A continuous annealing device for alloy aluminum wire

An annealing device and a technology for alloying aluminum, applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of uneven soft and hard inner and outer layers, unstable quality, uneven temperature, etc., and achieve convenient and uniform annealing and good annealing effect. , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

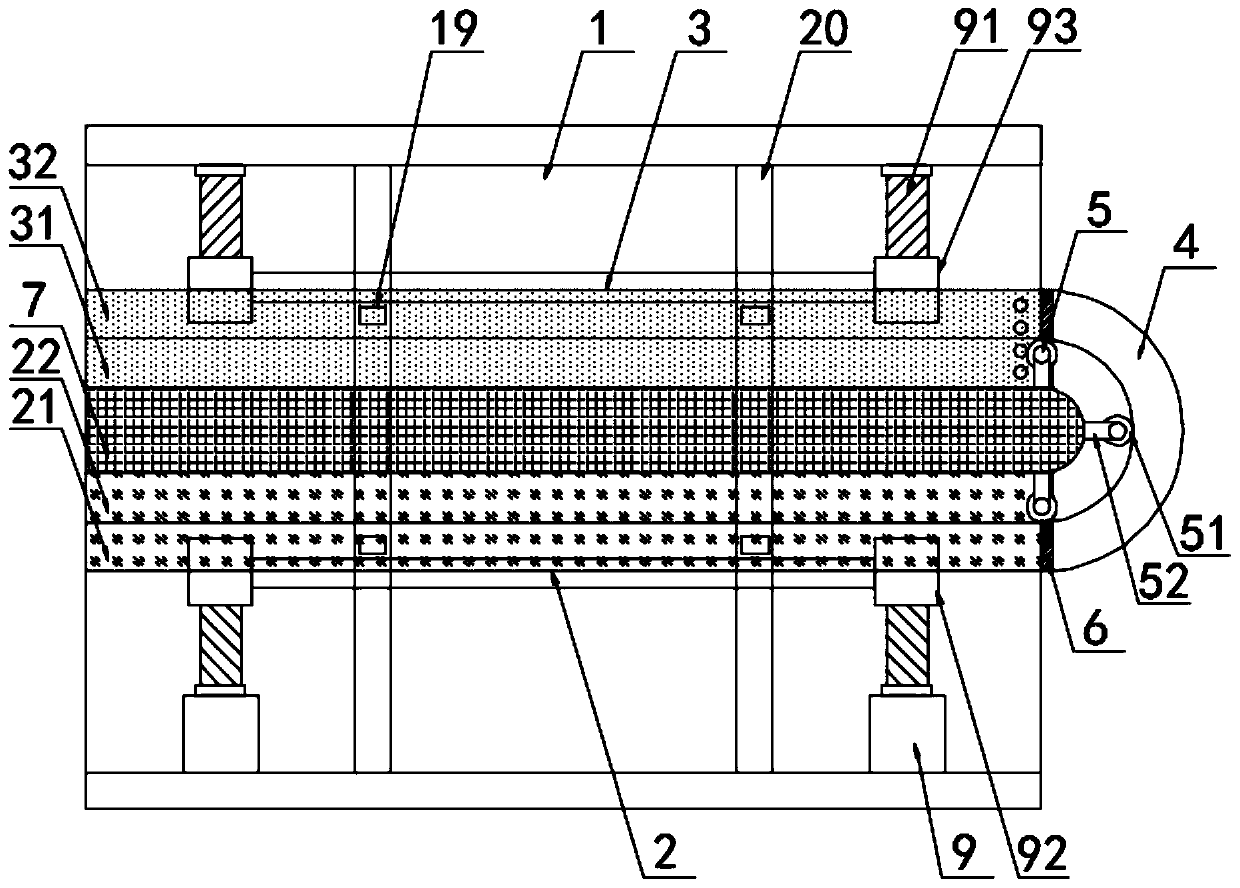

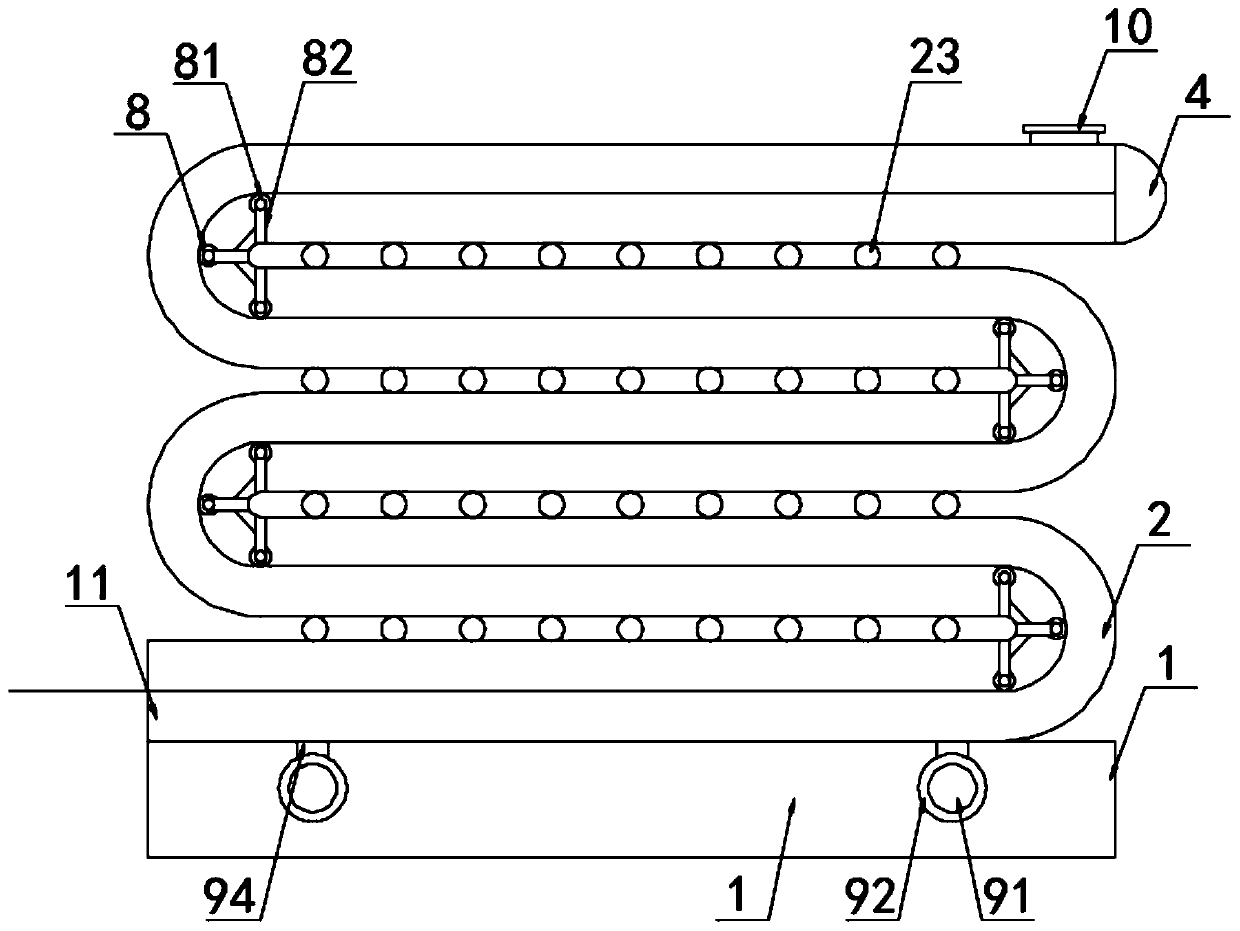

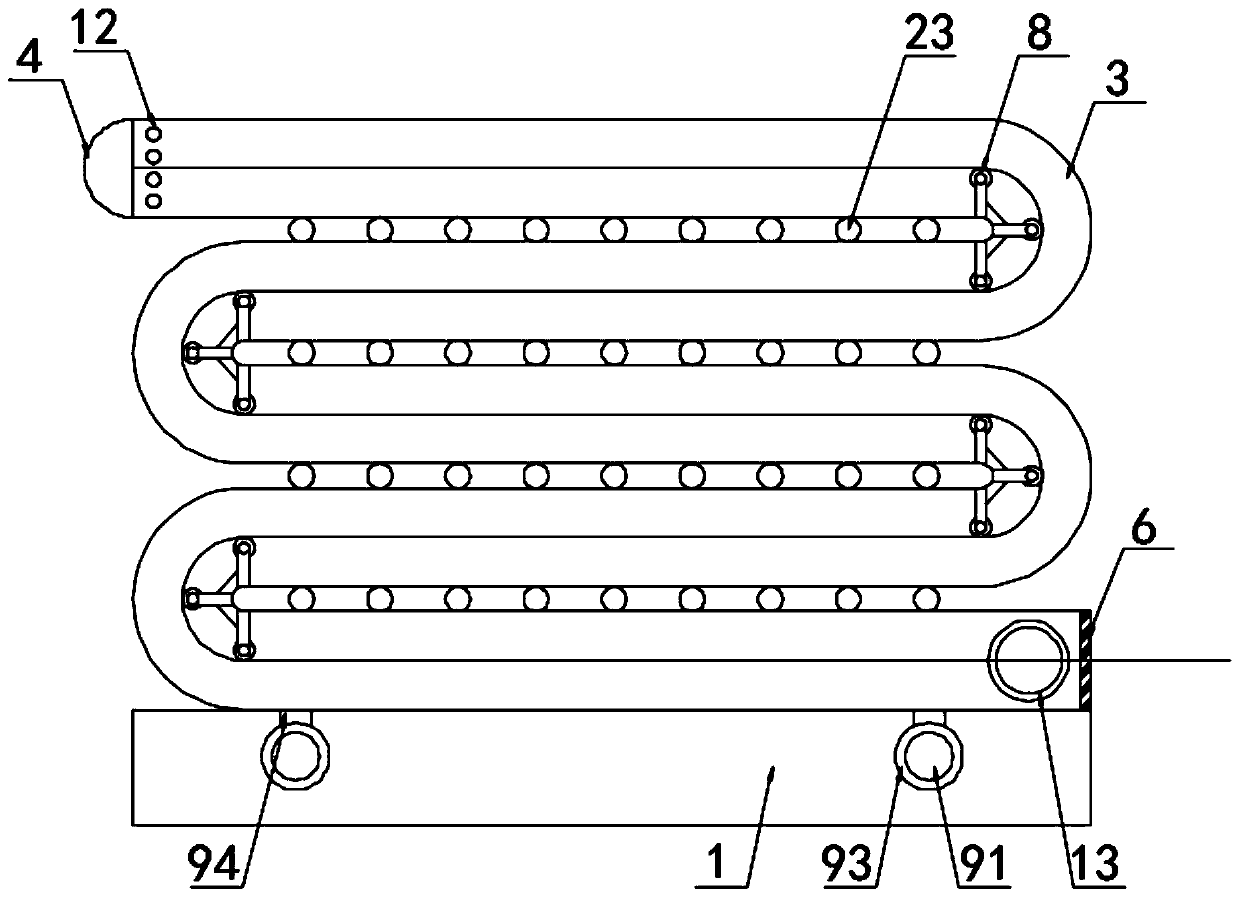

[0027] according to Figure 1-2 The shown continuous annealing device for alloy aluminum wire includes a substrate 1, a hot air elbow 2 and a cold air elbow 3 are arranged on the top of the substrate 1, and the cold air elbow 3 is arranged on one side of the hot air elbow 2. The hot air elbow 2 and the cold air elbow 3 are fixedly connected