High-frequency annealing device of semi-automatic bearing

A high-frequency annealing, semi-automatic technology, applied in the field of bearing processing, can solve the problems of large randomness, difficult quality assurance, insufficient channel hardness, etc., and achieve the effects of good stability, improved processing quality, and uniform annealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

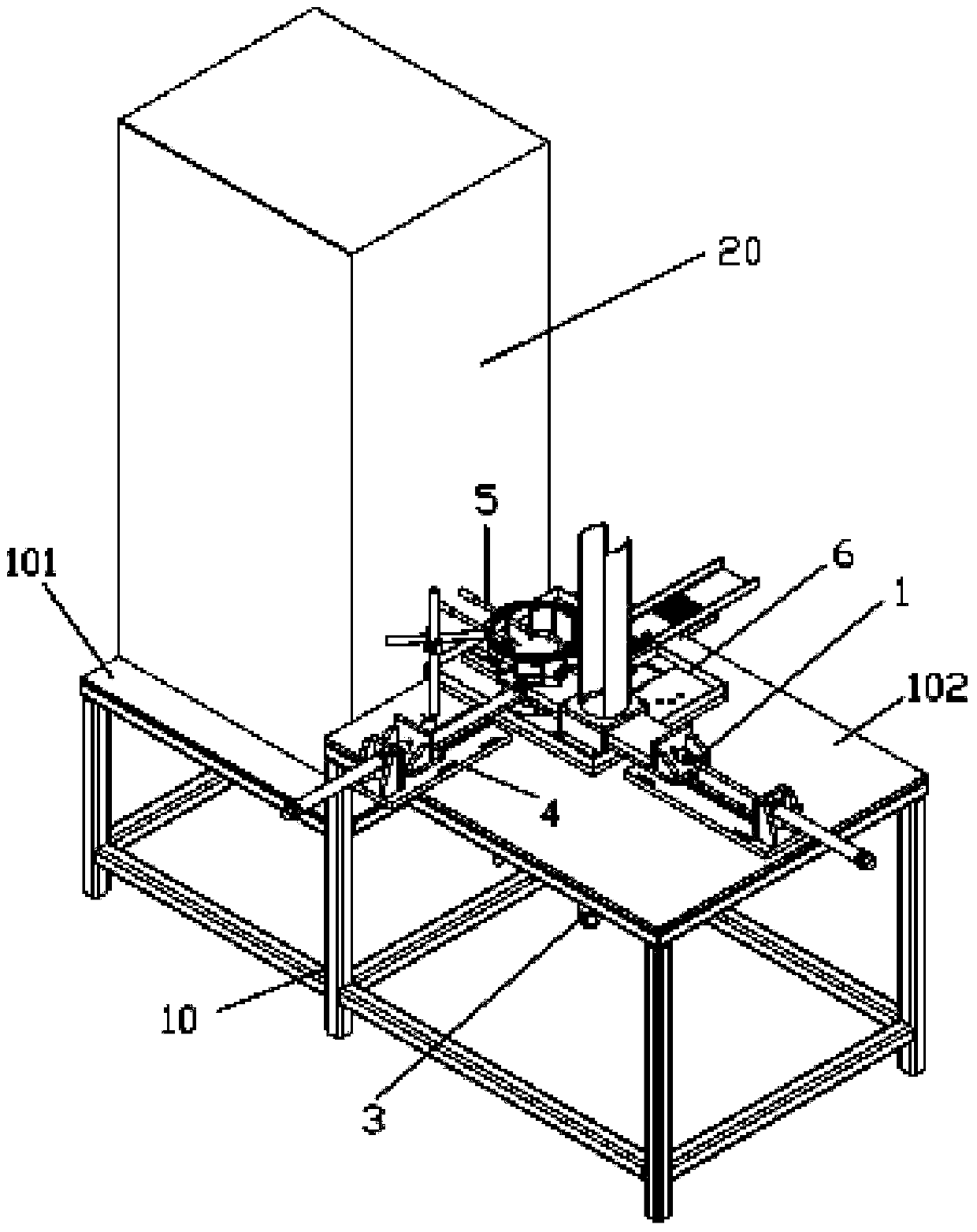

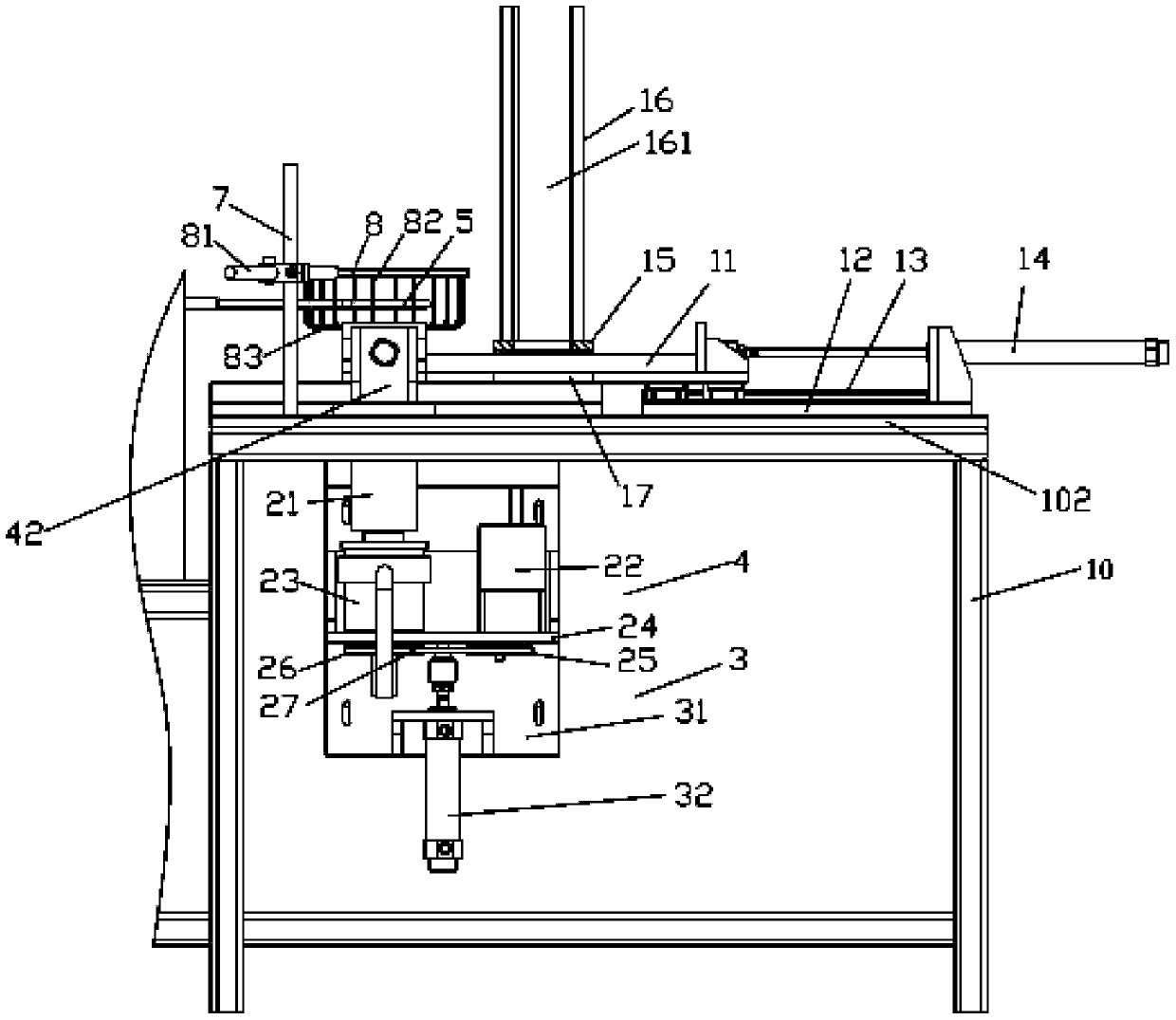

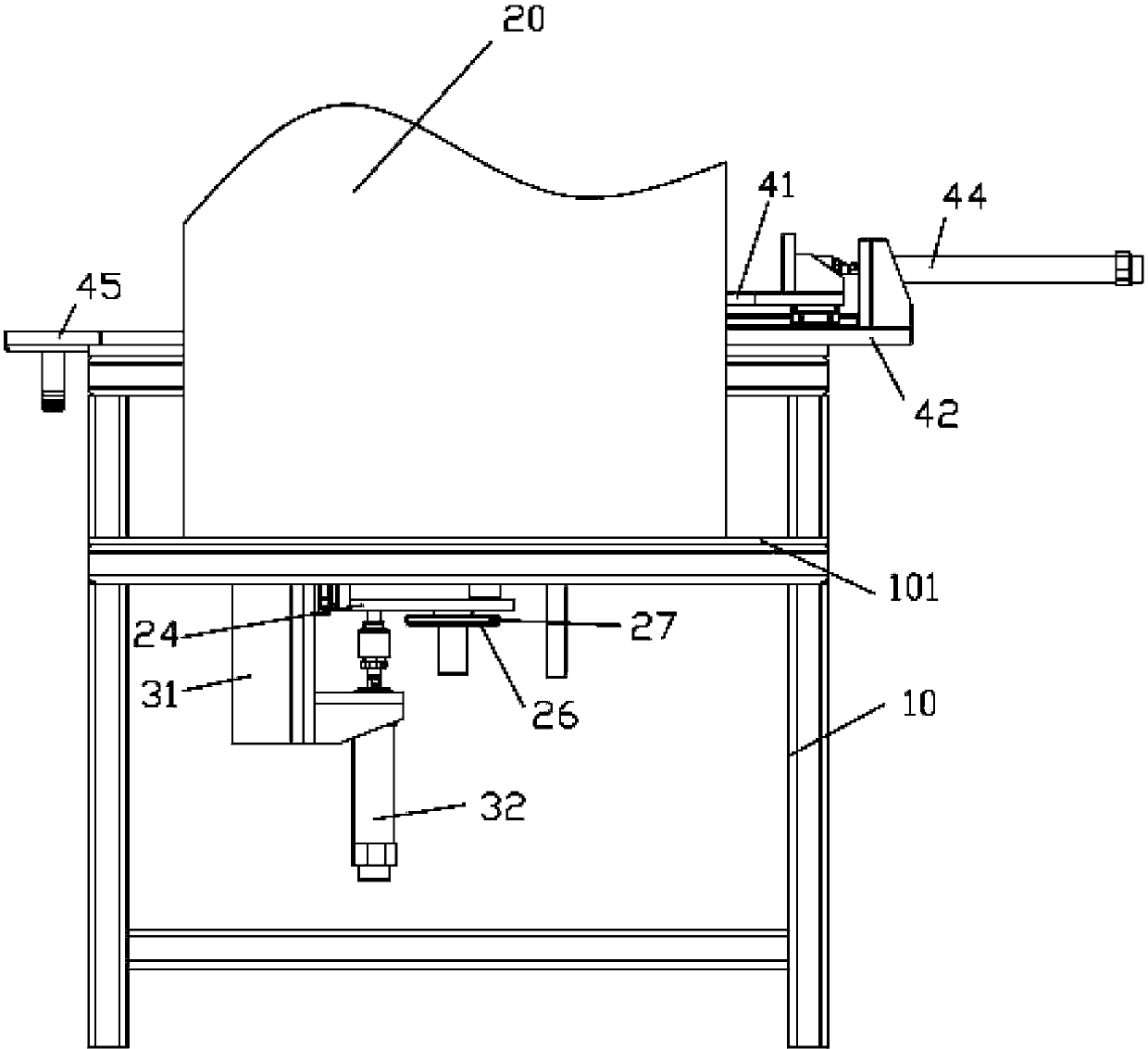

[0026] Examples, see e.g. Figures 1 to 8 As shown, a semi-automatic bearing high-frequency annealing device includes a frame 10 and a high-frequency power supply device 20. The high-frequency power supply device 20 is fixed on the left support plate 101 of the frame 10, and the right side of the frame 10 supports The plate 102 is fixed with a feeding device 1, a rotating device 2, a lifting device 3 and a material return device 4, the lifting device 3 is fixed on the back side of the right support plate 102 of the frame 10, and the push rod of the lifting device 3 is fixed with a rotating Device 2, the rotating shaft 21 of the rotating device 2 is inserted into the circular through hole 103 formed on the right support plate 102, and the induction coil 5 is installed on the high frequency power supply device 20, and the induction coil 5 is mounted on the right support plate 102 above, its central axis is the same axis as the central axis of the rotating shaft 21, the feeding d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com