Patents

Literature

47results about How to "Uniform annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

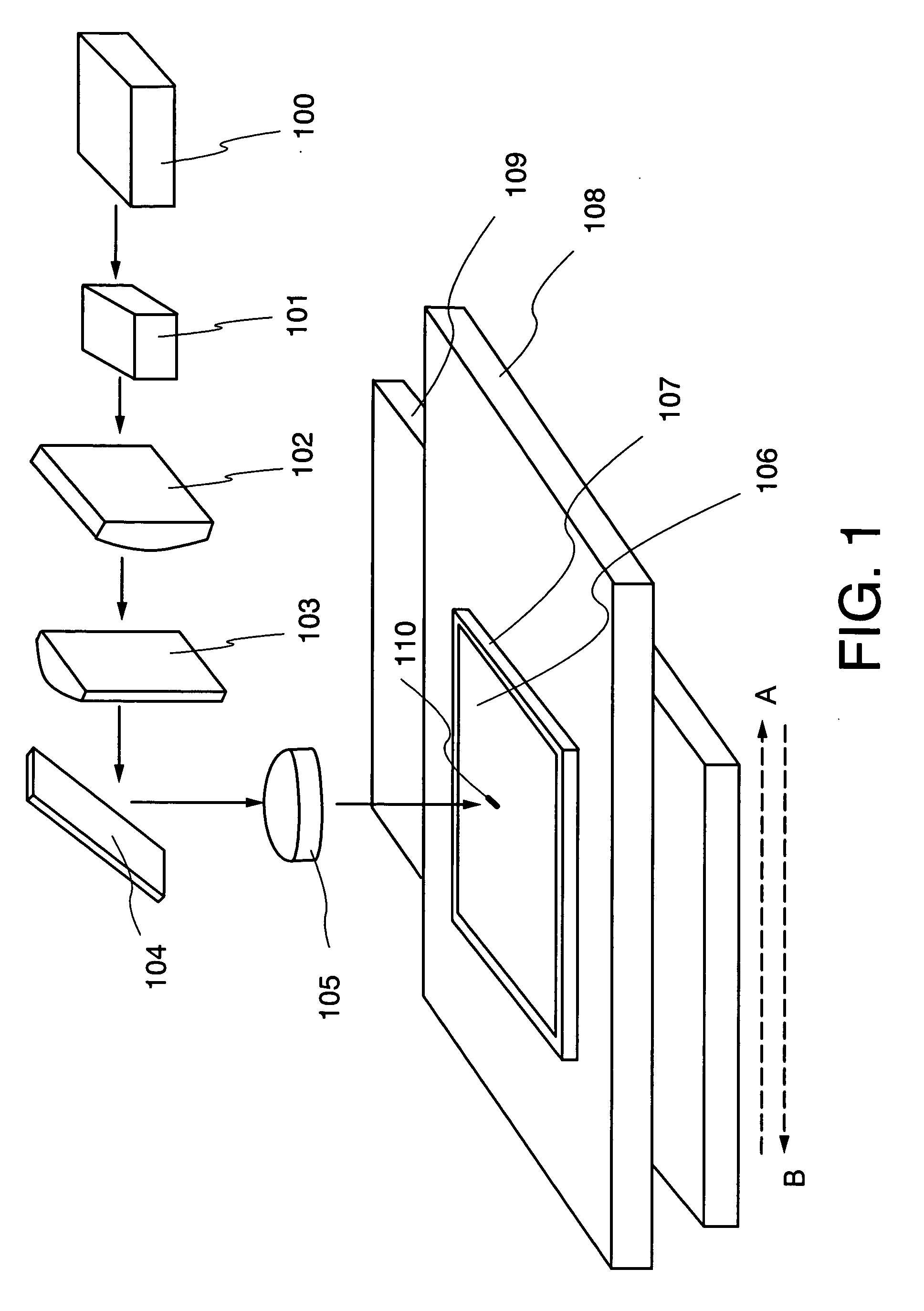

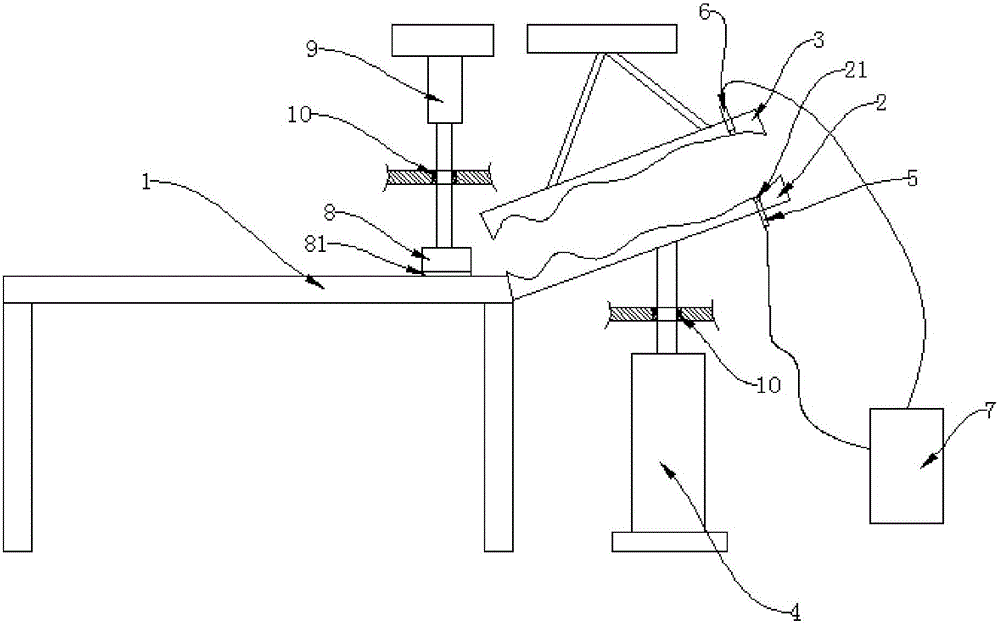

Laser irradiation apparatus, laser irradiation method, and method of manufacturing a semiconductor device

InactiveUS6852947B2Reduce weightIncreased durabilityTransistorLaser detailsUltrasound attenuationLaser light

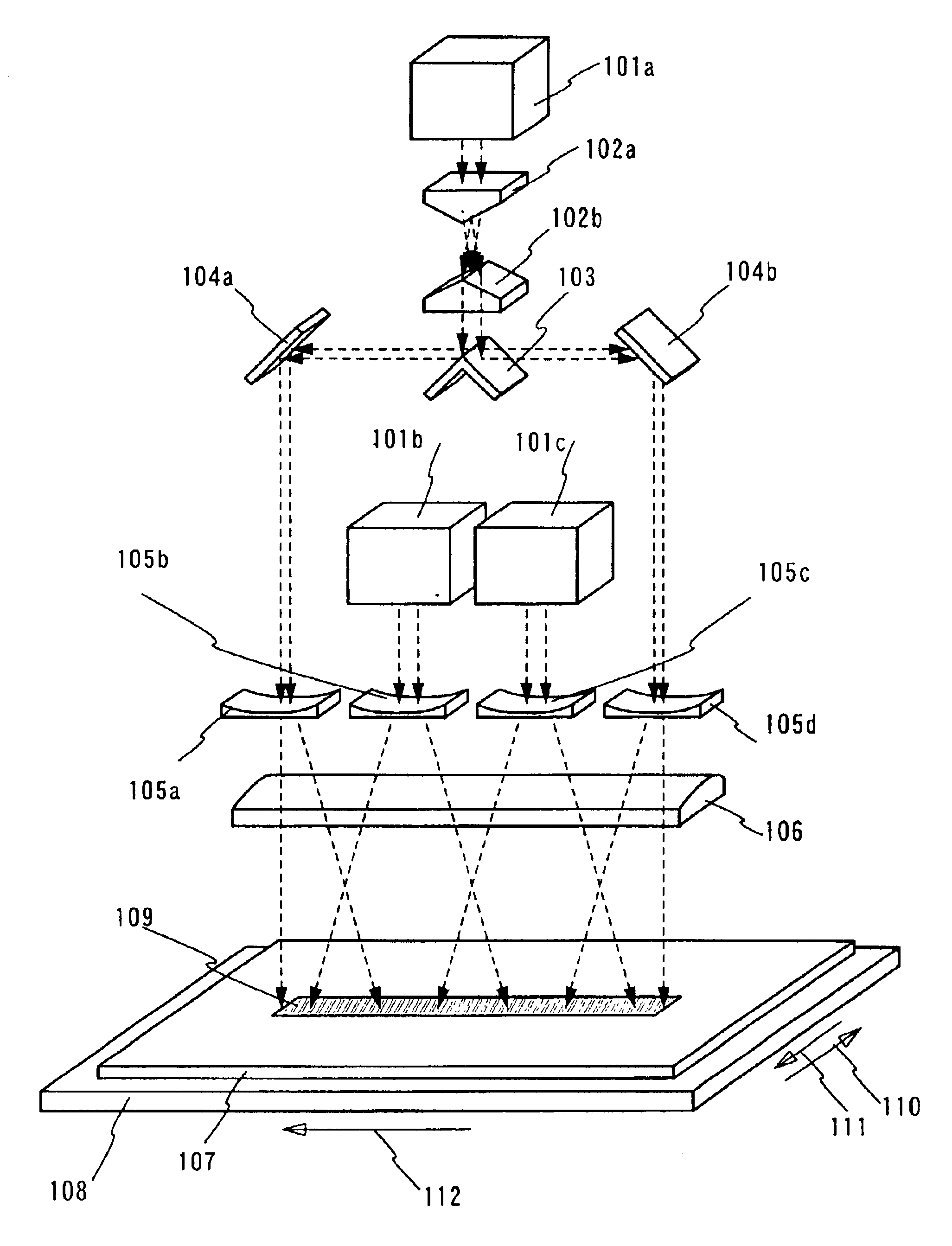

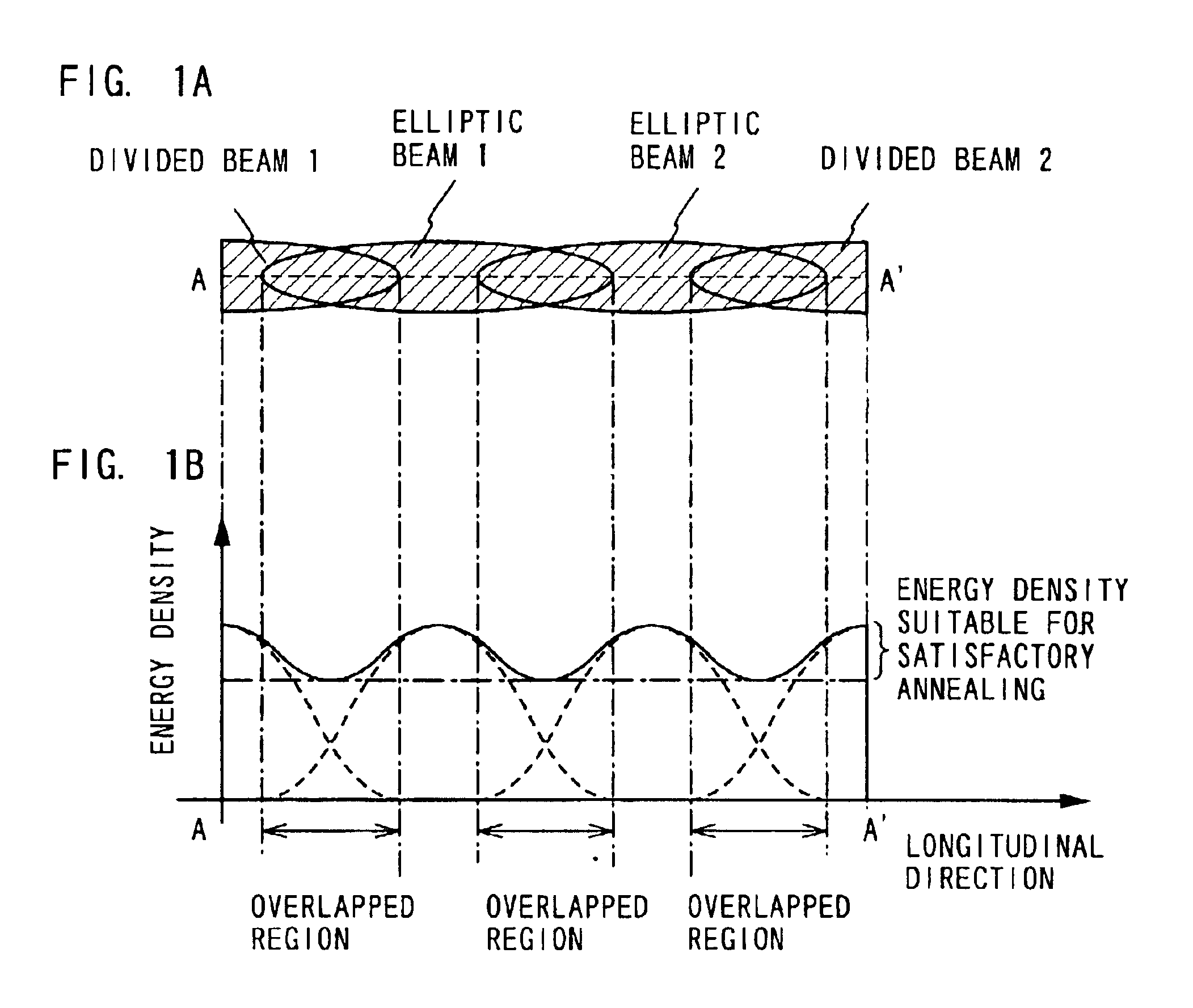

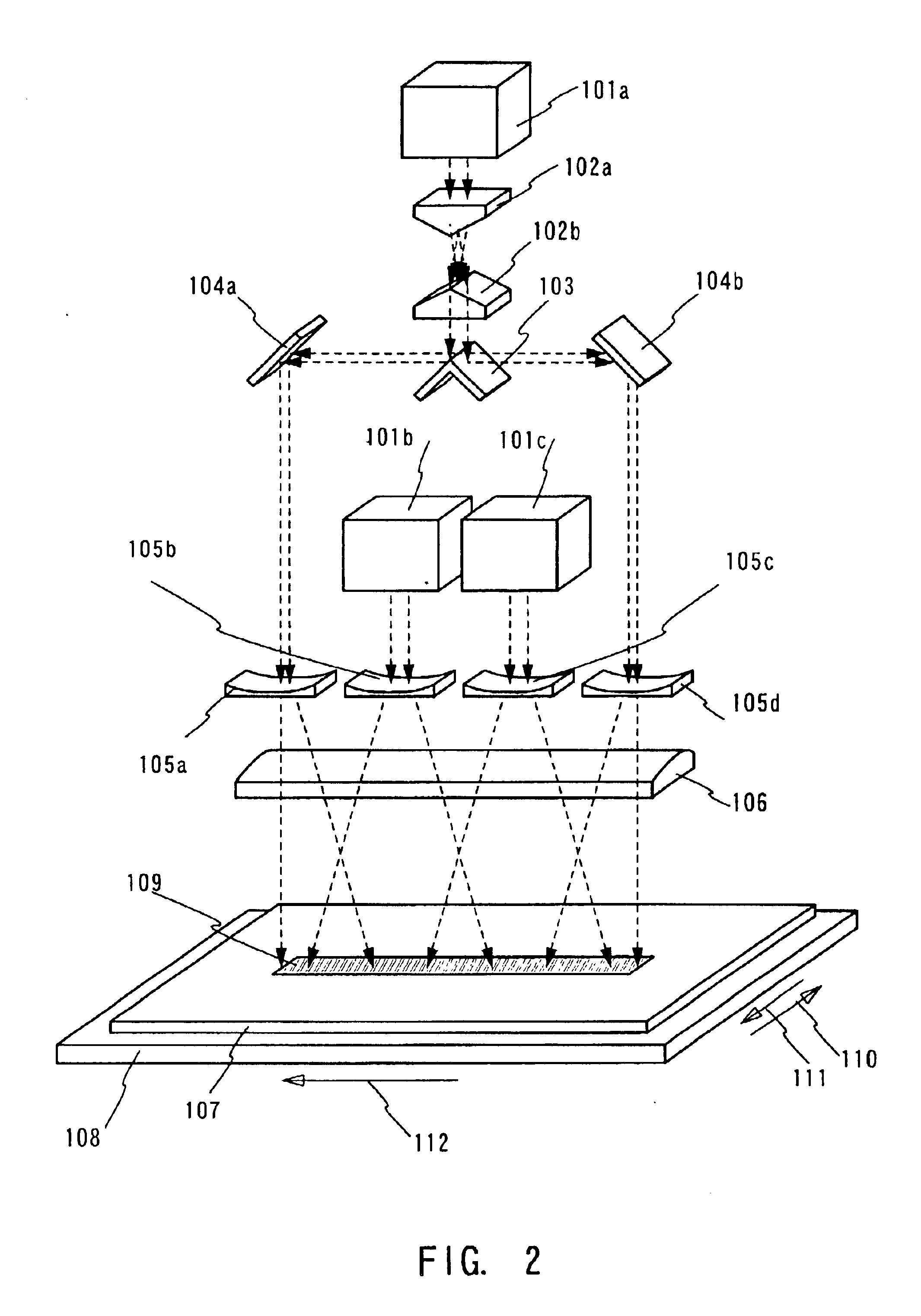

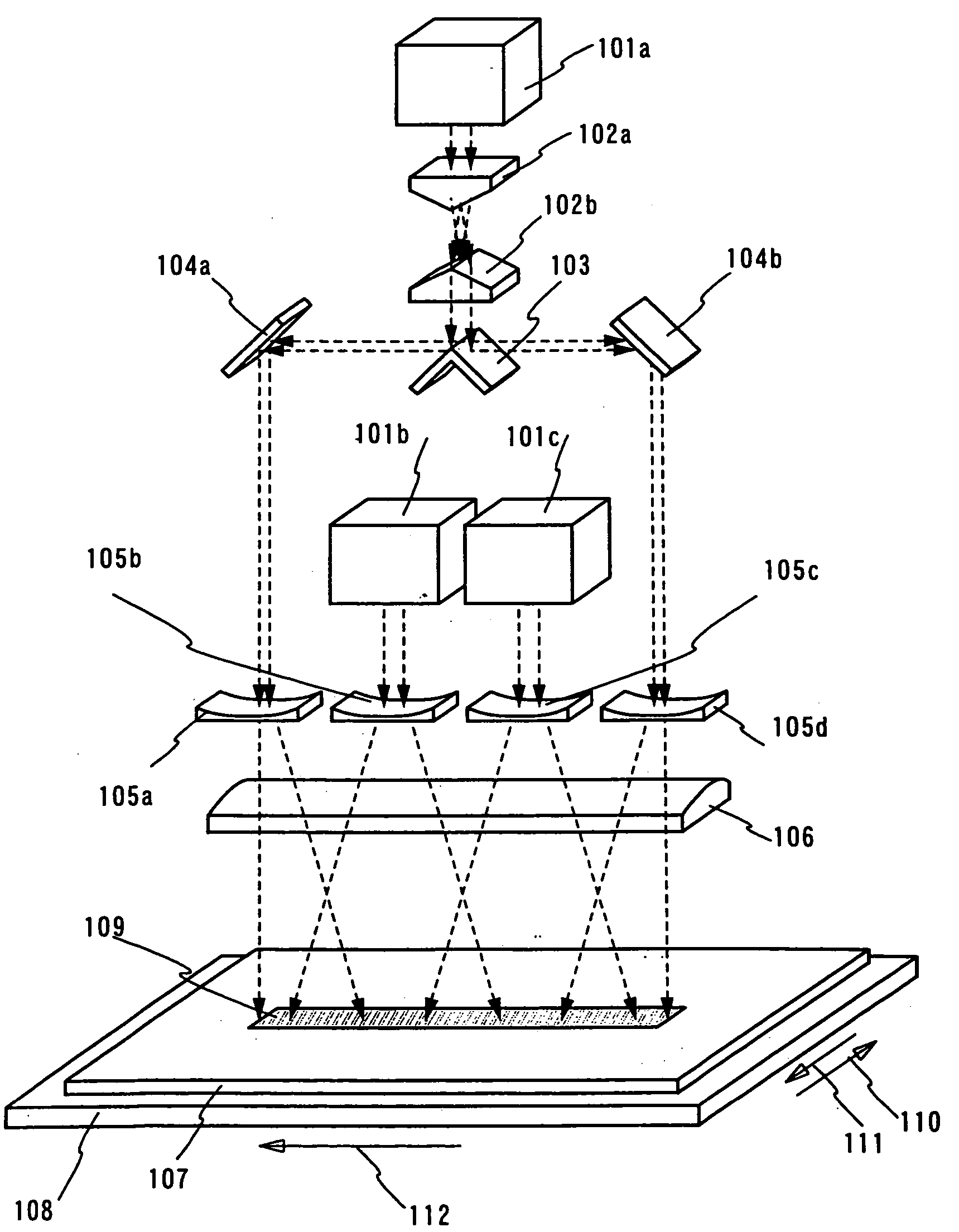

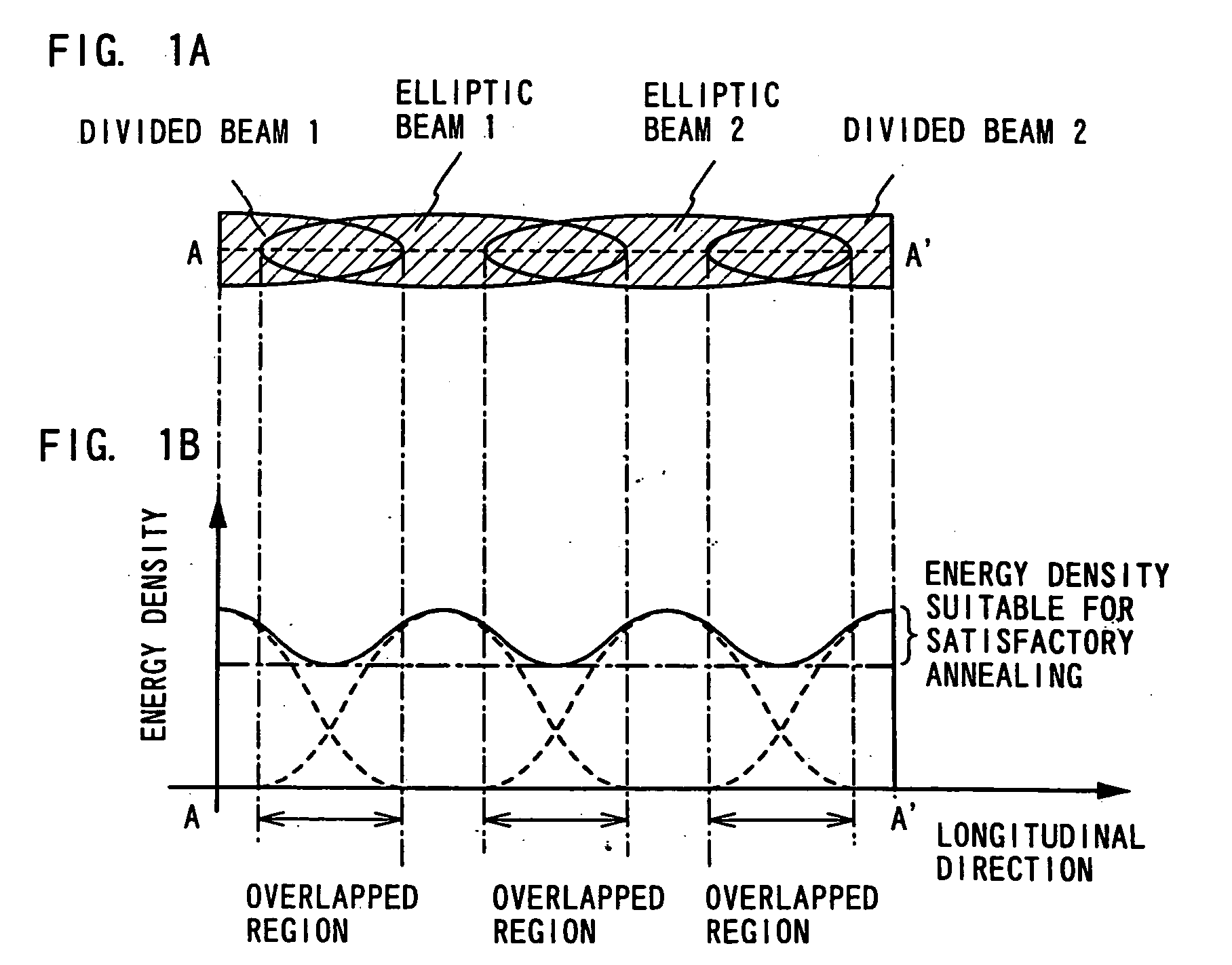

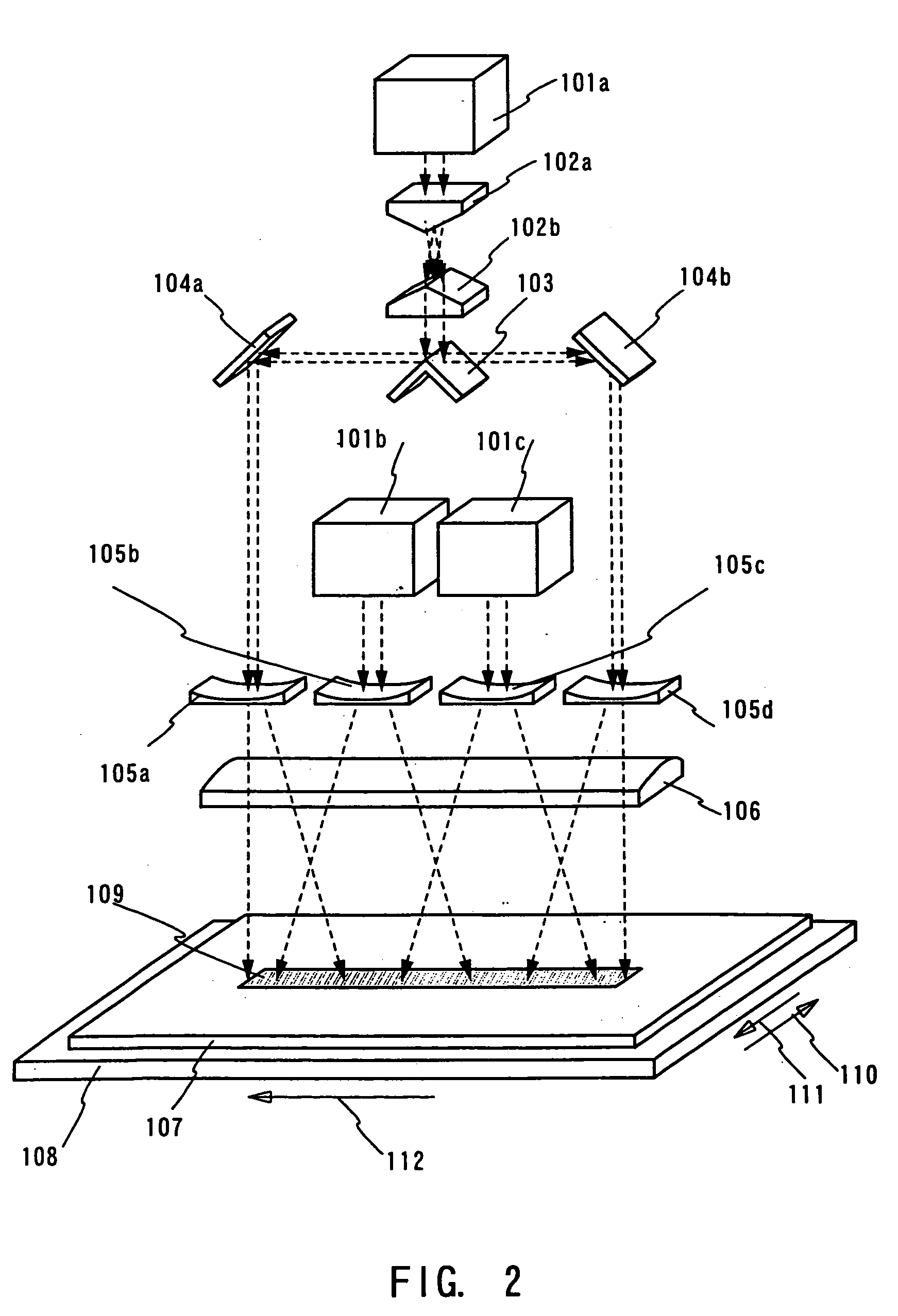

At edges of laser light on an irradiation surface or in the vicinity thereof, the energy density is attenuated gradually due to aberration of a lens or the like. Since such regions (attenuation regions) do not have enough energy density for annealing of an irradiation object, uniform annealing of the irradiation object is not possible.In the present invention, one of the plural laser beams is divided into two laser beams so that each section of the two laser beams serves as an edge of the resultant laser light. Each attenuation region of the two laser beams is synthesized with an attenuation region of another laser beam. In this way, laser light every part of which has an energy density suitable for satisfactory annealing of an irradiation object can be obtained from plural laser beams having attenuation regions.

