Electrolytic capacitor aluminum foil continuous annealing process

An annealing process and aluminum foil technology, applied in electrolytic capacitors, capacitors, circuits, etc., can solve the problems of low production efficiency, shortened annealing time, unevenness, etc., and achieve the effects of high production efficiency, uniform annealing, and fast annealing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

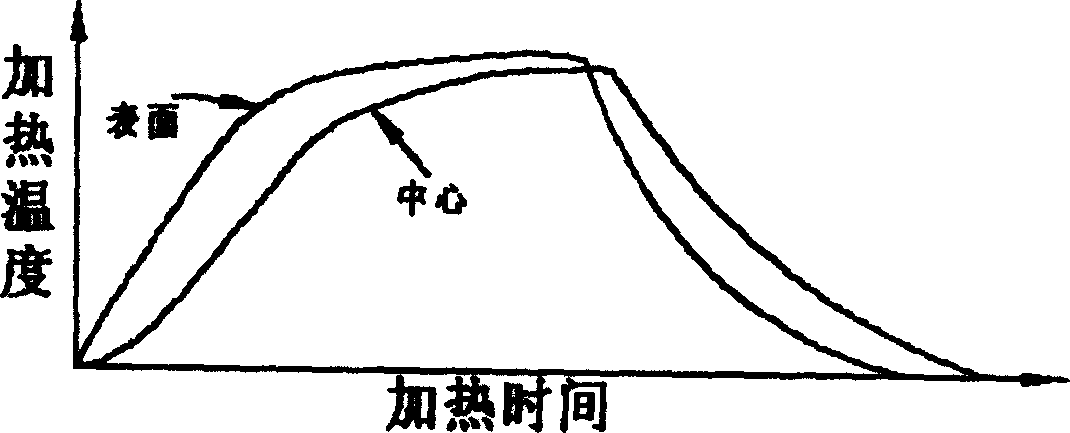

[0009] Fill the continuous annealing furnace with a protective atmosphere, and maintain a positive pressure on the atmosphere outside the furnace. Adjust the heating sections of the continuous annealing furnace to the corresponding furnace temperature. The annealed aluminum coil is uncoiled on the foil roll rack at the entrance of the continuous annealing furnace. Re-roll into an aluminum coil. Therefore, the aluminum coils enter the continuous annealing furnace sequentially and evenly from the beginning to the end to complete the annealing process, and are re-rolled into annealed aluminum coils. When the previous aluminum coil is opened to the end of the coil, the coil head of the next aluminum coil can be welded to the coil tail of the previous aluminum coil, so that continuous annealing of multiple aluminum coils can be carried out without interruption. By adjusting the running speed of the aluminum coil in the continuous annealing furnace and cooperating with the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com