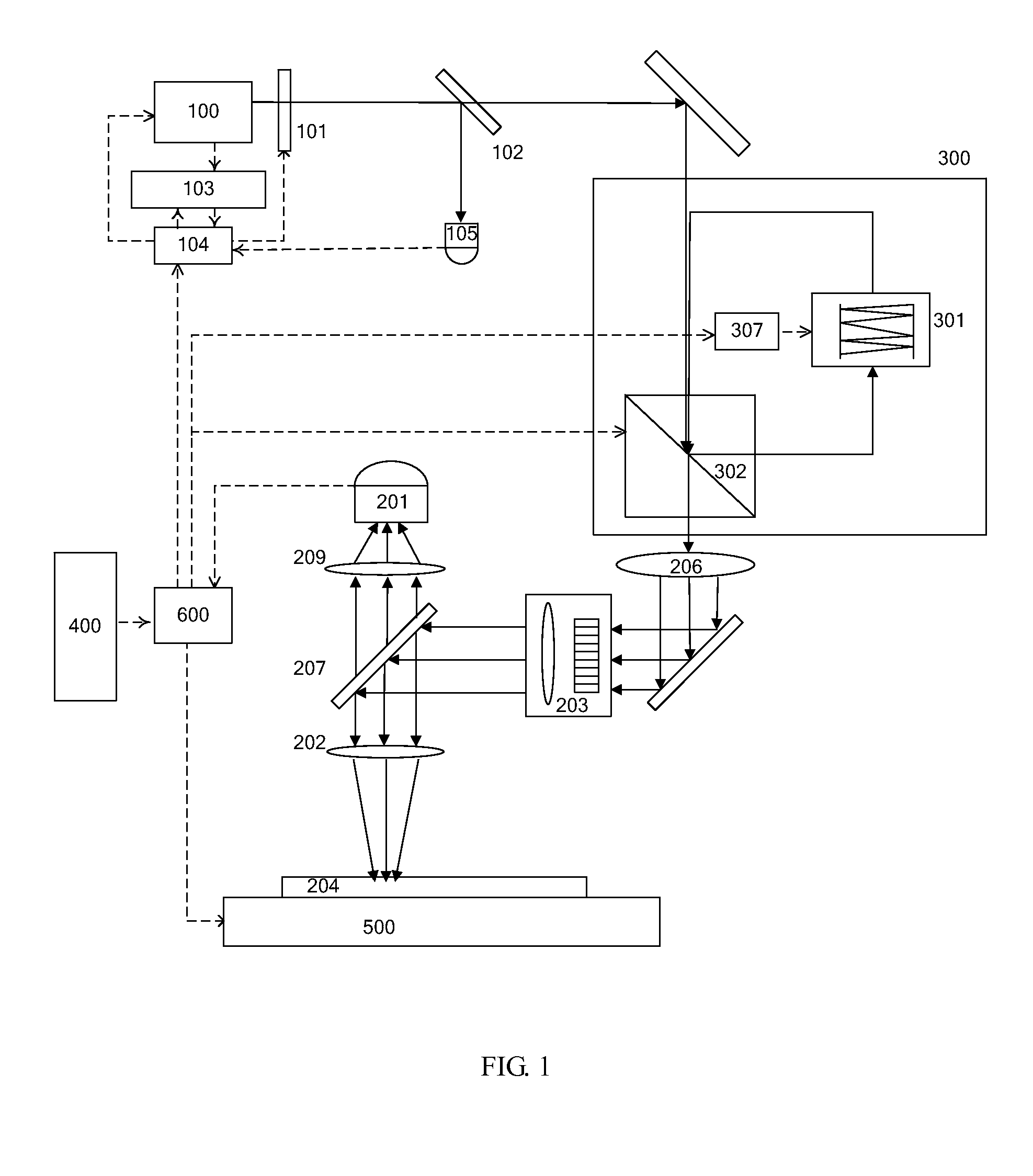

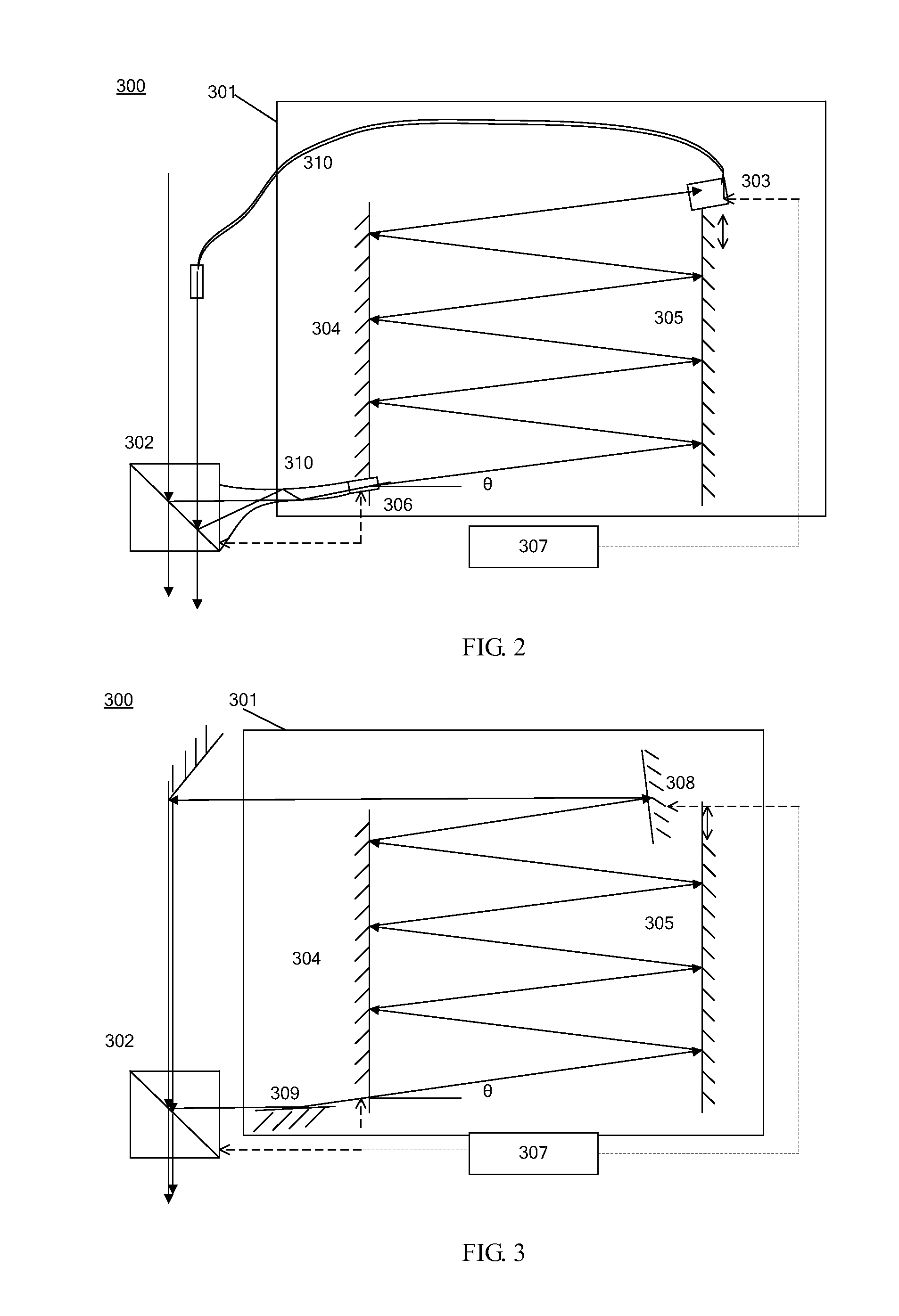

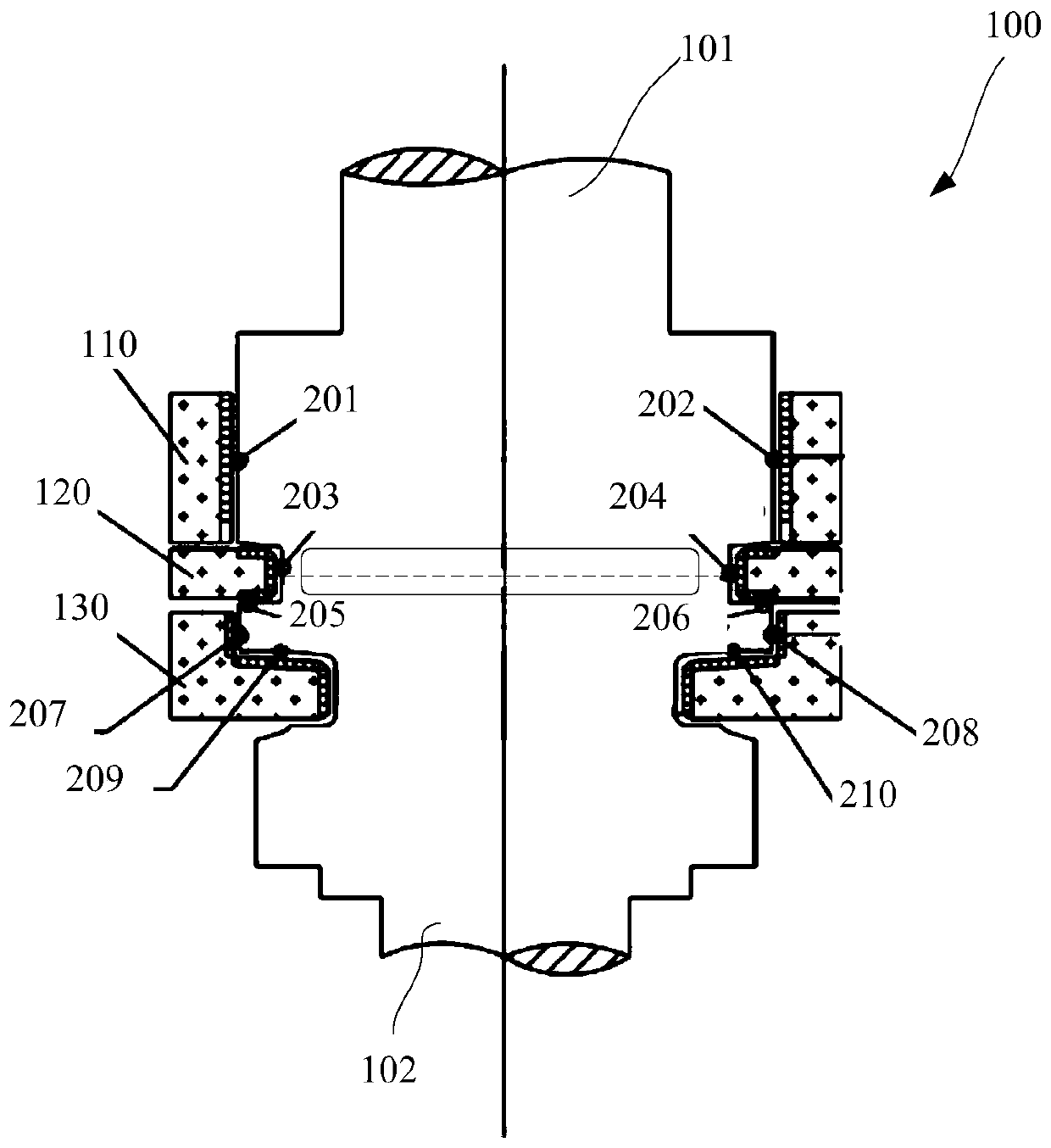

Laser Annealing Apparatus and Laser Annealing Method

ActiveUS20150037984A1Improving laser energy utilization efficiencyImprove the annealing effectSemiconductor/solid-state device manufacturingWelding/soldering/cutting articlesLaser annealingSingle pulse

A laser annealing apparatus includes: a laser beam generator for providing a stable single-pulse laser; a cyclic delay unit (300) for splitting the single-pulse laser into several pulsed lasers; an optical module for converging one or more of the pulsed lasers on a substrate (204); and a movable stage (500) for providing the substrate (204) with movement in at least one degree of freedom. A laser annealing method includes: providing a stable single-pulse laser; splitting the single-pulse laser into several pulsed lasers according to a delay requirement and an energy ratio; and irradiating a substrate (204) successively with one or more of the pulsed lasers to keep a surface temperature of the wafer around the melting point or around a needed annealing temperature for a sufficiently long time during the annealing process, thus resulting in an improvement in both the laser energy utilization efficiency and effect of the annealing process.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