Owner:SEMICON ENERGY LAB CO LTD

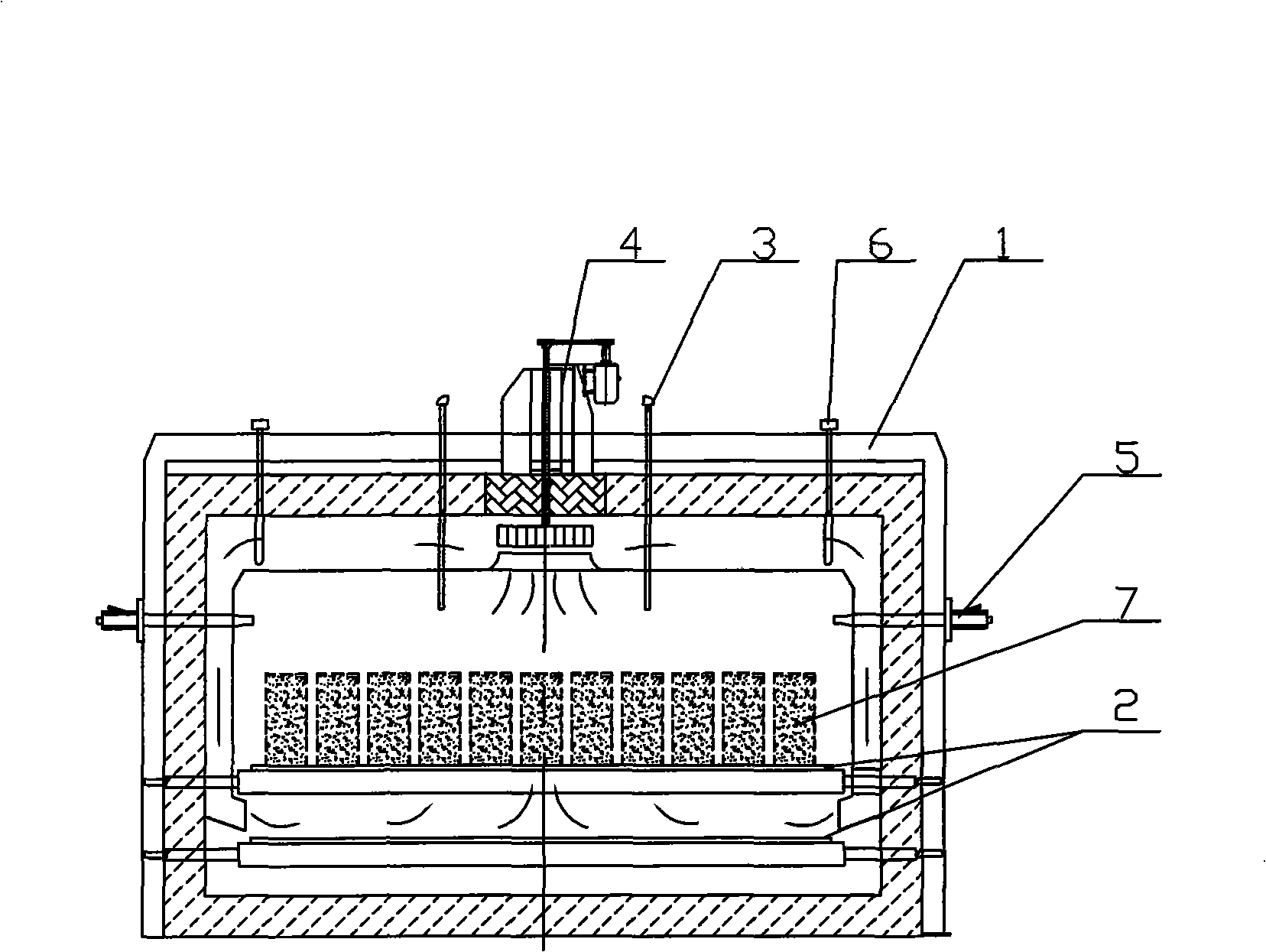

Annealing method of sapphire wafer

InactiveCN102634850AUniform annealingEliminate processing stressPolycrystalline material growthAfter-treatment detailsWaferingCrystalline materials

The invention relates to an annealing method of a sapphire wafer, belonging to the technical field of the machining of a crystalline material. The invention provides the annealing method of the high-quality sapphire wafer, comprising the following steps of: raising the temperature on the sapphire wafer which is cut, milled or polished by sections and keeping the heat for a period of time at 900-1600 DEG C; carrying out annealing treatment on the sapphire wafer so as to eliminate machining stress for cutting, milling or polishing; and rotating the wafer at a heat-preservation phase to uniformly anneal the whole wafer, so as to eliminate the influence that a temperature field of an annealing furnace is not uniform. The machining stress of the wafer annealed by the method is basically eliminated and the whole wafer is uniformly annealed; and the warping degree of the annealed wafer is small.

Owner:CHANGZHOU TONGTAI PHOTOELECTRIC

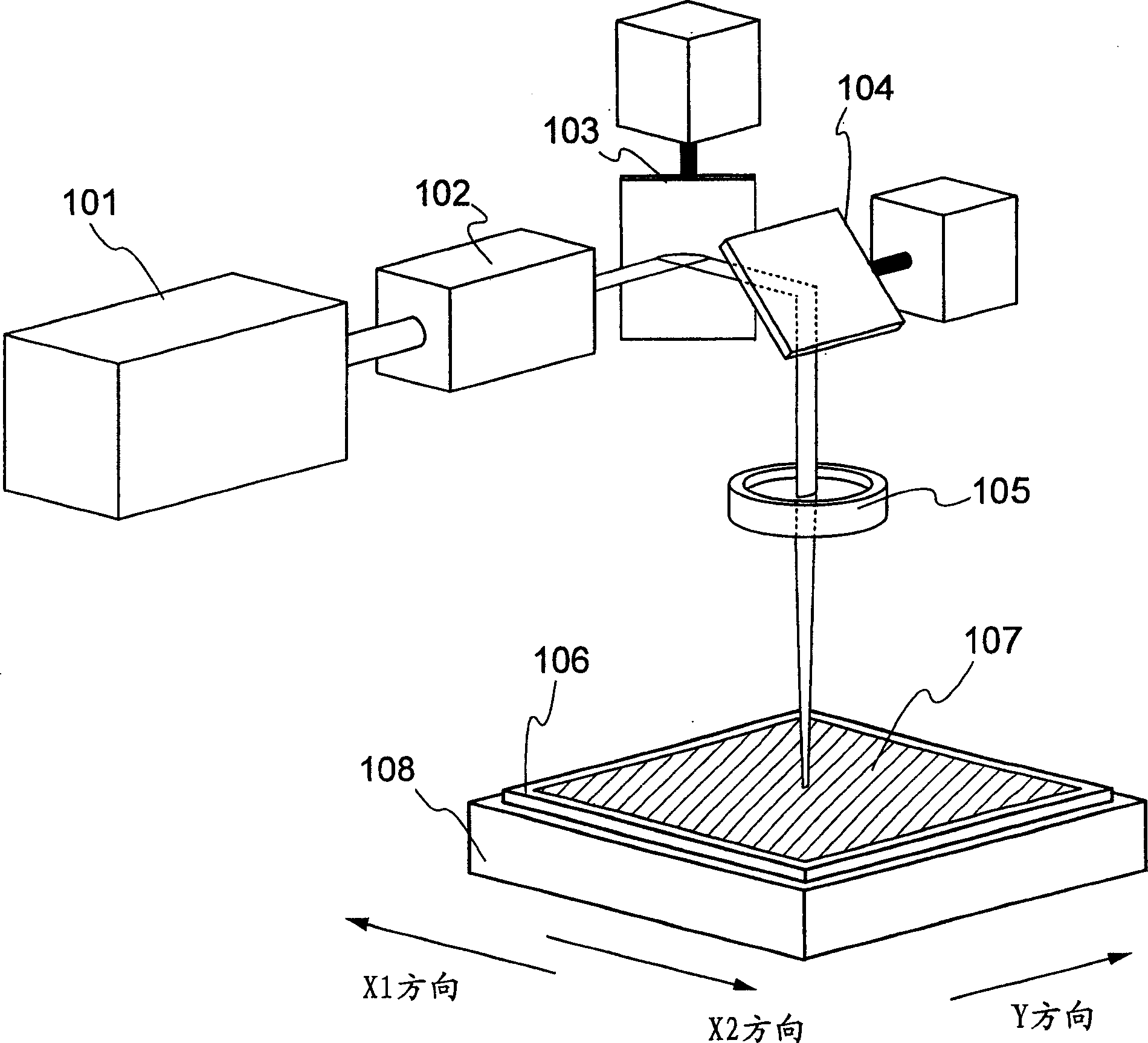

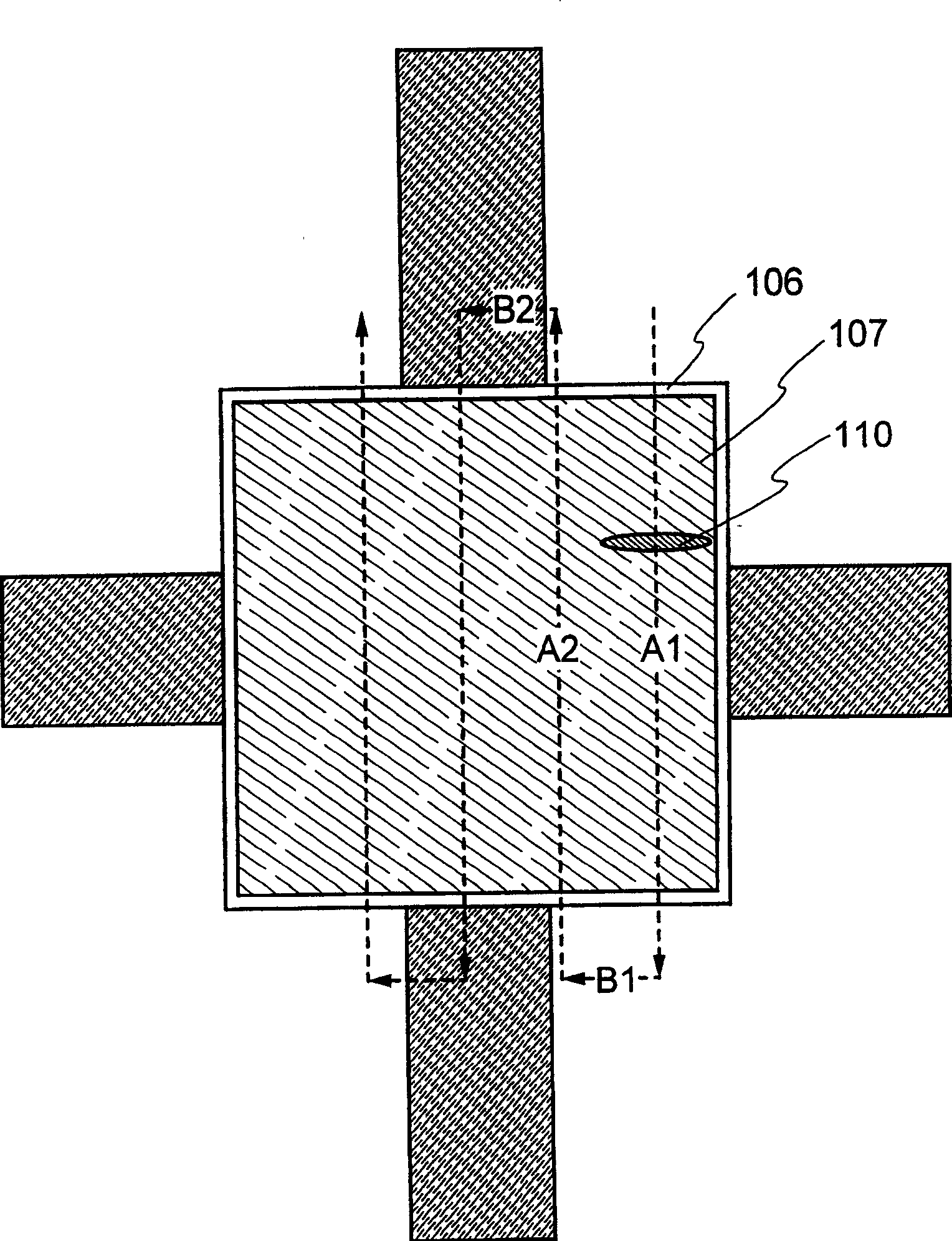

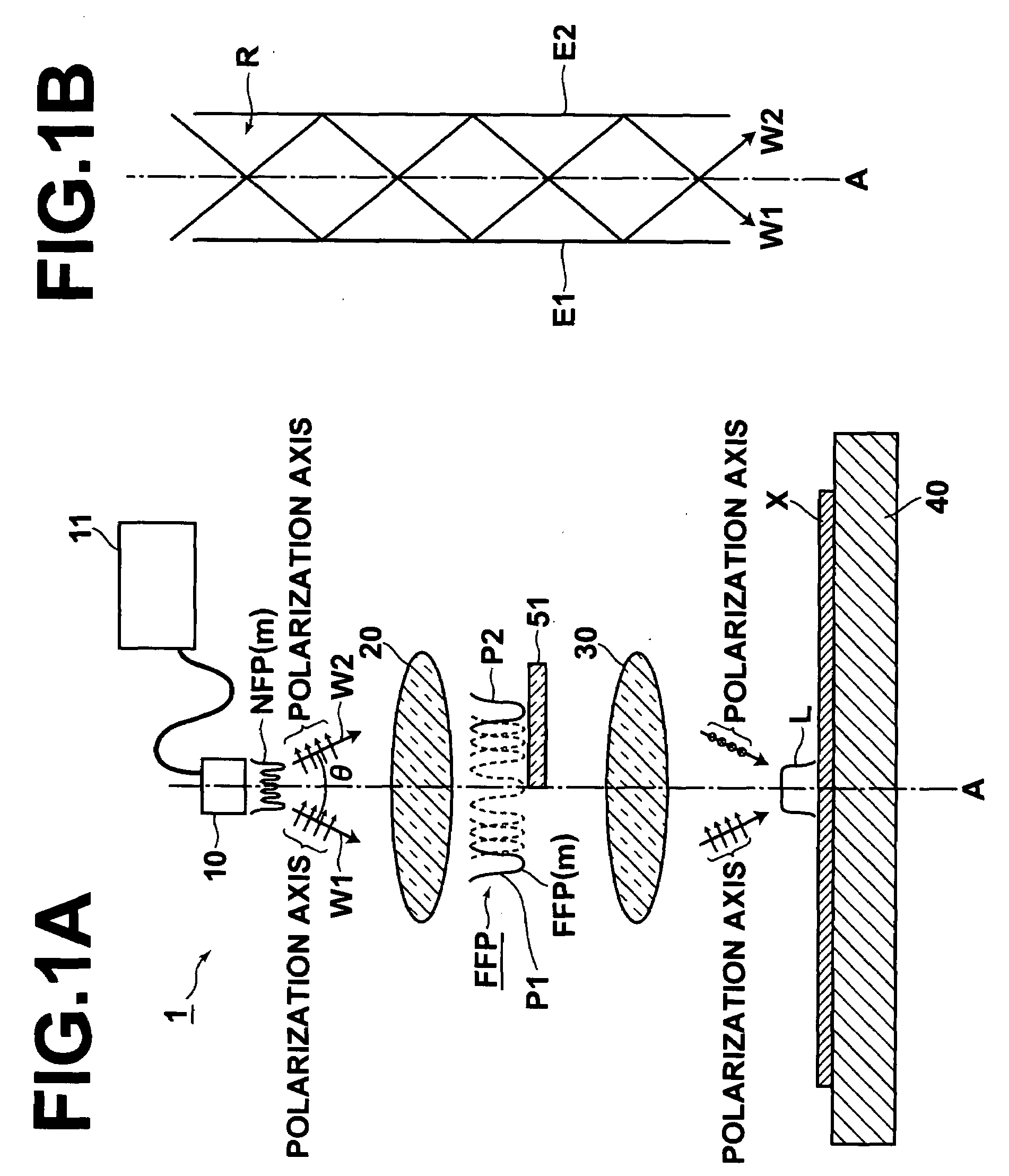

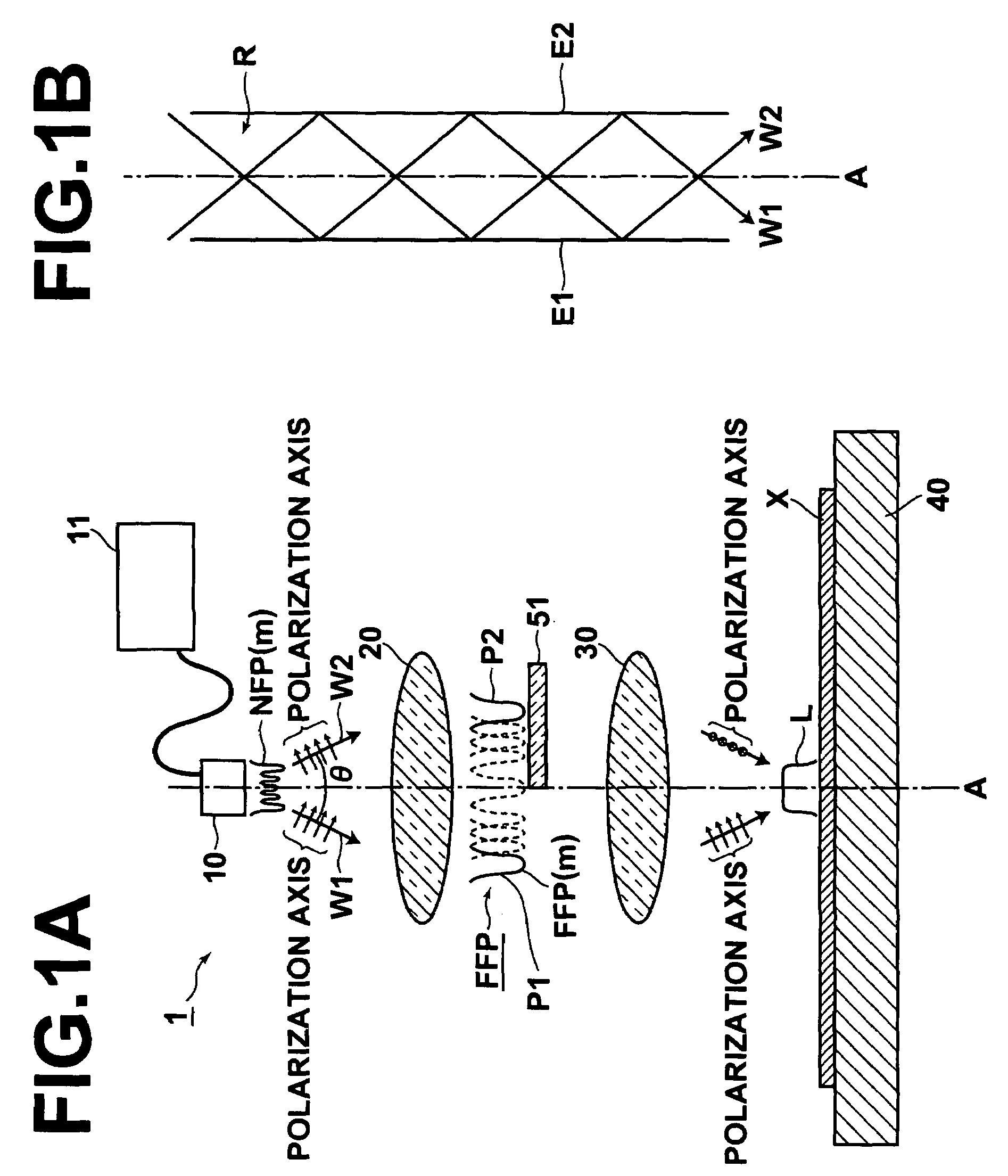

Beam irradiation apparatus, beam irradiation method, and method for manufacturing semiconductor device

ActiveUS20050037552A1Reduce manufacturing costEase of mass productionSolid-state devicesSemiconductor/solid-state device manufacturingLight beamGalvanometer

