Preparation method of copper-chromium contact material

A copper-chromium contact and copper powder technology, which is used in contacts, electrical components, circuits, etc., can solve the problems of poor contact resistance welding performance, low contact mechanical strength, and low contact material density. Good material density, good copper infiltration effect, and sufficient capillary action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] First, 10 grams of copper powder and 40 grams of chromium powder were ball milled for 7 hours under vacuum conditions with a vacuum degree of 0.06 MPa to obtain ball milling powder; then 50 grams of copper powder and ball milling powder were added to mix evenly to obtain a mixed powder; Sieve, disperse and place in containers to dry. Press the obtained mixed powder on a 100-ton four-column hydraulic press with a mold diameter of 36 cm and a pressure of 340 MPa for 5 seconds to form a compact; put the compact into a graphite crucible, place a copper sheet on it, and place the compact in a 0.1 Pa vacuum sintering furnace medium sintering. The sintering temperature is 870 degrees centigrade, and the time is 5 hours; the obtained sintered product is further heated to 1200 degrees centigrade in a vacuum sintering furnace for infiltration, and the time is 10 minutes. Vacuum annealing at 600°C for 7 hours to obtain a CuCr30 contact material.

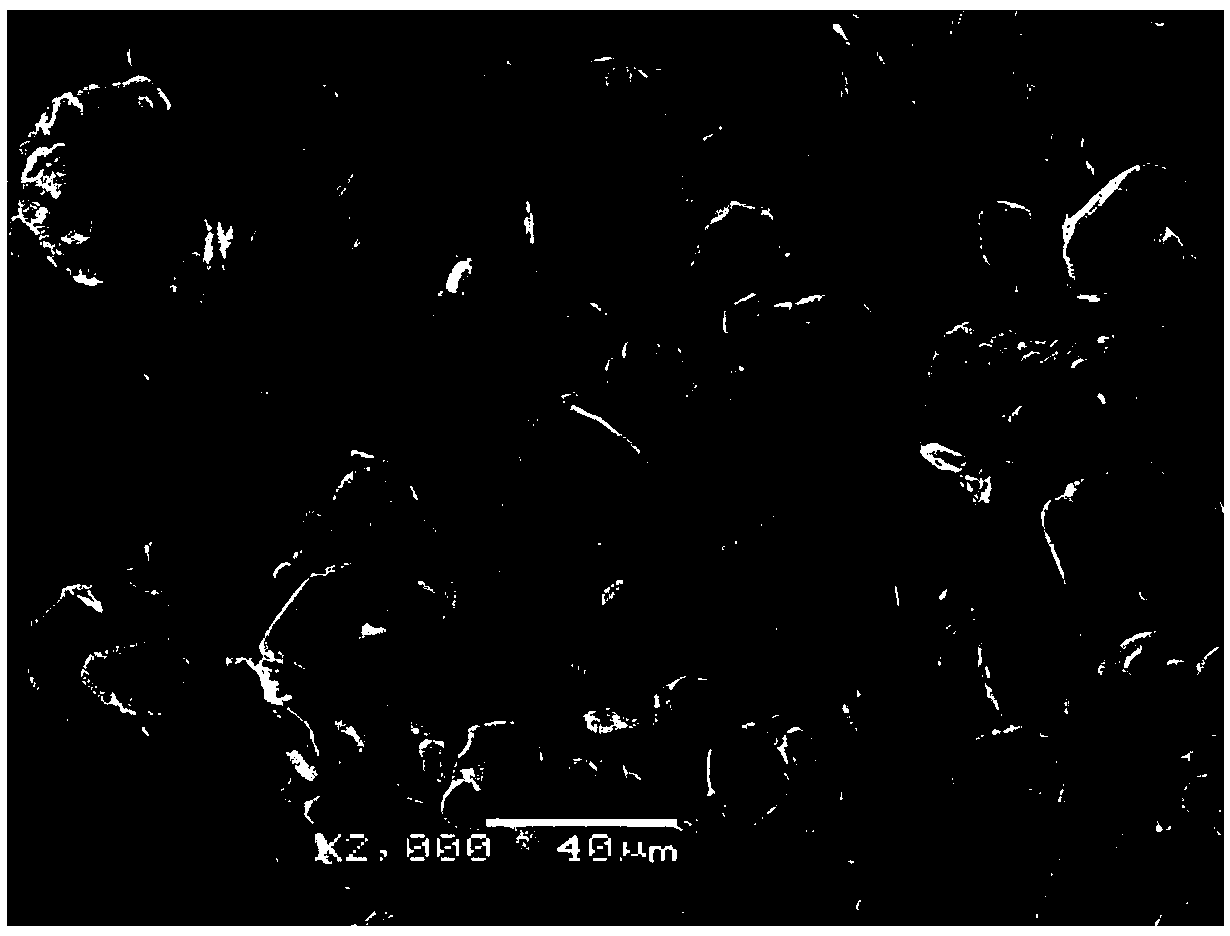

[0032] figure 1 It is a TEM ph...

