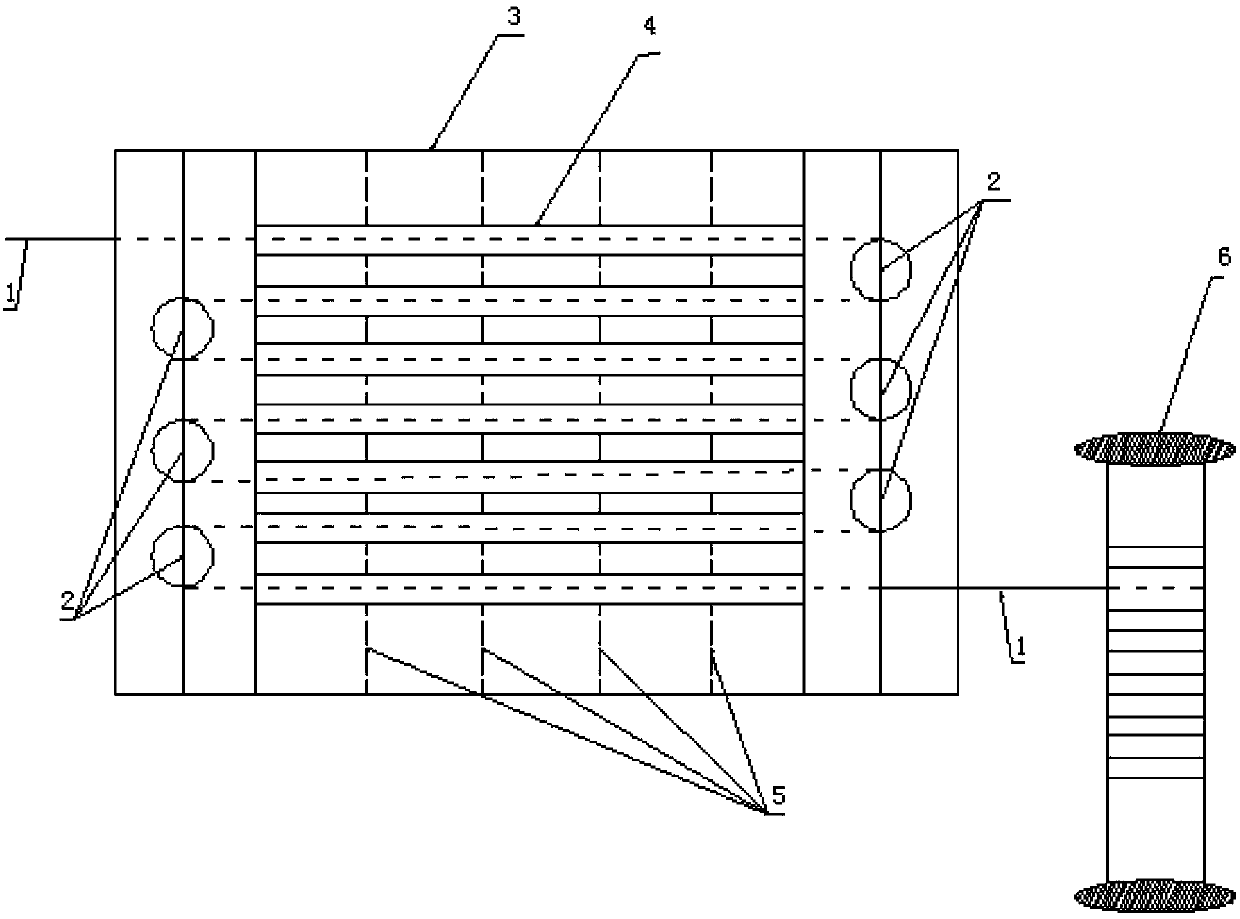

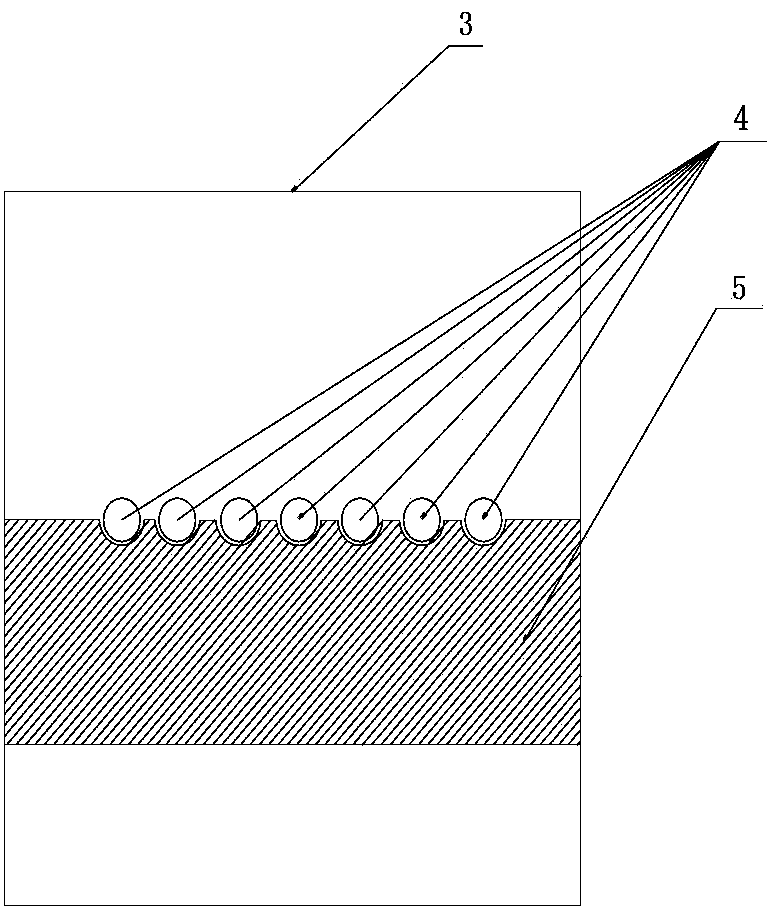

Continuous annealing apparatus and annealing method of titanium and titanium alloy coiled wire material

An annealing device, a technology for titanium alloys, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of uneven annealing of titanium and titanium alloy coiled wires, and achieve continuous and uniform annealing, avoiding deformation and distortion, and uniform performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1, pure titanium wire: TA1, Φ4.5mm, coiled wire with a coil weight of 20kg and a length of 280m is annealed to perform the above-mentioned annealing method of the present invention, with a heating temperature of 680°C and a speed of 9m / min; for the annealed Six sections of pure titanium wire were randomly sampled at the head, middle, and tail respectively. After testing, the mechanical properties at room temperature are shown in Table 1; the microstructures of samples 2, 4, and 6 are as follows: figure 1 , 2 , 3 shown.

[0048] Table 1. Mechanical properties of Φ4.5mm TA1 pure titanium wire at room temperature after continuous annealing

[0049]

Embodiment 2

[0050] Example 2: α+β-type titanium alloy wire, TC4 (Ti-6Al-4V), Φ1.5mm, coil weight 5kg, length 500m Coiled wire annealing Perform the above-mentioned annealing method of the present invention, and the heating temperature is 890°C , speed 22m / min. The annealed α+β-type titanium alloy wire was randomly sampled at 10 sections at the head, middle and tail respectively for testing, and its properties are shown in Table 2; the microstructures of samples 2, 4, 8, and 10 are as follows figure 2 shown.

[0051] Table 2. Mechanical properties of Φ1.5mm TC4 titanium alloy wire at room temperature after continuous annealing

[0052] parts

[0053] 6

[0054]It can be seen from the test results in Table 1 and Table 2 that after the wire material is annealed by the annealing method of the present invention, its performance is uniform and the consistency is very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com