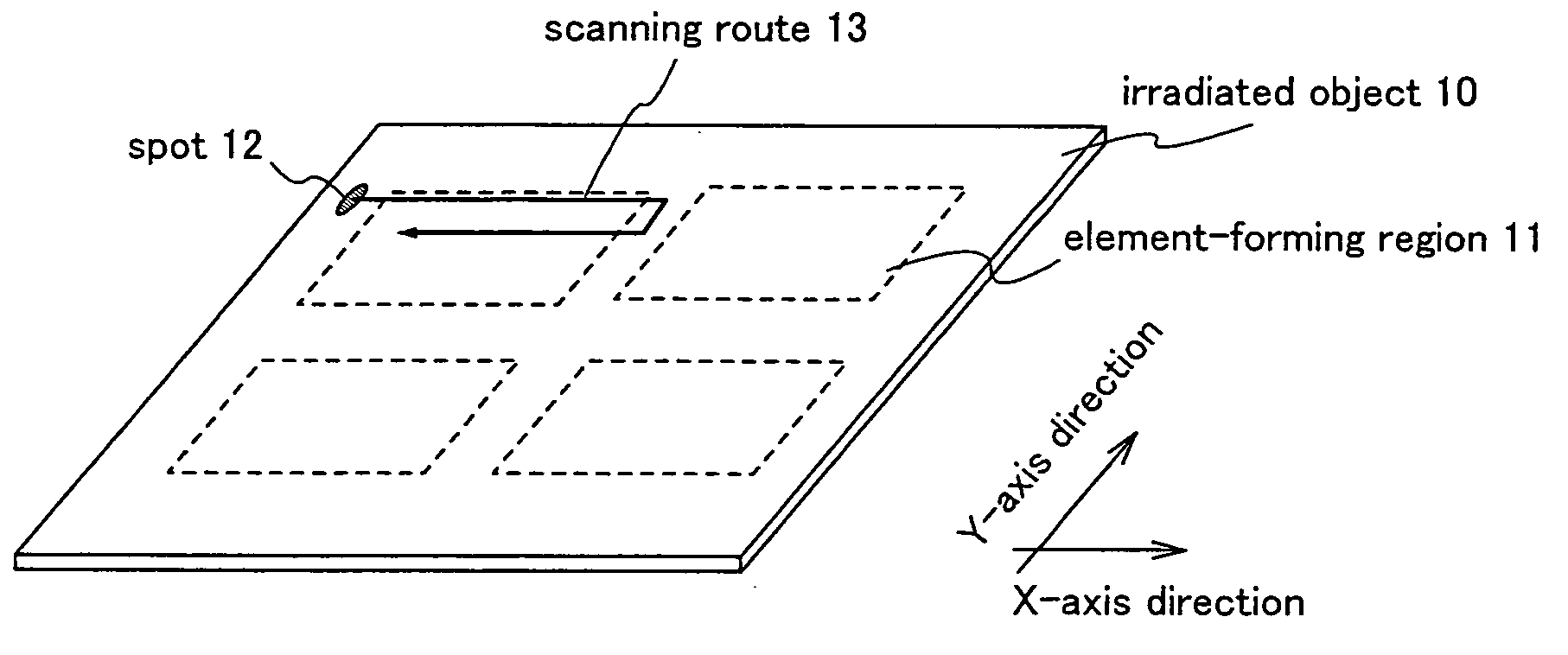

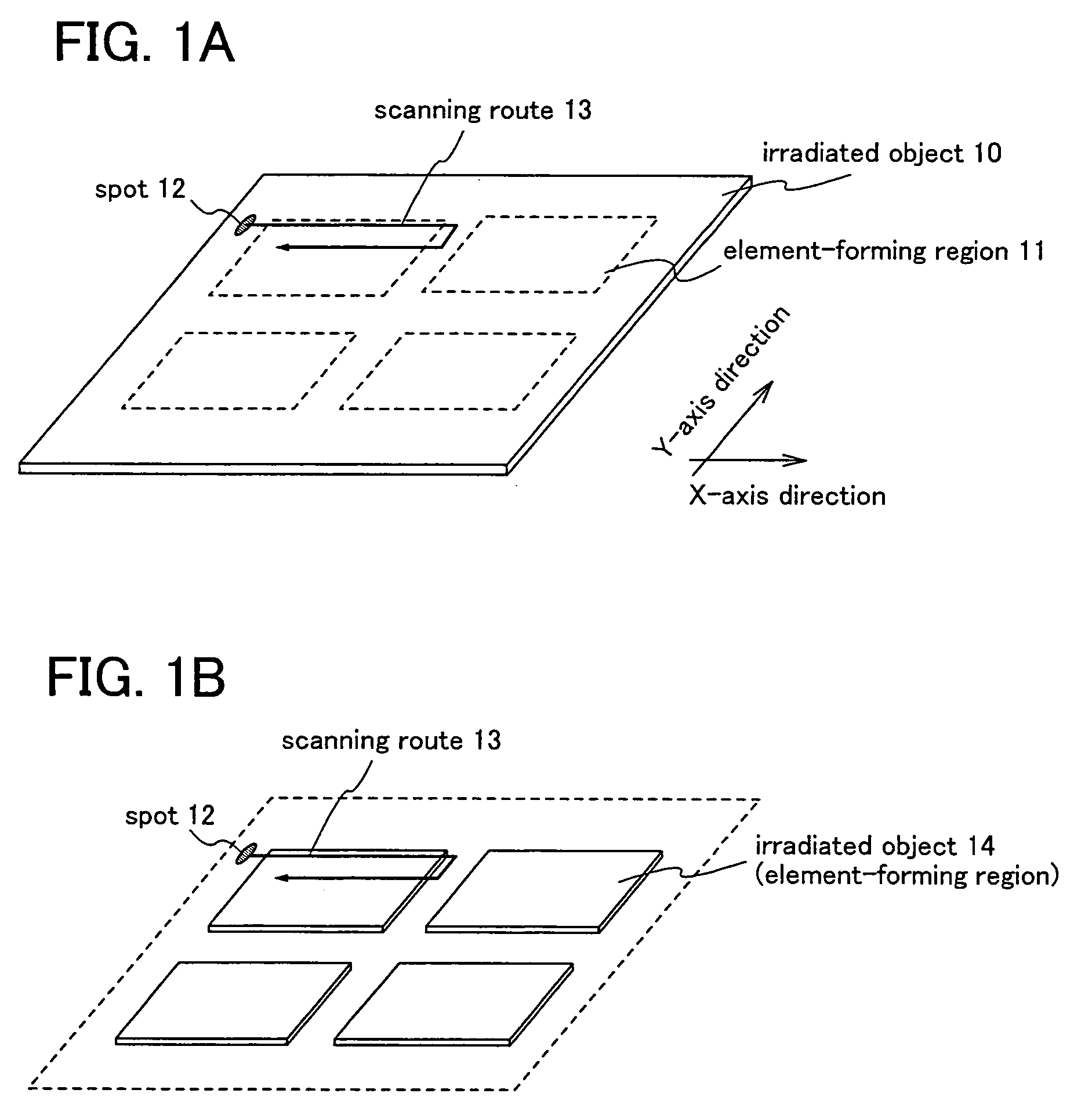

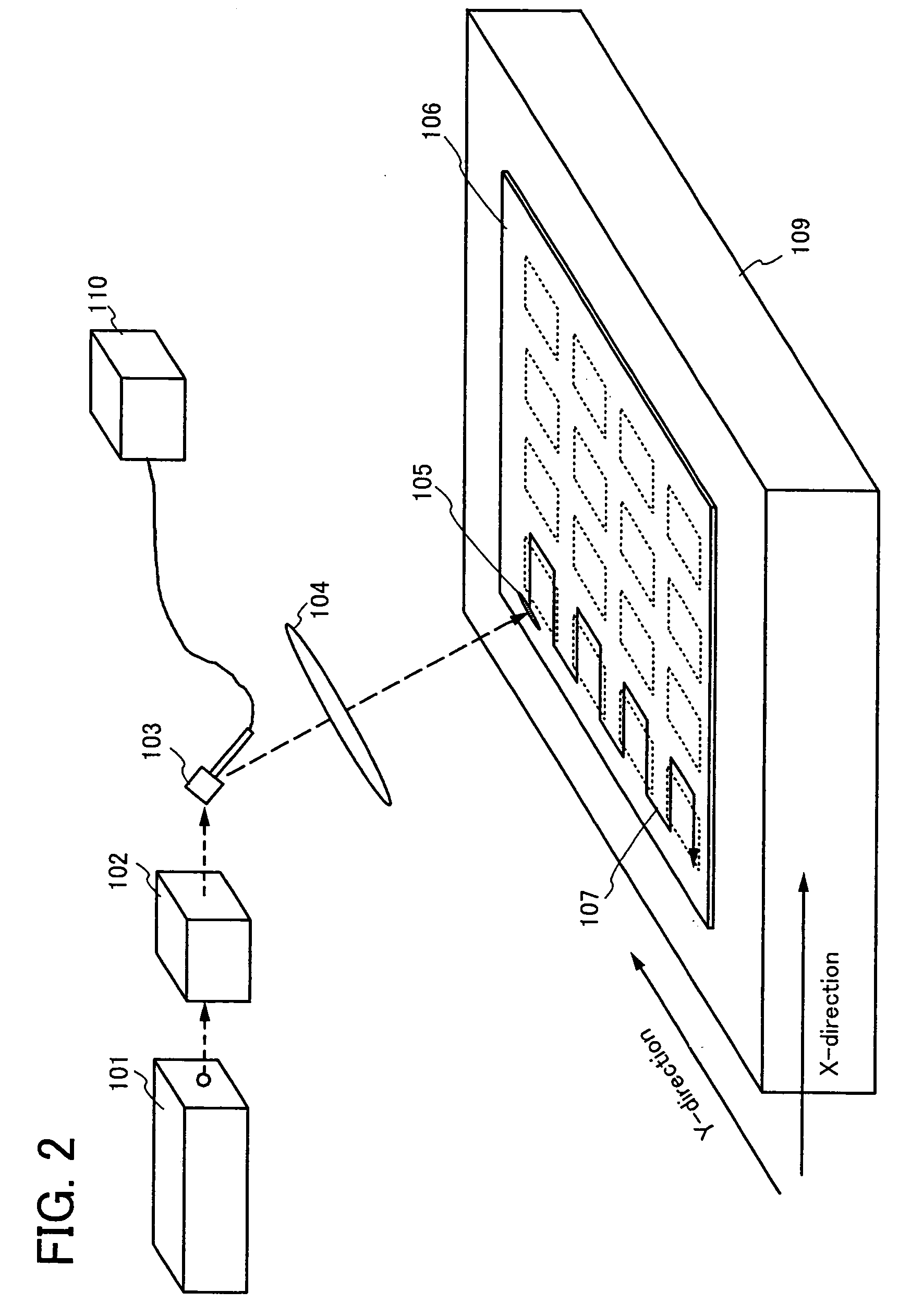

The speed of the laser scanned by the scanning means such as a galvanometer mirror or a polygon mirror is not constant in the center portion and in the end portion of the scanning width. As a result, the object, for example an amorphous semiconductor film, is irradiated with the excessive energy and therefore there is a risk that the amorphous semiconductor film is peeled. In the present invention, in the case where the laser spot of the energy beam output continuously on the irradiated object is scanned by moving it back and forth with the use of the scanning means or the like, the beam is irradiated to the outside of the element-forming region when the scanning speed of the spot is not the predetermined value, for example when the speed is not constant, and accelerates, decelerates, or is zero, for example in the positions where the scanning direction changes, or where the scanning starts or ends.

Owner:SEMICON ENERGY LAB CO LTD

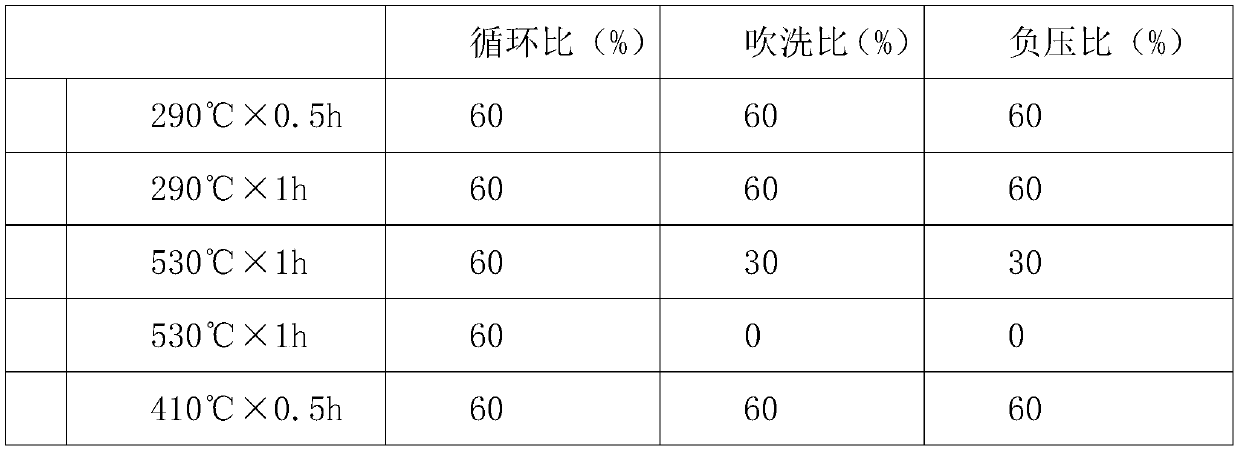

Annealing process for growing large-size sapphire crystal by kyropoulos method

InactiveCN103540998AReduce dislocation densityReduce internal stressPolycrystalline material growthAfter-treatment detailsThermal insulationSingle crystal

The invention relates to an annealing process for growing a large-size sapphire crystal by a kyropoulos method. After a large-size sapphire crystal grows by a kyropoulos method, the vacuum degree in a single crystal furnace is maintained, the heater power is gradually reduced, and the cooling is performed in five stages until the heater power is zero; through staged thermal insulation annealing, the dislocation density of large-size sapphire can be effectively reduced, internal stress of the crystal is eliminated, and the quality and the utilization rate of the crystal are improved; the annealing time is short, the energy consumption is reduced, and the growth period of the large-size sapphire crystal is shortened; moreover, the sapphire crystal is rotated in a thermal insulation stage so that the sapphire crystal annealing is uniform and the influence of non-uniform temperature field in annealing is eliminated.