Embodiment 2

[0034] First, 15 grams of copper powder and 40 grams of chromium powder were ball milled for 7 hours under vacuum conditions with a vacuum degree of 0.06 MPa to obtain ball milling powder; then 45 grams of copper powder and ball milling powder were added to mix evenly to obtain a mixed powder; Sieve, disperse and place in containers to dry. Press the obtained mixed powder on a 100-ton four-column hydraulic press with a mold diameter of 36 cm and a pressure of 340 MPa for 5 seconds to form a compact; put the compact into a graphite crucible, place a copper sheet on it, and place the compact in a 0.1 Pa vacuum sintering furnace medium sintering. The sintering temperature is 870 degrees centigrade, and the time is 5 hours; the obtained sintered product is further heated to 1200 degrees centigrade in a vacuum sintering furnace for infiltration, and the time is 10 minutes. Vacuum annealing at 600°C for 7 hours to obtain a CuCr30 contact material.

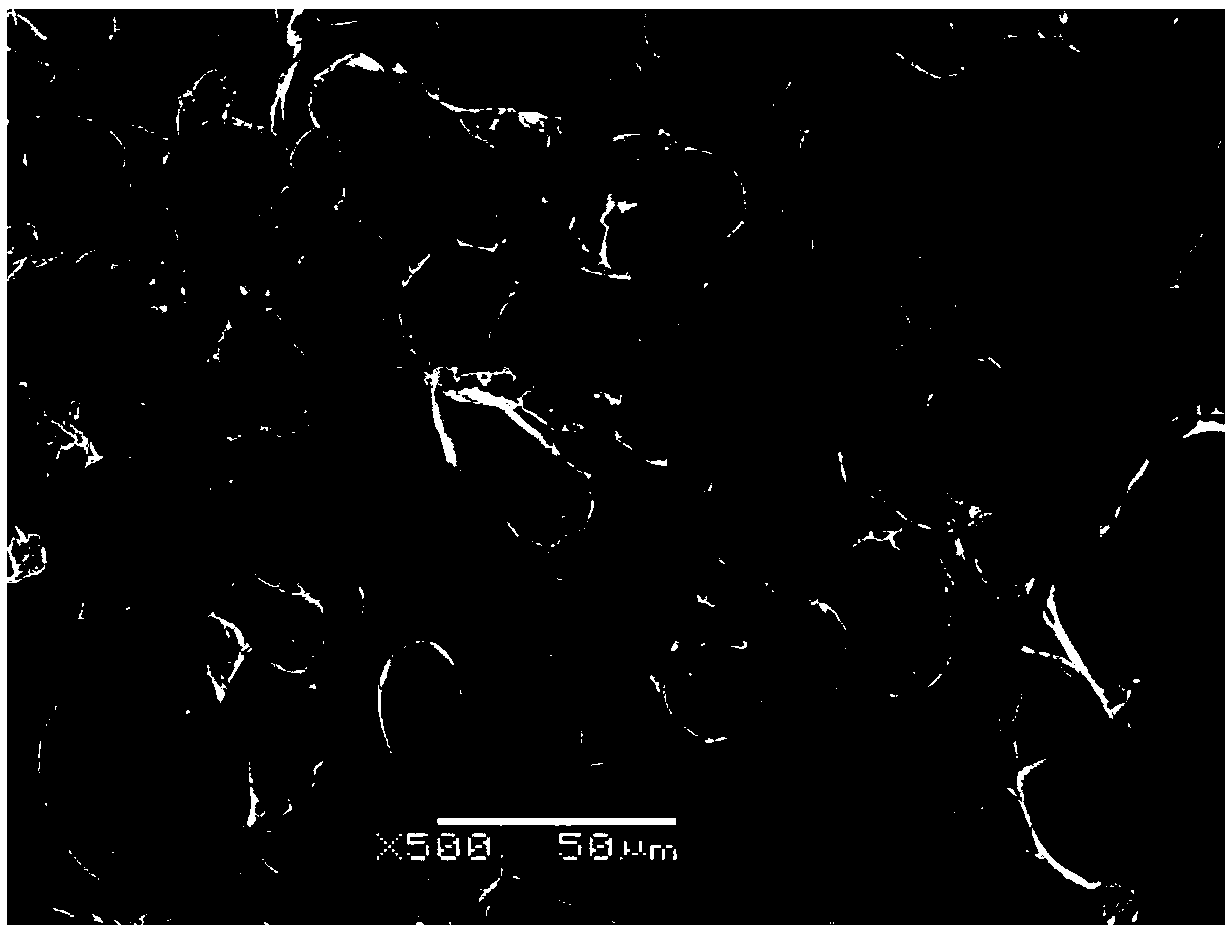

[0035] In this embodiment, the ...

Embodiment 3

[0037] Take by weighing 20 grams of induced copper powder and 40 grams of chromium powder respectively, under vacuum conditions, vacuum degree is 0.06MPa, ball mill 7 hours, obtain ball mill powder; Add 40 grams of copper powder and ball mill powder and mix evenly, obtain mixed powder; The powder is sieved, dispersed and placed in containers to dry. Press the obtained mixed powder on a 100-ton four-column hydraulic press with a mold diameter of 36 cm and a pressure of 340 MPa for 5 seconds to form a compact; put the compact into a graphite crucible, place a copper sheet on it, and place the compact in a 0.1 Pa vacuum sintering furnace medium sintering. The sintering temperature is 870 degrees centigrade, and the time is 5 hours; the obtained sintered product is further heated to 1200 degrees centigrade in a vacuum sintering furnace for infiltration, and the time is 10 minutes. Vacuum annealing at 600°C for 7 hours to obtain a CuCr30 contact material.

[0038] In this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com