Induction annealing process of 95CrMo steel for rock drilling rod

An annealing process and a drill rod technology are applied in the field of induction annealing process of 95CrMo steel used for rock drilling rods, which can solve the problems of high energy consumption, long production cycle and high production cost of the 95CrMo drill rod annealing process, and achieve low energy consumption, The heating device is simple and practical, and the production cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

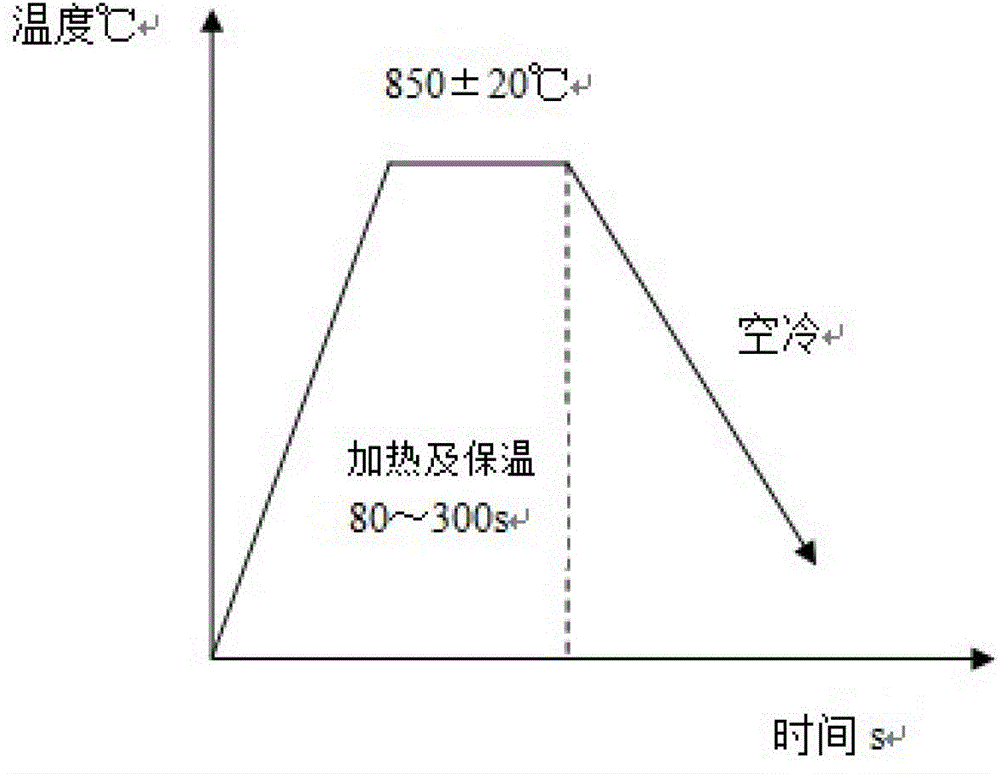

[0024] Example 1. The induction annealing process of 95CrMo steel for rock drilling rods, the 95CrMo steel, by weight percentage, its main components are C0.9-1.00%, Si0.15-0.40%, Mn0.15-0.40%, Cr0. 8~1.20%, Mo0.15~0.30%, P≤0.025%, S≤0.025%, Cu≤0.25%, the balance is Fe and unavoidable impurities; medium frequency induction heating is adopted, and the heating temperature is controlled at 830~880℃ , The heating and holding time is controlled at 80~300s, the cooling method is air cooling, and the annealing hardness is ≤255HB.

Embodiment 2

[0025] Example 2. The induction annealing process of 95CrMo steel for rock drilling rods, the 95CrMo steel, by weight percentage, its main components are C0.9-1.00%, Si0.15-0.40%, Mn0.15-0.40%, Cr0. 8~1.20%, Mo0.15~0.30%, P≤0.025%, S≤0.025%, Cu≤0.25%, the balance is Fe and unavoidable impurities; medium frequency induction heating is adopted, and the heating temperature is controlled at 830~880℃ , The heating and holding time is controlled at 120~300s, the cooling method is air cooling, and the annealing hardness is ≤255HB.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com