Owner:江西东海蓝玉光电科技有限公司

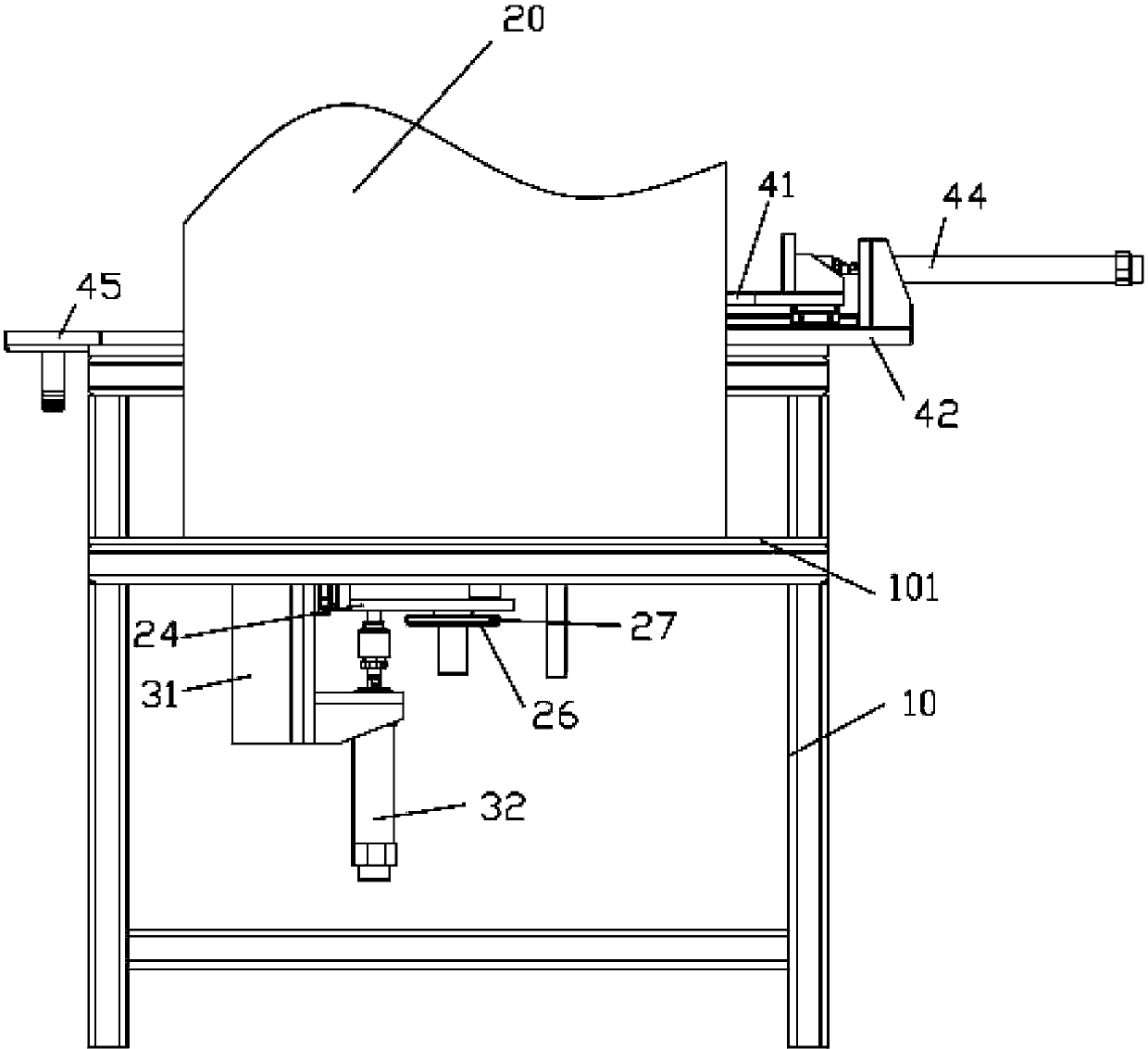

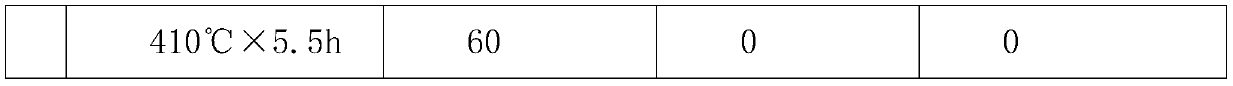

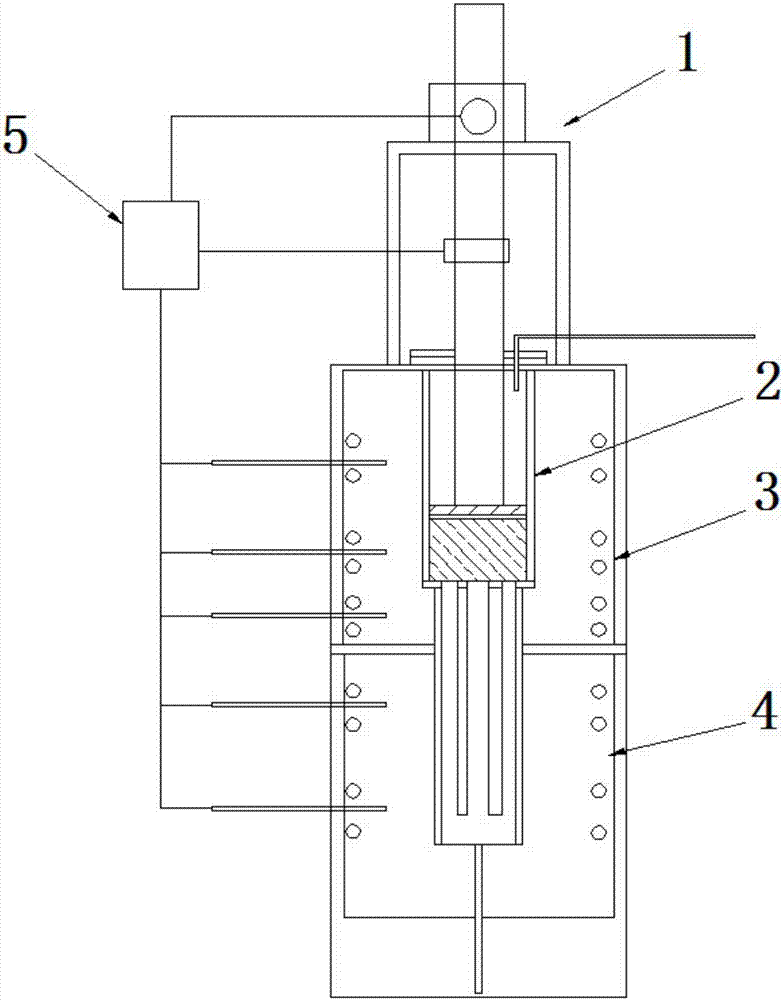

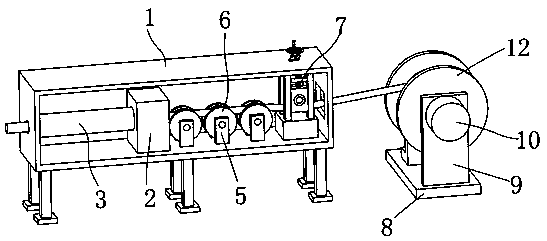

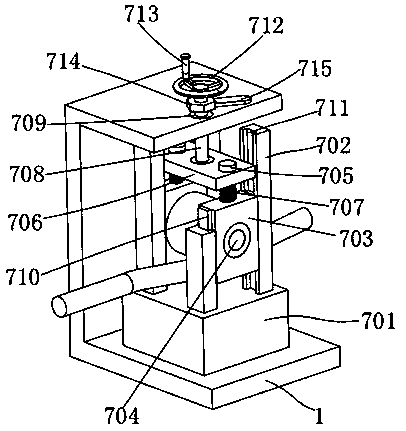

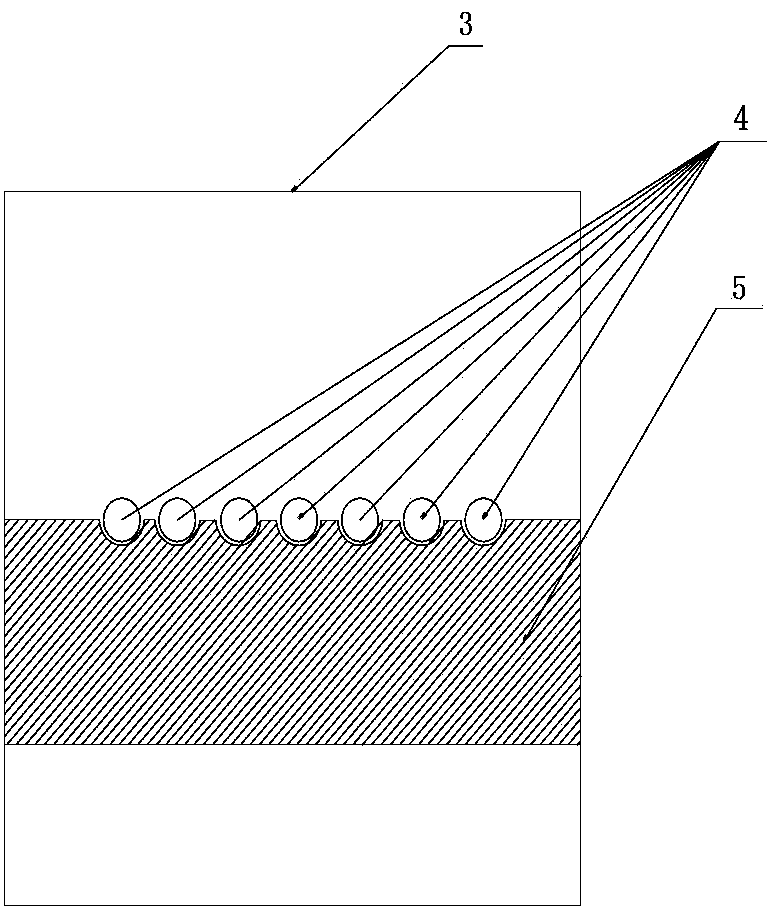

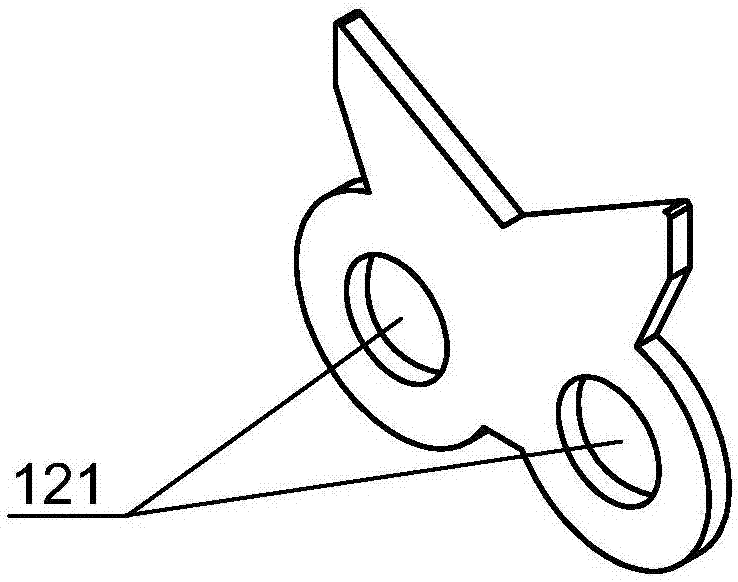

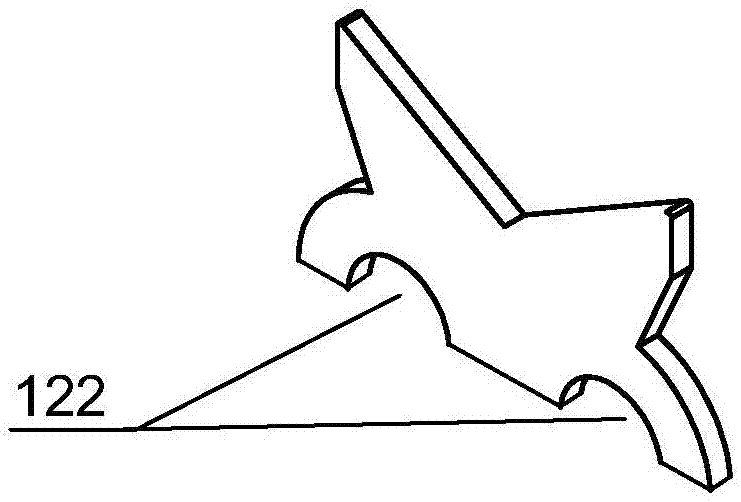

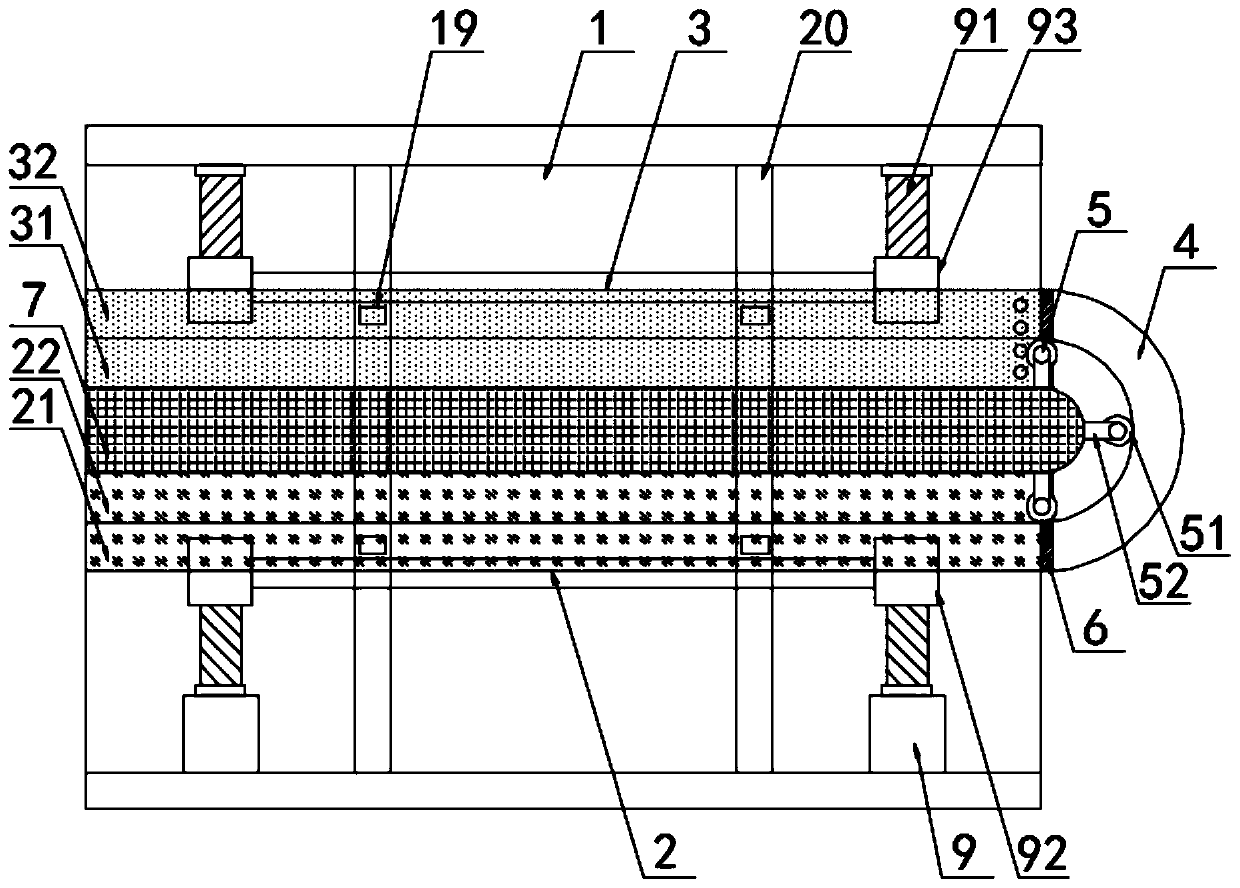

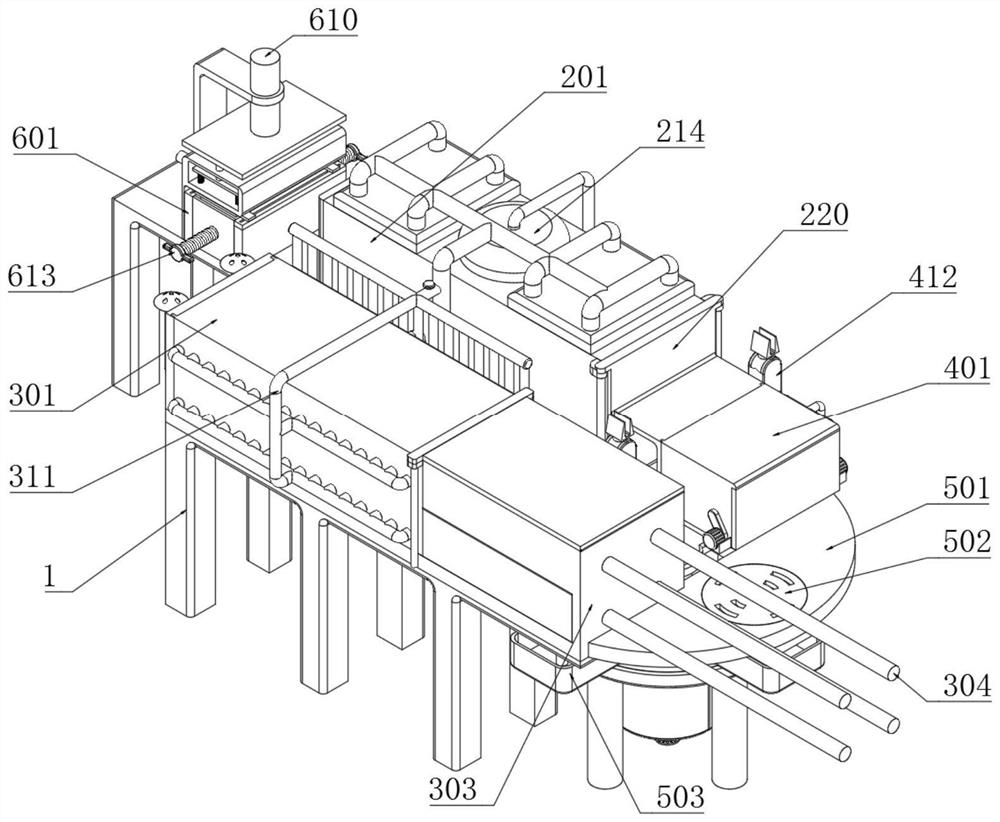

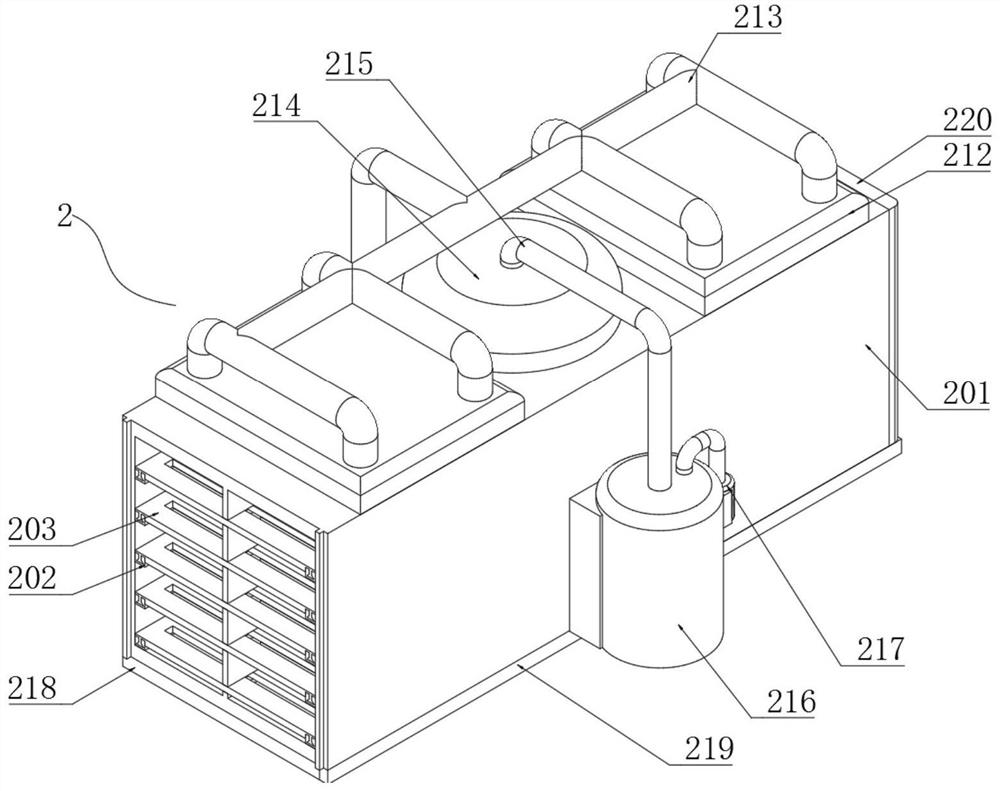

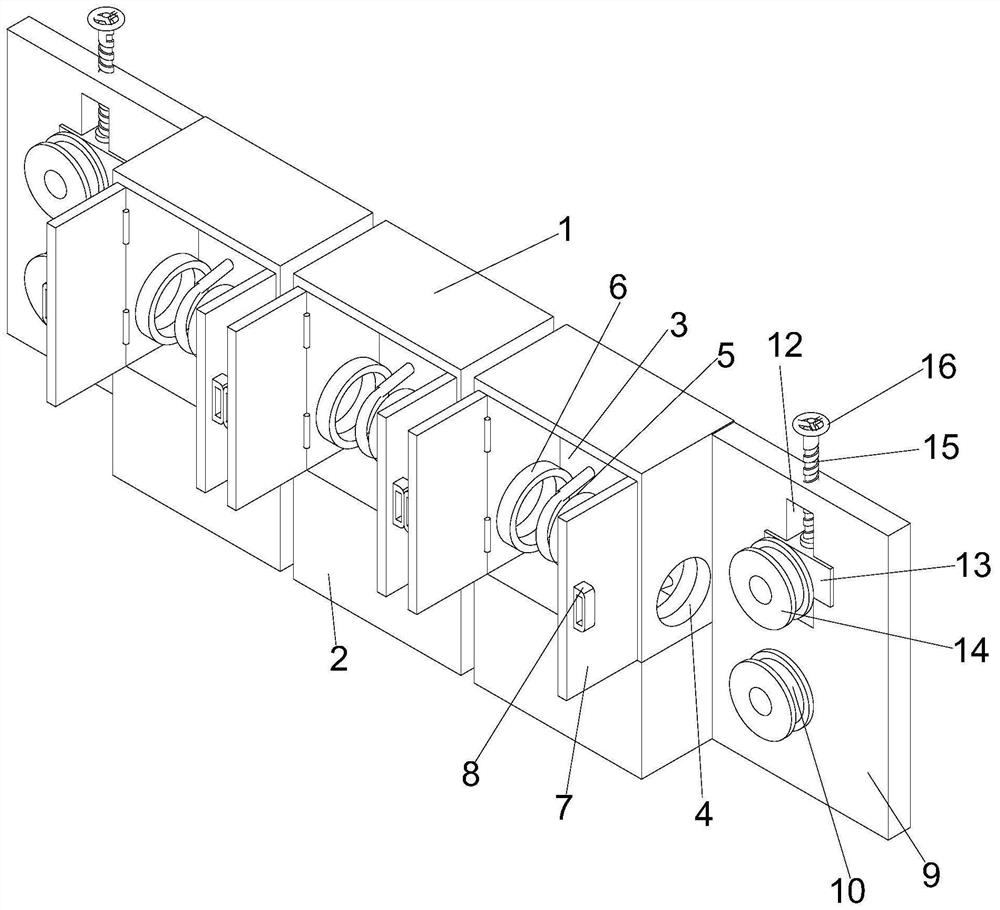

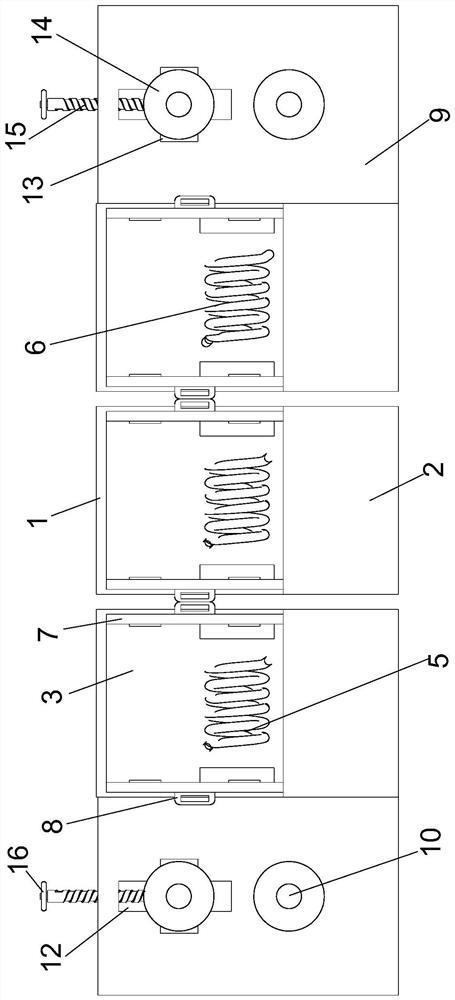

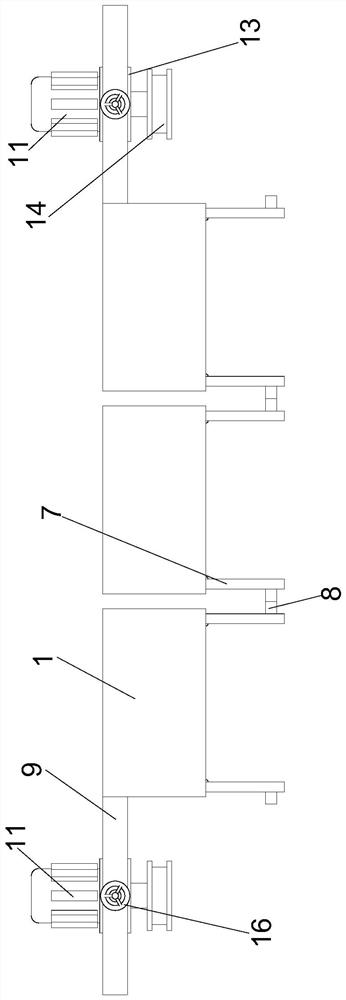

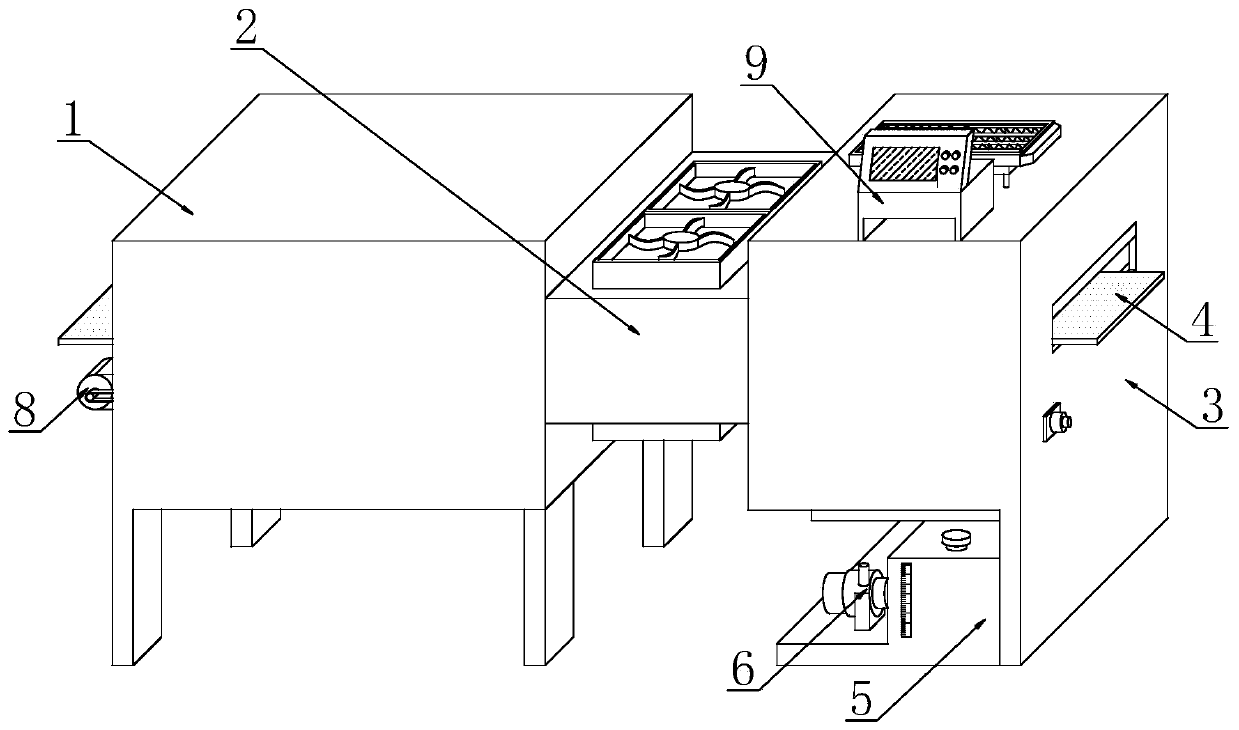

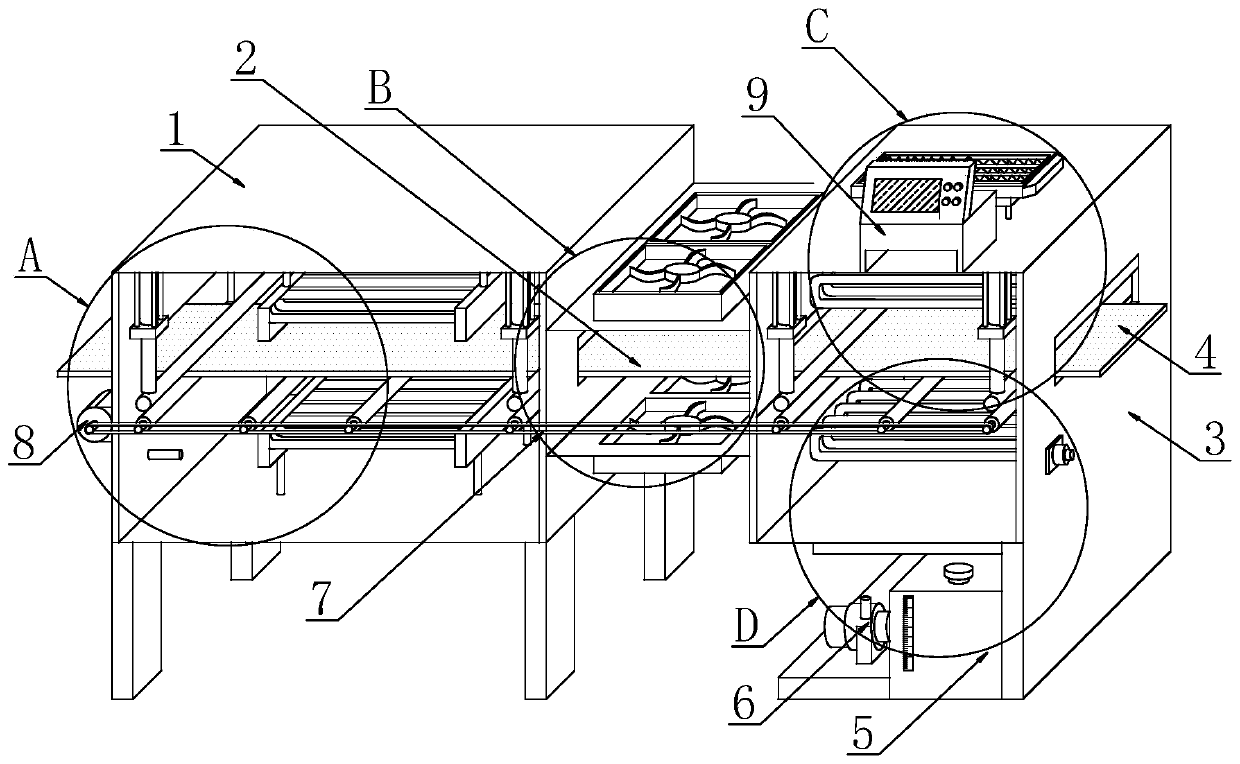

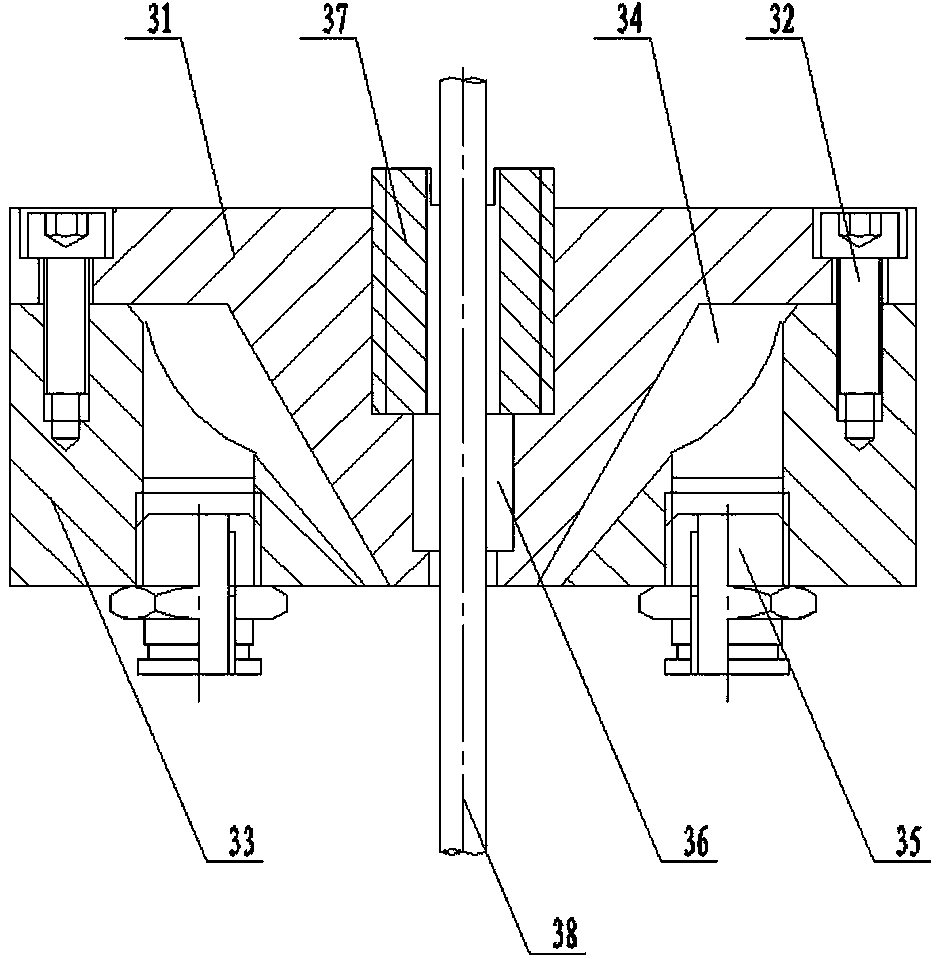

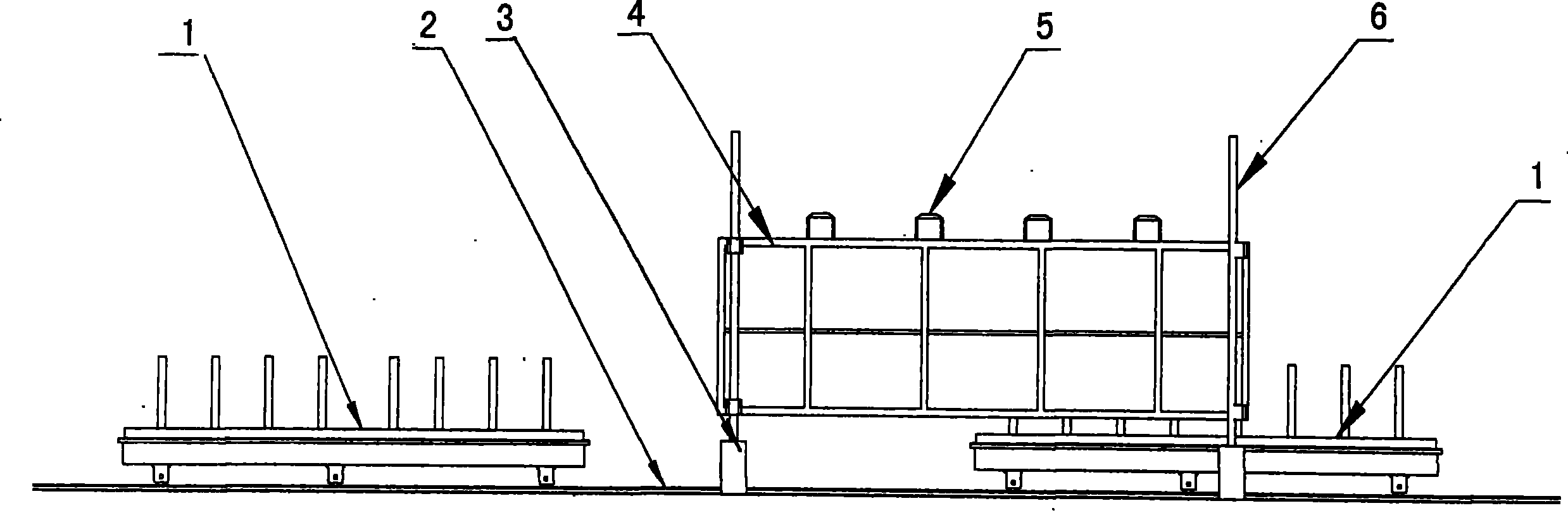

High-frequency annealing device of semi-automatic bearing

ActiveCN103740923AUniform annealingImprove processing qualityFurnace typesHeat treatment furnacesQuenchingEngineering

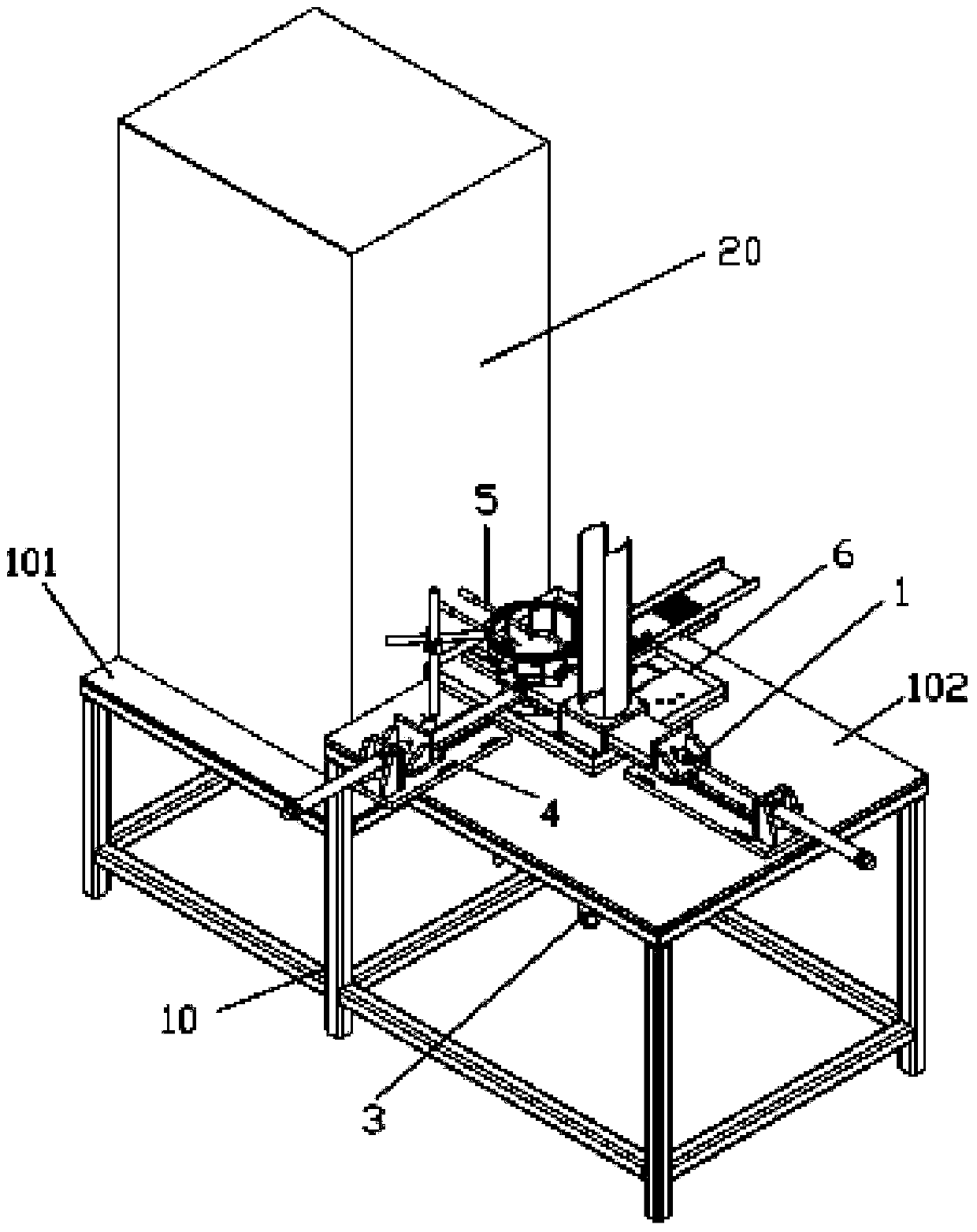

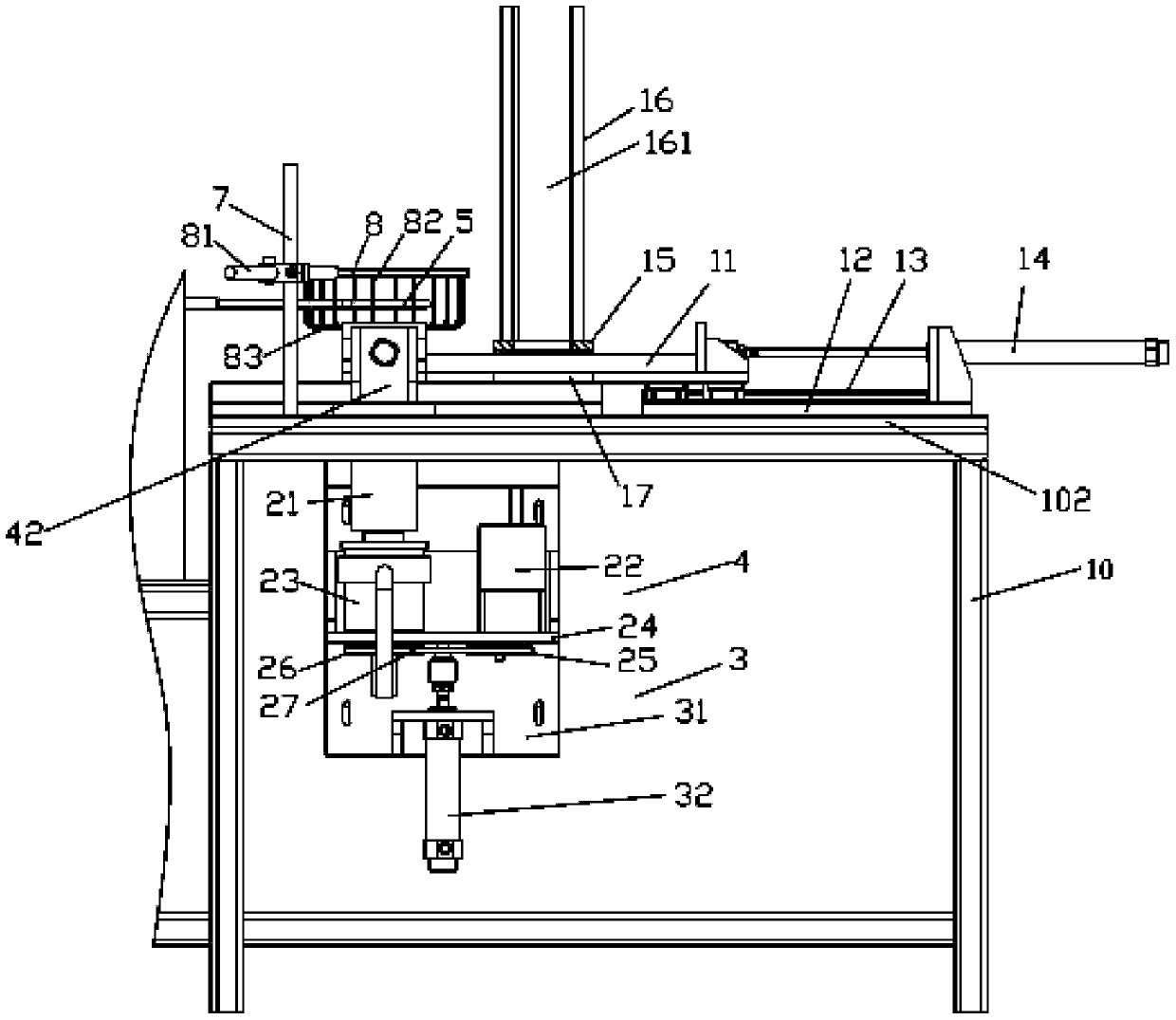

The invention discloses a high-frequency annealing device of a semi-automatic bearing. The high-frequency annealing device comprises a machine frame and a high-frequency power supply device, wherein the high-frequency power supply device is fixed on a left-side supporting plate of the machine frame; a feeding device, a rotating device, a lifting device and a discharging device are fixed on the right-side supporting plate of the machine frame, the lifting device is fixed on the reverse side of the right-side supporting plate of the machine frame, the rotating device is fixed on a push rod of the lifting device, and a rotating shaft of the rotating device is inserted and sleeved in a circular through hole formed in the right-side supporting plate; an induction coil is mounted on the high-frequency power supply device, and is above the right-side supporting plate, and the induction coil and the rotating shaft share the same central axis; the feeding device and the discharging device are fixed on the upper plane of the right-side supporting plate, a feed end of a feed plate of the feeding device faces to the circular through hole, and a discharging end of a discharging plate of the discharging device faces to the circular through hole. The high-frequency annealing device can automatically feed to anneal, the hardness of the inner ring of the bearing is ensured, annealing is even, the secondary quenching phenomenon is not generated, the processing quality is increased, and the stability is good.