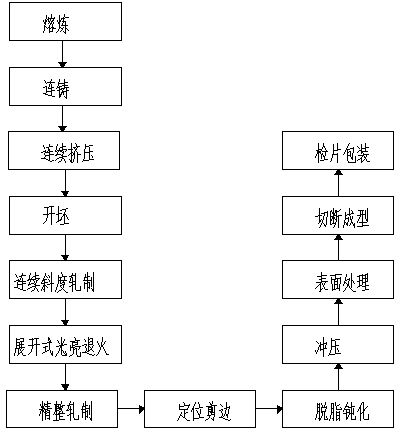

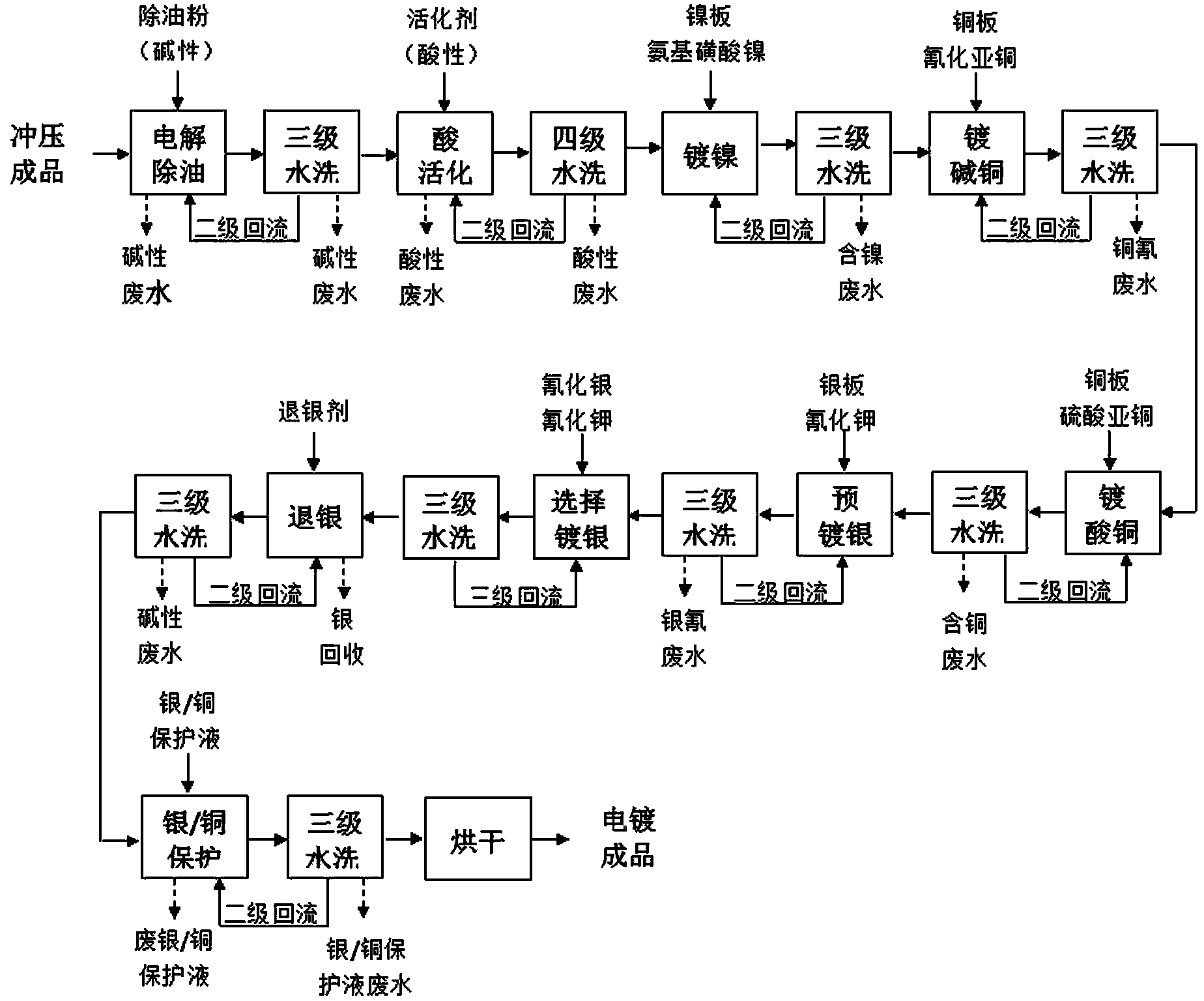

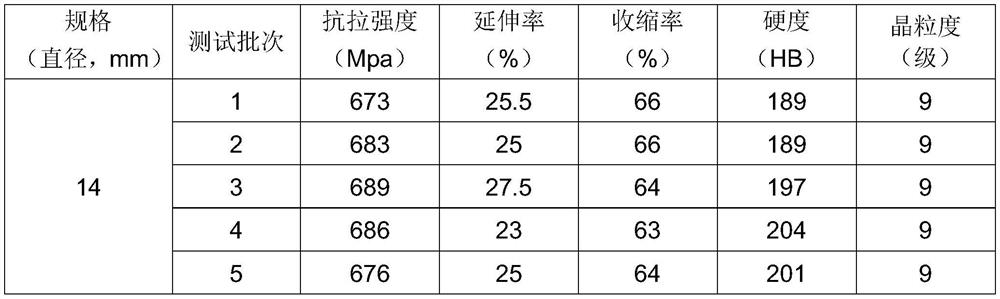

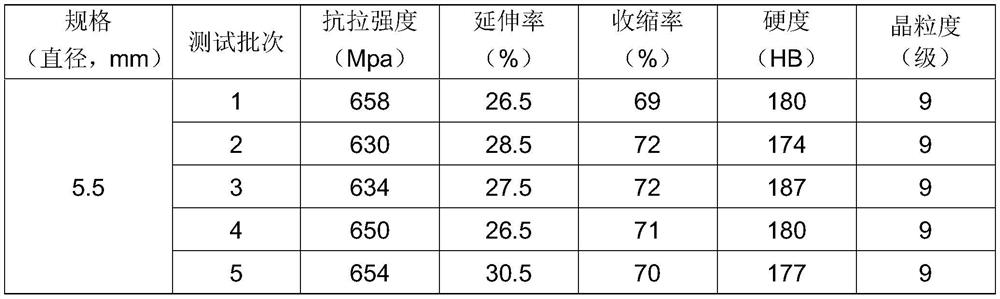

Semi-conductor lead framework production process

ActiveCN103928351AExact widthAdequate heat dissipationSemiconductor/solid-state device manufacturingMechanical engineeringSemiconductor

The invention relates to a semi-conductor lead framework production process which includes the steps of smelting, continuous casting, continuous extrusion, cogging, severe convection annealing, continuous inclination rolling, spreading-type bright annealing, finishing rolling, positioning-type edge shearing, degreasing passivation, stamping, surface processing, cutting forming and detection piece packaging. The production process is characterized in that the two work procedures of finishing rolling and positioning-type edge shearing are provided with continuous grooving procedures, when continuous grooving is carried out, precise grooving processing is carried out through a grooving machine, the rotation speed of the grooving machine is 1800-2000 r / min, the flow of cooling liquid is 45-50 L / min, and dovetail groove forming achieving through the process cannot cause strip width changes after forming, and the size of a formed semi-conductor lead framework is accurate.

Owner:SICHUAN JINGJIAN ELECTRONICS MATERIAL

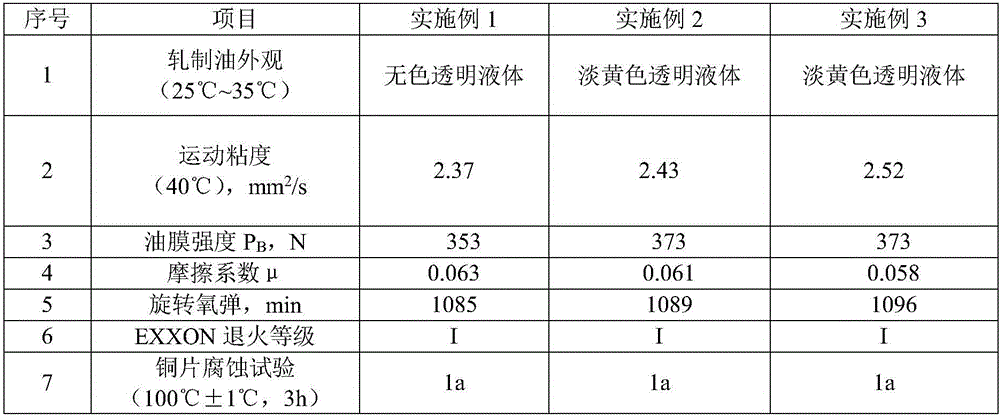

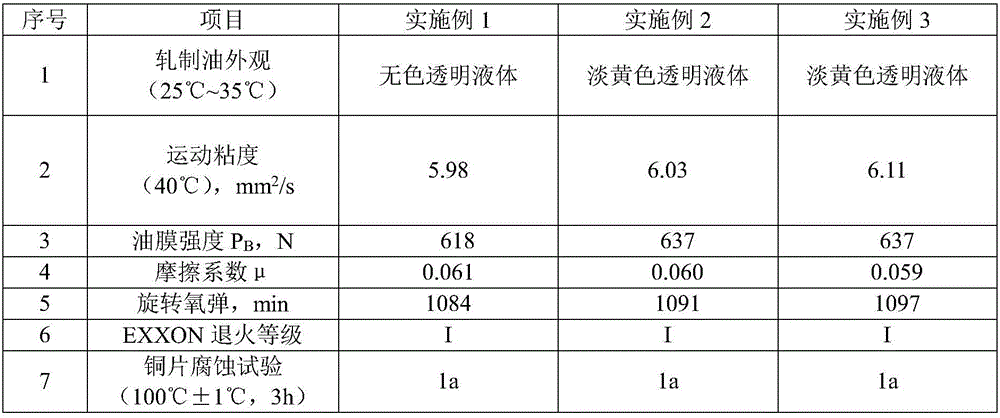

Universal nonferrous metal and stainless steel cold rolling oil composite additive and preparation method thereof

ActiveCN106566598AImprove anti-friction and anti-wear effectImprove anti-wear and anti-friction performanceAdditivesAntioxidantSolvent

The invention provides a universal nonferrous metal and stainless steel cold rolling oil composite additive and a preparation method thereof and belongs to the field of lubricating agents. According to the universal nonferrous metal and stainless steel cold rolling oil composite additive, lauryl alcohol, butyl stearate, pentaerythritol oleate and lauric acid are selected as oily agents; 2,6-di-tert-butyl-4-methylphenol is selected as an antioxidant; benzotriazole and thiadiazole derivatives are used as metal deactivators; dialkyl phosphorodithioate serves as an antiwear agent; and hydrogenated base oil serves as a solvent. The alcohol-ester type oily agents are mainly used for compounding with a little amount of acid oily agents as supplementation; a little amount of dialkyl phosphorodithioate is used as the antiwear agent to reinforce an oil film so as to improve the surface quality of a rolled stock; the service life of rolling oil is prolonged through a little amount of the antioxidant and the metal deactivators, the cyclic use frequency is increased, and rolled pieces are protected against corrosion. The universal nonferrous metal and stainless steel cold rolling oil composite additive is convenient to use, low in cost and little in dosage, and has the characteristics of high oil film strength, good antiwear and antifriction effect, high oxidation resistance and excellent annealing performance.

Owner:UNIV OF SCI & TECH BEIJING

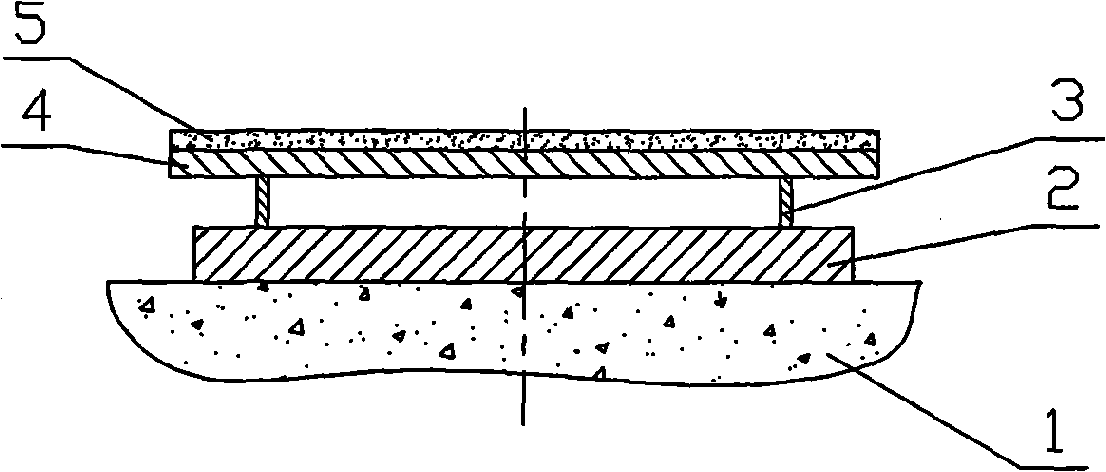

Process for manufacturing high bonding strength copper clad aluminum wire

InactiveCN101537532AImprove the bonding strength of the interfaceIncreasing the thicknessNon-electric welding apparatusLayer thicknessCopper

The invention discloses a process for manufacturing high bonding strength copper clad aluminum wire, comprising the following steps: (1) explosive welding: a baseplate, a support ring, a covering plate and explosive are sequentially overlapped from the bottom up on a foundation, wherein one of the baseplate and the covering plate is a copper plate and the other one is an aluminum plate, the explosive is ignited, the covering plate impacts the baseplate at a high speed, and the covering plate and the baseplate are integrated by welding to obtain copper-aluminum composite plate blank; and (2) the copper-aluminum composite plate blank is processed by subsequent processing procedures to obtain the copper clad aluminum wire. The process improves the interfacial bonding strength, the copper layer thickness and the electric conductivity of the copper clad aluminum wire, thereby ensuring the usage reliability thereof.

