A continuous high-frequency heating and annealing device for aluminum alloy cables

A high-frequency heating and annealing device technology, used in heat treatment furnaces, heat treatment equipment, and energy efficiency improvements, can solve problems such as high energy consumption, long time, and poor product consistency, and achieve high efficiency, short time, and good energy-saving effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

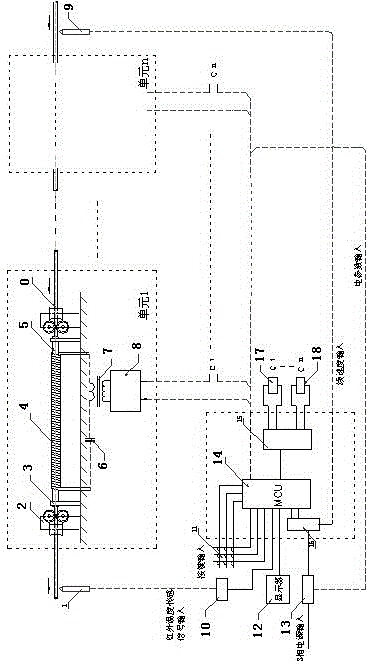

[0014] Please refer to the accompanying drawings, the present invention passes through the aluminum alloy cable 0 in a long hollow tube 5, and the induction coil 4 is wound on the hollow tube 5, and the induction coil 4 is connected with the output end of the impedance transformer 7, The input end of the impedance converter 7 is connected to the high-frequency power generator 8, and the high-frequency power generator 8 inputs high-frequency power, so that the induction coil 4 generates high-frequency, low-voltage and high-current, and the aluminum alloy cable 0 in the hollow tube 5, Heated by high-frequency and high-current induction; the two ends of the aluminum alloy cable passing through the hollow tube 5 are driven forward by the roller transmission mechanism 2 to realize continuous high-frequency heating of the aluminum alloy cable and adjust the high-frequency power generation The size of the power of the device 8 reaches the annealing heating temperature set by adjusting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com