Owner:ZHEJIANG XCC GRP CO LTD

Laser irradiation apparatus, laser irradiation method, and method for manufacturing crystalline semiconductor film

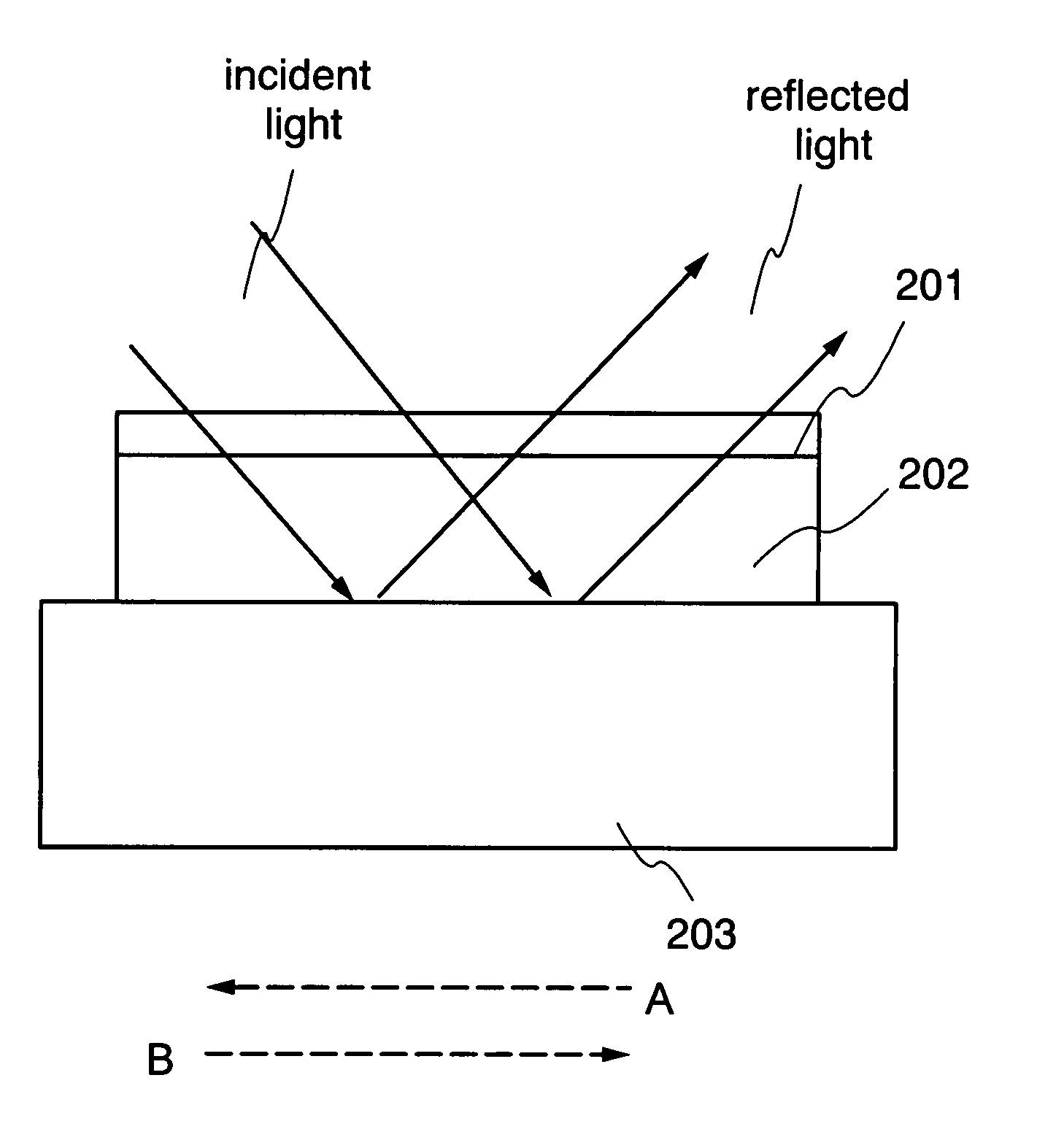

InactiveCN1638039AReduce characteristic unevennessUniform laser irradiation intensityTransistorElectroluminescent light sourcesLight speedRefractive index

An object of the present invention is to provide a compact laser irradiation device and a laser irradiation method using an optical system including an electric mirror and an fθ lens, which can suppress interference caused by secondary beams on the back side of a substrate Therefore, uniform laser annealing can be performed on the irradiated object, and the throughput can be improved. In the present invention, when it is assumed that the thickness of the substrate on which the object to be irradiated is formed is d, the refractive index is n, and the speed of light in vacuum is defined as c, the pulse width t of the laser beam satisfies the inequality ct<2nd. In the above structure, even if an optical system including an electric mirror and an fθ lens is used, the influence of interference due to the secondary beams on the backside of the substrate can be reduced, so that uniform laser annealing can be performed on the object to be irradiated.

Owner:SEMICON ENERGY LAB CO LTD

Laser irradiation apparatus, laser irradiation method, and method of manufacturing a semiconductor device

InactiveUS20050111339A1Efficient executionReduce weightTransistorCombination recordingUltrasound attenuationDevice material

At edges of laser light on an irradiation surface or in the vicinity thereof, the energy density is attenuated gradually due to aberration of a lens or the like. Since such regions (attenuation regions) do not have enough energy density for annealing of an irradiation object, uniform annealing of the irradiation object is not possible. In the present invention, one of the plural laser beams is divided into two laser beams so that each section of the two laser beams serves as an edge of the resultant laser light. Each attenuation region of the two laser beams is synthesized with an attenuation region of another laser beam. In this way, laser light every part of which has an energy density suitable for satisfactory annealing of an irradiation object can be obtained from plural laser beams having attenuation regions.

Owner:SEMICON ENERGY LAB CO LTD

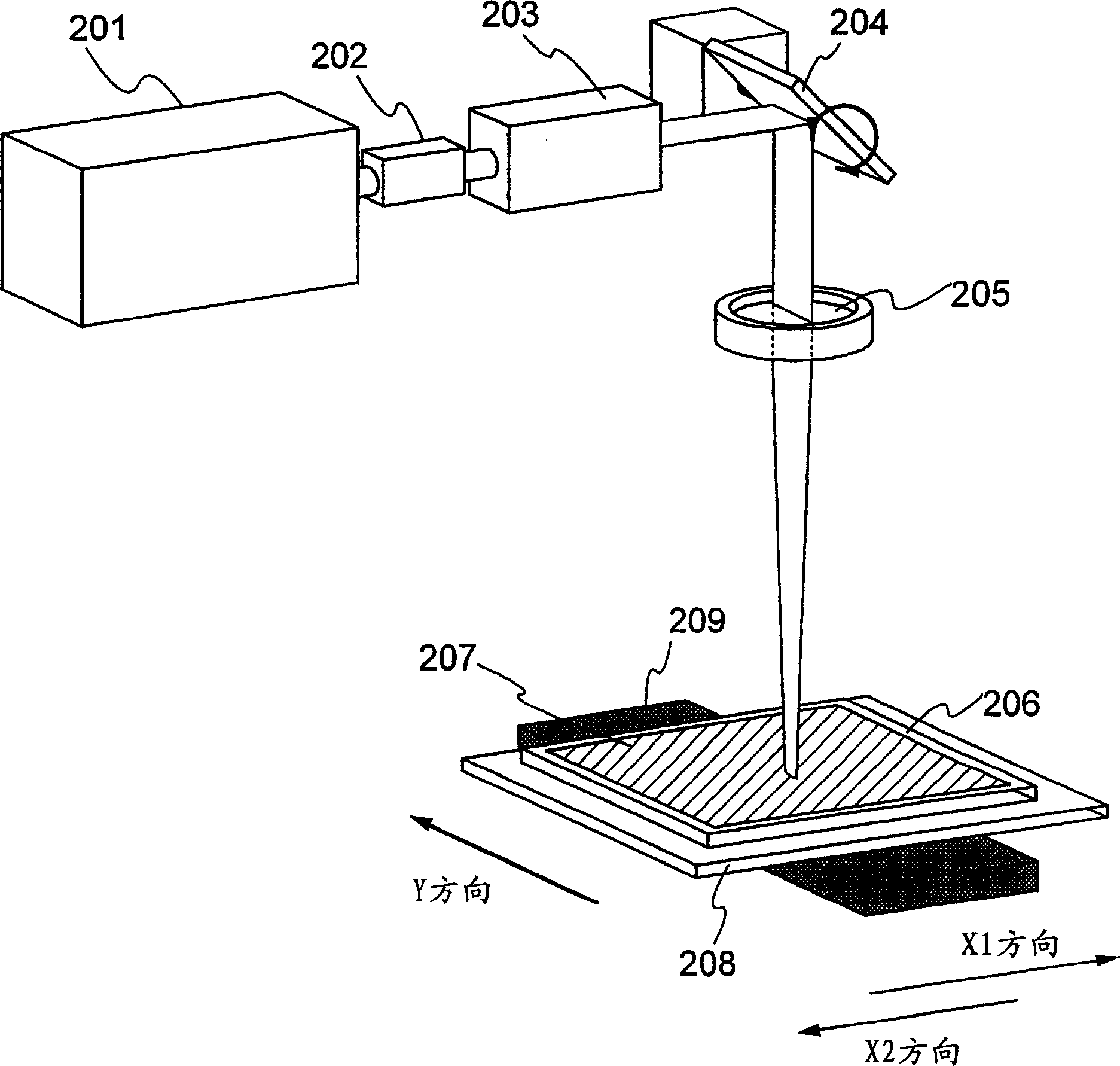

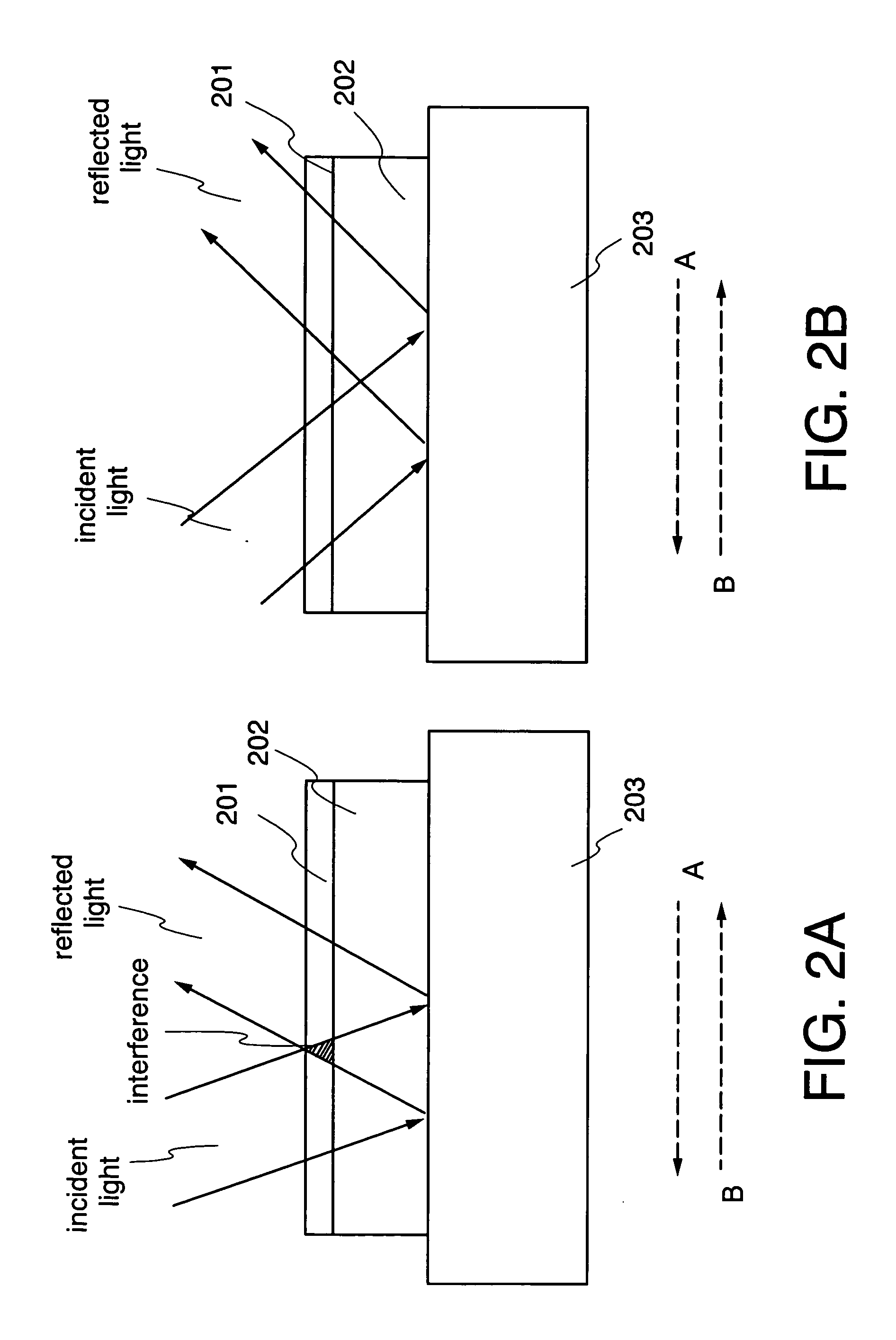

Laser irradiation method, method for manufacturing a semiconductor device, and a semiconductor device

InactiveUS20050037553A1Improve uniformitySmall transmittanceTransistorSemiconductor/solid-state device manufacturingDevice materialLight beam

The present invention discloses the semiconductor device having the substrate that reflects the laser beam on a surface; that absorbs the laser beam therein; or that partially reflects the laser beam on the surface and partially absorbs the laser beam in the laser annealing. Moreover, the substrate has a poly-crystalline semiconductor film having a large grain size. The present invention suppresses the effect due to the reflected light from a rear surface of the substrate and therefore the uniform laser annealing can be performed.

Owner:SEMICON ENERGY LAB CO LTD

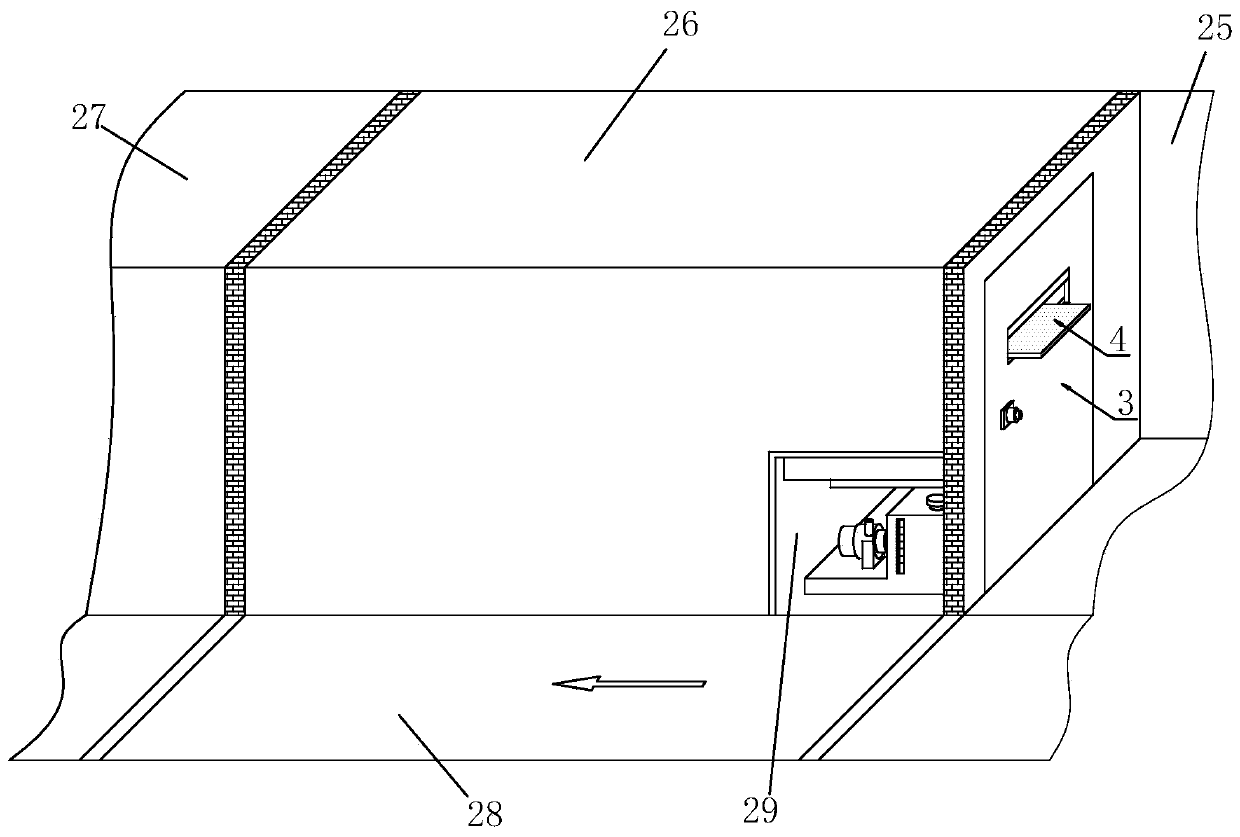

Annealing process and equipment for foamed glass blank

The invention relates to an annealing technique and an annealing device. The annealing technique for chunk foam glass is as follows: the annealing is performed in a kiln, and the chunk foam glass is annealed by adoption of the continuous mesh-belt conveying means; and the temperature of a hearth of the kiln is gradually reduced from the high temperature on an inlet to the normal temperature on an outlet. The annealing device for the chunk foam glass comprises the kiln, wherein, the inside of the furnace is provided with a continuous mesh-belt conveyer, provided with 20 to 50 temperature decreasing regions from the inlet to the outlet, and is also provided with a temperature control system. Due to adoption of continuous mesh-belt conveying of the chunk foam glass, continuous operation is realized; due to adoption of gradual temperature reduction in the kiln, the uniform annealing for a long time is realized, thereby high-performance foam glass with difficulty in fracture, high strength and low thermal conduction is produced; and due to arrangement of a plurality of temperature regions inside the furnace, the temperature is convenient to control independently.

Owner:ZHEJIANG ZHENSHEN INSULATION TECH CORP

Method for preparing wide range pure nickel cold rolling coiled material

The invention discloses a method for preparing a wide range pure nickel cold rolling coiled material. The method includes the following steps of (1) subjecting pure nickel hot rolled plates to atmosphere annealing treatment; (2) subjecting the pure nickel hot rolled plates to cold rolling scale breaking, and removing oxide-scales by acid pickling to obtain plates; (3) cutting and trimming heads and tails of multiple plates on a finishing machine, then performing plasma tailor welding, and rolling to obtain a rolled billet; (4) rolling the rolled billet for one rolling process to obtain a coiled material; (5) performing oil removal processing; (6) performing vacuum annealing treatment; and (7) uncoiling, and cutting and removing head and tail leading tape portions to obtain the wide range pure nickel cold rolling coiled material, or repeating the steps (4), (5) and (6) once, uncoiling, and cutting and removing the head and tail leading tape portions to obtain the wide range pure nickel cold rolling coiled material. The method has the advantages that the method is simple, the industrialized production is easy to achieve, the pure nickel coiled material with the thickness of 0.5mm to 2.0mm and the breadth of 1200mm to 1400mm can be prepared through one to two times of cold rolling, and the blank of domestic wide range pure nickel coiled material is filled.

Owner:WESTERN TITANIUM TECH

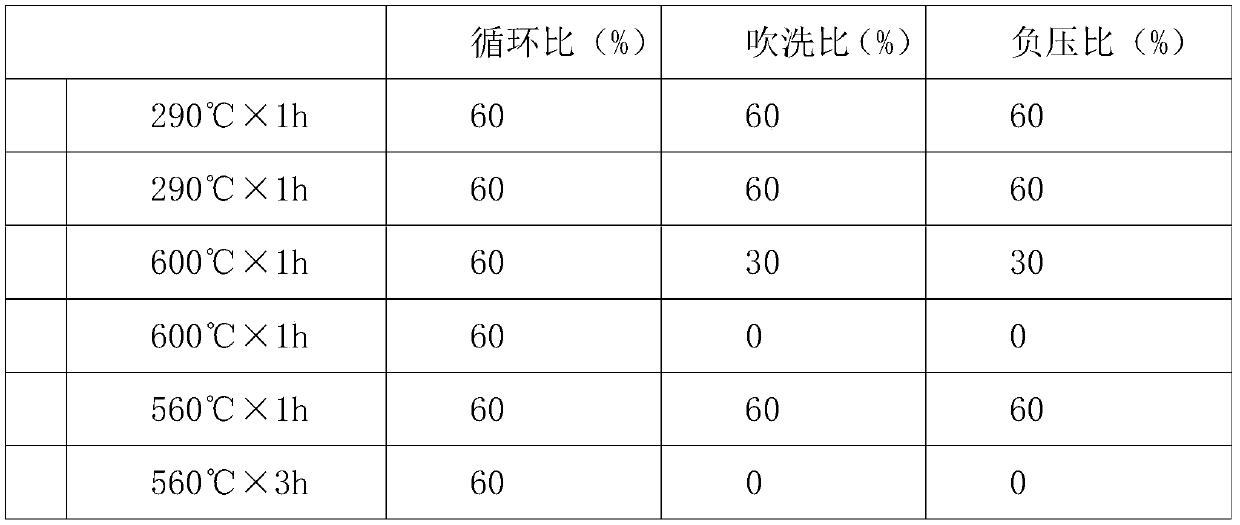

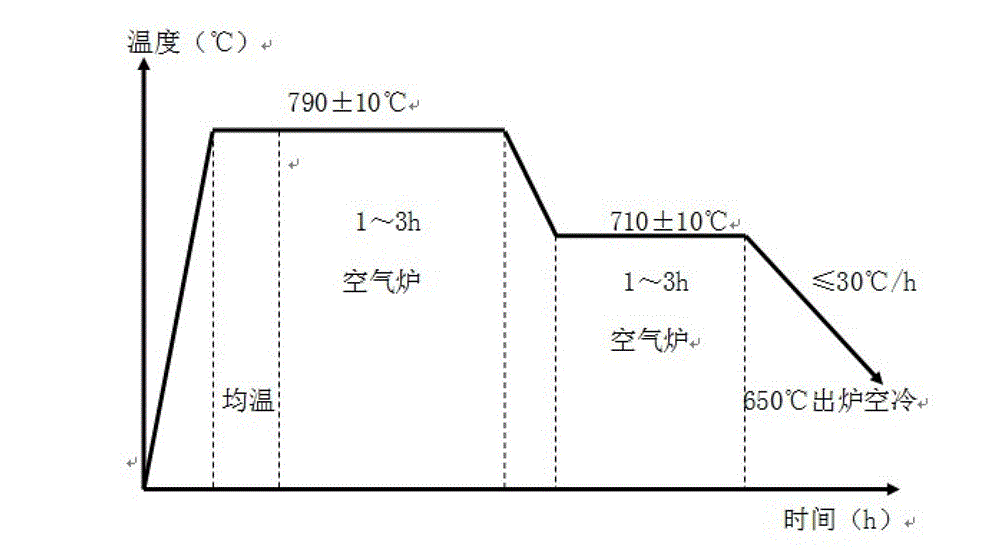

Annealing technology for 8006-alloy double zero aluminum foil

InactiveCN110387514AReduce in quantityReduce depthFurnace typesProcess efficiency improvementAlloyAluminum foil

The invention relates to the technical field of double zero aluminum foil annealing and discloses an annealing technology for 8006-alloy double zero aluminum foil. The annealing technology for the 8006-alloy double zero aluminum foil comprises the following specific steps that firstly, outside-furnace standing is conducted; secondly, inside-furnace pretreatment is conducted; thirdly, uniform annealing is conducted; fourthly, intermediate temperature annealing is conducted; fifthly, low temperature annealing is conducted; sixthly, inside-furnace cooling is conducted; and seventhly, the aluminumfoil is discharged from the furnace. By means of the annealing technology for the 8006-alloy double zero aluminum foil, the number of hot-bulged rolls and the hot bulging depth can be lowered; the scrapping amount generated by hot bulging is lowered; and the production cost is lowered.

Owner:安徽中基电池箔科技有限公司

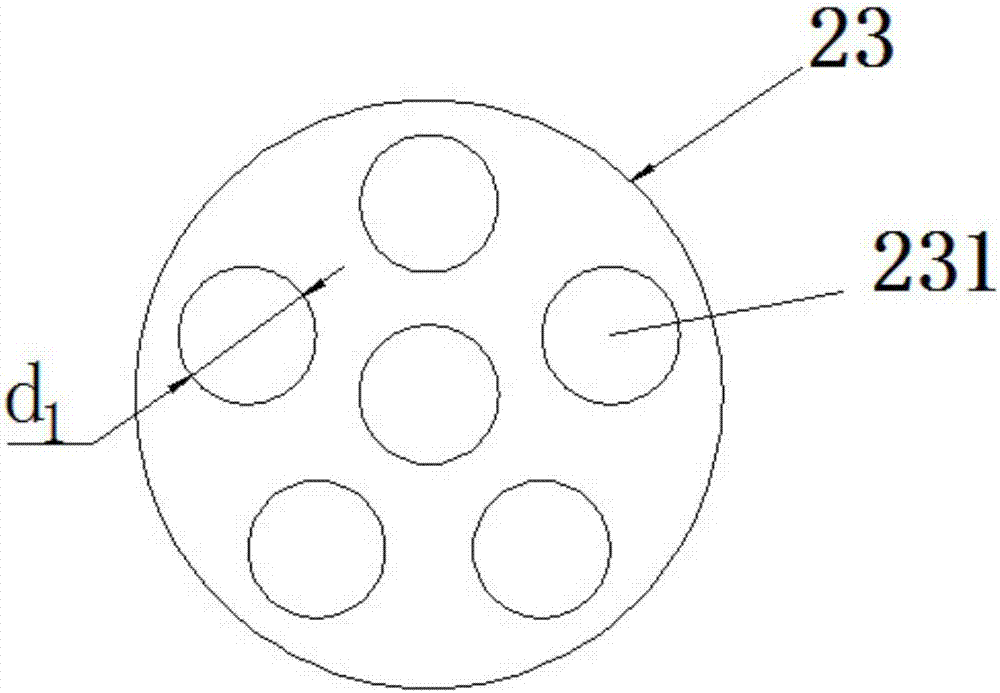

Glass rod material preparation method and preparation device

The invention relates to a glass rod material preparation method and a glass rod material preparation device. The glass rod material preparation method comprises the following steps: (a) putting a material into a material barrel; (b) feeding protection gas into the material barrel, a forming mold and a collimating mold; (c) controlling a heating unit to perform heating, preserving the heat till the temperature in the heating unit reaches softening temperature Ts of the material, controlling an annealing unit to be heated, and preserving the heat till the temperature in the annealing unit reaches annealing temperature of the material; (d) extruding the softened material, wherein after passing through the material barrel and being prepared into a rod material through the forming mold, the material enters the collimating mold; (e) enabling the heating unit to stop heating, naturally cooling the heating unit, preserving the heat of the annealing unit, and after the annealing unit is subjected to heat preservation for T, naturally cooling the annealing unit; and (f) after the annealing unit is cooled, taking out the material, and collimating and forming the material through the collimating mold, thus preparing the glass rod material. The forming mold is detachable, thus facilitating production of glass rod materials with different sizes; and furthermore, one forming mold can be provided with multiple through holes, so that the glass rod material production efficiency is improved.

