Conveying mechanism for penicillin bottles during annealing of penicillin bottles

A technology of transmission mechanism and vials, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems of not being applicable to automatic production lines, affecting the quality of vials, secondary stress of vials, etc., and achieves improved primary transmission rate, simple structure, Uniform annealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

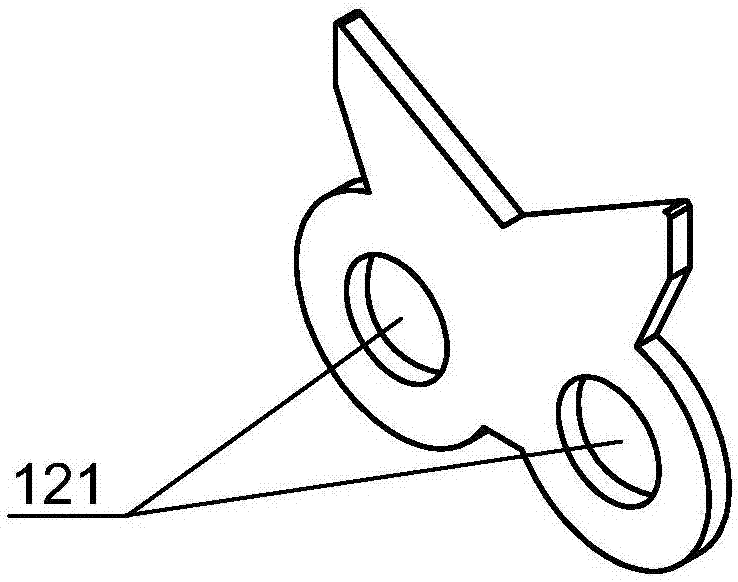

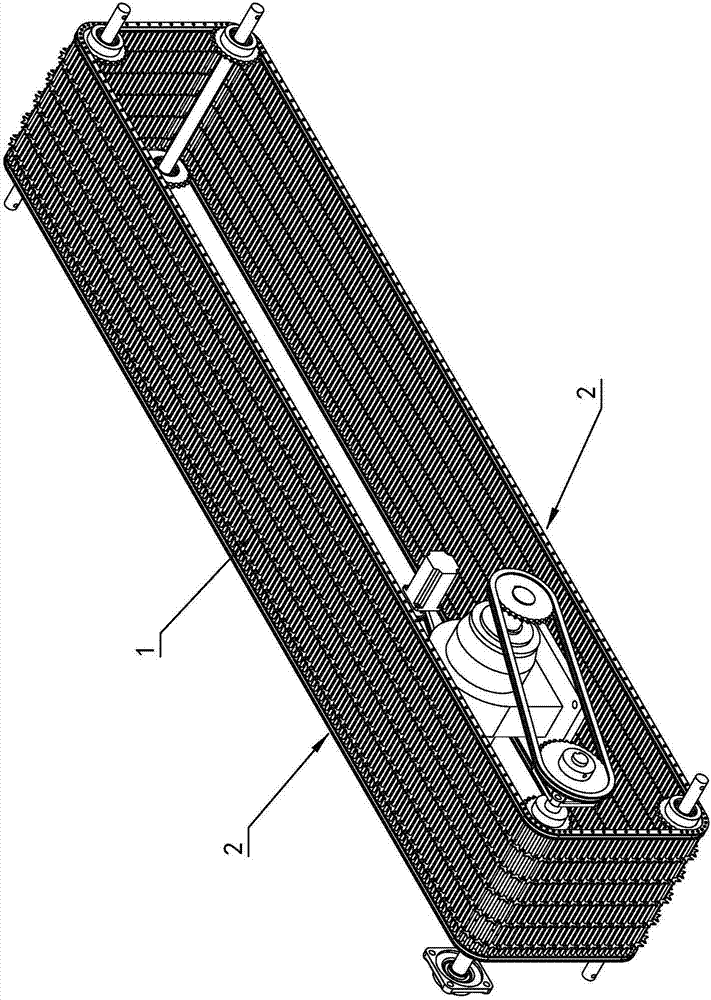

[0024] Such as Figure 3 to Figure 5 As shown, a vial annealing transmission mechanism includes an annealing furnace mesh belt 1 and a transmission chain 2 arranged on both sides of the annealing furnace mesh belt 1. The transmission chain 2 includes a chain link 21 and a chain pin 22, and the chain pin 22 is integrated inwardly. Connecting pins (not shown in the figure) are extended. The mesh belt 1 of the annealing furnace includes a plurality of conveying rollers 11 arranged side by side. Both ends of the conveying rollers 11 are provided with connecting holes 111. The connecting pins 22 are inserted into the connecting holes 111. The annealing furnace There are multiple V-shaped pillow board groups (not shown in the figure) arranged side by side on the mesh belt 1 along the conveying direction. The V-shaped pillow board 12 is composed of two through-holes 121 arranged at the bottom of the V-shaped pillow board 12, and the two conveying rollers 11 respectively pass through ...

Embodiment 2

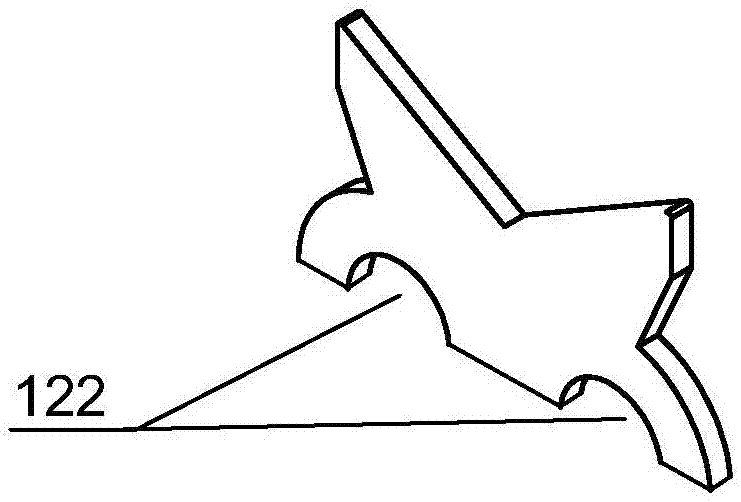

[0027] The technical features are the same as those in Embodiment 1, the difference being that the lower part of the V-shaped pillow board 12 is provided with two card slots 122 (such as Figure 6 shown), the conveying roller 11 is inserted into the card slot 122 and fixedly connected with the V-shaped pillow board 12 .

[0028] In order to reduce the quality of the entire annealing furnace mesh belt, in the above embodiment, the transmission roller 11 is a hollow long tube, and the connecting pin 22 is inserted into the end of the hollow long tube, so that the input energy required for the work of the vial annealing transmission mechanism is greatly reduced , thereby effectively reducing energy consumption.

[0029] In the above embodiments, the V-shaped pillow plate 12 and the driving roller 11 are integrally cast, which also belongs to the same technical solution as the present invention.

[0030] In the above embodiment, the upper structural shape of the V-shaped pillow b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com