Owner:CNGC YIBIN NORTH XINAN COMPOSITE MATERIALS

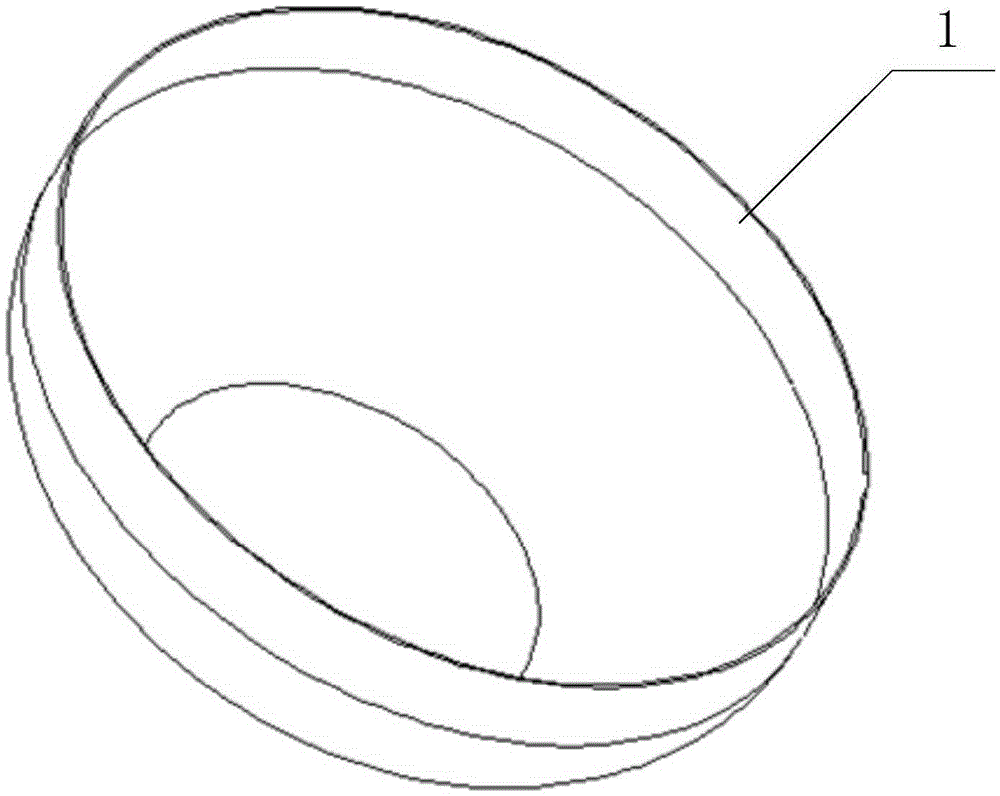

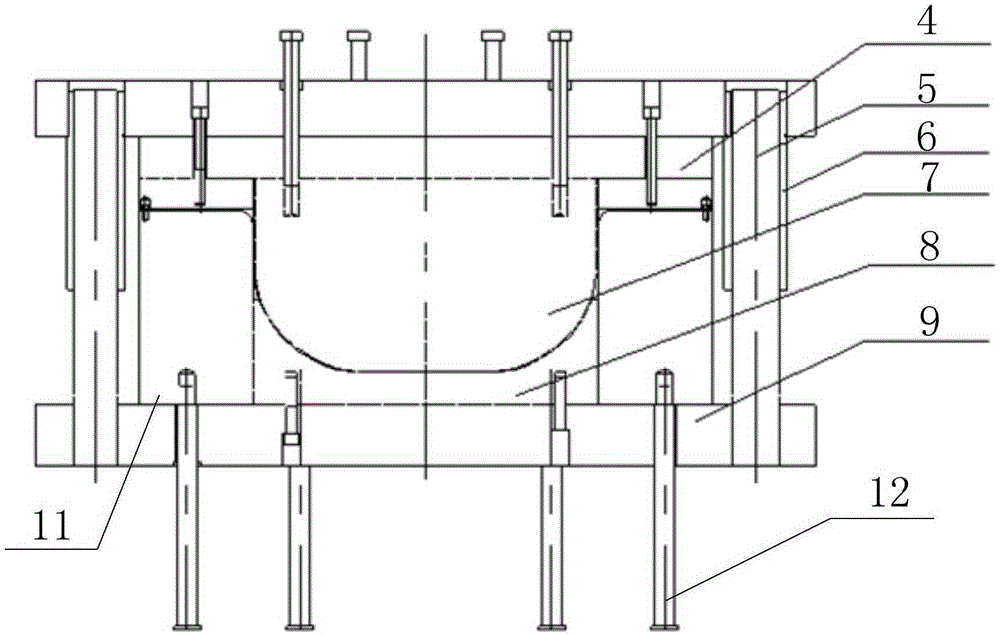

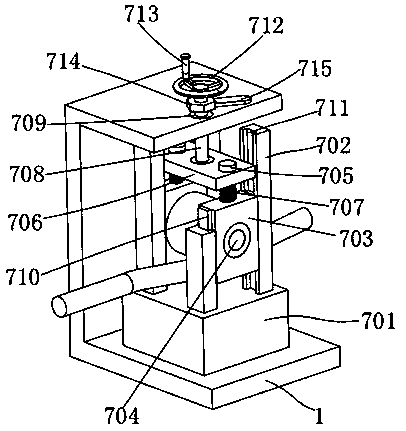

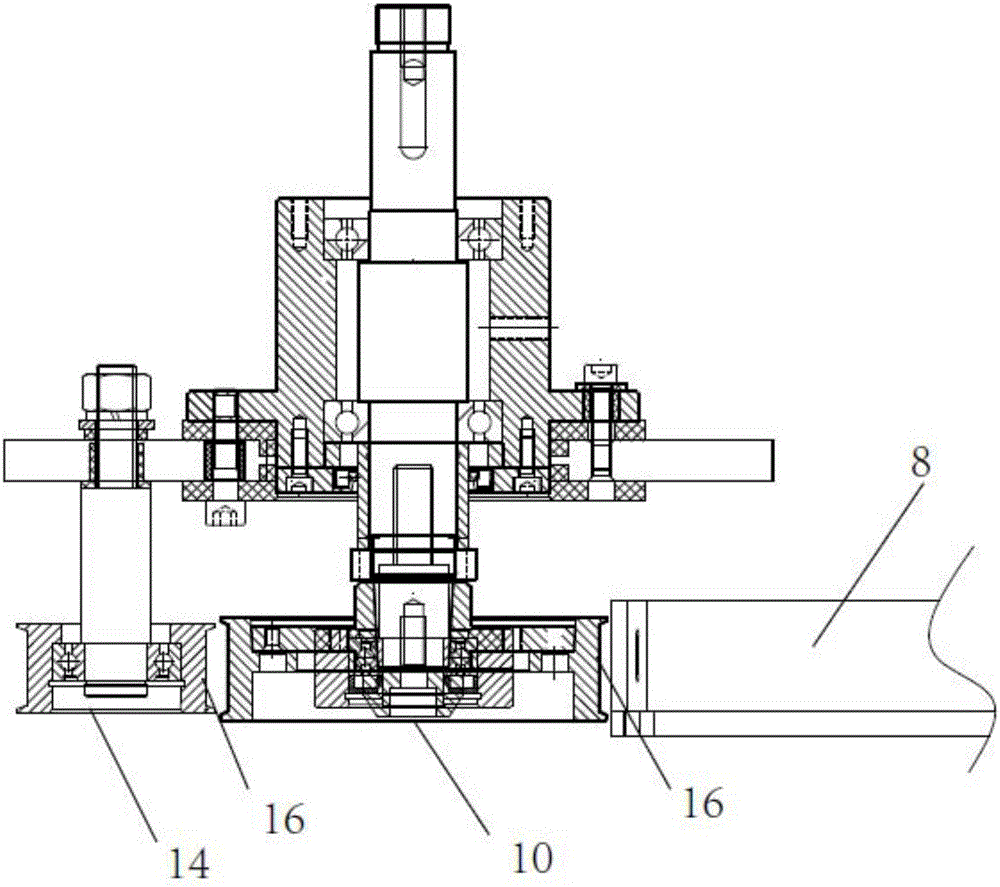

Drawing forming device and method of rotary part

ActiveCN105414299AAvoid wrinklesImprove wear resistanceMetal working apparatusEngineeringMaterials processing

The invention relates to the technical field of metal material machining, in particular to a drawing forcing device and method of a rotary part. The device comprises an upper combined die, a male die, a female die, a female die frame, a lower die, a guide column, a guide sleeve, an ejection rod and an ejection plate. The male die is fixedly connected with the lower end of a lower combined die, the female die is arranged in the female die frame, the female die is fixedly connected with the upper end of the lower die, the lower end of the ejection rod is connected with the ejection plate, and the upper end of the ejection rod penetrates the lower die to be fixedly connected with the female die frame; and the female die is arranged below the male die, and the axis of the male die coincides with the axis of the female die. One end of the guide sleeve is fixedly connected with the upper combined die, and fixedly connected with the lower die, and the other end of the guide column is inserted in the other end of the guide sleeve in a penetrating manner. The method comprises blank manufacturing, blank positioning, blank drawing, blank annealing, die pressure maintaining and mechanical machining. According to the drawing forcing device and method of the rotary part, the problem that in the drawing process of the rotary part, ripping, wrinkling and scrapping are prone to appearing is solved.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Total-hydrogen bell type furnace annealing method for cold-rolled strip steel

InactiveCN104745771AImprove the annealing effectImprove uniformityFurnace typesHeat treatment furnacesLow speedHydrogen

The invention discloses a total-hydrogen bell type furnace annealing method for cold-rolled strip steel. The annealing method comprises the following steps: a, placing to-be-annealed strip steel on a charging furnace base, and cleaning a heated bell, so that the content of the heated bell is no more than 1%; b, placing a cooling bell on the furnace base, and starting air cooling; c, when the furnace temperature is lowered to 270 DEG C, stopping air cooling, and stopping the running of a furnace base fan; d, performing water spraying cooling for ten minutes, then performing low-speed running on the furnace base fan for ten minutes, then performing high-speed running until the hottest spot temperature is lowered to 160 DEG C, and then performing low-speed running on the fan base fan; e, cleaning hydrogen gas again with nitrogen gas until the content of the hydrogen gas is no more than 5%; and f, hoisting out the cooling bell and the inner cover, and hoisting the annealed strip steel out of the furnace. The total hydrogen is adopted as a protective gas for annealing, so that not only can the heat transfer efficiency be significantly improved, and the annealing capability of the bell type furnace can be enhanced, but also the furnace temperature uniformity is improved, the mechanical performance of the strip steel can be guaranteed, and the internal quality and surface quality of cold-rolled plates can be increased.

Owner:JIANGSU KAITEER INDAL FURNACE

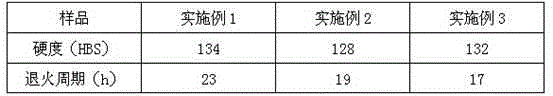

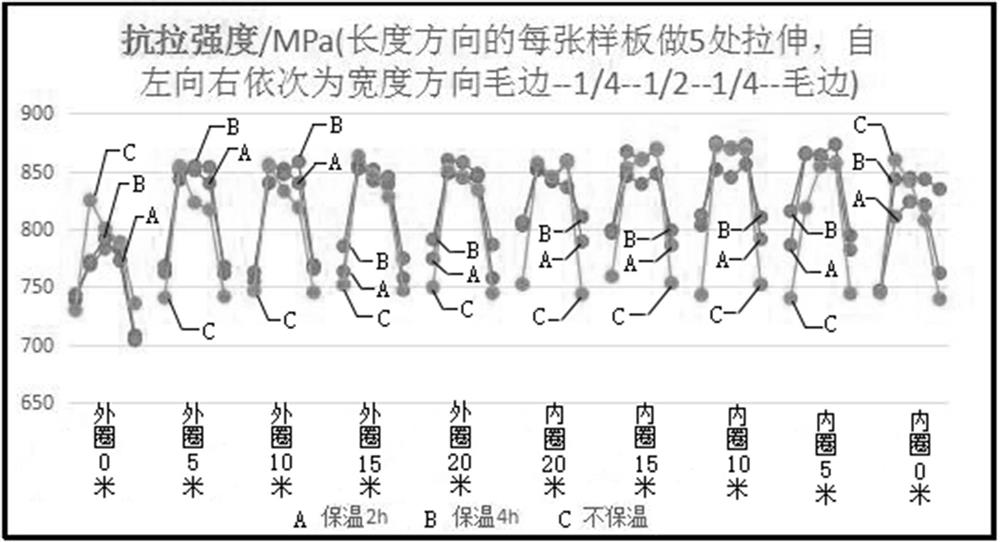

Spheroidized annealing process for shortening annealing cycle of hot rolled wire rods

The invention relates to a spheroidized annealing process for shortening the annealing cycle of hot rolled wire rods, belongs to the technical field of metal wire annealing process. The technical scheme of the spheroidized annealing process lies in that firstly, lamellar pearlites are heated to 770-790 DEG C, heat preservation is carried out for a certain time to enable the lamellar pearlite to be fused quickly, so that the undissolved carbide particles can promote the transformation of austenite into the spheroidized microscopic structure; the temperature is lowered to 710-730 DEG C, heat preservation is performed for 4-6 hours to enable the fused cementite to gather spherically, and along with the time extension of heat preservation, the rate of spheroidization of the cementite is gradually improved, and the uniformity is gradually improved. A slow three-stage cooling manner is adopted, so that the uniformity of the spheroidized structure is improved. According to the spheroidized annealing process for shortening the annealing cycle of hot rolled wire rods, the following advantages are achieved: the annealing effect is good, the technological process is simple, the annealing cycle is short, the production efficiency is high, and the cost is low. With the adoption of the spheroidized annealing process provided by the invention, the processed wire rods of fasteners are uniform in metallographic structure, high in toughness, high in malleability, low in harness, are suitable for subsequent moulding and processing forming, and the products are low in cold-forming cracking rate.