Owner:NINGBO SUNNY INFRARED TECH COMPANY

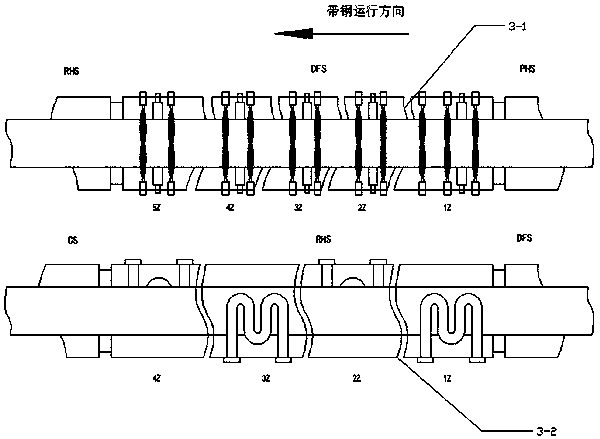

Method for preventing weld seam strip breakage of thin material strip steel

ActiveCN109014646AEffective controlReduce tensionWelding/cutting auxillary devicesAuxillary welding devicesWeld seamStrip steel

The invention relates to a method for preventing weld seam strip breakage of thin material strip steel. The method is characterized by comprising the following steps of (1) welding control; (2) entryloop control; (3) continuous annealing control; (4) air knife control; and (5) leveling and withdrawing-straightening control. The method effectively avoids the technical problem of the weld seam strip breakage of the strip steel through the coordinated control of multiple steps.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

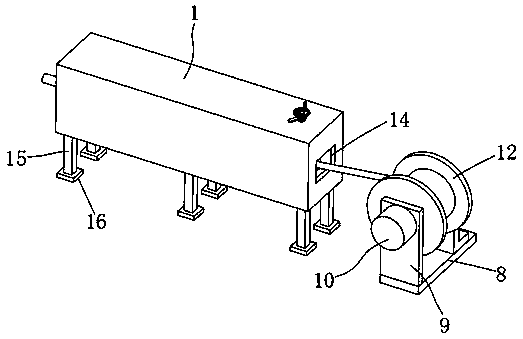

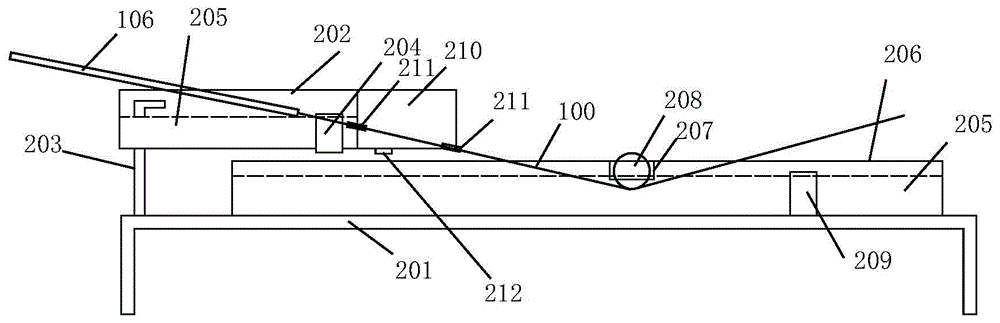

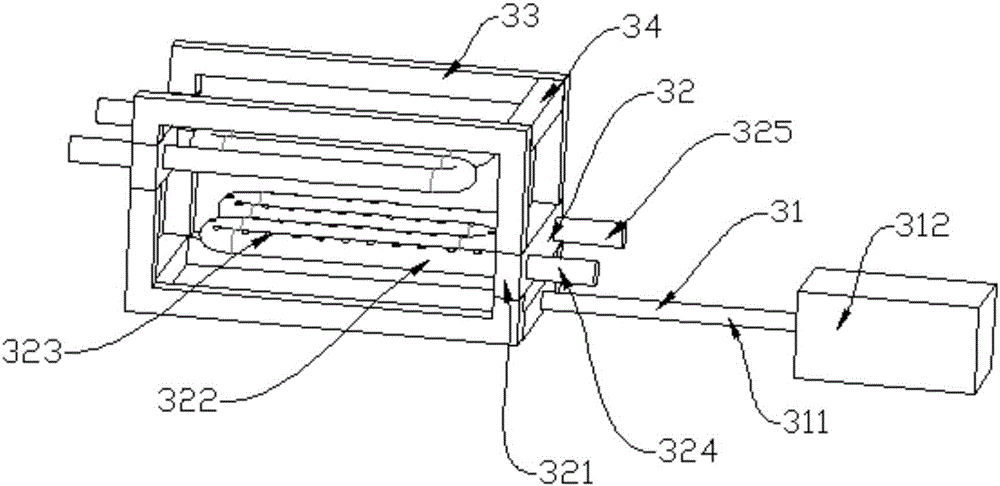

Annealing and drawing device for oxygen-free copper tube, with high diameter-to-thickness ratio, for mobile phone heat pipe

PendingCN110227731AImprove the annealing effectReduce volumeExtrusion profiling toolsFurnace typesMobile phoneMaterials science

The invention discloses an annealing and drawing device for an oxygen-free copper tube, with high diameter-to-thickness ratio, for a mobile phone heat pipe. The annealing and drawing device comprisesa box body; a drawing die is mounted in the box body; an annealing pipe is mounted between the drawing die and the box body; a heating wire is wound around the side wall of the annealing pipe; a fixing plate is arranged on one side of the drawing die; a supporting roller is rotationally connected onto the fixing plate; a tension adjusting mechanism is arranged on one side of the supporting roller;a mounting plate is arranged on the outer side of one end, close to the tension adjusting mechanism, of the box body; the mounting plate is mounted on the ground; a supporting frame is fixed to one side of the upper end of the mounting plate; a servo motor is fixed to the upper end of the supporting frame; a rotating shaft is fixed to the end part of an output shaft of the servo motor; a windingwheel is in keyed connection onto the rotating shaft; and a supporting mechanism is arranged at one end, far from the servo motor, of the rotating shaft. Through the adoption of the structure, the oxygen-free copper tube for the mobile phone heat pipe is uniform in annealing, and uniform in drawing traction, and the production quality of a rope is improved.

Owner:JIANGXI NAILE COPPER IND

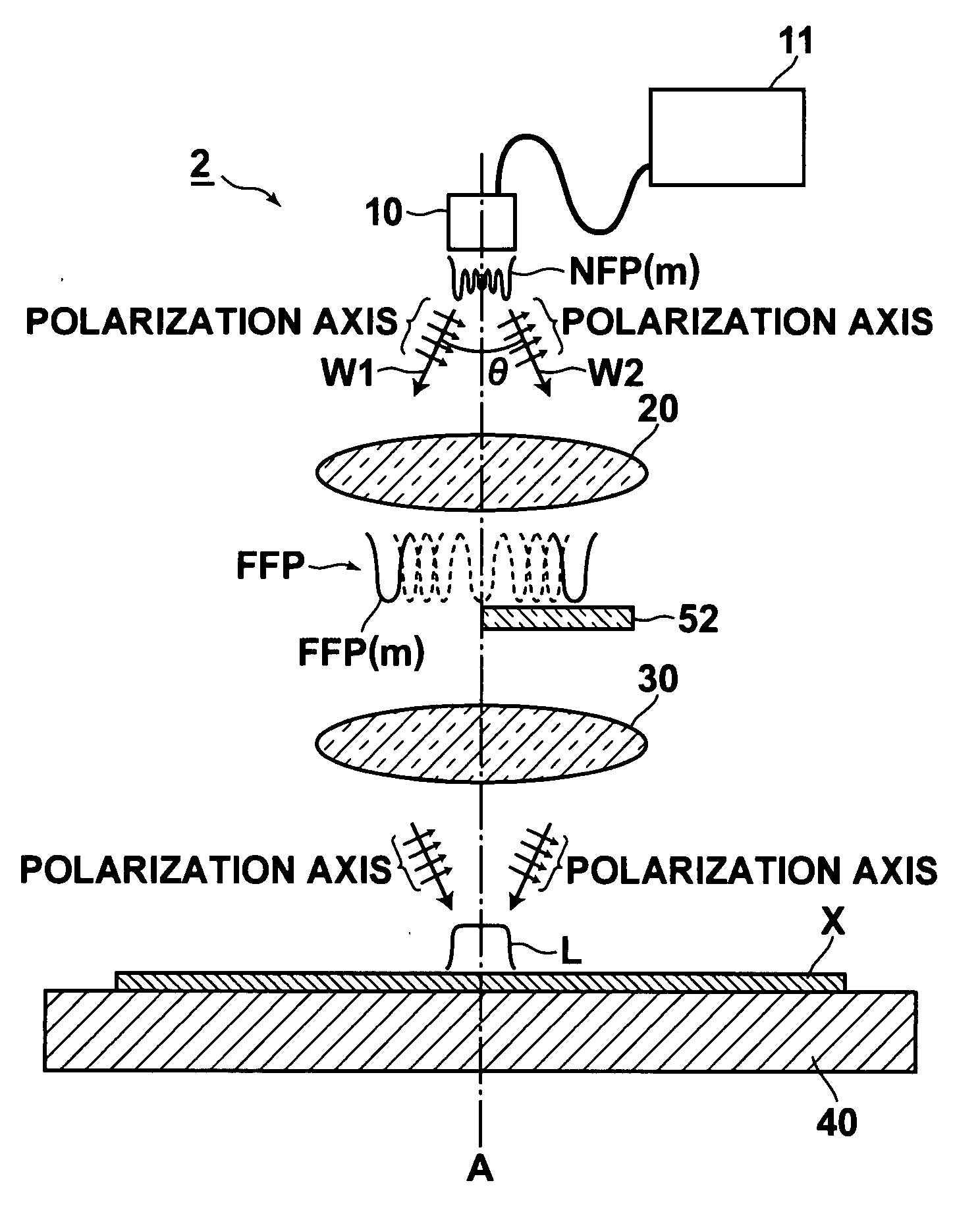

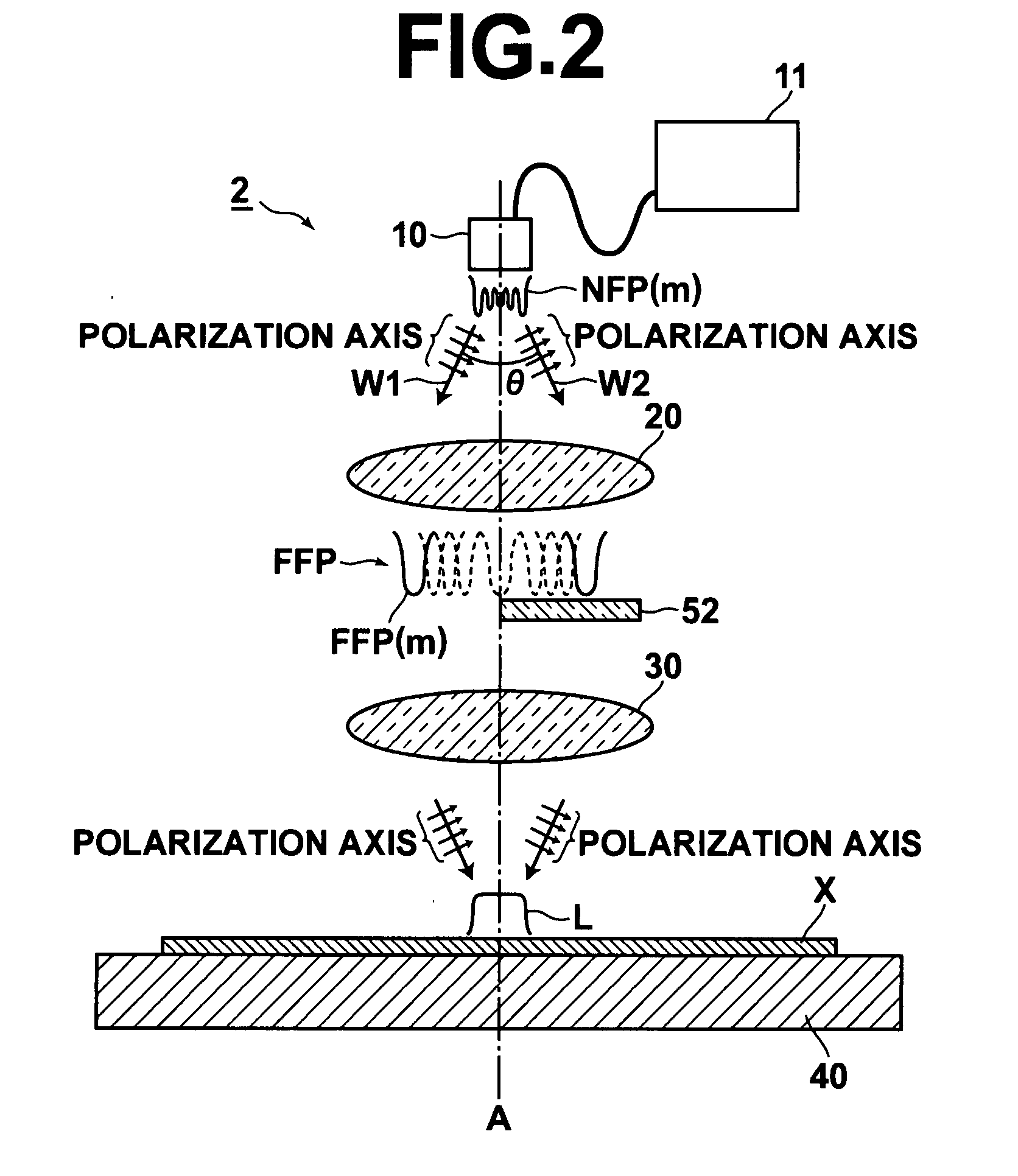

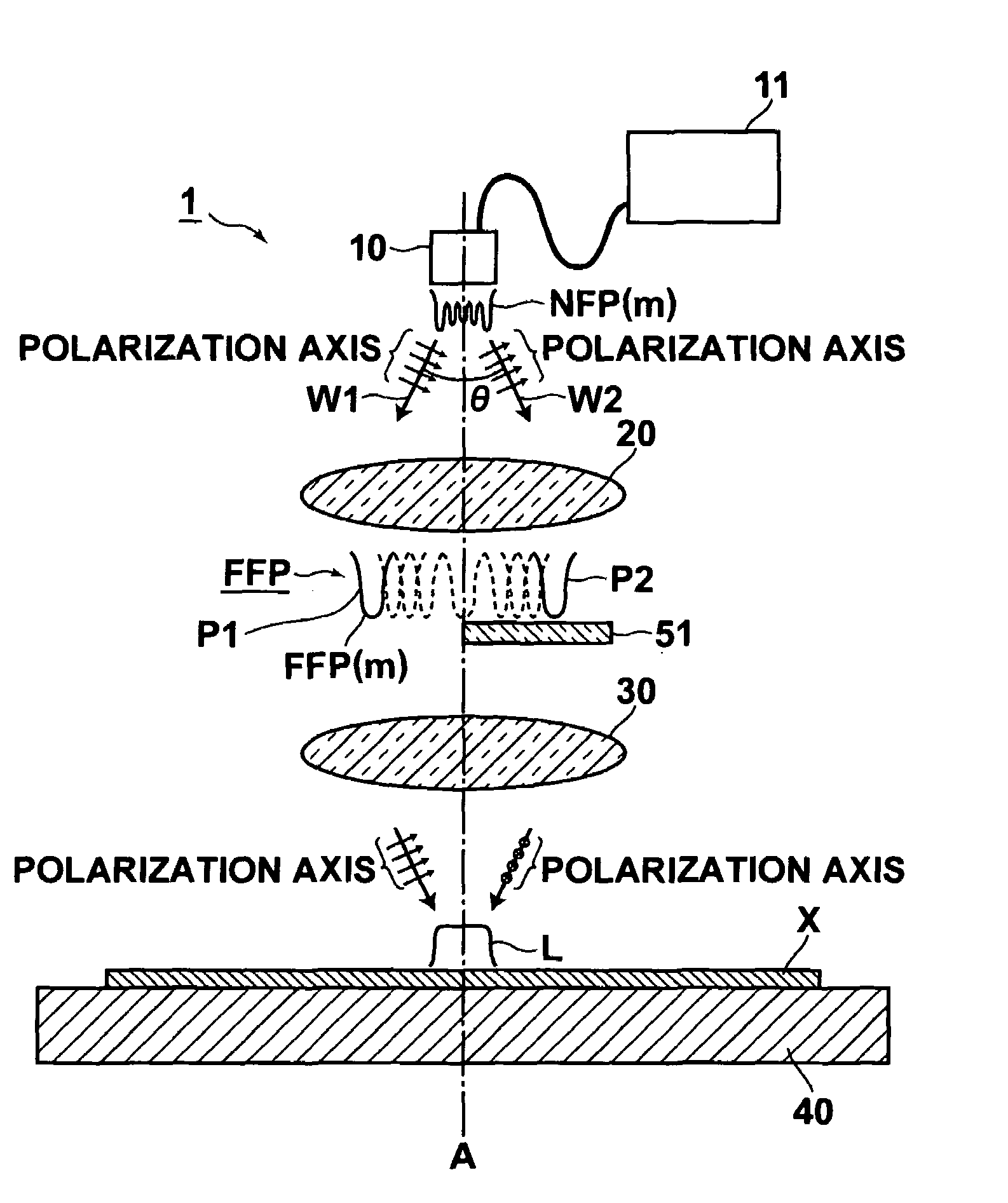

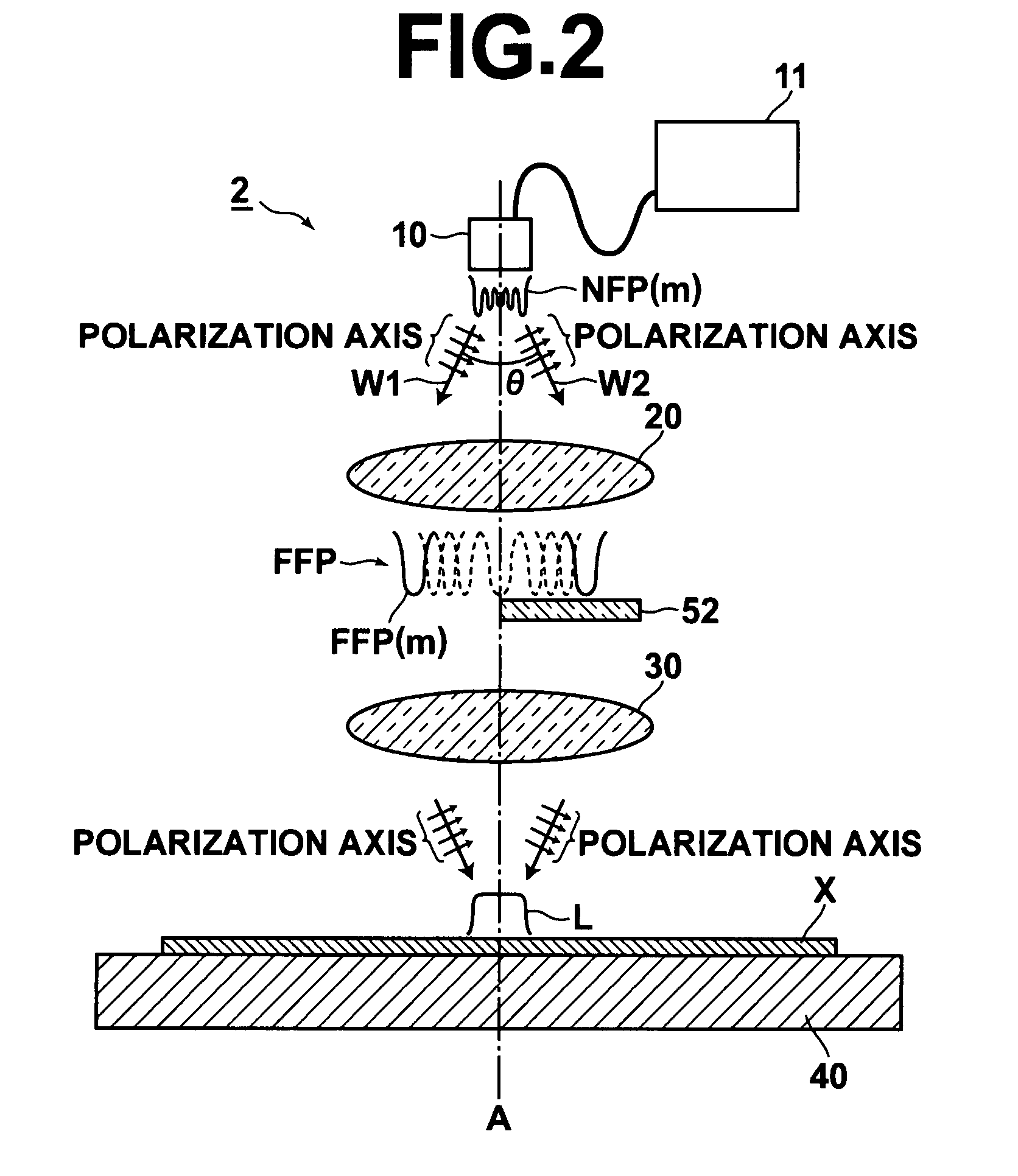

Laser exposure apparatus and laser annealing apparatus

InactiveUS20070205185A1Reduction of coherencyUniform annealingSemiconductor/solid-state device manufacturingPhotographic printingOptical axisLaser exposure

A laser exposure apparatus is disclosed. The laser exposure apparatus includes: a laser light source including a multi-transverse mode semiconductor laser; a far-field pattern forming optical system for forming a far-field pattern of multi-transverse mode laser light emitted from the laser light source; a condensing optical system for condensing the laser light emitted from the far-field pattern forming optical system and applying the condensed laser light to a substance to be exposed; and a coherency reducing means disposed in an optical path between the laser light source and the substance to be exposed, for reducing coherency of two wavefront components that are contained in high-order transverse mode light of each order emitted from the laser light source and propagate in substantially symmetrical directions with respect to the optical axis.

Owner:FUJIFILM CORP

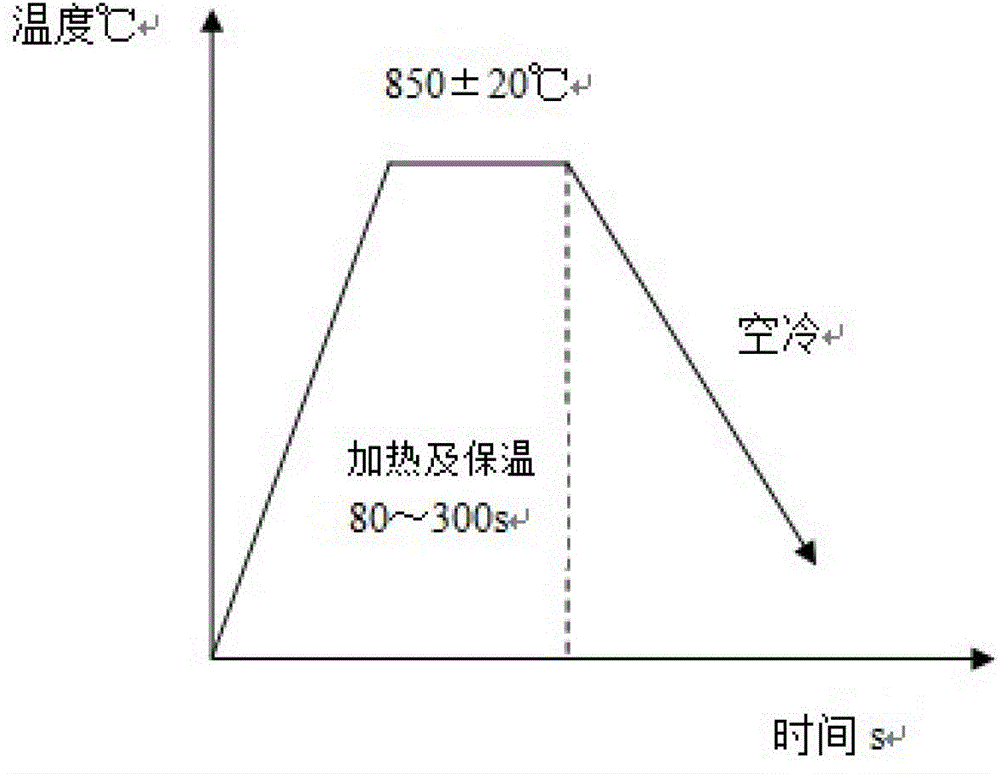

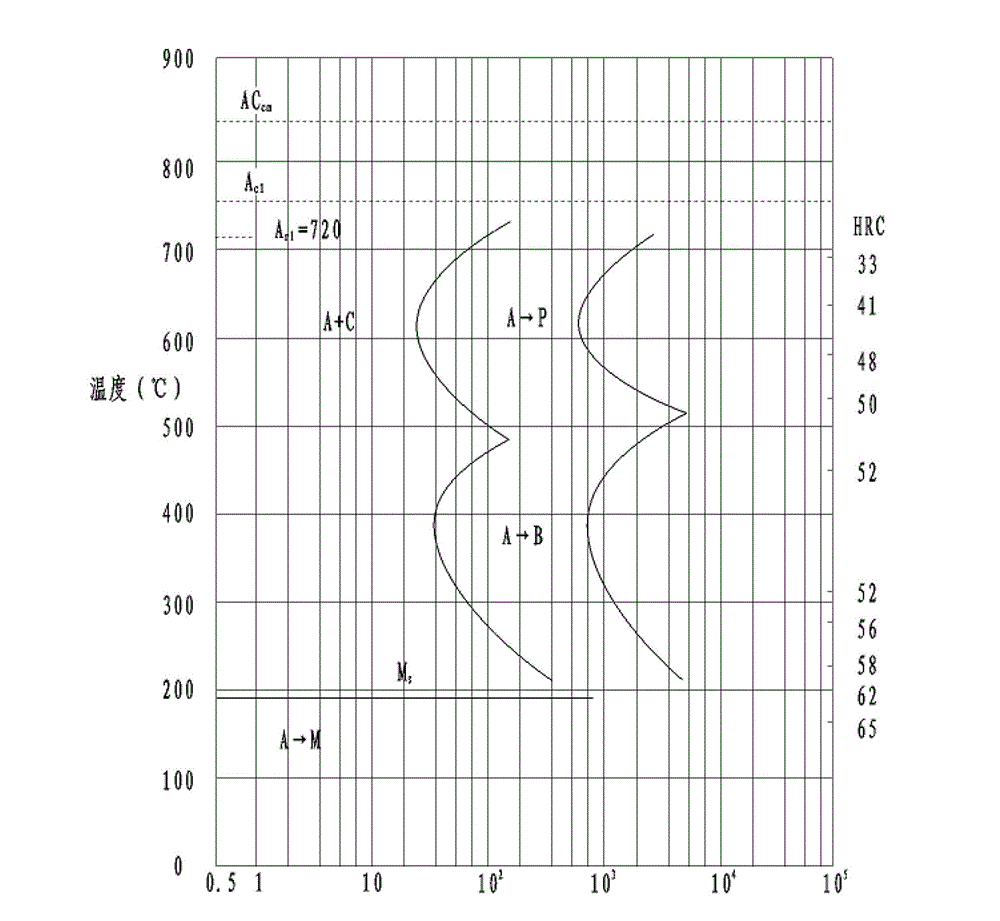

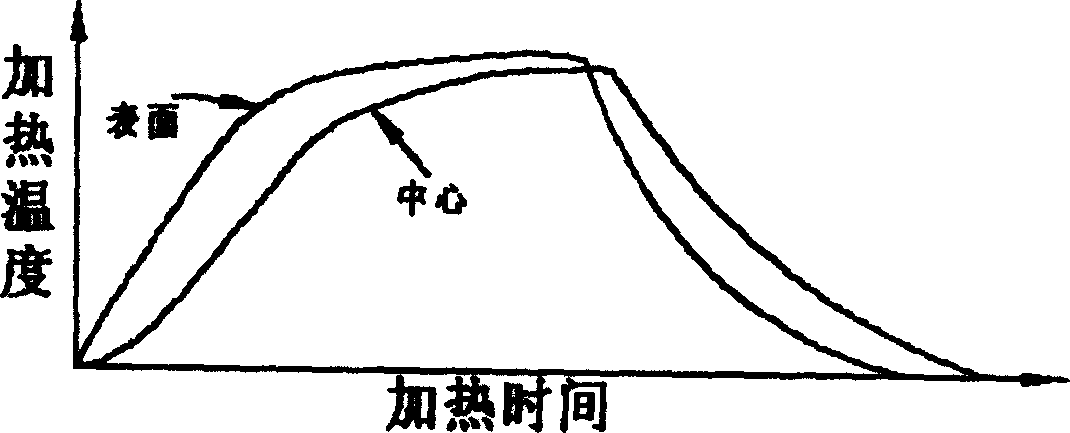

Induction annealing process of 95CrMo steel for rock drilling rod

InactiveCN103146894AReduce energy consumptionShorten the production cycleIncreasing energy efficiencyMedium frequencyHardness

The invention discloses an induction annealing process of 95CrMo steel for a rock drilling rod. In the process, medium frequency induction heating is adopted, the heating temperature is controlled to be 830-880 DEG C, the heating and heat-insulating time is controlled to be 80-300 seconds, the cooling mode is air-cooling, and the annealing hardness is not greater than 255 HB. The induction annealing process disclosed by the invention is an overturn for the traditional annealing process of 95CrMo steel for a rock drilling rod, has the advantages of short heating and heat-insulating time, uniform annealing, low energy consumption, short production cycle, low production cost and the like, does not need a cooling device, is a historic transformation for the annealing process for 95CrMo steel for a drilling tool, and has great use value and economic value at present when energy conservation and environment protection are advocated in the whole society.

