Martensitic stainless steel 2Cr13 wire annealing process

A martensitic stainless steel and wire rod annealing technology, which is applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of substandard annealing performance, high annealing tensile strength and hardness, etc., and achieve good annealing effect, short annealing cycle, and good Effect of drawing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The martensitic stainless steel 2Cr13 wire rod annealing process of embodiment 1 comprises:

[0028] 1. Place the 2Cr13 wire coil in the heat treatment furnace, fill the heat treatment furnace with industrial nitrogen with a purity of 99.99%, raise the temperature of the heat treatment furnace to 810 °C at a heating rate of 80 °C / h, and keep it for 10 hours;

[0029] 2. In the first stage of cooling, the heat treatment furnace is cooled to 780°C at a cooling rate of 20°C / h by means of cooling fan blowing;

[0030] 3. In the second stage of cooling, cool down the heat treatment furnace at a cooling rate of 45°C / h to 650°C by means of blowing cooling by the cooling fan, turn off the industrial nitrogen, and then continue to cool the heat treatment furnace by blowing the cooling fan at a temperature of 30°C / h The cooling rate of h is lowered to 500°C;

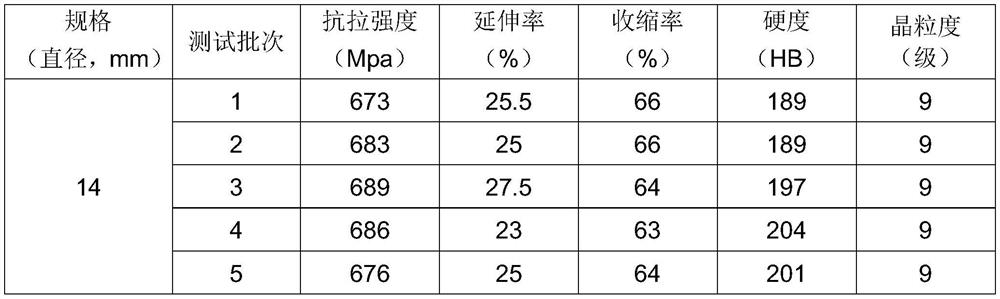

[0031] 4. In the third stage of cooling, the 2Cr13 wire rod is coiled out of the furnace and naturally cooled to room te...

Embodiment 2

[0035] The martensitic stainless steel 2Cr13 wire rod annealing process of embodiment 2 comprises:

[0036] 1. Place the 2Cr13 wire coil in a heat treatment furnace, fill the heat treatment furnace with industrial nitrogen with a purity of 99.99%, raise the temperature of the heat treatment furnace to 820 °C at a heating rate of 100 °C / h, and keep it for 9 hours;

[0037] 2. In the first stage of cooling, the heat treatment furnace is cooled to 770°C at a cooling rate of 15°C / h by means of cooling fan blowing;

[0038] 3. In the second stage of cooling, cool down the heat treatment furnace at a cooling rate of 40°C / h to 650°C by means of blowing cooling by the cooling fan, turn off the industrial nitrogen, and then continue to cool the heat treatment furnace by blowing the cooling fan at a temperature of 20°C / h The cooling rate of h is lowered to 500°C;

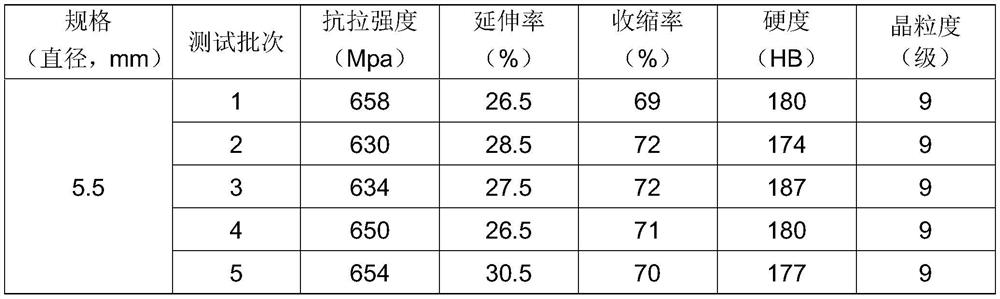

[0039] 4. In the third stage of cooling, the 2Cr13 wire rod is coiled out of the furnace and naturally cooled to room temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com