Owner:XINGTAI IRON & STEEL

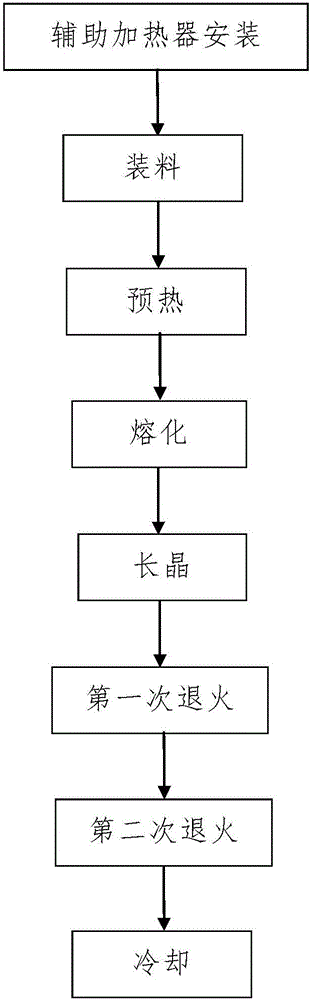

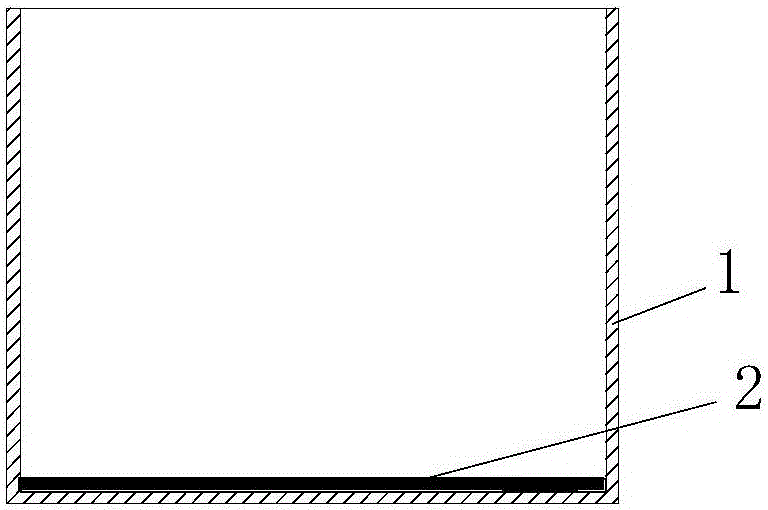

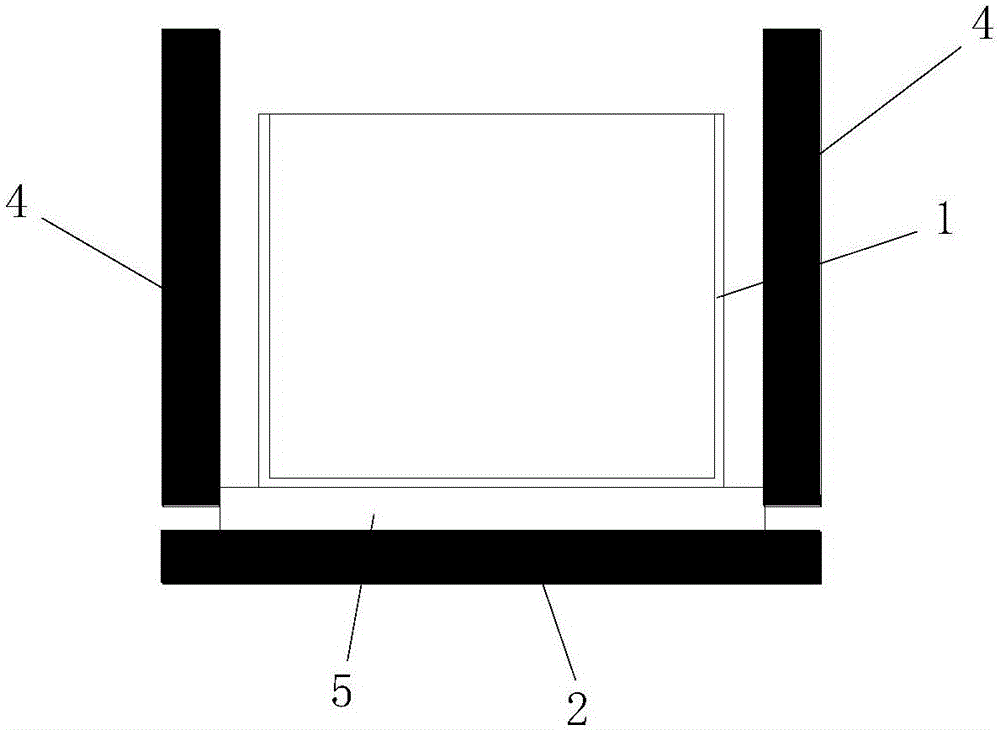

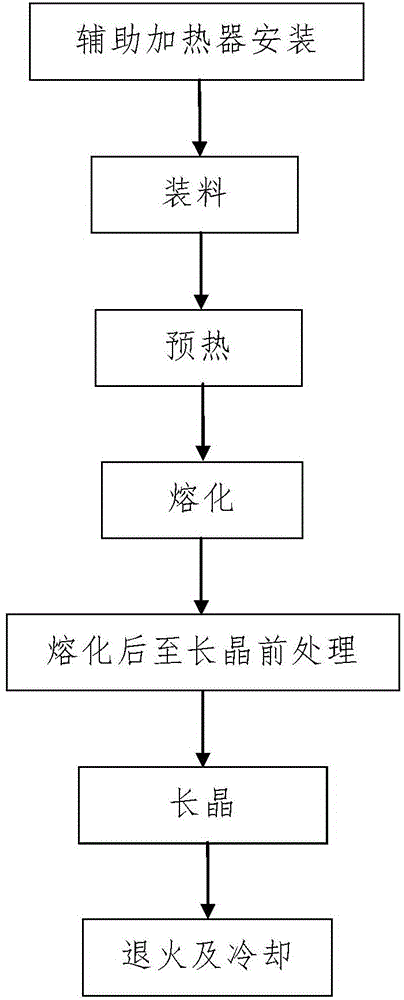

Method for polycrystalline silicon ingot casting

InactiveCN106087053AThe method steps are simpleReasonable designPolycrystalline material growthAfter-treatment detailsCrucibleIngot casting

The invention discloses a method for polycrystalline silicon ingot casting. The method comprises a first step of installation of an auxiliary heater, wherein the auxiliary heater is installed in a polycrystalline silicon ingot furnace, the auxiliary heater is a bottom heater below a crucible, and the auxiliary heater forms a six-side heating device together with a top heater and four side heaters; a second step of charging; a third step of preheating; a fourth step of melting: six-side heating melting, fifth-side heating melting and follow-up melting; a fifth step of crystal growth; a sixth step of annealing and cooling which comprise primary annealing, secondary annealing and cooling, wherein during the primary annealing, the heating temperature of the polycrystalline silicon ingot furnace is reduced to T4 and heat insulation is performed for 2-3 h, and T4=1250-1280 DEG C; during the secondary annealing, the heating temperature of the polycrystalline silicon ingot furnace is reduced to T5 and heat insulation is performed for 2-3 h, and T5=900-950 DEG C. The method is simple in steps, reasonable in design, convenient to implement and good in using effect. The six-side heating device is adopted for heating, the oxygen content of the bottom of the crucible can be effectively reduced; the annealing process is adjusted, and the quality of a finished ingot can be effectively improved.

Owner:XIAN HUAJING ELECTRONICS TECH

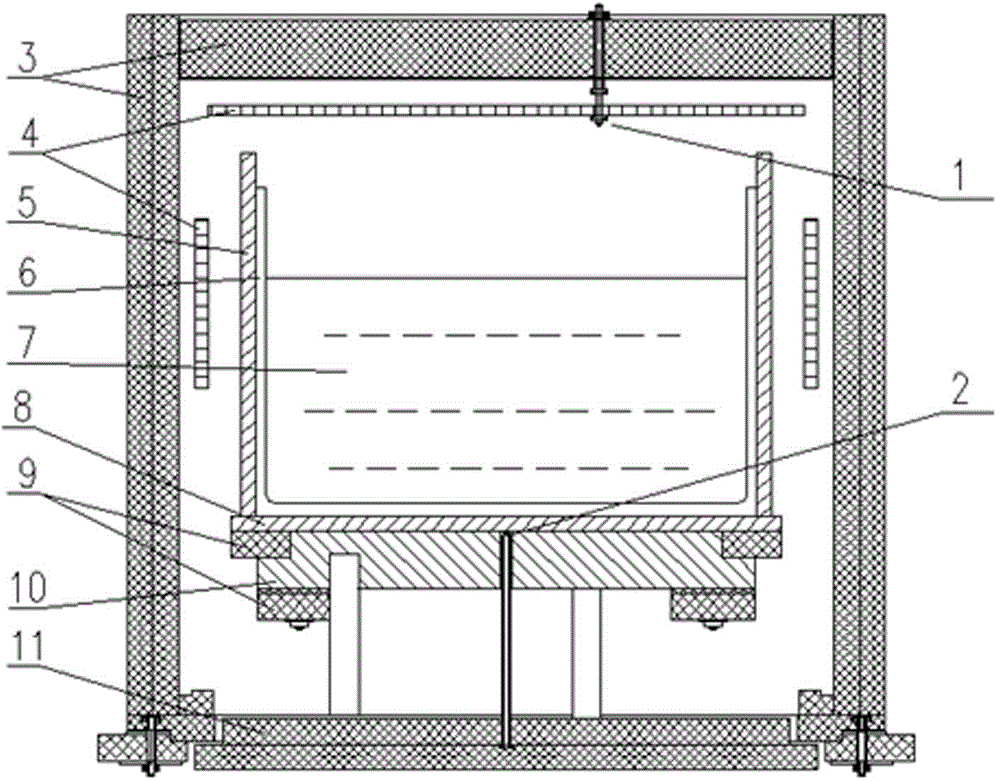

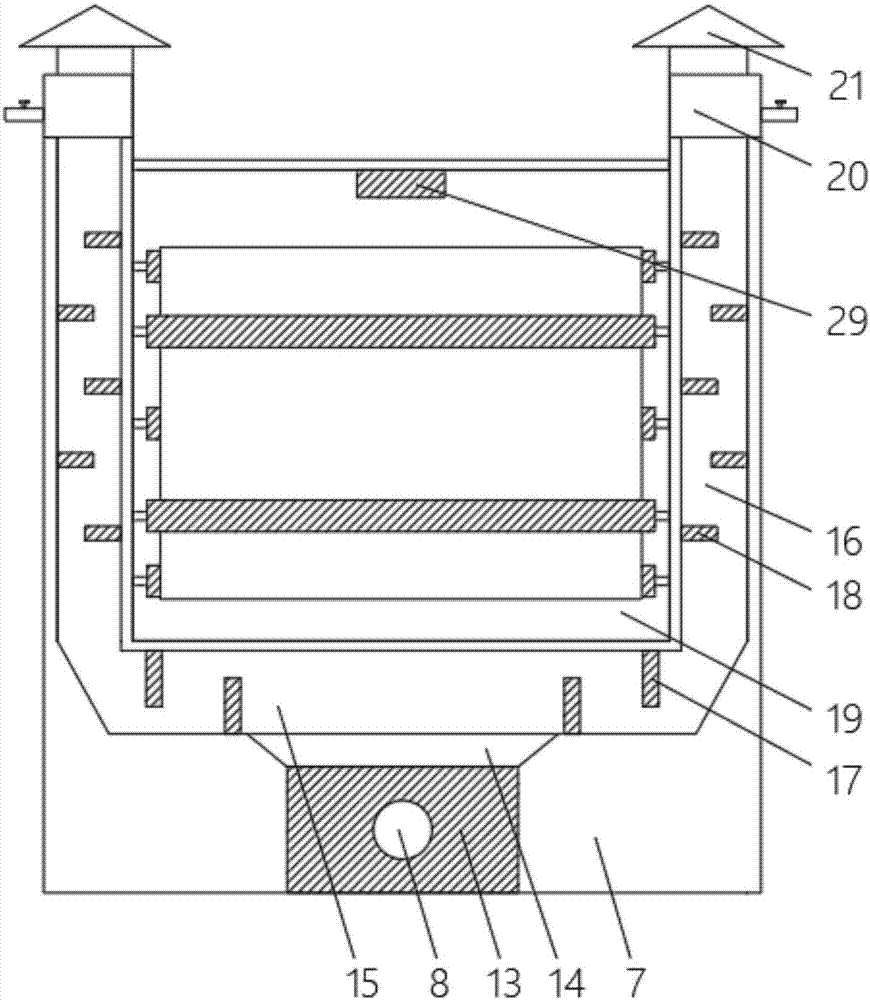

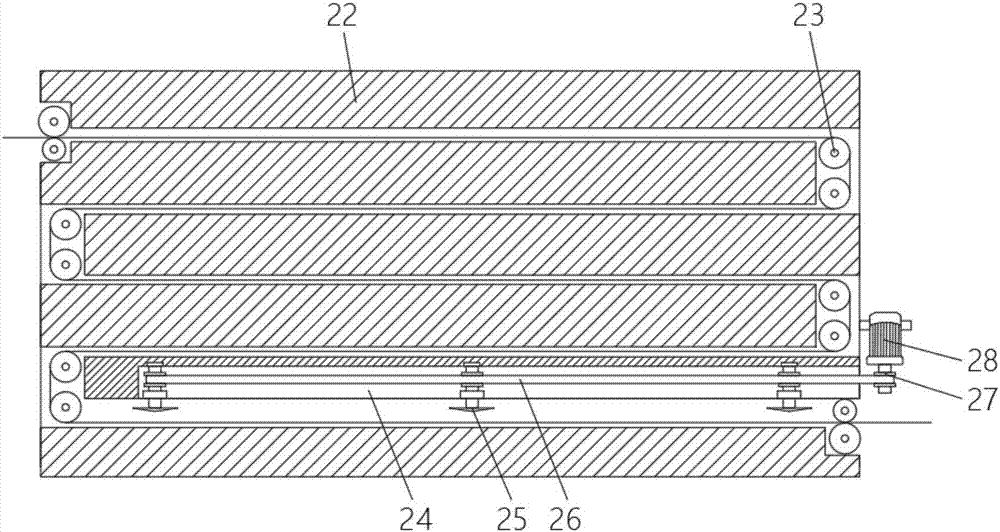

Glass product annealing furnace

InactiveCN102795764BMulti-heating timeReduce cooling rateGlass productionCombustion chamberMetallurgy

The invention discloses a glass product annealing furnace capable of balancing the heated quantities of the direct heated surface and the indirect heated surface of a glass product while passing through the furnace chamber. The glass product annealing furnace comprises a frame, and a furnace body arranged on the frame, wherein a combustion chamber and a furnace chamber located above the combustion chamber are arranged in the furnace body; a furnace body inlet and a furnace body outlet are formed at the two ends of the furnace body, respectively; a smoke discharge channel communicated with the furnace chamber is formed to penetrate through the top of the furnace body; a thermal insulating channel which is encircled by a thermal insulating layer made of a thermal insulating material and which is communicated with the furnace chamber is further arranged in the furnace body; the distance between the sidewall of the furnace chamber at the side in the vicinity of the thermal insulating channel and the furnace body inlet is larger than that between the sidewall of the combustion chamber at the side in the vicinity of the thermal insulating channel and the furnace body inlet; the smoke discharge channel is arranged close to the sidewall of the furnace chamber at the side in the vicinity of the thermal insulating channel; and a conveying device for conveying the glass products is arranged on the frame. The glass product annealing furnace is especially suitable for eliminating internal stress generated in the manufacture process of various hollow glass products (such as glass bottles).