Owner:SHOUGANG GUIYANG SPECIAL STEEL

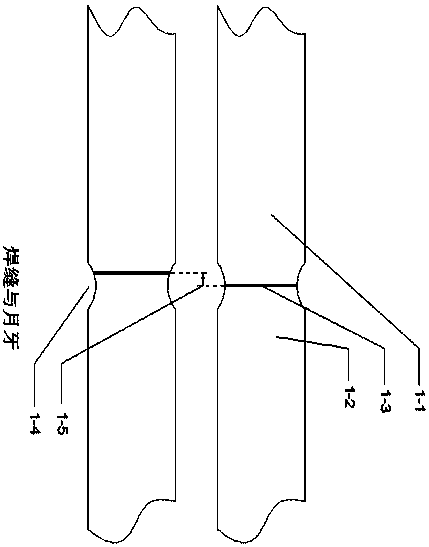

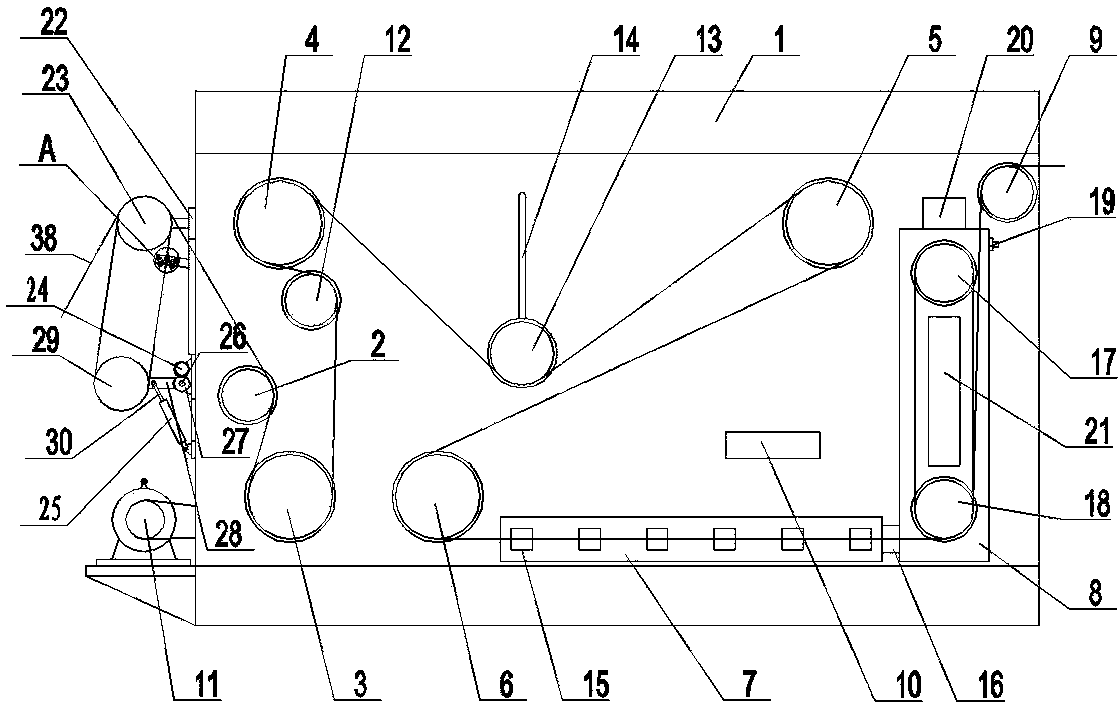

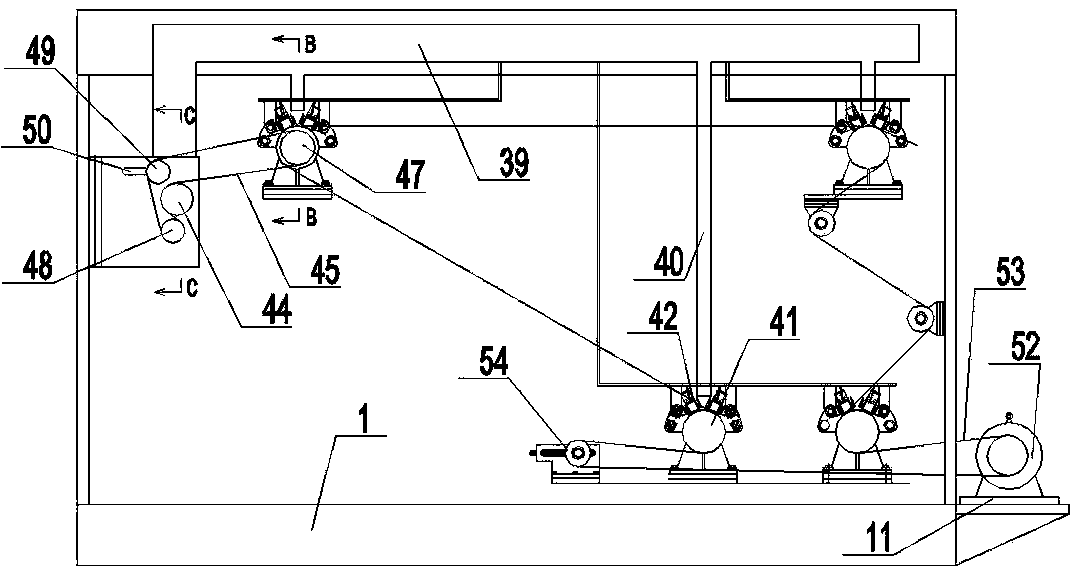

Aluminum wire straightening method of enamelling machine annealing furnace and mechanism of enamelling machine annealing furnace

InactiveCN104021884AGood collimationUniform annealingInsulating conductors/cablesMetallurgyCooling effect

The invention discloses an aluminum wire straightening method of an enamelling machine annealing furnace and a mechanism of the enamelling machine annealing furnace. The method comprises the following step of straightening an aluminum wire in an annealing furnace body by bypassing more than two straightening wheels sequentially, thereby improving the straightness of an enamelled wire after annealing. According to the invention, the straightness of the aluminum wire can be improved effectively; the problem of naked aluminum lead surface scratch caused by poor straightness is solved; the product performance is improved; additionally, the cooling effect in the annealing working procedure is ideal, and the quality problem of instability of paint membrane continuity, breakdown voltage and the like which are troubled for a long time in the aluminum enamelling wire manufacturing industry is solved. Meanwhile, the aluminum wire straightening method of the enamelling machine annealing furnace and the mechanism of of the enamelling machine annealing furnace are simple in structure, low in cost and suitable for industrialization.

Owner:张亚东

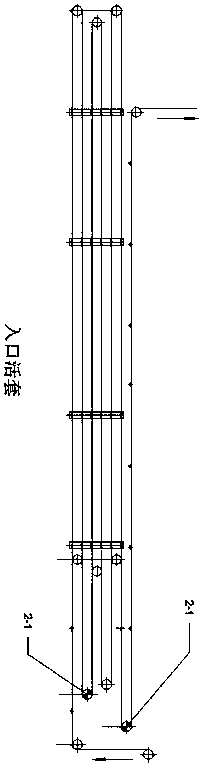

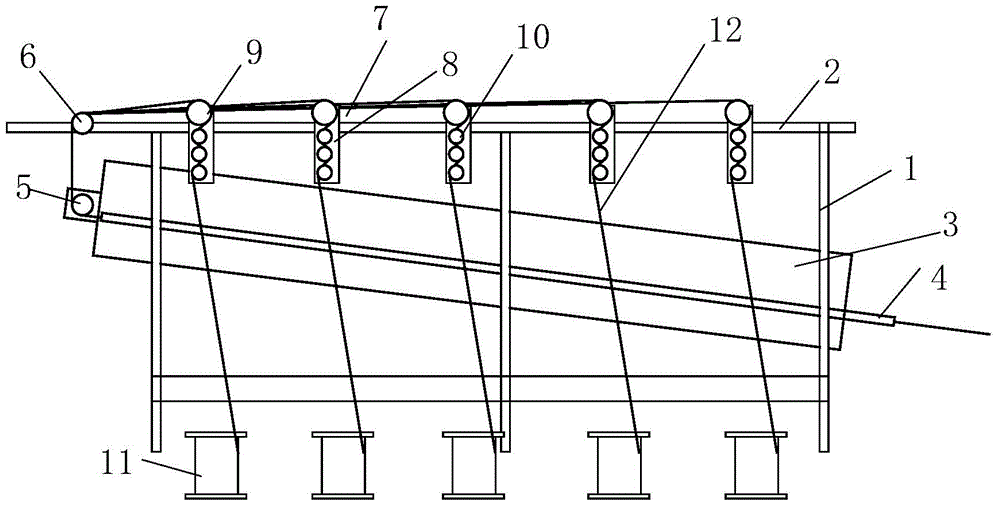

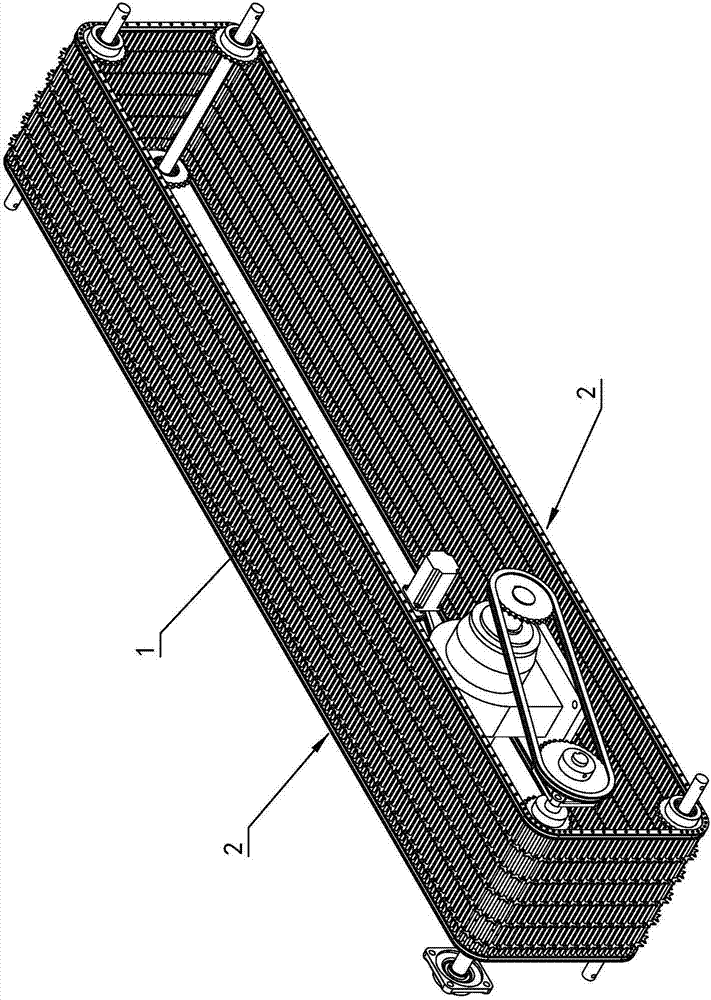

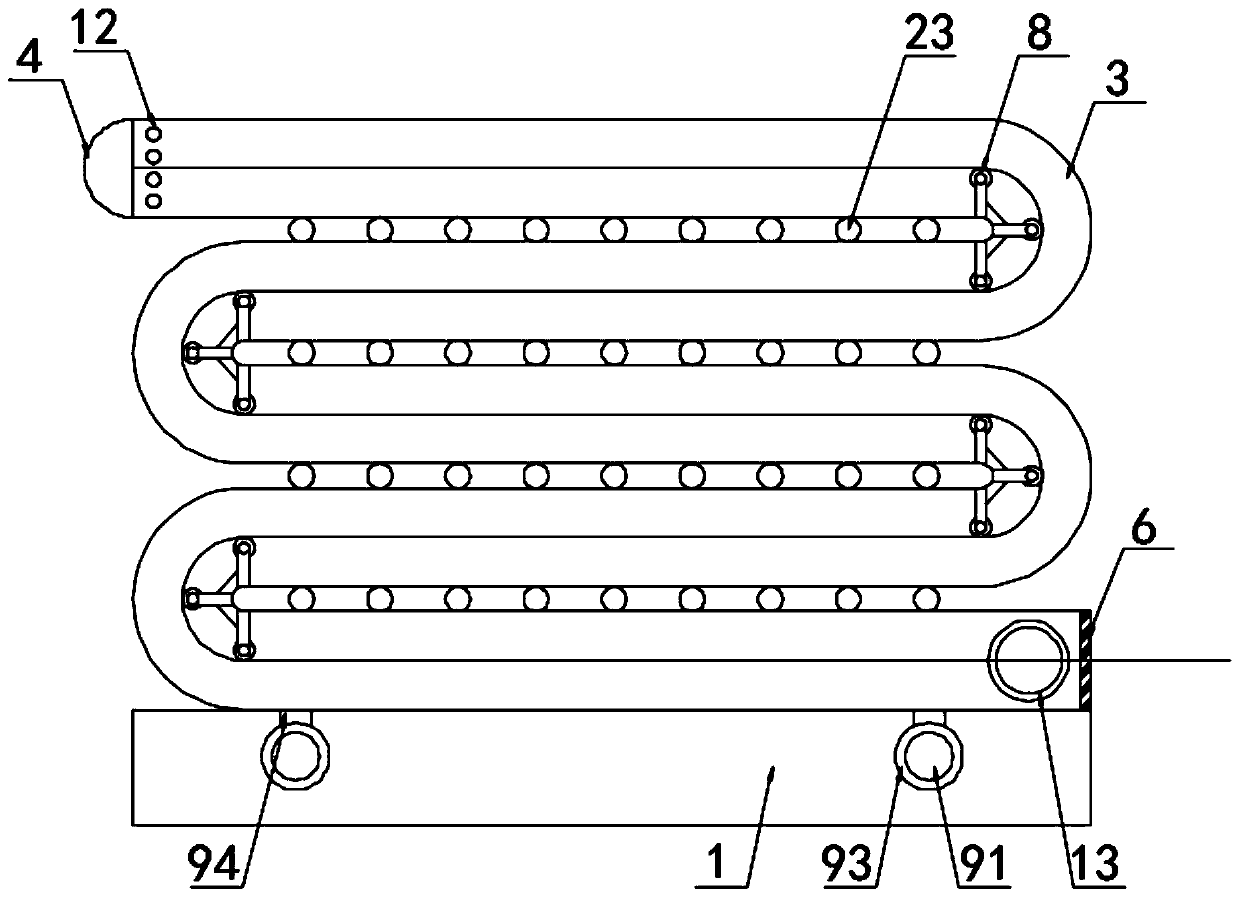

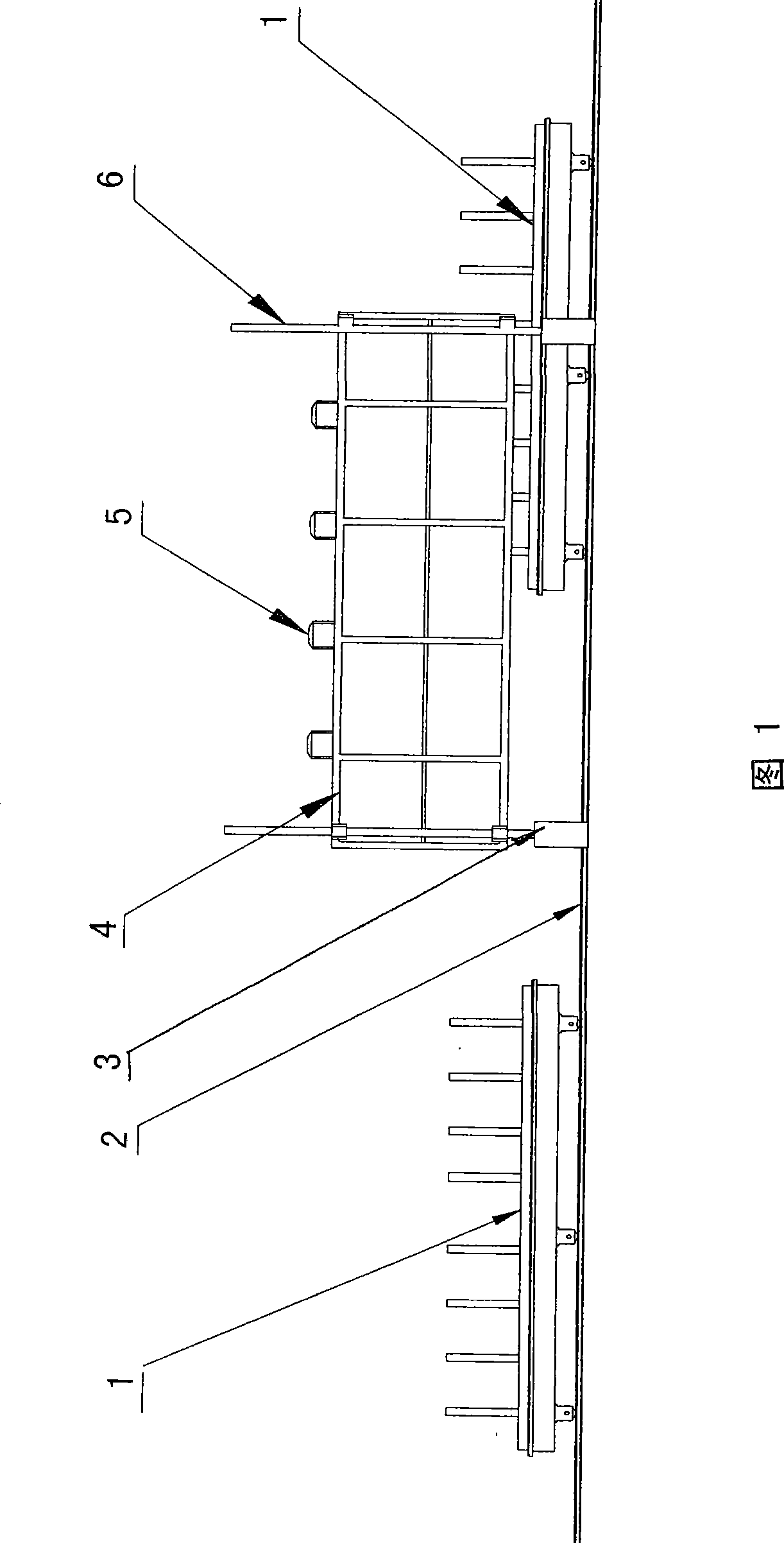

Continuous annealing apparatus and annealing method of titanium and titanium alloy coiled wire material

ActiveCN103469134AContinuous annealingUniform annealingFurnace typesHeat treatment furnacesTitaniumHeating furnace

The invention provides a continuous annealing apparatus and an annealing method of titanium and titanium alloy coiled wire material. The continuous annealing apparatus of titanium and titanium alloy coiled wire material comprises a heating mechanism and a continuous conveying mechanism, wherein, the heating mechanism comprises a box type heating furnace, and the continuous conveying mechanism comprises an internally fixed steel pipe of a wire material furnace, two sets of fixed pulleys and a continuous multiple winding wire rotating mechanism; the internally fixed steel pipe of the wire material furnace is equipped in the box type heating furnace, and the two sets of fixed pulleys are respectively arranged at two ends of the box type heating furnace, and are kept at the same horizontal line of the center line of the internally fixed steel pipe of the wire material furnace. The processed wire materials cross the heating furnace at a uniform speed, can be continuously and multiply wound, thereby realizing continuous and uniform annealing of wire materials with simple structure and good working reliability. The annealing method provided by the invention can be used for continuous and uniform constant temperature heating of single wire material, and during the moving process of wire material, the speed is constant, the heating is uniform, and the obtained wire material has uniform performance.

Owner:西安赛特思迈钛业有限公司

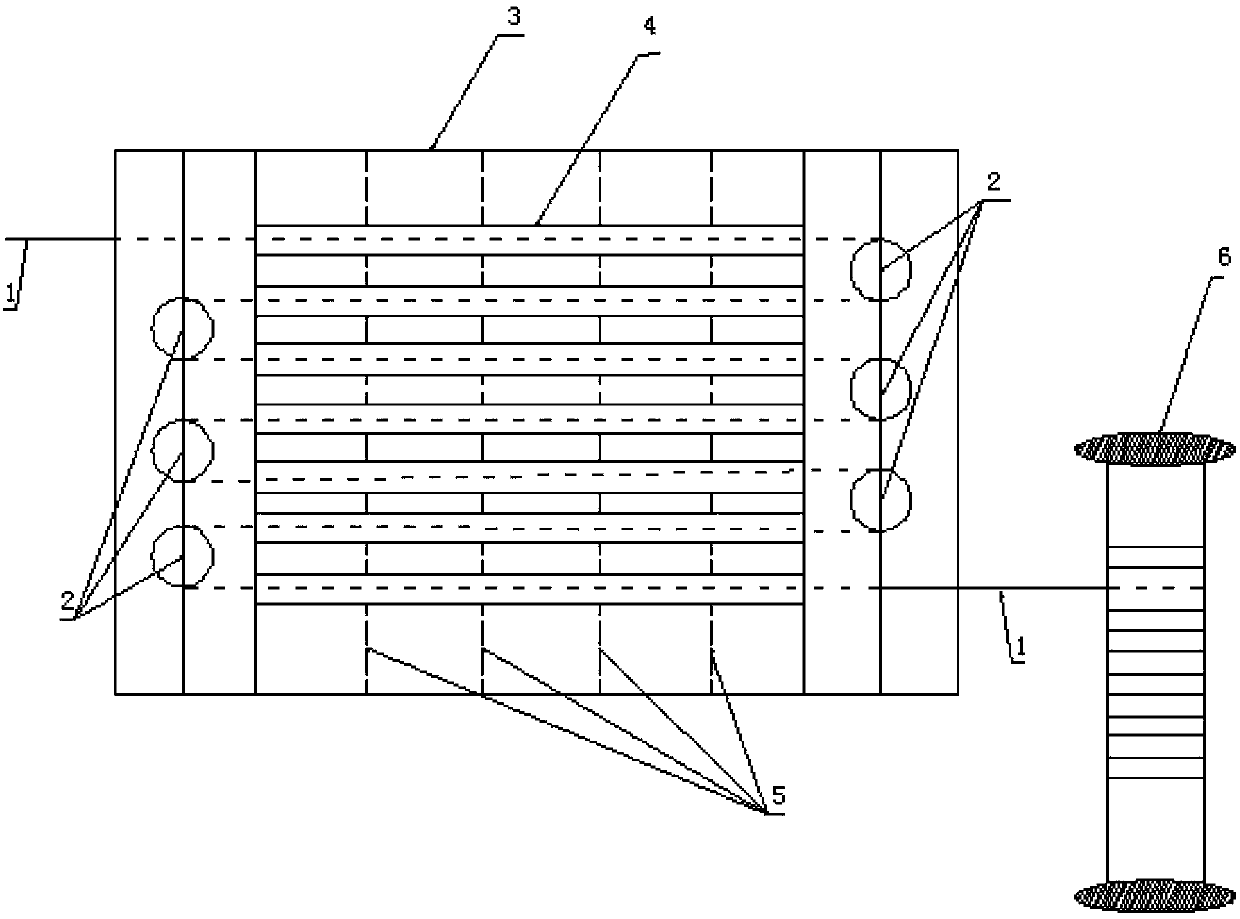

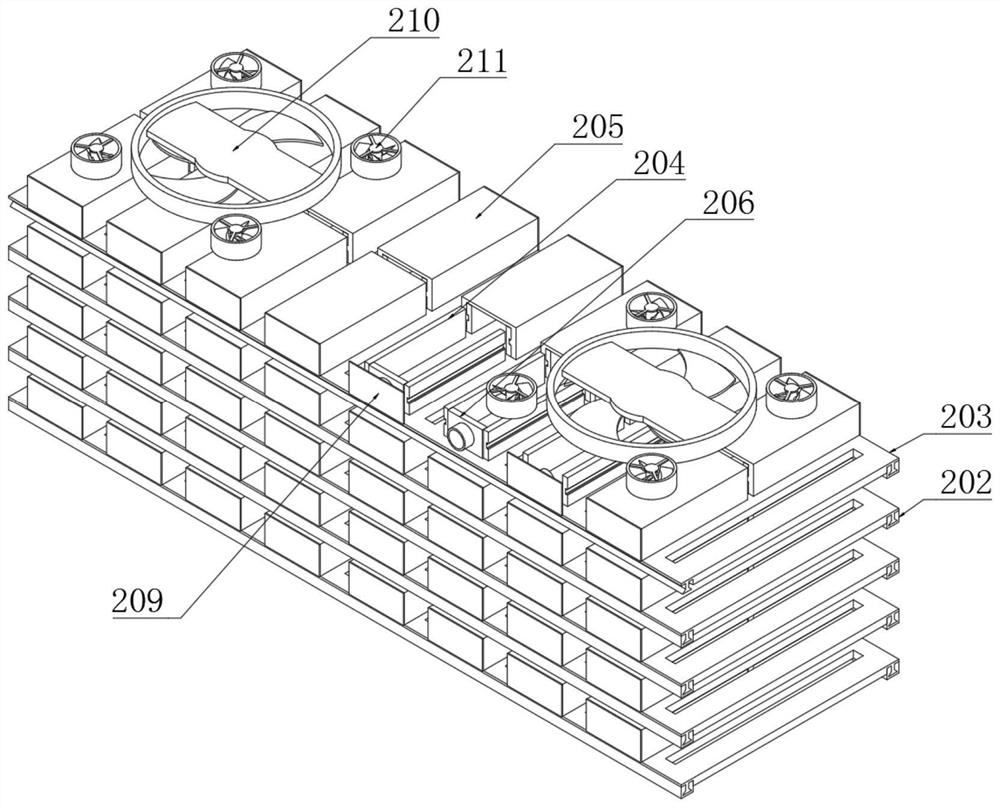

Conveying mechanism for penicillin bottles during annealing of penicillin bottles

The invention discloses a conveying mechanism for penicillin bottles during annealing of penicillin bottles. The conveying mechanism comprises an annealing furnace net belt and transmission chains arranged on two sides of the annealing furnace net belt, wherein the transmission chains comprise chain links and chain pins; the transmission chains are characterized in that chain pins are arranged inwards in an extending manner to be provided with connecting pins; the annealing furnace net belt comprises a plurality of conveying rollers which are arranged in parallel; the end parts of the conveying rollers are connected with the connecting pins; a plurality of V-shaped pillow plate groups are arranged in parallel along the conveying direction on the annealing furnace net belt; and each of the V-shaped pillow plate groups consists of at least two V-shaped pillow plates which are axially arranged on the conveying rollers along the conveying rollers from one end to the other end. The conveying mechanism disclosed by the invention has the advantages of being suitable can be for automated production line, capable of effectively guaranteeing the quality of the penicillin bottles, and being simple in structure and simple and convenient to produce.

