Grain-oriented electrical steel sheet and manufacturing method thereof

A technology for oriented electrical steel sheets and manufacturing methods, which is applied in the direction of manufacturing tools, metal material coating processes, furnaces, etc., and can solve problems such as reduced yield, magnetic deviation between outer and inner coils, and difficult processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0089] Production example: Manufacture of grain-oriented electrical steel sheet substrate

[0090] A steel slab containing 3.23% Si by weight, 0.25% C by weight, and Fe and other unavoidable impurities in the remaining % is heated at a temperature of 1250° C., hot-rolled with a thickness of 1.6 mm, and then annealed at a temperature of 870 ℃ and a dew point temperature of 60 ℃ for 120 seconds, and then annealing and cooling the hot-rolled sheet at an annealing temperature of 1100 ℃ for 200 seconds in an atmosphere of hydrogen and nitrogen mixed gas with a dew point temperature of 0 ℃ or less. , carry out pickling and conduct a cold rolling at a reduction rate of 60%.

[0091] After the cold-rolled plate is annealed again at an annealing temperature of 870°C and a dew point temperature of 60°C for 60 seconds, it is then annealed at an annealing temperature of 1100°C for 50 seconds in an atmosphere of hydrogen, hydrogen, and nitrogen with a dew point temperature below 0°C. Seco...

Embodiment 1

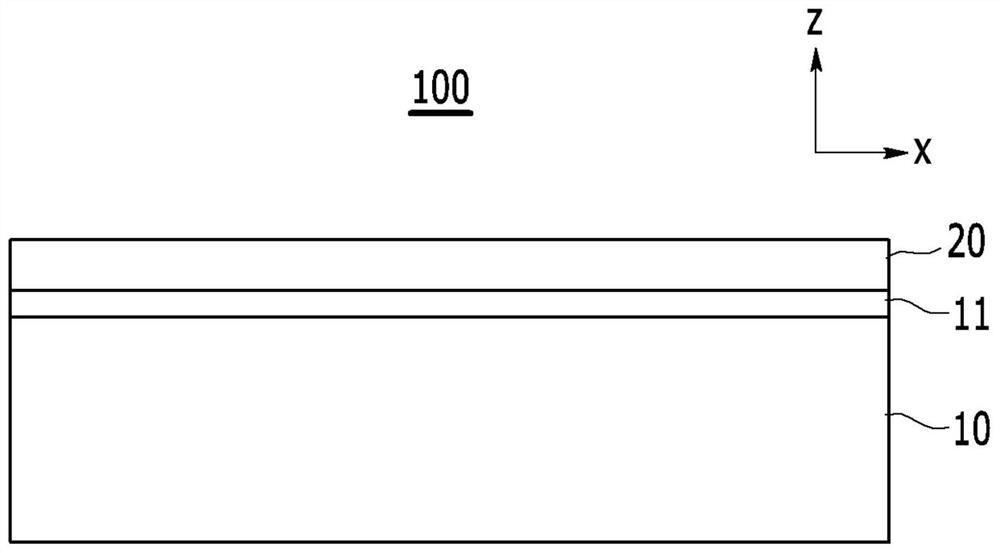

[0107] The grain-oriented electrical steel sheet substrate produced in the production example was pickled using a 25% by weight aqueous HCl solution at 80°C. After that, Al is formed on the entire surface of the steel sheet with a thickness of 3 μm 2 o 3 film.

[0108] Table 3 shows changes in thickness and magnetic properties of the original steel sheets according to pickling time. In addition, the amount of oxygen in the oxygen-deficient layer at a depth of 3 μm from the surface was measured and shown in Table 3. In addition, the iron loss magnetic flux density was measured by a single sheet measurement method, and the iron loss (W 17 / 50 ) and the magnetic flux density induced under a magnetic field of 1000A / m (B 10 ). The results thereof are shown in Table 3 below.

[0109] 【table 3】

[0110]

[0111] As shown in Table 3, the magnetic properties of Invention Material 1 to Invention Material 7 subjected to the pickling step were superior to those of Comparative Mat...

Embodiment 2

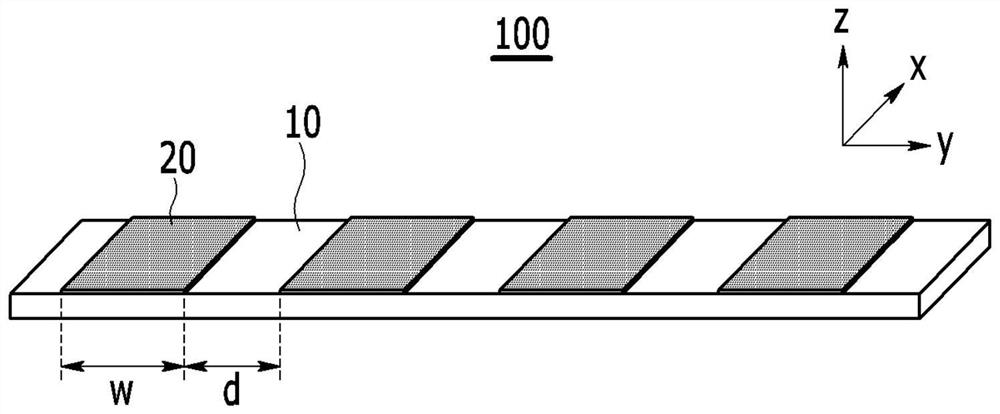

[0113] The grain-oriented electrical steel sheet substrate produced in the production example was pickled using a 25% by weight aqueous HCl solution at 80°C. Thereafter, ceramic powder was supplied to a heat source for plasmaization with argon (Ar) gas at an output of 200 kW, thereby forming a ceramic coating layer. At this time, a pattern was formed with a coating width (w) of 30 mm and a coating interval (d) of 20 mm. The types of ceramics and the thickness of the ceramic coating were changed according to Table 4 below, and the corresponding changes in magnetic properties are shown in Table 4.

[0114] 【Table 4】

[0115]

[0116] As shown in Table 2, the improvement in magnetic properties can be more achieved by properly forming the ceramic coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com