Owner:ZHANGJIAGANG JUNFENG GLASS PRODS

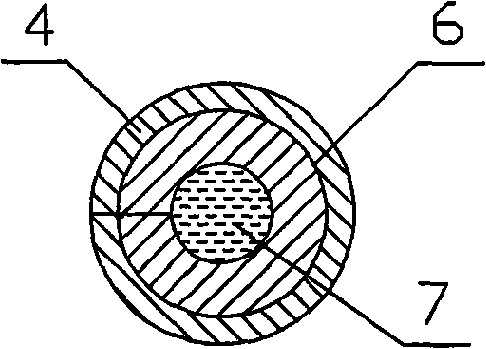

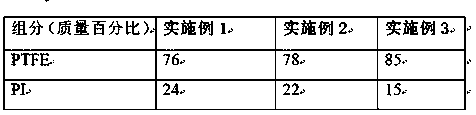

PTFE compound piston ring and preparation method thereof

InactiveCN109593307AHigh hardnessHigh impact strengthPositive displacement pump componentsPositive-displacement liquid enginesPolymer scienceFlexural strength

The invention discloses a PTFE compound piston ring. The piston ring is characterized by being prepared from a PTFE compound material which is prepared from 76-85 percent of PTFE and 15-24 percent ofPI in percentage by mass. The invention further discloses a preparation method of the PTFE compound piston ring. Polyimide PI is a heat-resistant polymer material with stable aromatic heterocycle structural unit, has remarkable thermal stability, has the glass state temperature Tg of 260 DEG C or above, can endure the high temperature of 250-400 DEG C, has excellent mechanical performance, radiation resistance and solvent resistance, has good frictional wear performance in high-temperature, high / low-pressure, high-speed and other extreme environments. The hardness, impact strength and bendingstrength of the compound material can be improved after the PI is added into PTFE, the comprehensive mechanical performance can be promoted, toughness of PTFE substrate resin can be assisted due to acertain amount of PI, and the crack propagation and toughening performance of PTFE can be improved.

Owner:NANJING COMPTECH COMPOSITES CORP +1

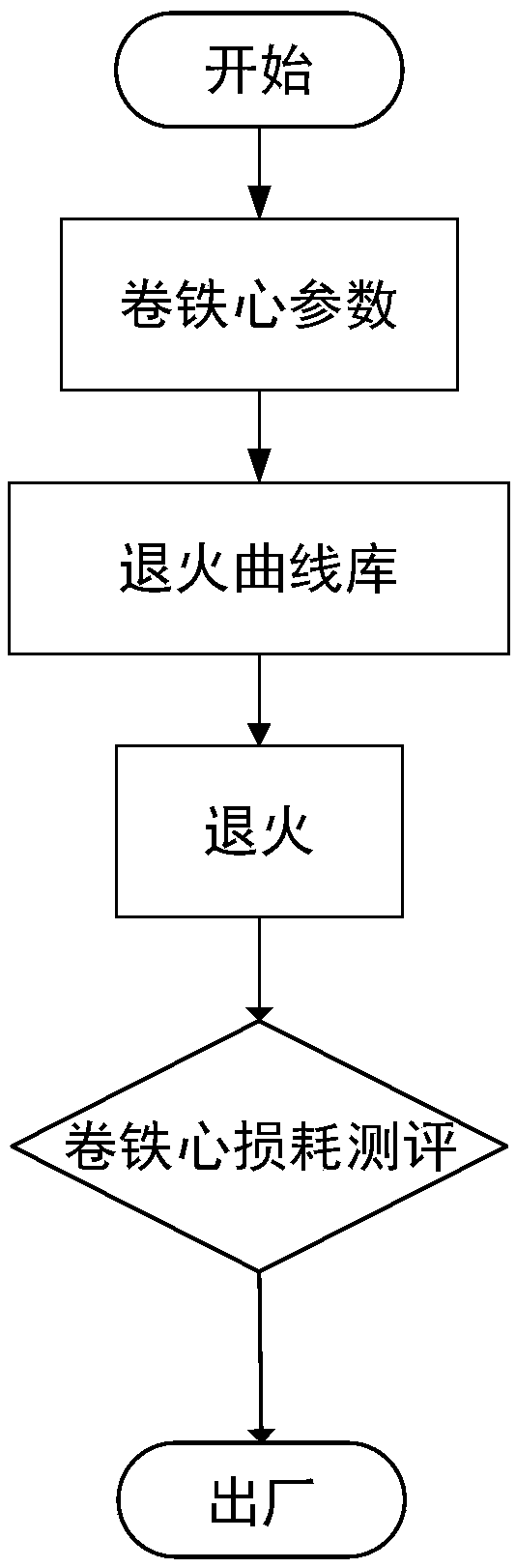

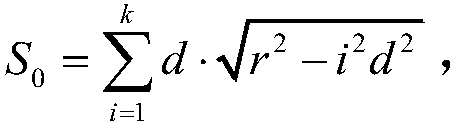

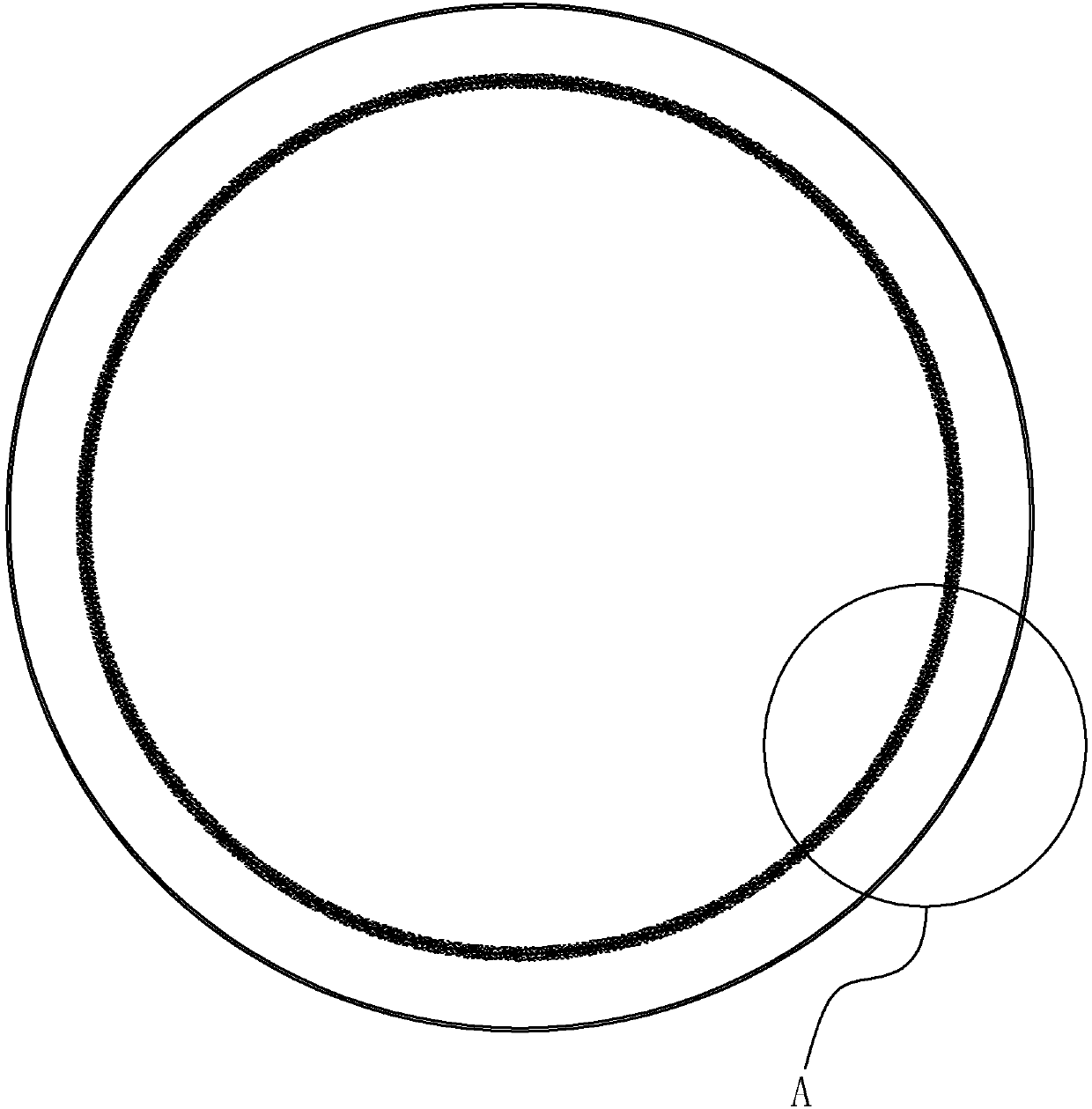

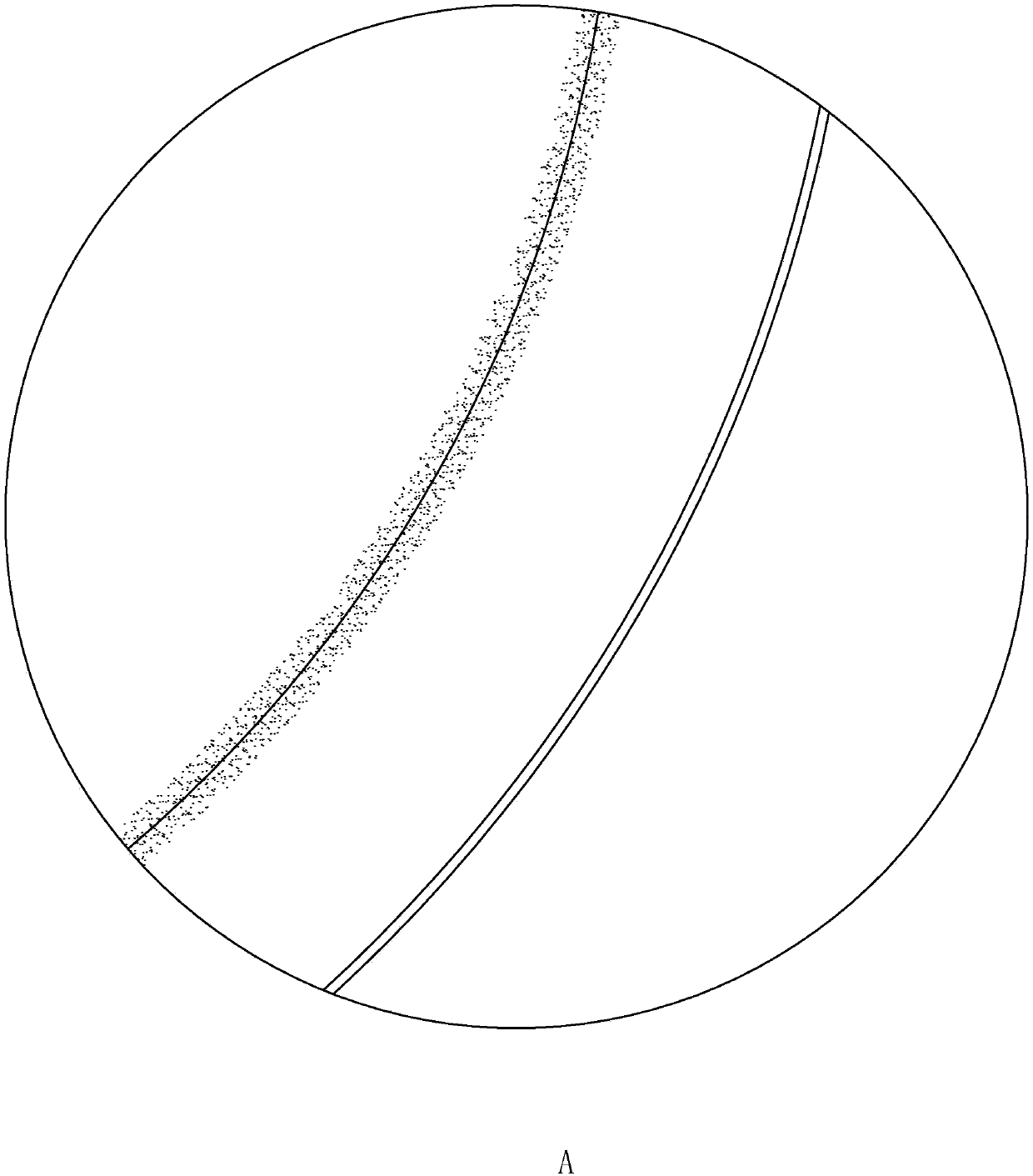

Method for evaluating annealing effect of large-size wound iron core

ActiveCN108693418AEvaluation of annealing effectImprove the annealing effectElectrical testingElectrical resistance and conductanceEvaluation result

The invention discloses a method for evaluating the annealing effect of a large-size wound iron core. The method comprises the steps: carrying out the annealing of different types of wound iron cores,and measuring the no-load loss of the wound iron cores after annealing; deducing a resistance definition equation of a silicon steel strip in a winding direction based on the length of a winding pathand sections of the iron cores, and calculating a theoretical power value; finally comparing an experiment value and a theoretical value, and judging the annealing technical effect of the iron cores.The method can achieve the effective evaluation of the annealing effect of the iron cores, can achieve the further improvement of the existing annealing technology according to an evaluation result,facilitates the improvement of the annealing technology of the iron cores, and improves the energy-saving effect of a transformer.

Owner:SOUTHWEST JIAOTONG UNIV

Carbon-doped titanium sapphire crystal and its growing method and application

ActiveCN102851737AImprove the annealing effectReduce dislocationPolycrystalline material growthFrom frozen solutionsCrucibleRoom temperature

The invention relates to a carbon-doped titanium sapphire crystal and its growing method and application. The growing method includes adding 1,000-10,000 ppm graphite powder in the titanium sapphire raw material, performing growth of the carbon-doped titanium sapphire crystal by Bridgman-Stockbarger method, and performing in situ annealing on the grown crystal at 1,700-1,900 DEG C. for 40-56 h; and cooling the crystal after annealing at a slow rate of 15-30 DEG C. / h to room temperature. The inventive carbon-doped titanium sapphire crystal has residual infrared absorption coefficient reduced to 0.01-0.001 cm<-1> at normal temperature of 25 DEG C., quality factor FOM of more than 200, and high optical uniformity, and is applied to solid tunable laser.