through the connecting pipe 4, the inside of the hot air elbow 2, the cold air elbow 3 and the connecting pipe 4 are provided with alloy aluminum wires, and the inside of the connecting pipe 4 is provided with a first alignment line Mechanism 5, the first alignment mechanism 5 includes three first rotating rollers 51, the two ends of the first rotating rollers 51 are provided with first brackets 52, and the first brackets 52 are fixedly connected to the inner wall of the connecting pipe 4, The three first rotating rollers 51 are vertically arranged in pairs to facilitate fixing the transmission direction of the alloy aluminum wire. The two ...

Embodiment 2

[0030] according to Figure 1-2 In the shown continuous annealing device for alloy aluminum wire, the driving mechanism 9 includes two rotating shafts 91, one end of the rotating shaft 91 is provided with a positive and negative motor and the other end is provided with a bearing, and the outer wall of one end of the rotating shaft 91 is provided with a forward direction The thread and the outer wall of the other end are provided with reverse threads, the outside of the forward thread is provided with a first movable sleeve 92, the outside of the reverse thread is provided with a second movable sleeve 93, two first movable sleeves 92 and The two second movable sleeves 93 are all fixedly connected by connecting rods, and the inner walls of the first movable sleeve 92 and the second movable sleeve 93 are provided with internal threads matched with forward threads and reverse threads. A movable sleeve 92 is fixedly connected with the first hot air half pipe 21 and the second movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com