A vacuum annealing method for an airbag outlet valve

A technology of airbag and air outlet valve, applied in the direction of furnace, furnace type, heat treatment equipment, etc., can solve the problems of difficult to meet terminal manufacturers, uneven product performance, etc., and achieve the effect of high hardness and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

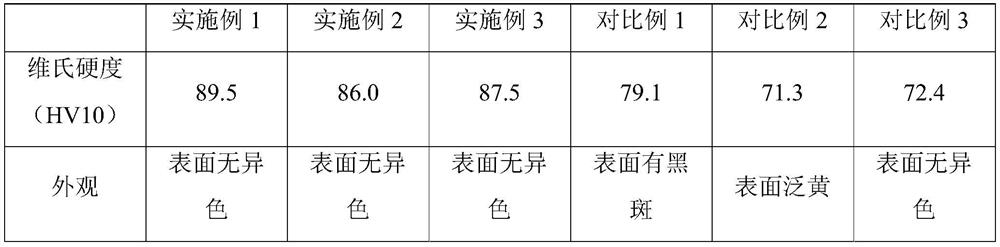

Examples

Embodiment 1

[0018] The present embodiment provides a vacuum annealing method for an airbag outlet valve, which comprises the following steps:

[0019] (a) Check that the tooling (that is, the tray) has no deformation or cracking; parts and sundries left in the tooling; the tooling is clean and free of oil and dust; place the material rack neatly in the vacuum furnace charging area; put the tooling on the material rack , loading materials so that the outlet valves are placed in the tooling in a neat manner (the rack has 7 layers in total, and 6 layers can be loaded; each layer can hold 4 toolings, and each tooling can hold 150 outlet valves, so that the furnace is full 3600 outlet valves), vacuuming to ≤3Pa;

[0020] (b) It takes 30 minutes to raise the temperature from room temperature to 480°C, and keep it warm for 30 minutes;

[0021] (c) Vacuumize to ≤0.1Pa, heat up to 710°C in 40 minutes, and keep warm for 180 minutes;

[0022] (d) Cool down to 480°C (circulating water cooling) with...

Embodiment 2

[0024] The present embodiment provides a kind of vacuum annealing method of safety air bag outlet valve, and it is basically consistent with embodiment 1, and difference is, in step (b)-step (d), heat preservation temperature and heat preservation time are different, specifically:

[0025] (b) It takes 10 minutes to raise the temperature from room temperature to 490°C, and keep it warm for 50 minutes;

[0026] (c) Vacuumize to ≤0.1Pa, heat up to 720°C in 20 minutes, and keep warm for 170 minutes;

[0027] (d) Cool down to 470°C (circulating water cooling) with the furnace for 40 minutes, and keep warm for 10 minutes; then fill the vacuum furnace with nitrogen at a pressure of 0.3±0.1MPa to cool down to room temperature in 15 minutes.

Embodiment 3

[0029] The present embodiment provides a kind of vacuum annealing method of safety air bag outlet valve, and it is basically consistent with embodiment 1, and difference is, in step (b)-step (d), heat preservation temperature and heat preservation time are different, specifically:

[0030] (b) It takes 50 minutes to raise the temperature from room temperature to 470°C, and keep it warm for 10 minutes;

[0031] (c) Vacuumize to ≤0.1Pa, heat up to 700°C in 60 minutes, and keep warm for 190 minutes;

[0032] (d) Cool down to 490°C (circulating water cooling) with the furnace for 100 minutes, and keep warm for 8 minutes; then fill the vacuum furnace with nitrogen at a pressure of 0.3±0.1MPa to cool down to room temperature in 35 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com