Owner:JIANGSU XIEXIN SILICON MATERIAL TECH DEV

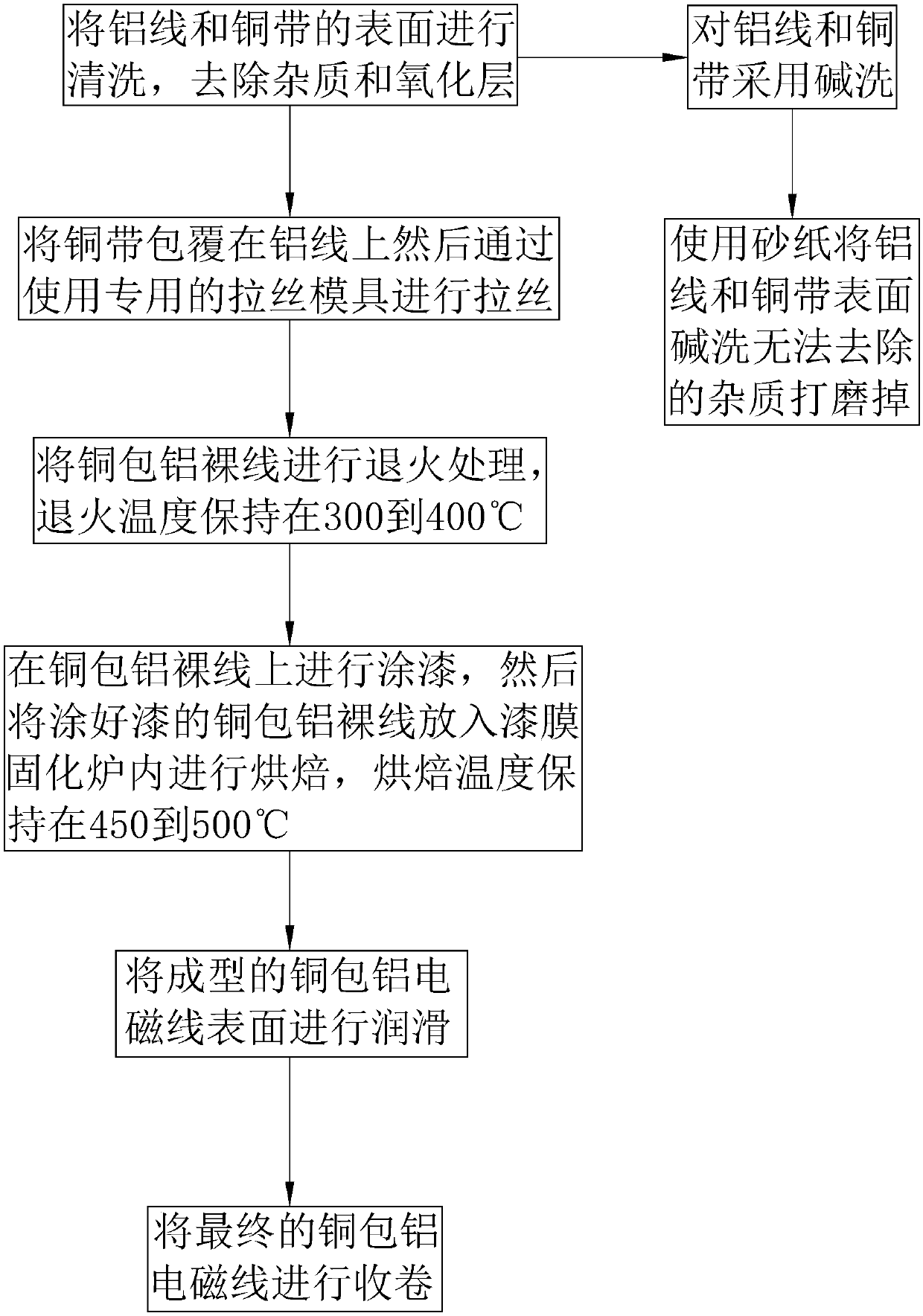

Production process of class 200 copper-clad aluminum electromagnetic wire

InactiveCN108597687AImprove bindingImprove toughnessManufacturing extensible conductors/cablesInsulating conductors/cablesCopperToughness

The invention discloses a production process of a class 200 copper-clad aluminum electromagnetic wire, belonging to the field of copper-clad aluminum electromagnetic wires, and the technical proposalthereof comprises the following steps of: cleaning the surfaces of the aluminum wire and the copper strip to remove impurities and an oxide layer; coating the copper strip on the aluminum wire and then drawing by using a special wire drawing die; annealing the copper-clad aluminum bare wire, maintaining the annealing temperature at 300 to 400 degrees centigrade; painting the copper-clad aluminum bare wire to ensure uniform painting, placing the painted copper-clad aluminum bare wire in the film curing oven for baking, and maintaining the baking temperature at 450 to 500 degrees centigrade; lubricating the surface of the formed copper-clad aluminum electromagnetic wire to make the surface of the copper-clad aluminum electromagnetic wire smooth and uniform in thickness; and winding up the final copper-clad aluminum magnet wire, thereby solving the problem that it is difficult to select a suitable temperature in the production process of the copper-clad aluminum magnet wire, and improvingthe quality of the copper-clad aluminum magnet wire, so that the connection between copper and aluminum is tight and the toughness is good.

Owner:天津精达漆包线有限公司

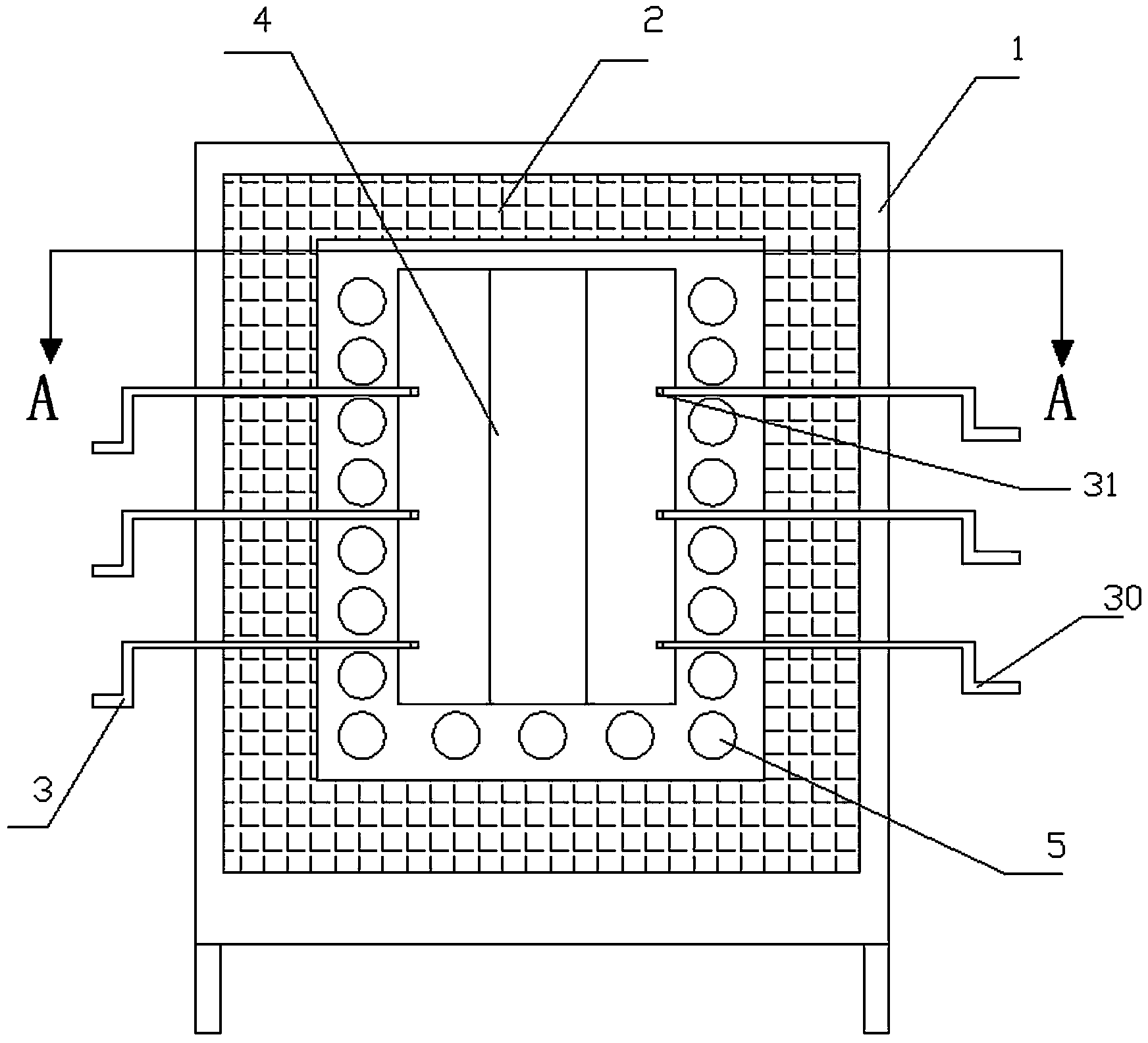

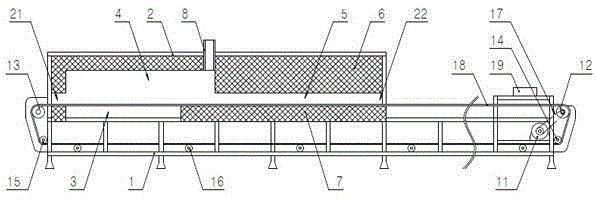

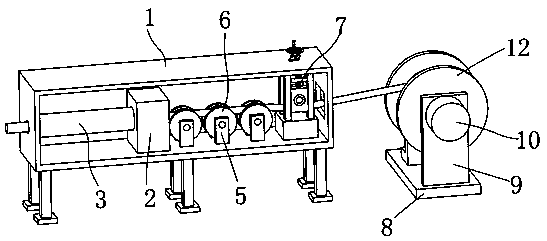

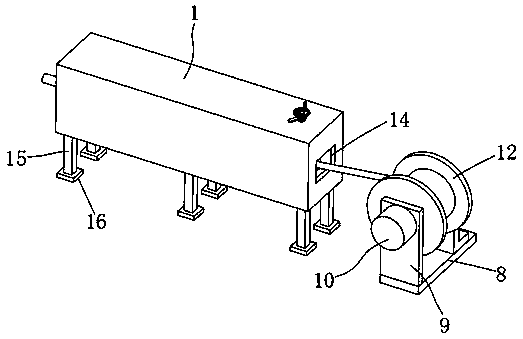

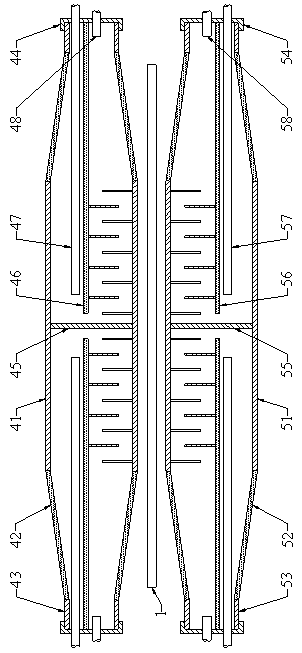

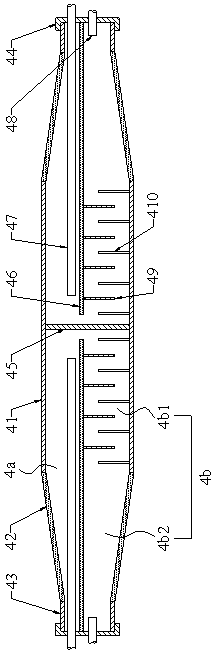

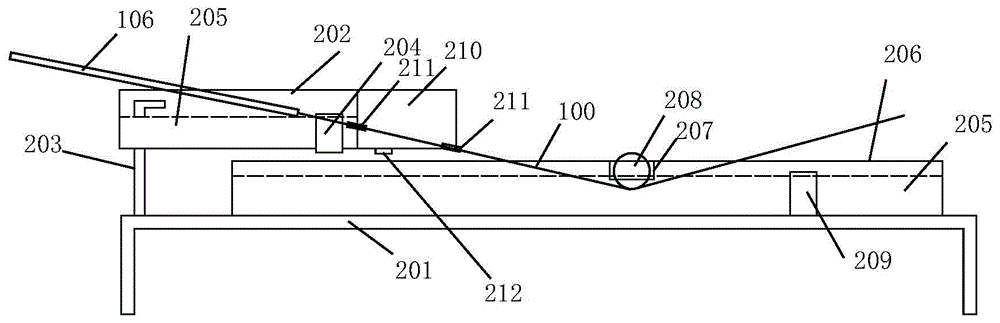

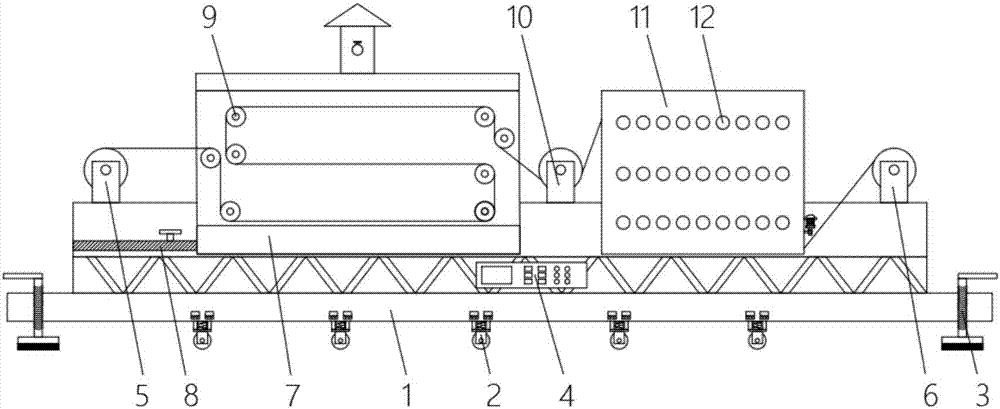

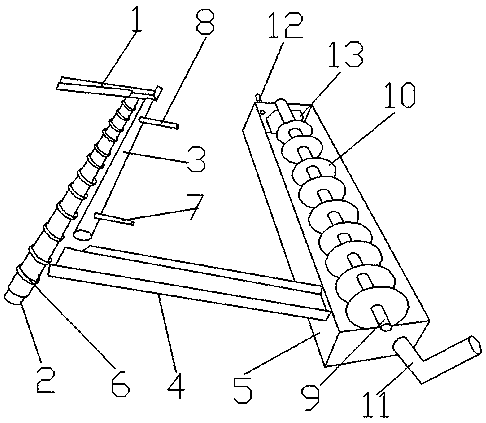

Annealing and drawing device for oxygen-free copper tube, with high diameter-to-thickness ratio, for mobile phone heat pipe