Owner:宁波正力药品包装有限公司

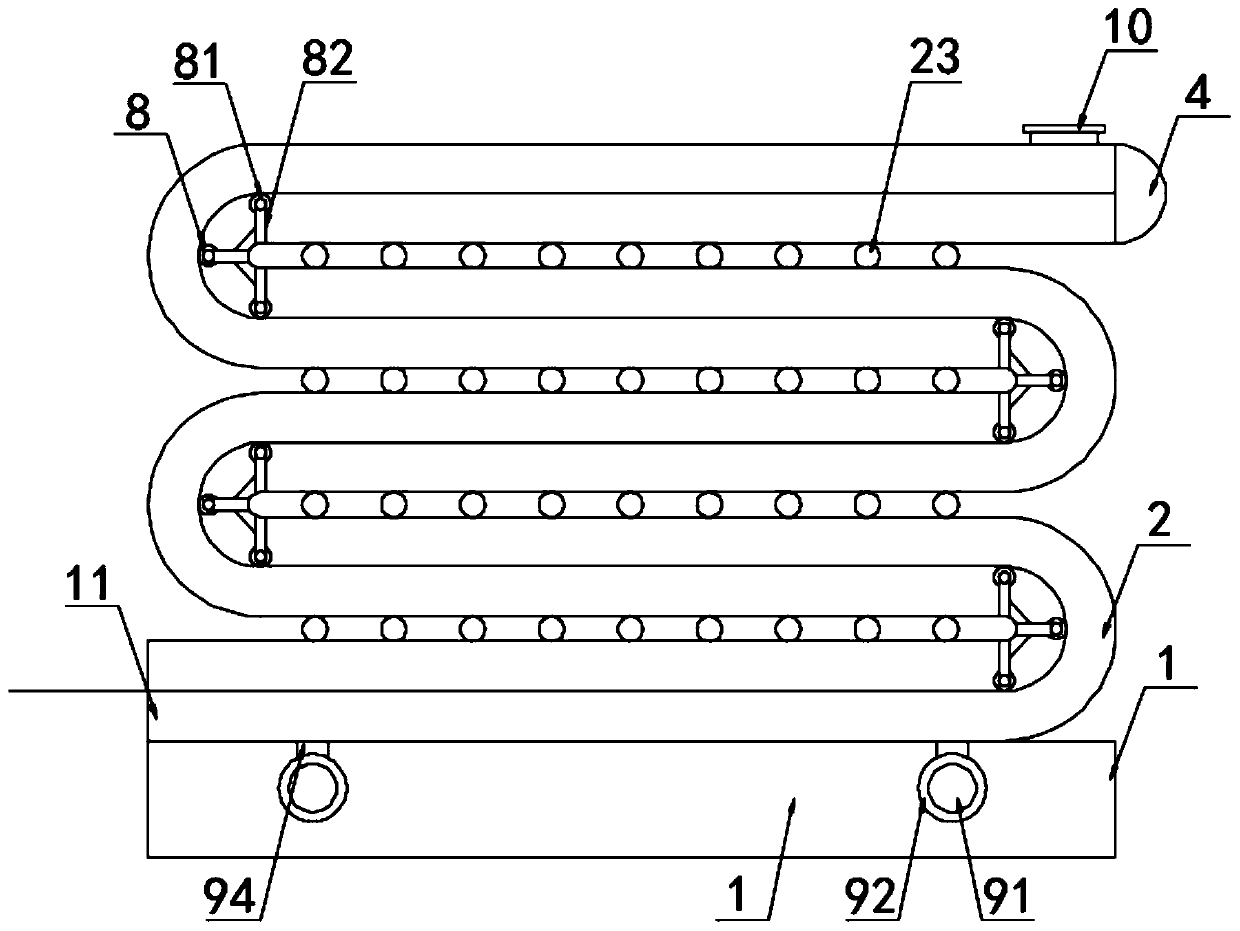

A continuous annealing device for alloy aluminum wire

ActiveCN108411098BSlow and even continuous heatingImprove the annealing effectFurnace typesHeat treatment furnacesCold airAlloy

The invention discloses a continuous annealing device for alloy aluminum wires. The continuous annealing device comprises a basal plate, wherein a hot air bent pipe and a cold air bent pipe are arranged at the top of the basal plate; the cold air bent pipe is arranged at one side of the hot air bent pipe; the hot air bent pipe is fixedly connected with the cold air bent pipe through a connecting pipe; alloy aluminum wires are arranged inside the hot air bent pipe, the cold air bent pipe and the connecting pipe; a first alignment mechanism is arranged inside the connecting pipe; air baffles arearranged at the two ends of the connecting pipe and the bottom end of the cold air bent pipe; a heat insulation plate is arranged between the hot air bent pipe and the cold air bent pipe; second alignment mechanisms are arranged inside the hot air bent pipe and the cold air bent pipe; the hot air bent pipe comprises a first hot air semi-pipe and a second hot air semi-pipe; and the cold air bent pipe comprises a first cold air semi-pipe and a second cold air semi-pipe. By utilizing the loss principle of the temperature of hot air and cold air flowing inside pipelines, slow and uniform continuous heating as well as slow and uniform continuous heat dissipation of the alloy aluminum wires in a conveying process are realized, the annealing effect is better, and the structure is simple.

Owner:ANHUI CABLE

Laser exposure apparatus and laser annealing apparatus

InactiveUS7851724B2Reduction of coherencyUniform annealingSemiconductor/solid-state device manufacturingPhotographic printingOptical axisLaser exposure

A laser exposure which includes: a laser light source including a multi-transverse mode semiconductor laser; a far-field pattern forming optical system for forming a far-field pattern of multi-transverse mode laser light emitted from the laser light source; a condensing optical system for condensing the laser light emitted from the far-field pattern forming optical system and applying the condensed laser light to a substance to be exposed; and a coherency reducing element disposed in an optical path between the laser light source and the substance to be exposed, for reducing coherency of two wavefront components that are contained in high-order transverse mode light of each order emitted from the laser light source and propagate in substantially symmetrical directions with respect to the optical axis.

Owner:FUJIFILM CORP

Preparation device for high-strength corrosion-resistant alloy plate, and corrosion-resistant alloy plate thereof

The invention discloses a preparation device for a high-strength corrosion-resistant alloy plate, and a corrosion-resistant alloy plate thereof. A limiting plate is welded at the top end of a sintering placement plate, and a shaping box is clamped at the side end of the limiting plate; an inner extrusion plate is placed at one end of the shaping box, and an extrusion spring is welded at one end of the inner extrusion plate; the outer side of the extrusion spring is sleeved with a double-layer protection sleeve; one end of the extrusion spring is spot-welded on an outer extrusion plate, and a cooling fan is installed at the top end of a sintering furnace; an exhaust pipe penetrates through the top end of an air collecting box, and an inlet-outlet pipe penetrates through the top end of an inlet-outlet box; the air inlet end of the inlet-outlet pipe is installed at the top end of the gas tank in a penetrating mode. Liquid-phase metal is extruded through the inner extrusion plate an the extrusion spring, and therefore the occupied space of molten metal is reduced; meanwhile, gas contained in liquid phases can be extruded during extrusion, and therefore the amount of the gas in the metal is reduced; the gas in the metal is exhausted through repeated pumping and inflating of the gas tank, and the influence of the gas on the metal in a solid-liquid state during sintering is reduced; and the quality and yield of the metal are guaranteed.

Owner:李红

Multi-temperature-zone annealing equipment and method for high-flexibility conductor material

PendingCN114292988AUniform annealingImprove annealing efficiencyFurnace typesIncreasing energy efficiencyElectrical conductorElectric machine

The invention relates to the technical field of annealing equipment, in particular to high-flexibility conductor material multi-temperature-zone annealing equipment and method.The high-flexibility conductor material multi-temperature-zone annealing equipment can evenly anneal conductor materials and effectively improve the annealing efficiency, the high-flexibility conductor material multi-temperature-zone annealing equipment comprises a plurality of annealing boxes, temperature controllers are arranged at the bottom ends of the annealing boxes, and annealing bins are arranged in the annealing boxes; through grooves are formed in the left portion and the right portion of each annealing box, a heat insulation ring is installed in each through groove, an electromagnetic heating ring is arranged in each annealing bin, an opening and closing door is arranged at the front end of each annealing box, supporting plates are arranged on the two sides of each annealing box, and a conveying wheel is arranged at the front end of the bottom of each supporting plate. A driving motor is arranged at the rear end of the bottom of each supporting plate, a sliding groove is formed in the top of each supporting plate, a sliding block is installed in each sliding groove, an adjusting guide wheel is arranged at the front end of each sliding block, a driving shaft is arranged at the top of each sliding block, and a rotating disc is arranged at the top of each driving shaft.

Owner:ANHUI CHUJIANG HIGH TECH ELECTRIC WIRE CO LTD

Efficient annealing system suitable for heat treatment of amorphous nano steel

InactiveCN110923419AAvoid blowingAvoid affecting the quality of annealingElectric machineryEngineering

The invention discloses an efficient annealing system suitable for heat treatment of amorphous nano steel. The efficient annealing system comprises a feeding chamber, a treatment chamber for centralized annealing treatment and a material taking chamber for receiving treated materials. An annealing device is arranged in the treatment chamber. The annealing device comprises a heating box. A heat dissipation box is welded to one side of the heating box in a penetrating mode. A cooling box is welded to one side of the heat dissipation box in a penetrating mode. Materials are placed in the heatingbox, the heat dissipation box and the cooling box. A water tank is installed below the cooling box. A water pump is installed on one side of the water tank. A transparent window is installed on the front surface of the water tank. A control box is installed on the upper surface of the cooling box. Chains are installed on the front surfaces of the heating box, the heat dissipation box and the cooling box. A motor is installed on one side of the heating box. A heat dissipation fan is installed on the upper surface of the heat dissipation box. According to the efficient annealing device for heattreatment of amorphous nano steel, the heating box, the heat dissipation box and the cooling box are arranged, the annealing structure is reasonable, the cooling device is provided with a heat dissipation structure, and the structure of the device is simple.

Owner:WUHU DINGHENG MATERIAL TECH

Continuous annealing device of alloy aluminum wires

ActiveCN103397167BWide range of annealed wire diametersFast annealing line speedFurnace typesHeat treatment furnacesAlloyControl valves

The invention discloses a high-production-efficiency continuous annealing device of alloy aluminum wires; the continuous annealing device comprises a body, and the body is provided with a wire incoming wheel, a negative pole preheating wheel, a positive pole preheating wheel, a positive pole annealing wheel, a negative pole annealing wheel, a lateral strong cold chamber, a vertical strong cold chamber, a wire outgoing wheel, an electric appliance control unit and a driving unit; a guide wheel is arranged on the body between the negative pole preheating wheel and the positive pole preheating wheel, a regulating wheel and a regulating sliding chute are arranged on the body between the positive pole preheating wheel and the positive pole annealing wheel, a plurality of air-blowing coolers are uniformly arranged in the lateral strong cold chamber, the lateral strong cold chamber and the vertical strong cold chamber are connected through a single-way control valve, an upper cooling wheel, a lower cooling wheel and a temperature detection unit are arranged in the vertical strong cold chamber, and an air outlet is arranged at the upper end of the vertical strong cold chamber.

Owner:JIANGSU NANHAI CABLE EQUIP

A continuous hot bending furnace

InactiveCN106495452AGuaranteed stabilityGuaranteed molding accuracyGlass reforming apparatusBogieStress concentration

A continuous hot bending furnace is provided and belongs to the field of glass processing equipment. The furnace comprises a furnace body, a glass bogie, a bending and positioning assembly and an annealing tank. The bending and positioning assembly includes a supporting plate disposed horizontally. One end of the upper end surface of the supporting plate is vertically provided with a press block. The press block is driven by an up-down air cylinder to vertically move up and down. One surface of the press block close to the supporting plate is provided with a high-temperature-resistant cotton cloth. One end of the supporting plate close to the press block is hinged with a rotating plate. A positioning plate is correspondingly arranged above the rotating plate. The annealing tank includes a drive assembly, a fixing support and two annealing tube assemblies disposed in an opposite manner. The furnace can ensure hot bending glass forming precision, and can avoid stress concentration generated in an annealing process. The qualified rate of finished products is high.

Owner:天津南玻节能玻璃有限公司

Electrolytic capacitor aluminum foil continuous annealing process

InactiveCN1232675CGuaranteed uniformityUniform annealingElectrolytic capacitorsTemperature controlElectrolysis

The invention discloses a continuous annealing process for aluminum foil of an electrolytic capacitor, which belongs to the technical field of heat treatment of nonferrous metals. The invention proposes a new annealing process based on a protective atmosphere continuous annealing furnace in a rapid manner. During the annealing process, the aluminum coils are opened and heated in a continuous furnace with a protective atmosphere from the beginning to the end. The control range of the line speed to the exit of the furnace is 0.1-80 meters per minute; during the heating stage in the furnace, the aluminum foil heats up at a speed of 5-600 °C per minute, and the temperature range is 180-600 °C; Keep warm at the temperature, and the time for each place is 1 to 600 minutes; after the heat preservation, the cooling speed is 5 to 600 ° C per minute. The invention has the characteristics of fast annealing speed, high production efficiency, high temperature control precision and uniform annealing of aluminum foils in various parts of the aluminum coil, and is suitable for use in aluminum foil production enterprises for electrolytic capacitors.

Owner:UNIV OF SCI & TECH BEIJING

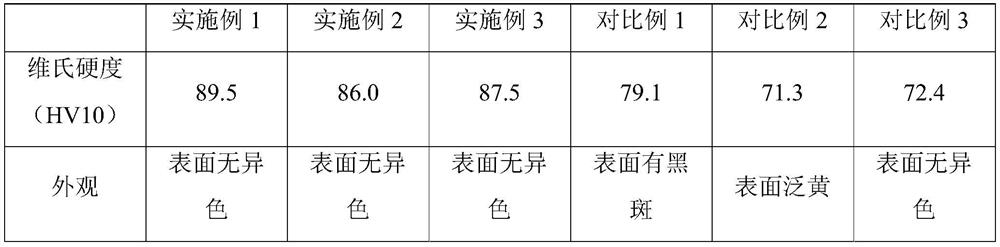

A vacuum annealing method for an airbag outlet valve

ActiveCN109777925BUniform annealingImprove stabilityFurnace typesHeat treatment furnacesNitrogen gasPumping vacuum

The invention relates to a vacuum annealing method of safety air bag air outlet valves. The vacuum annealing method includes the following steps that (a) the air outlet valves are placed in a tray which is then placed in a vacuum furnace, and the pressure is reduced to be less than or equal to 3 Pa through vacuumizing; (b) the temperature is increased from the room temperature to 470-490 DEG C in10-50 min, and the temperature is kept for 10-50 min; (c) the pressure is reduced to be less than or equal to 0.1 Pa through vacuumizing, the temperature is increased to 700-720 DEG C in 20-60 min, and the temperature is kept for 170-190 min; and (d) the temperature is reduced to 470-490 DEG C through furnace cooling in 40-100 min, the temperature is kept for 5-10 min, then the vacuum furnace is filled with nitrogen with the pressure of 0.2-0.4 Mpa, and the temperature is reduced to the room temperature in 15-35 min. The air outlet valves of the same batch can be evenly annealed, the stabilityis good, the hardness is high, the appearance has a white and bright metal color, and no yellowing and blackening phenomenon occurs.

Owner:苏州腾凯金属材料有限公司

Composite type annealing furnace

Owner:NINGBO CHANGZHEN COPPER CO LTD

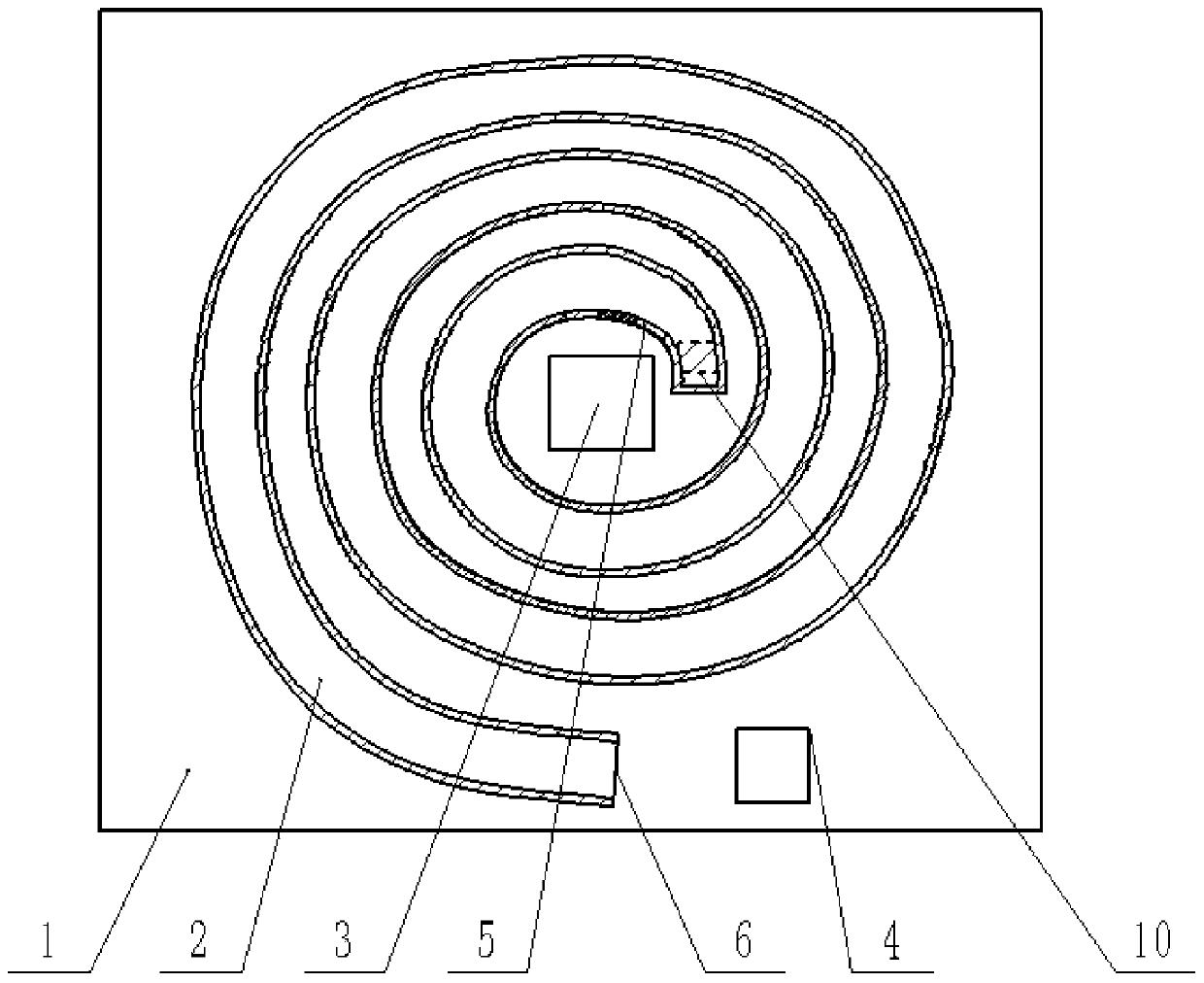

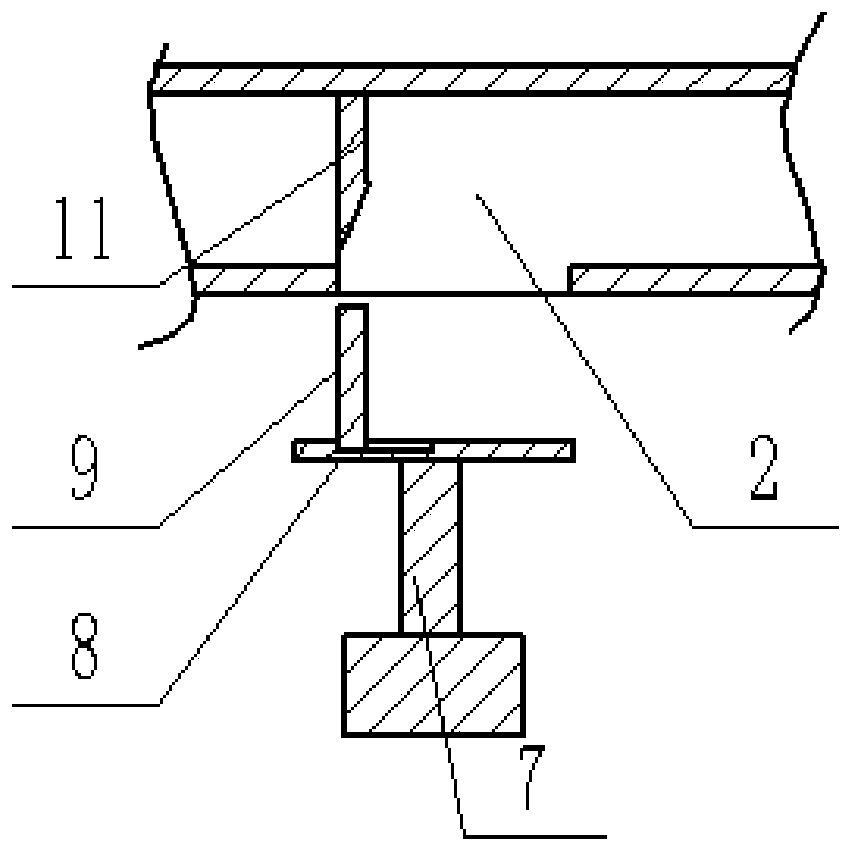

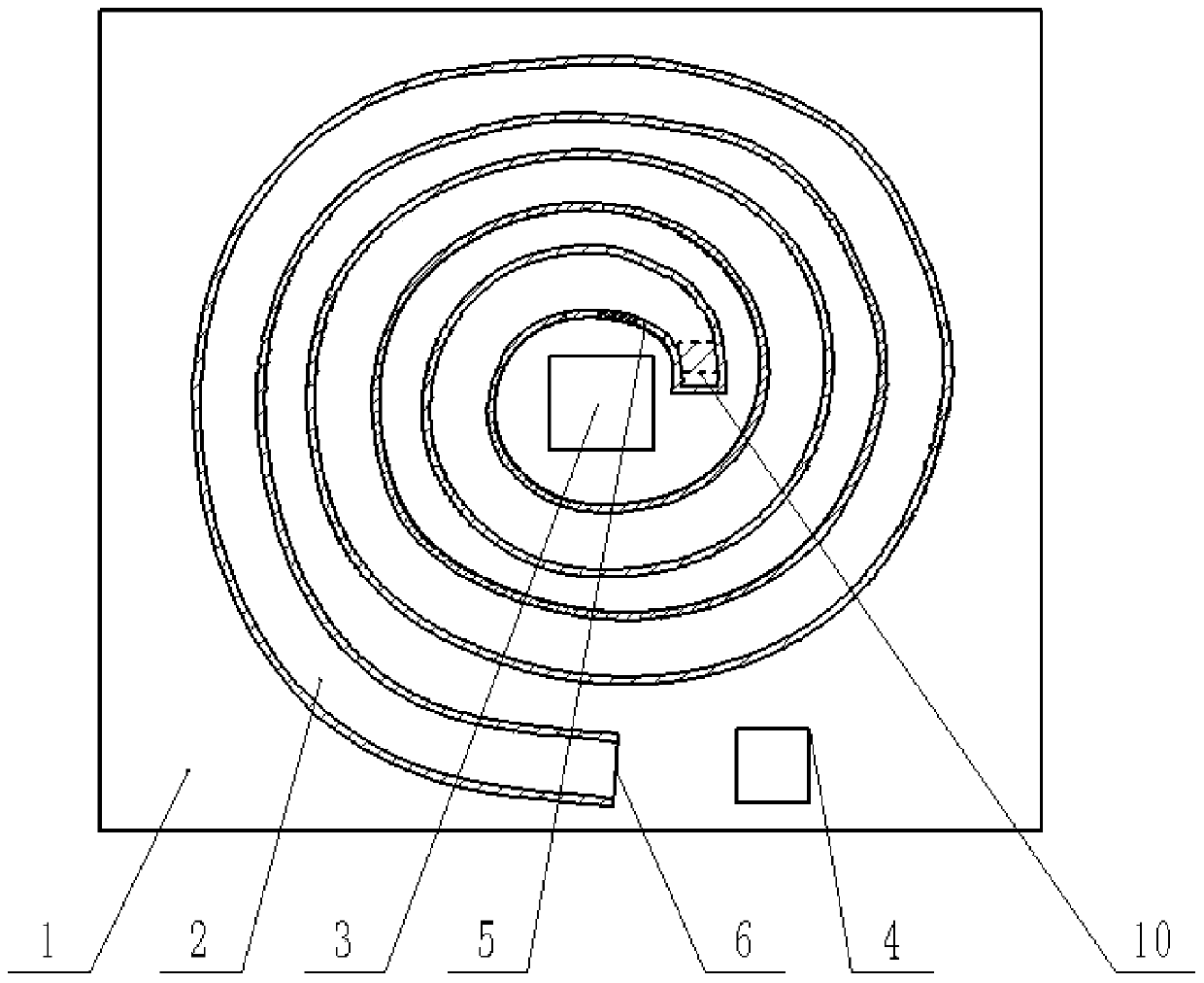

Foam glass blank annealing device

The method relates to the technical field of glass product annealing, and particularly discloses a foam glass blank annealing device. The device comprises a bottom plate, an electric motor, an annealing mechanism and a feeding mechanism, wherein the annealing mechanism comprises a screw cap, a heating device located in the spiral center of the screw cap and an exhaust fan; the screw cap is made ofa thermal insulation material and buckled on the bottom plate to form a closed spiral space with the bottom plate, air holes are formed in the side wall of a ring with the minimum diameter of the screw cap, a foam glass discharging port is formed in the end with the maximum diameter of the screw cap, and the exhaust fan faces the discharging port and acts on the inside of the screw cap; the feeding mechanism comprises a vertical telescopic cylinder, an output end of the vertical telescopic cylinder is connected with a feeding plate, and a push plate is glidingly connected onto the feeding plate; a feeding port matched with the feeding mechanism is formed in the bottom plate constituting the spiral space, and a wedge rod matched with the push plate is further arranged on the screw cap. With the adoption of the technical scheme, the problem of large space occupied by the conventional foam glass blank annealing device can be solved. Therefore, the device can be widely applied to foam glass annealing.

Owner:CHONGQING HECHUAN JINXING GLASS PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com