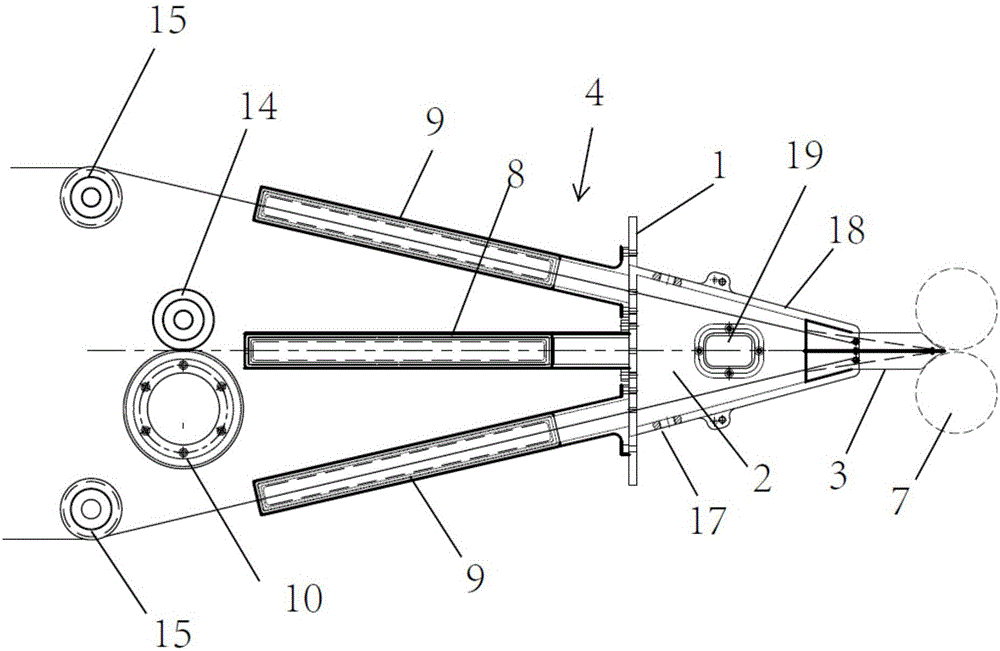

PendingCN110227731AImprove the annealing effectReduce volumeExtrusion profiling toolsFurnace typesMobile phoneMaterials science

The invention discloses an annealing and drawing device for an oxygen-free copper tube, with high diameter-to-thickness ratio, for a mobile phone heat pipe. The annealing and drawing device comprisesa box body; a drawing die is mounted in the box body; an annealing pipe is mounted between the drawing die and the box body; a heating wire is wound around the side wall of the annealing pipe; a fixing plate is arranged on one side of the drawing die; a supporting roller is rotationally connected onto the fixing plate; a tension adjusting mechanism is arranged on one side of the supporting roller;a mounting plate is arranged on the outer side of one end, close to the tension adjusting mechanism, of the box body; the mounting plate is mounted on the ground; a supporting frame is fixed to one side of the upper end of the mounting plate; a servo motor is fixed to the upper end of the supporting frame; a rotating shaft is fixed to the end part of an output shaft of the servo motor; a windingwheel is in keyed connection onto the rotating shaft; and a supporting mechanism is arranged at one end, far from the servo motor, of the rotating shaft. Through the adoption of the structure, the oxygen-free copper tube for the mobile phone heat pipe is uniform in annealing, and uniform in drawing traction, and the production quality of a rope is improved.

Owner:JIANGXI NAILE COPPER IND

Special annealing kiln for producing float glass

ActiveCN108483882ADoes not affect continuous productionNot easy to bendGlass productionTemperature differenceKiln

The invention relates to a special annealing kiln for producing float glass. The special annealing kiln comprises a kiln body, wherein an inlet for the float glass to enter is formed in one side of the kiln body; a plurality of upper heat insulation boards are fixedly arranged inside the kiln body; the upper part of the kiln body is divided into a plurality of upper annealing regions by the upperheat insulation boards; lower heat insulation boards are arranged under the upper heat insulation boards; the lower part of the kiln body is divided into a plurality of lower annealing regions by thelower heat insulation boards; a wind screen mechanism is arranged outside the inlet; an upper cooling mechanism is arranged in each upper annealing region; a lower cooling mechanism is arranged in each lower annealing region. According to the special annealing kiln for producing the float glass, a wind curtain wall is formed by the wind screen mechanism arranged on the outer side of the inlet of the kiln body and is used for stopping external heat from entering the annealing kiln, so that the annealing effect is ensured, the operation is facilitated and the influence on continuous production of the float glass is avoided; by matching the upper cooling mechanisms with the lower cooling mechanisms, temperature difference between the side part and the middle part of the float glass is reduced, and the annealed float glass is not easy to bend.

Owner:TG ANHUI GLASS

Annealing process for improving mechanical property of glass

InactiveCN109879589AImprove mechanical propertiesImprove the annealing effectMechanical propertyGlass forming

The invention discloses an annealing process for improving mechanical property of glass. The annealing process includes the following steps that firstly, freshly formed glass is subjected to primary annealing; secondly, the glass after primary annealing is quickly cooled; thirdly, the glass after primary annealing is slowly cooled; fourthly, then the glass obtained by primary annealing is slowly heated to the optimal annealing temperature to be subjected to secondary annealing, and secondary annealing is conducted for 3 minutes by adopting the optimal temperature and for 3 minutes by adoptingthe lowest temperature; fifthly, the glass after secondary annealing is subjected to important cooling, and permanent stress is prevented from producing inside the glass; and sixthly, then the glass after important cooling is quickly cooled, and thus the finished glass is obtained. According to the annealing process for improving the mechanical property of the glass, the annealing effect of the glass is improved, the content of residual stress inside the glass after forming is decreased, meanwhile, the permanent stress after forming of the glass is reduced to the minimum, and thus the mechanical property of the glass after forming is improved, so that the glass is more stable.

Owner:安徽晶晶玻璃制品有限公司

Annealing technique of cast polycrystalline silicon

InactiveCN104695014ASmall temperature differenceReduce thermal stressPolycrystalline material growthAfter-treatment detailsCrucibleIngot casting

The invention relates to an annealing technique of cast polycrystalline silicon, which uses a polycrystalline silicon ingot casting furnace, wherein the polycrystalline silicon ingot casting furnace comprises a heat insulation cage and a heat insulation base plate arranged below the heat insulation cage, a crucible is arranged in the heat insulation cage, and the external surface of the bottom of the crucible is provided with a graphite base plate. After the polycrystalline silicon growth step in the crucible, the height of the heat insulation cage or heat insulation base plate is lowered or enhanced to adjust the distance between the heat insulation cage and heat insulation base plate, so that the temperature in the crucible drops at the rate of 0.5-5 DEG C / minute, and the crucible bottom temperature fluctuation does not exceed 50 DEG C; and when the difference between the temperature in the crucible and the temperature of the crucible bottom is within 50 DEG C, the annealing is completed. The crucible bottom temperature is the temperature below the crucible bottom graphite protecting sheet. The technique reduces the back diffusion of impurities, greatly enhances the yield of the silicon bulk, and saves the energy consumption.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

Aluminum wire straightening method of enamelling machine annealing furnace and mechanism of enamelling machine annealing furnace

InactiveCN104021884AGood collimationUniform annealingInsulating conductors/cablesMetallurgyCooling effect

The invention discloses an aluminum wire straightening method of an enamelling machine annealing furnace and a mechanism of the enamelling machine annealing furnace. The method comprises the following step of straightening an aluminum wire in an annealing furnace body by bypassing more than two straightening wheels sequentially, thereby improving the straightness of an enamelled wire after annealing. According to the invention, the straightness of the aluminum wire can be improved effectively; the problem of naked aluminum lead surface scratch caused by poor straightness is solved; the product performance is improved; additionally, the cooling effect in the annealing working procedure is ideal, and the quality problem of instability of paint membrane continuity, breakdown voltage and the like which are troubled for a long time in the aluminum enamelling wire manufacturing industry is solved. Meanwhile, the aluminum wire straightening method of the enamelling machine annealing furnace and the mechanism of of the enamelling machine annealing furnace are simple in structure, low in cost and suitable for industrialization.

Owner:张亚东

Polycrystalline silicon ingot casting technology

InactiveCN106283182ASimple stepsReasonable designPolycrystalline material growthAfter-treatment detailsCrucibleIngot casting

The invention discloses a polycrystalline silicon ingot casting technology. The technology comprises the following steps of 1 auxiliary heater installing, wherein an auxiliary heater is installed in a polycrystalline silicon ingot casting furnace and is a bottom heater arranged under a crucible; 2 charging; 3 preheating; 4 melting, wherein the process comprises the following steps of six-side heating melting, five-side heating melting and follow-up melting; 5 crystal growing pretreating after melting, wherein the process comprises the steps of temperature decreasing and temperature increasing; 6 crystal growing; 7 annealing and cooling, wherein after the crystal growing process in the step 6 is completed, annealing and cooling are conducted, and processed and formed polycrystalline silicon ingots are obtained. The technology is simple in step, reasonable in design, easy and convenient to achieve and good in using effect, heating is conducted by adopting a six-side heating device, and by adding the step of conducting crystal growing pretreating after melting and regulating a crystal growing process, the grain size can be effectively decreased, and the quality of the finished ingots is improved.

Owner:XIAN HUAJING ELECTRONICS TECH

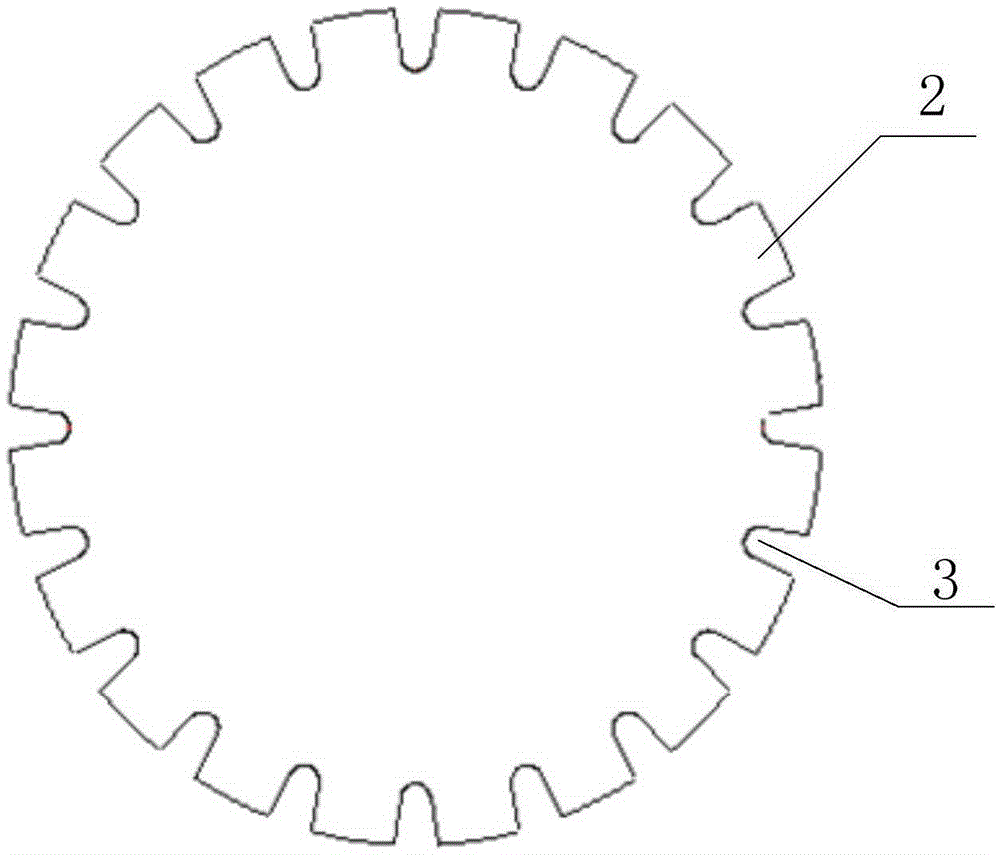

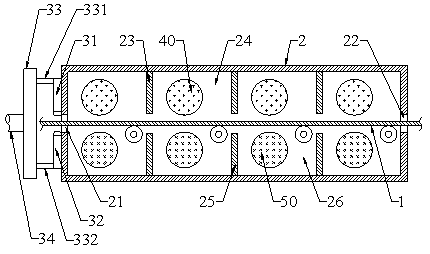

Lateral composite position guide device for three-layer composite material

ActiveCN106180179AReduce mutual interferenceReduce difficultyGuiding/positioning/aligning arrangementsFurnace typesComposite PositionEngineering

The invention discloses a lateral composite position guide device for a three-layer composite material. The lateral composite position guide device comprises a composite body, wherein a cavity is formed in the composite body; a wire guide nozzle is arranged on one side of the composite body, and a plurality of wire feeding rails are arranged on the other side of the composite body; a cavity penetrates through a wire guide channel of the wire guide nozzle and wire feeding channels of the wire feeding rails; a plurality of guide arrangement assemblies are arranged in the wire guide channel of the wire guide nozzle; and a composite rolling part is arranged on one side of the wire discharging end of the wire guide nozzle. The lateral composite position guide device is reasonable in design and compact in structure, can quickly enable three strips to be laterally and closely attached together, and can provide a basis for subsequent machining.

Owner:SUZHOU CHUANGHAO NEW MATERIAL TECH CO LTD

Perovskite light absorption layer thin film, preparation method thereof and solar cell using perovskite light absorption layer thin film

PendingCN111063804ASimple preparation processRaw materials are easy to getFinal product manufactureSolid-state devicesOrganic solventPhysical chemistry

The invention provides a perovskite light absorption layer thin film, a preparation method thereof and a solar cell using the perovskite light absorption layer thin film. The preparation method comprises the steps of taking haloid acid as an additive, and preparing the perovskite light absorption layer thin film. According to the method for preparing the perovskite light absorption layer thin film, haloid acid is used as an additive, so that the annealing temperature in the preparation process of the perovskite light absorption layer thin film is greatly reduced; the preparation raw materialsare easy to obtain; the preparation process is simple; a large amount of organic solvents harmful to the environment are prevented from being used; operation under high-temperature and high-pressure or vacuum conditions is avoided; and the solar cell prepared from the perovskite light absorption layer thin film has relatively good energy conversion efficiency.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

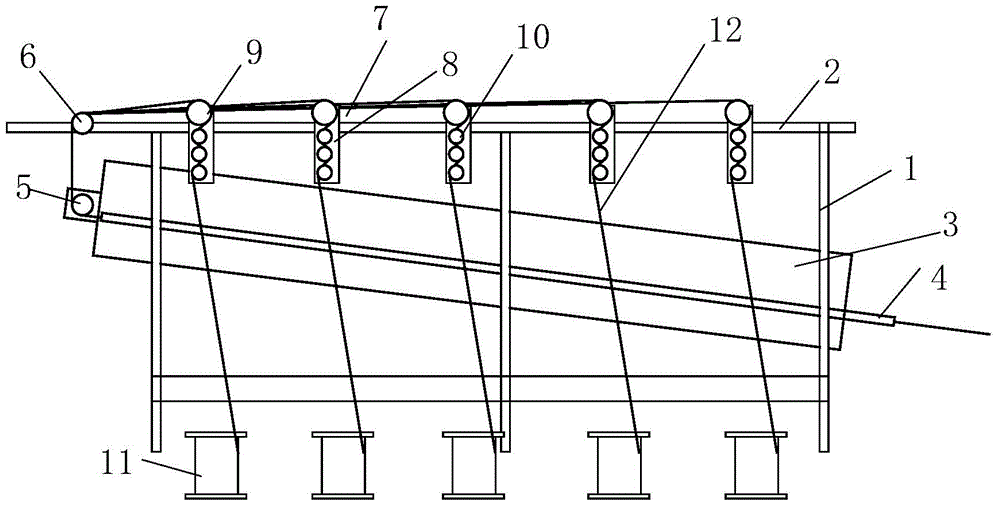

Continuous annealing apparatus and annealing method of titanium and titanium alloy coiled wire material

ActiveCN103469134AContinuous annealingUniform annealingFurnace typesHeat treatment furnacesTitaniumHeating furnace

The invention provides a continuous annealing apparatus and an annealing method of titanium and titanium alloy coiled wire material. The continuous annealing apparatus of titanium and titanium alloy coiled wire material comprises a heating mechanism and a continuous conveying mechanism, wherein, the heating mechanism comprises a box type heating furnace, and the continuous conveying mechanism comprises an internally fixed steel pipe of a wire material furnace, two sets of fixed pulleys and a continuous multiple winding wire rotating mechanism; the internally fixed steel pipe of the wire material furnace is equipped in the box type heating furnace, and the two sets of fixed pulleys are respectively arranged at two ends of the box type heating furnace, and are kept at the same horizontal line of the center line of the internally fixed steel pipe of the wire material furnace. The processed wire materials cross the heating furnace at a uniform speed, can be continuously and multiply wound, thereby realizing continuous and uniform annealing of wire materials with simple structure and good working reliability. The annealing method provided by the invention can be used for continuous and uniform constant temperature heating of single wire material, and during the moving process of wire material, the speed is constant, the heating is uniform, and the obtained wire material has uniform performance.

Owner:西安赛特思迈钛业有限公司

Annealing system and method for welded rotors

ActiveCN111020164AReduce local internal stressGuaranteed heating qualityFurnace typesHeat treatment process controlMechanical engineeringMaterials science

The invention puts forward an annealing system and method for welded rotors. The annealing system comprises multiple heating devices and multiple temperature measuring devices; the multiple heating devices are arranged on multiple heating zones of the welded rotors; the multiple temperature measuring devices are arranged on the multiple heating zones of the welded rotors and are connected with themultiple heating devices; and the annealing temperatures of the multiple heating zones are different. By the aid of the annealing system for the welded rotors, manual operations can be reduced, and the heating quality is stable.

Owner:SHANGHAI ELECTRIC POWER GENERATION EQUIPMENT CO LTD

Protective gas for annealing of metal materials

InactiveCN102181618AReasonable formulaEasy to prepareHydrogen productionMetalCarbon Dioxide / Helium

The invention discloses protective gas for the annealing of metal materials. In the protective gas, mixed gas comprises 75 percent of hydrogen and 25 percent of nitrogen, and a ratio of the mixed gas containing the hydrogen and the nitrogen is appropriate; and the protective gas is easy and convenient to prepare and high in quality after annealing.

Owner:TIANJIN YIBO STEEL MAKING

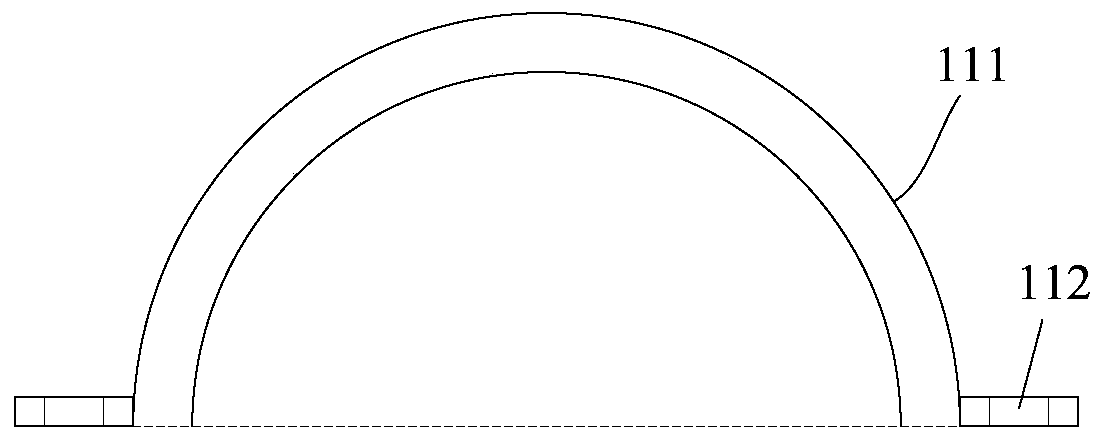

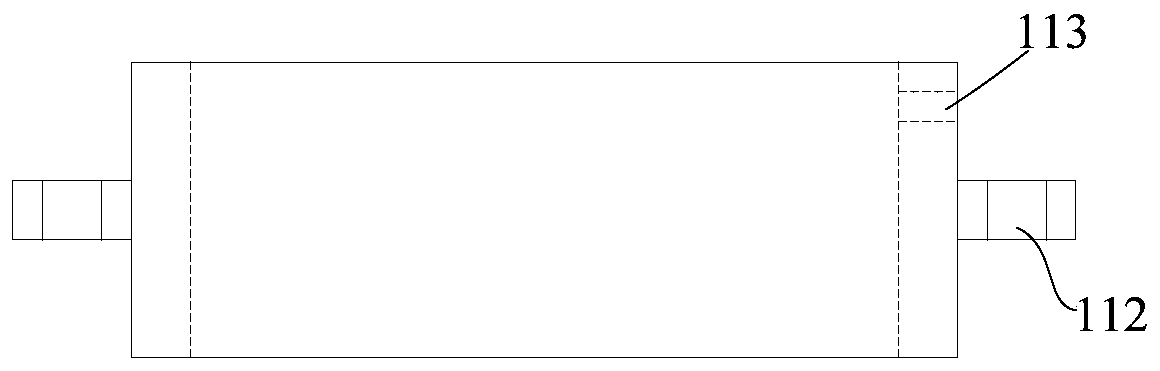

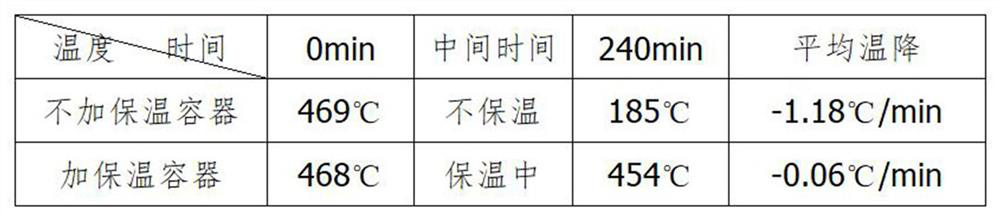

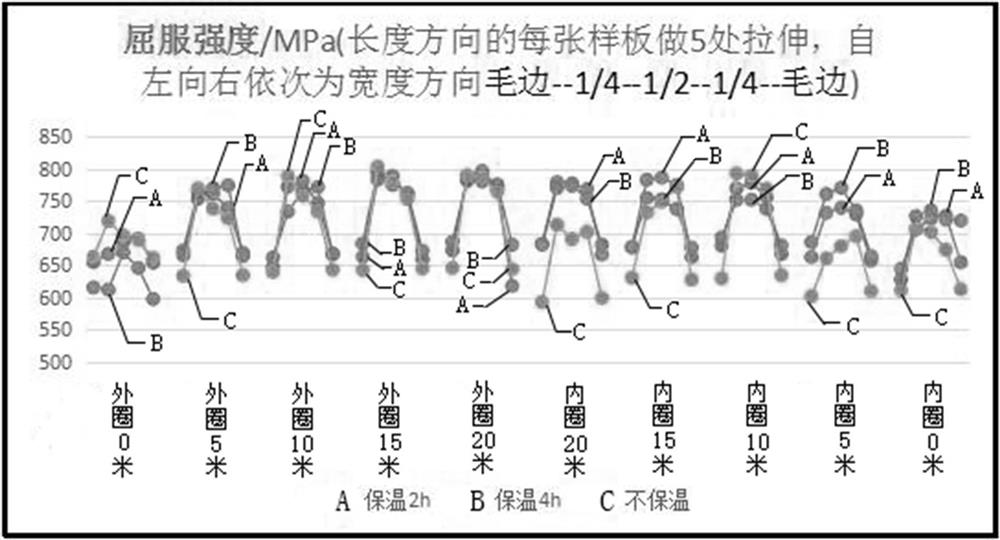

Method for improving performance uniformity of finished product through heat preservation and slow cooling after rolling

InactiveCN112063815AUniform temperatureAchieving uniformity of performanceFurnace typesHeat treatment furnacesShielding gasHeat conservation

The invention discloses a method for improving the performance uniformity of a finished product through heat preservation and slow cooling after rolling, which is used for a hot-rolled coil heat preservation cover device. The method comprises the following steps of: loading a produced steel coil onto the hot-rolled coil heat preservation cover device, and performing sealing treatment; starting aninternal ventilation device, and discharging high-temperature gas in a semicircular heat preservation cover; starting a gas protection device, and filling the semicircular heat preservation cover withprotective gas; starting an electric heating device, forming a heat preservation atmosphere in the semicircular heat preservation cover by utilizing residual heat of the steel coil, then waiting forthe own heat of the steel coil to dissipate, slowly cooling, checking the change of gas temperature in the semicircular heat preservation cover detected by a thermocouple, and finishing the heat treatment operation of the steel coil when the gas temperature value meets the production standard requirement; and loading the treated steel coil from the hot-rolled coil heat preservation cover device. The method has the beneficial effects that the performance uniformity of the finished product is effectively improved, the operation process is simple, the input cost is extremely low, and the actual effect is relatively good.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD

Martensitic stainless steel 2Cr13 wire annealing process

InactiveCN112280942AUniform annealing propertiesUniform metallographic structureFurnace typesHeat treatment process controlWire rodMartensitic stainless steel

The invention discloses a martensitic stainless steel 2Cr13 wire annealing process. The process comprises the following steps of 1, putting a 2Cr13 wire coil into a heat treatment furnace, introducingprotective gas into the heat treatment furnace, then heating the heat treatment furnace to 800-820 DEG C at the heating speed of 80-100 DEG C / h, and maintaining the temperature for 6-10 hours; 2, inthe first cooling stage, cooling the heat treatment furnace to 760-780 DEG C at the cooling speed of 15-20 DEG C / h; 3, in the second cooling stage, cooling the heat treatment furnace to 500 DEG C at the cooling speed of 20-50 DEG C / h; and 4, in the third cooling stage, discharging the 2Cr13 wire coil out of the furnace and naturally cooling the 2Cr13 wire coil to the normal temperature. By means of the martensitic stainless steel 2Cr13 wire annealing process, the martensitic stainless steel 2Cr13 wire can be uniform in annealing performance, and the wire obtained after annealing treatment is uniform in metallographic structure, high in ductility, good in plasticity, low in hardness, lower in tensile strength, better in drawing machining performance and suitable for subsequent plastic machining forming.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Bright annealing unit applied to stainless steel strips

InactiveCN107974552AAffects the elimination of internal stressExtended stayFurnace typesHeat treatment furnacesCombustionAlcohol

The invention discloses a bright annealing unit applied to stainless steel strips. The bright annealing unit comprises a base, wherein a plurality of traveling mechanisms are mounted at the bottom endof the base; braking mechanisms are mounted on two sides of the bottom of the base; a support device is arranged on the upper end of the base; a control panel is mounted on the support device; an uncoiling machine, a heating device, a dragging device, a cooling device and a coiling machine are successively arranged at the upper end of the support device from left to right; an alcohol-based combustion device is mounted at the bottom end of the heating device; the input end of the alcohol-based combustion device is connected with a feeding pipe; the output end of the alcohol-based combustion device is connected with a pipeline; the upper end of the pipeline is connected with a first smoke discharging pipeline. The bright annealing unit applied to stainless steel strips is stable in structure, convenient to operate, high in vibration resistance and convenient to move; the alcohol-based combustion device is adopted; the energy can be saved, and the emission can be reduced; meanwhile, thecooling device is capable of greatly reducing the occupation of the space; the cost can be reduced; a lot of time and energy of workers can be reduced; the bright annealing unit is worthy to be popularized.

Owner:FUQING HUIHUA STAINLESS STEEL PROD

Annealing and cooling device for hot-rolled steel balls

ActiveCN109082518BIncrease discharge temperatureReduce CooldownFurnace typesHeat treatment furnacesSpiral bladeSteel ball

Owner:TONGLING MINGCHENG FOUNDRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com